Elevating machine for fermented grains

A technology of a feeder and a fermented grain, applied in the field of a fermented gluten feeder, can solve the problems that the fermented grain is susceptible to infection by miscellaneous bacteria, affect the efficiency of scooping out the fermented grain, and have a great influence on human factors, and achieve a hygienic transfer process. Environmental protection, low labor intensity of workers, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]The principles and features of the present invention are described below in conjunction with examples, which are only used to explain the present invention and are not intended to limit the scope of the present invention.

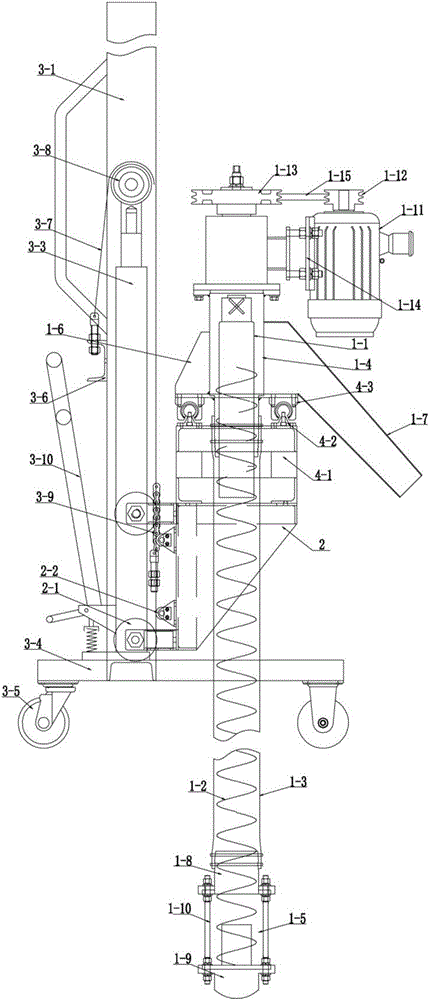

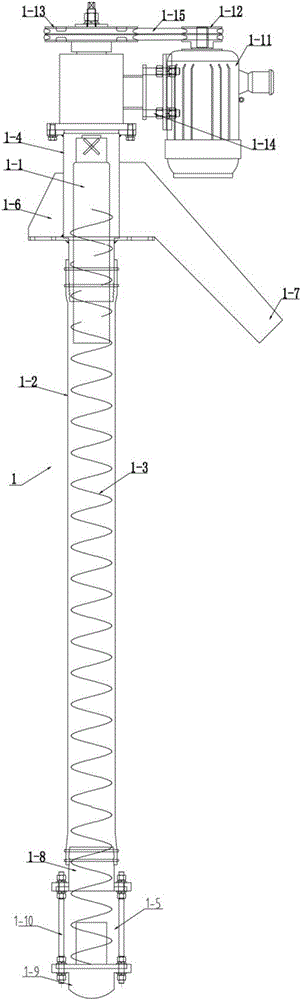

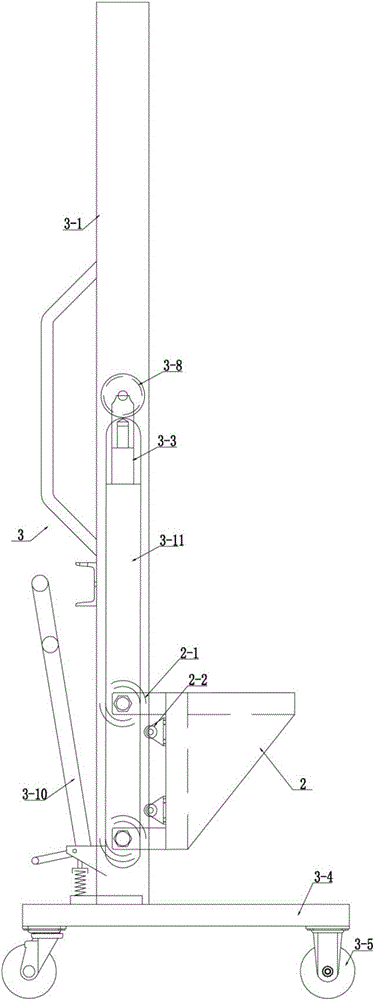

[0035] like Figure 1 to Figure 8 As shown, a wine unstrained spirits feeder includes a lifting platform 2, and the lifting platform 2 is arranged on a hydraulic lifting car 3, and the lifting platform can go up and down in the vertical direction under the action of the hydraulic lifting car. Move, the lifting platform is provided with a material lifting mechanism 1;

[0036] The material lifting mechanism 1 includes a rotating shaft 1-1, an outer jacket 1-4, a dragon 1-2 and a power mechanism for driving the rotating shaft to rotate, the dragon 1-2 is a spiral blade, and the outer sleeve of the dragon has Jiaolong shell 1-3, said Jiaolong shell 1-3 is made of hose, said Jiaolong 1-2 and Jiaolong shell 1-3 form a soft delivery pipeline, said jacket 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com