Method for treating sulfur slag

A treatment method and technology for sulfur residues, which are applied in the improvement of process efficiency, photography technology, instruments, etc., can solve the problems of incomplete oxidation and reduce production costs, and achieve complete separation and recovery, reduce production costs, and reduce energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

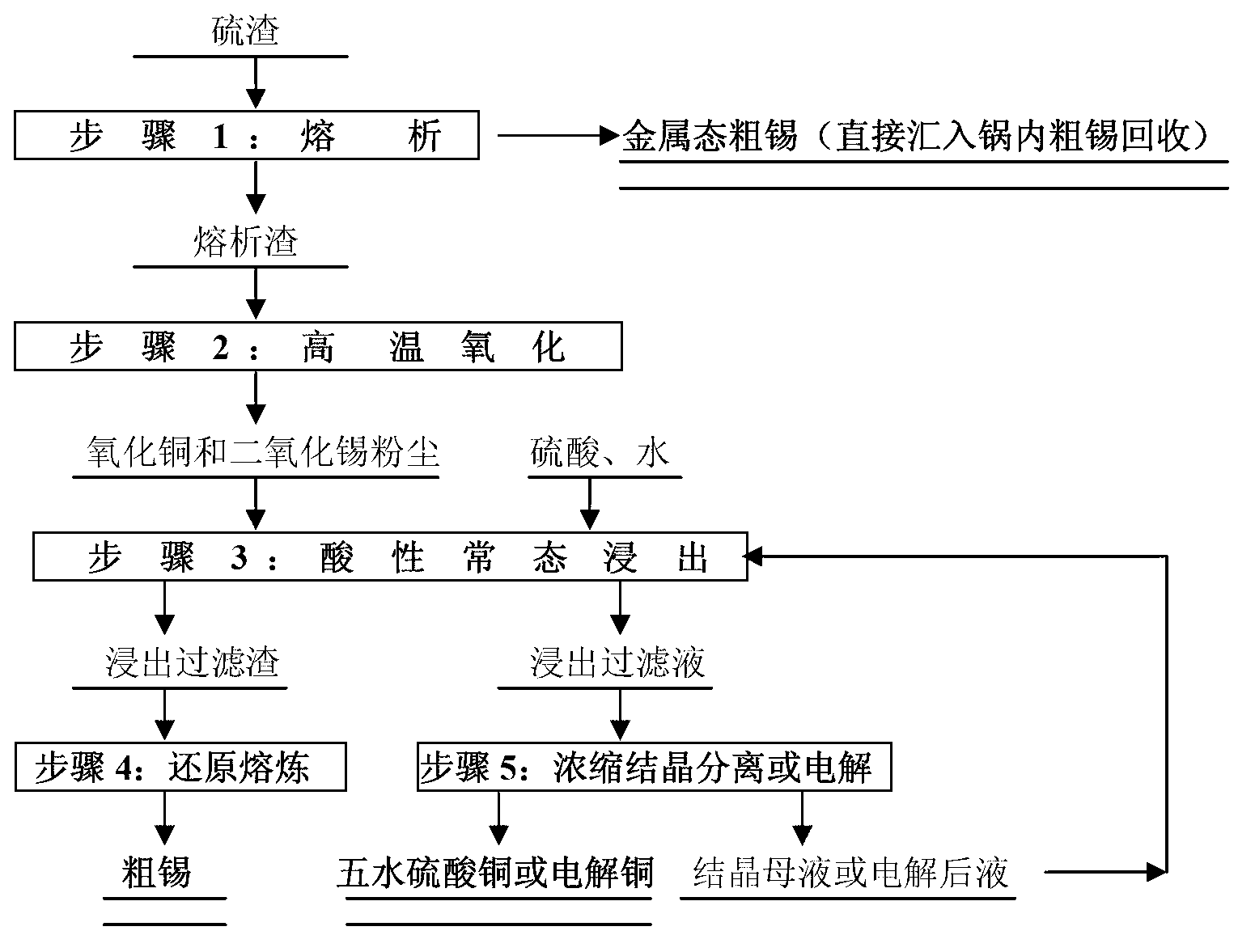

[0025] Present embodiment is the first example of the processing method of sulfur slag of the present invention, comprises the steps:

[0026] (1) Sulfur slag melting: place 4 tons of sulfur slag containing 65% tin and 6% copper in an iron pot with 4 tons of crude tin at 500°C, and carry out melting treatment under the action of a mechanical stirrer , obtain 1 ton of liquid crude tin containing 96% tin and 3 tons of slag containing 48% tin and 8% copper, and the liquid crude tin is directly recovered in the pot;

[0027] (2) High-temperature oxidation: put 3 tons of slag containing 48% tin and 8% copper into a top-blown converter with an inner diameter of 1.8 meters and an inner length of 2.1 meters. Oxygen is sprayed onto the surface of the sulfur slag at a flow rate of 10 cubic meters per minute, and all the sulfur slag is oxidized into dust. The oxidation process takes 90 minutes, consumes 900 cubic meters of industrial oxygen, and collects a total of 3.2 tons of copper oxi...

no. 2 example

[0032] Present embodiment is the second example of the treatment method of sulfur slag of the present invention, comprises the steps:

[0033] (1) Sulfur slag smelting: put 4 tons of sulfur slag containing 70% tin and 10% copper in an iron pot with 4 tons of crude tin at 600°C, under the action of a rotary arm type centrifugal iron remover , Carry out smelting treatment, obtain 1.35 tons of liquid crude tin containing 97% tin and 2.65 tons of molten slag containing 56.2% tin and 15.1% copper, the liquid crude tin is directly recycled in the pot;

[0034](2) High-temperature oxidation: put 2.65 tons of slag containing 56.2% tin and 15.1% copper into a top-blown converter with an inner diameter of 1.8 meters and an inner length of 2.1 meters. The industrial oxygen is sprayed onto the surface of the sulfur slag at a flow rate of 10 cubic meters per minute, and the sulfur slag is completely oxidized into dust. The oxidation process takes 100 minutes to consume 1,000 cubic meters o...

no. 3 example

[0039] Present embodiment is the 3rd example of the treatment method of sulfur slag of the present invention, comprises the steps:

[0040] (1) Sulfur slag melting: put 4 tons of sulfur slag containing 73% tin and 15% copper in an iron pot with 4 tons of crude tin at 700°C, and under the action of a bridge-type centrifugal iron remover, Carry out smelting treatment to obtain 1.4 tons of liquid crude tin containing 97.1% tin and 2.6 tons of molten slag containing 60% tin and 23% copper, and the liquid crude tin is directly recovered in the pot;

[0041] (2) High-temperature oxidation: put 2.6 tons of slag containing 60% tin and 23% copper into a top-blown converter with an inner diameter of 1.8 meters and an inner length of 2.1 meters. The industrial oxygen is sprayed onto the surface of the sulfur slag at a flow rate of 10 cubic meters per minute, and the sulfur slag is completely oxidized into dust. The oxidation process takes 110 minutes, consumes 1,100 cubic meters of indus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com