Utilization device of integral natural gas compressor energy-saving technique

A natural gas and compressor technology, applied in the field of integrated natural gas compressor energy-saving technology utilization devices, can solve problems such as corrosion of the rear pulley, easy dust contamination of the pulley, etc., and achieve the effect of convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

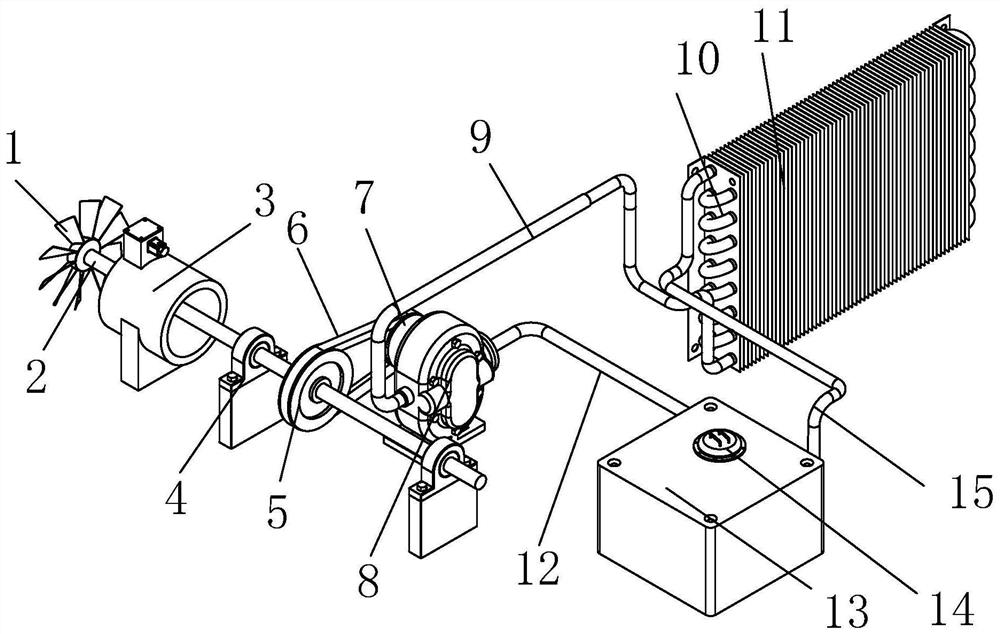

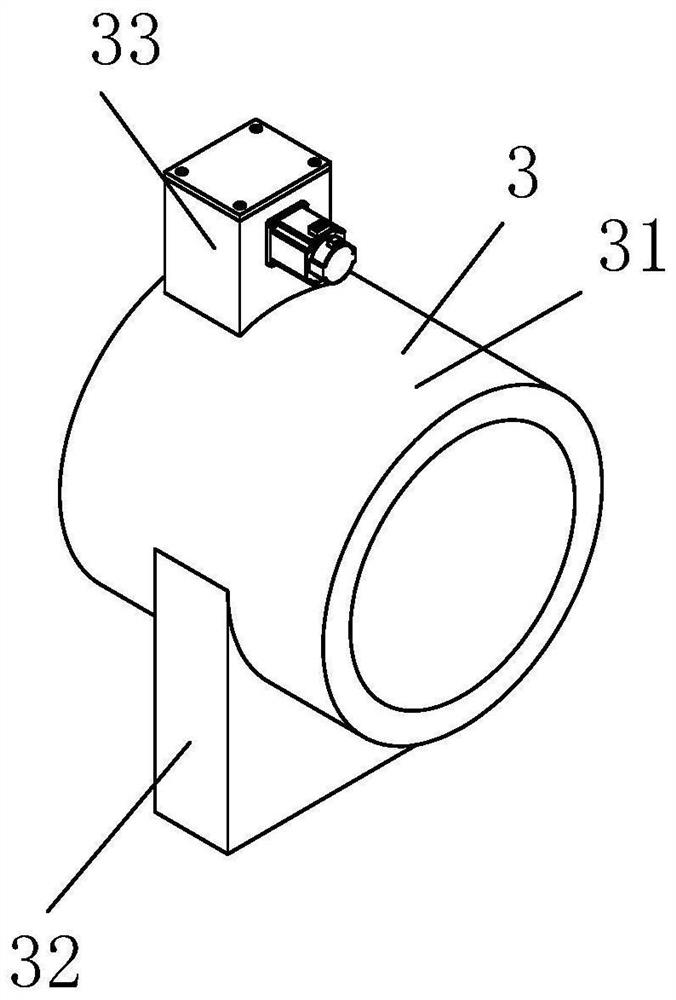

[0028] see figure 1 , the present invention provides an integrated natural gas compressor energy-saving technology utilization device through improvement, including fan blade 1, the inner middle part of fan blade 1 is fixed with transmission shaft 2, and the middle part of the outer diameter surface of transmission shaft 2 and the right end are fixed with shaft seats 4. The outer diameter surface of the transmission shaft 2 is sleeved with the driving pulley 5 near the right end of the middle part, and the outer diameter surface of the driving pulley 5 rotates synchronously with the driven pulley 7 through the timing belt 6, and the inner right end of the driven pulley 7 is connected with the circulation pump 8. The connecting shaft on the left side is connected by rotation. The lower end of the front end of the circulation pump 8 is connected to the copper pipe 10 through the drain pipe 9. The outer diameter surface of the copper pipe 10 is fixed with fins 11. The lower end of...

Embodiment 2

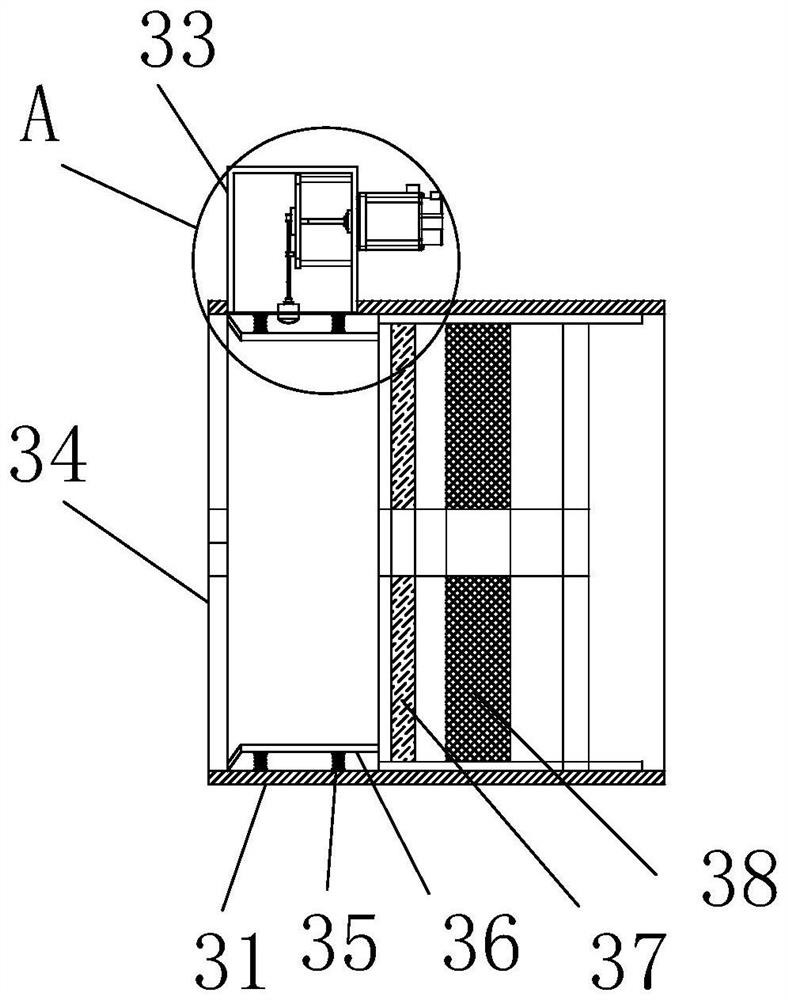

[0033] The present invention provides an integrated natural gas compressor energy-saving technology utilization device through improvement. The middle part of the primary effect filter 37 and the high-efficiency filter 38 is provided with a through hole to facilitate the stable passing of the transmission shaft 2; the middle part of the top of the box body 331 is provided There is a sealing cover, and the sealing cover is fixed with the box body 331 by bolts, which is convenient for internal inspection and maintenance; eight groups of springs 35 are arranged, and the eight groups of springs 35 are distributed in a ring, which is convenient for the stable vibration of the inner tube 36.

[0034] The present invention provides an integral natural gas compressor energy-saving technology utilization device through improvement, and its working principle is as follows;

[0035] First, when the equipment needs to be used, first place the equipment at the position where it needs to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com