Linear vibrating screen underneath type dust removal system and method

A technology of linear vibrating screen and dust removal system, which is applied in the direction of removing smoke and dust, separation method, cleaning method and utensils, etc. Avoid confounding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

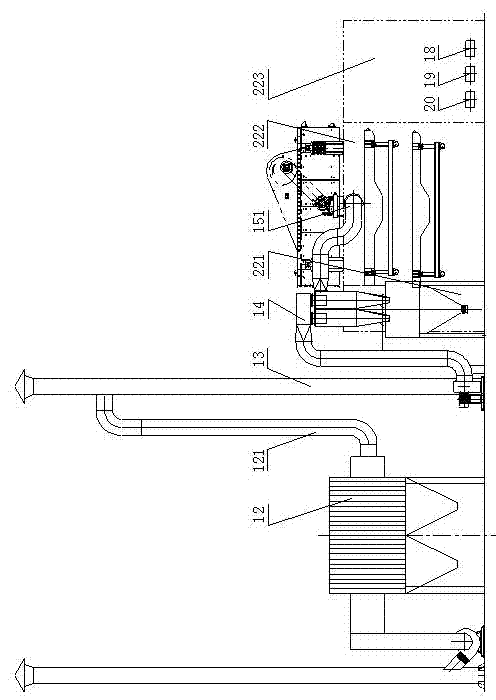

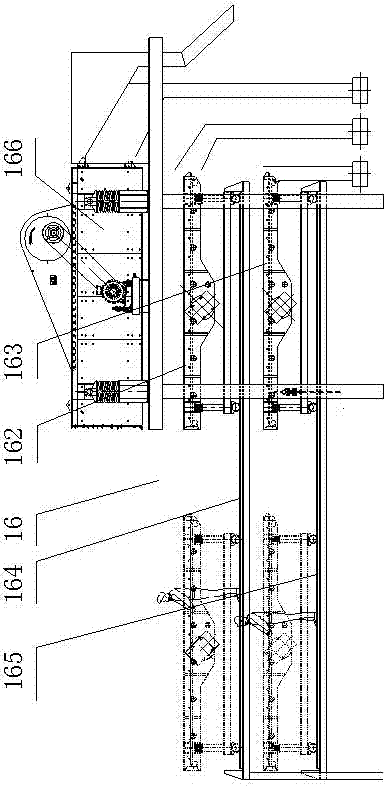

[0010] Embodiment 1: with reference to attached figure 1 and 2 . A lower-mounted dust removal system for a linear vibrating screen, the fixed linear vibrating screen 3 is provided with a multi-layer movable linear vibrating screen 4, the sealing cover 1 is covered around the outlet of the fixed linear vibrating screen 3 and the multi-layer mobile linear vibrating screen On the sieve 4, the negative pressure dust suction port 2 is located between the discharge port of the fixed linear vibrating screen 3 and the upper movable linear vibrating screen in the multi-layer mobile linear vibrating screen 4 and communicates with the sealing cover 1. The upper movable linear vibrating screen 162 and the lower movable linear vibrating screen 163 in the multi-layer mobile linear vibrating screen 4 are located on the upper linear vibrating screen guide rail 164 and the lower linear vibrating screen guide rail 165 respectively; The structure of the lower movable linear vibrating screen 16...

Embodiment 2

[0011] Embodiment 2: On the basis of Embodiment 1, a dust collection method of a linear vibrating screen under-mounted dust removal system, the negative pressure dust suction port 2 in the cyclone dust collector 5 sieves the bottom of the fixed linear vibrating screen 3 The dust is sucked into the cyclone dust collector 5 through the negative pressure dust suction port 2, and the fine dust negative pressure dust suction pipeline 7 connected with the upper part of the vertical dust discharge passage 6 in the cyclone dust collector 5 sucks the fine dust in the vertical dust discharge passage 6 After the pulse bag filter 8 is dedusted by the pulse bag filter 8, the clean gas is discharged from the exhaust pipe of the pulse bag filter 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com