Patents

Literature

35results about How to "Play a role in loosening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

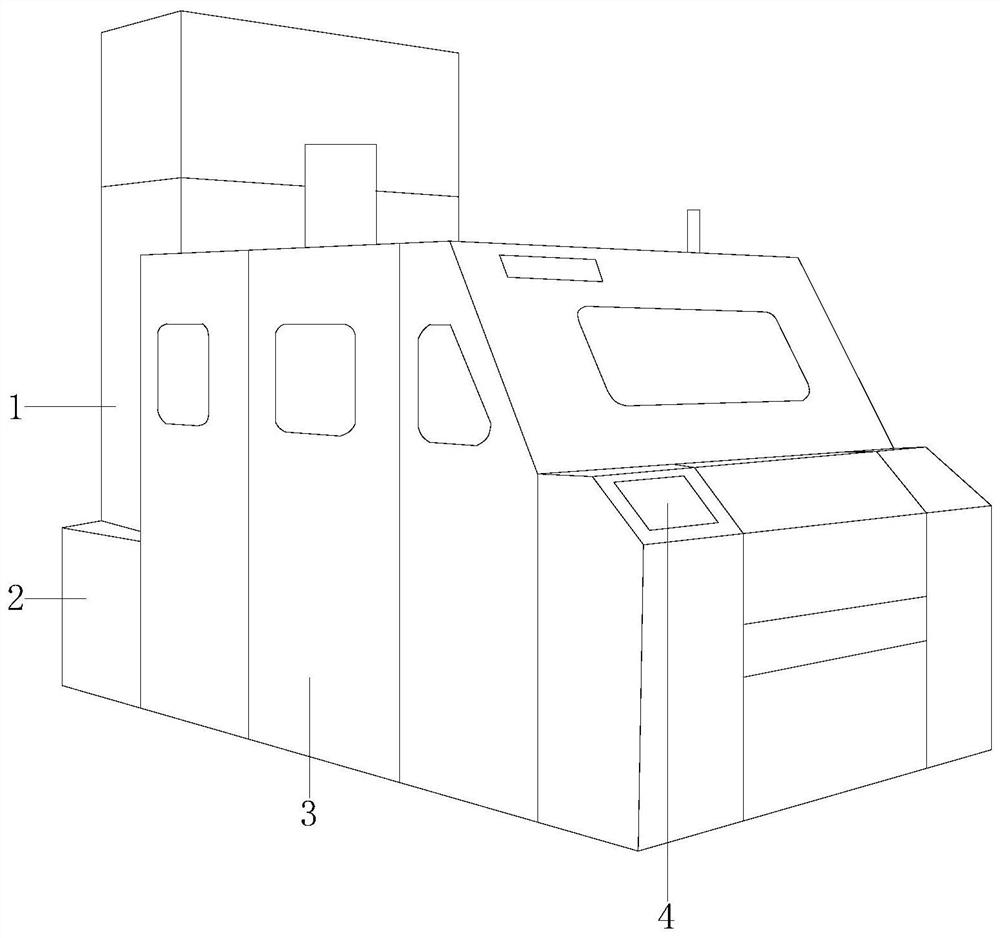

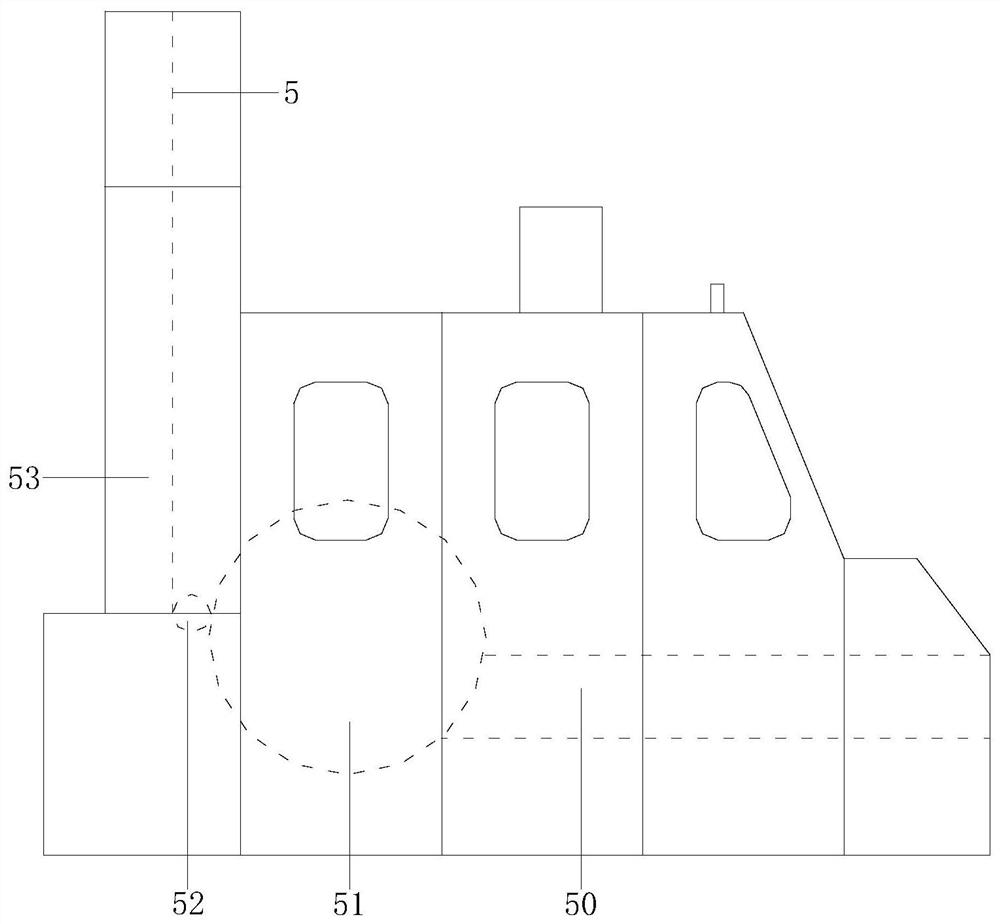

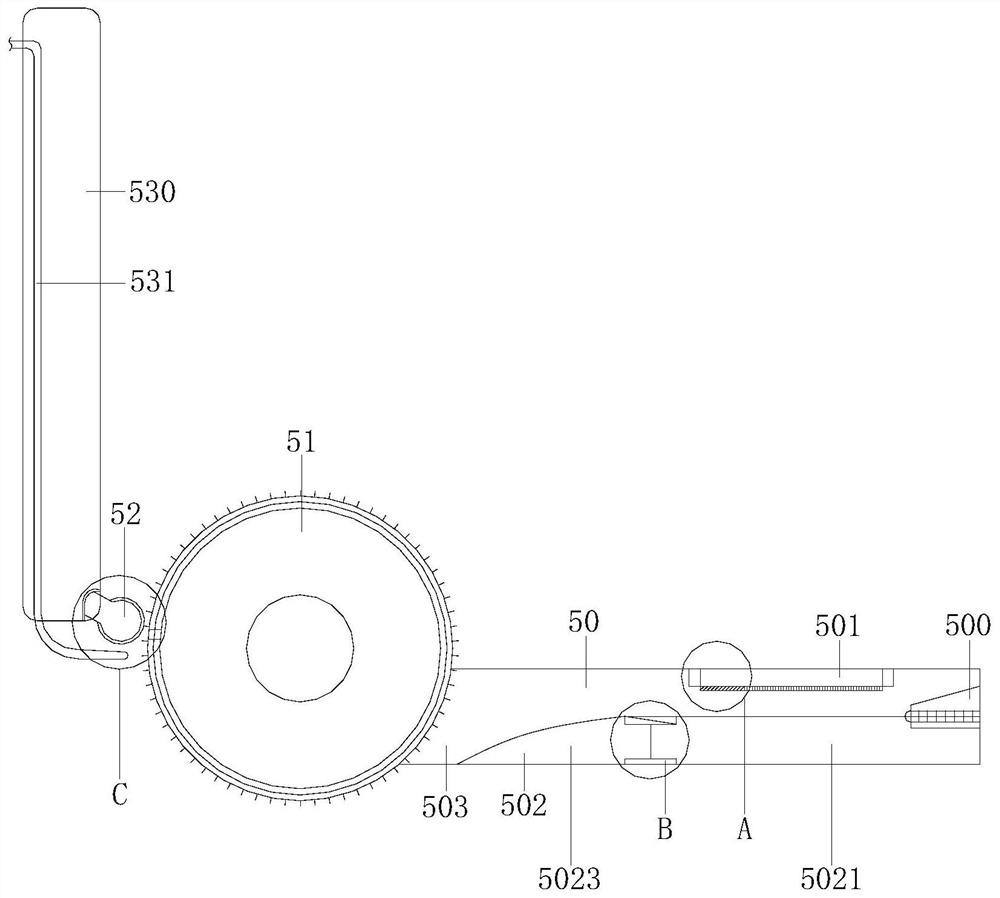

Closed silo composting reactor

InactiveCN105060962APrevent compactionRaise the fermentation temperatureBio-organic fraction processingOrganic fertiliser preparationEffective volumeFermentation

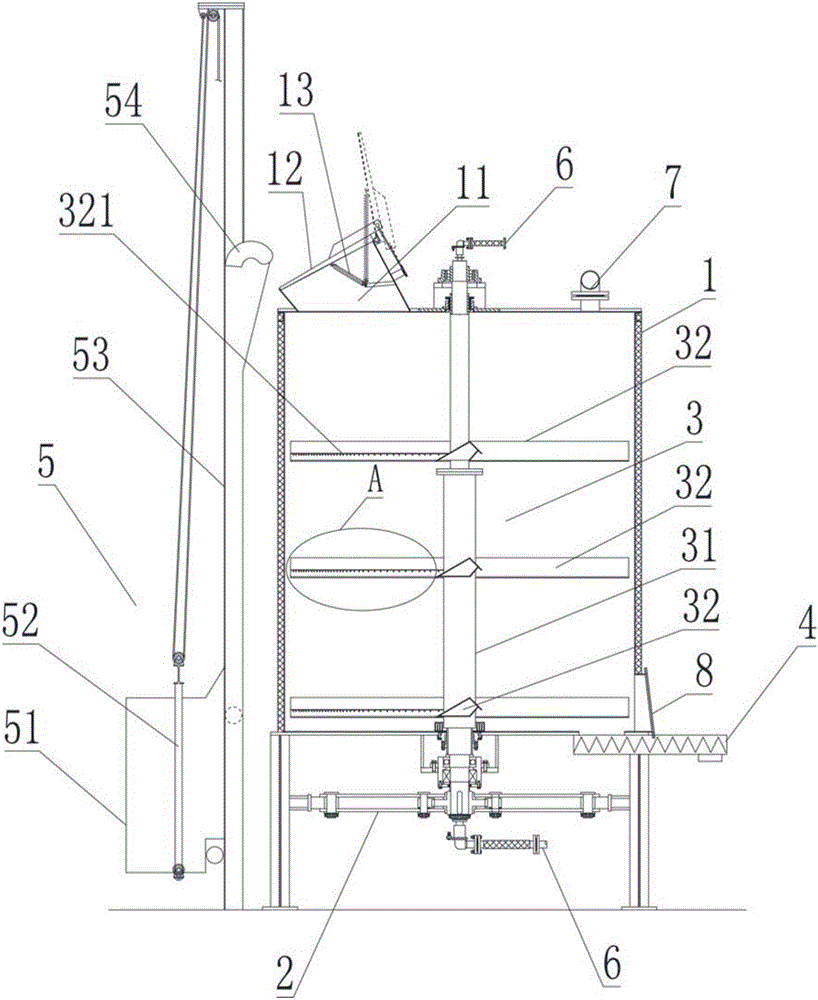

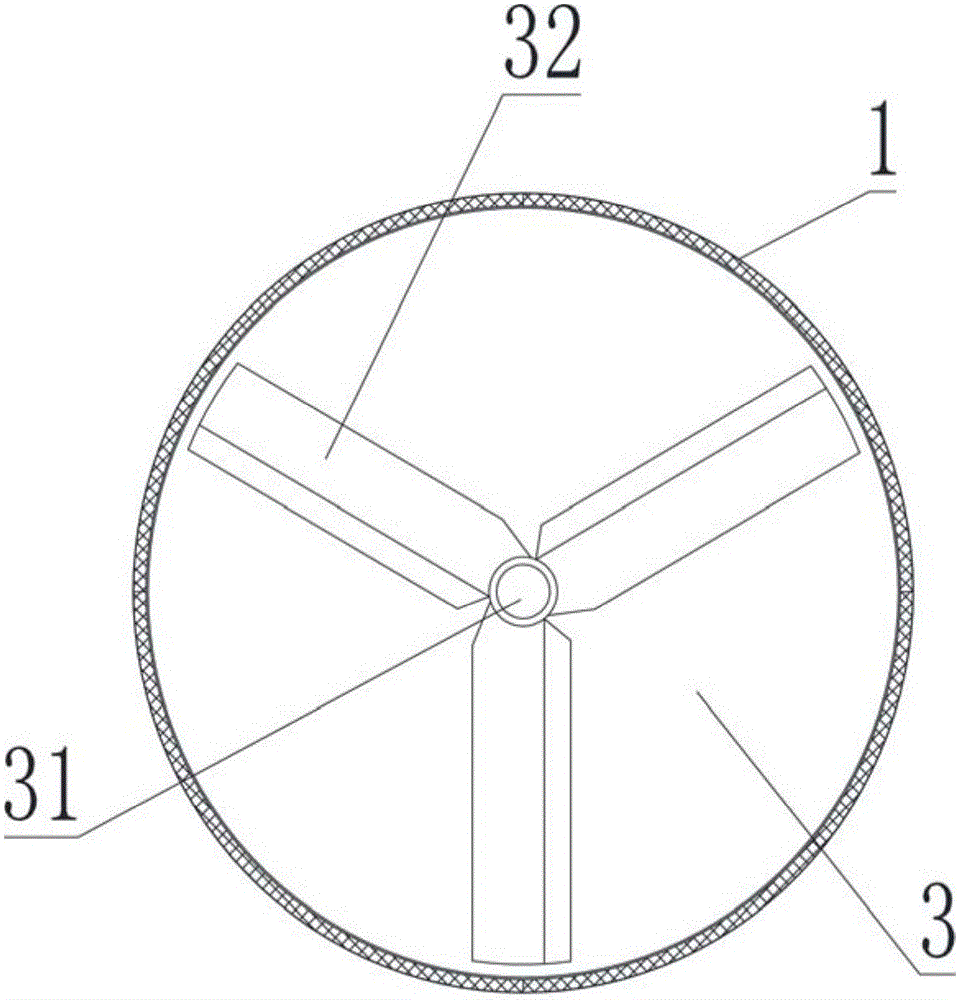

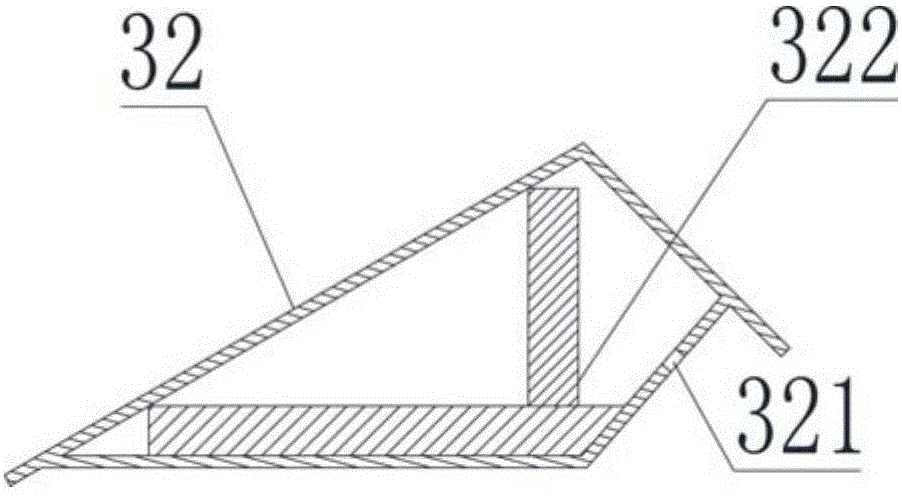

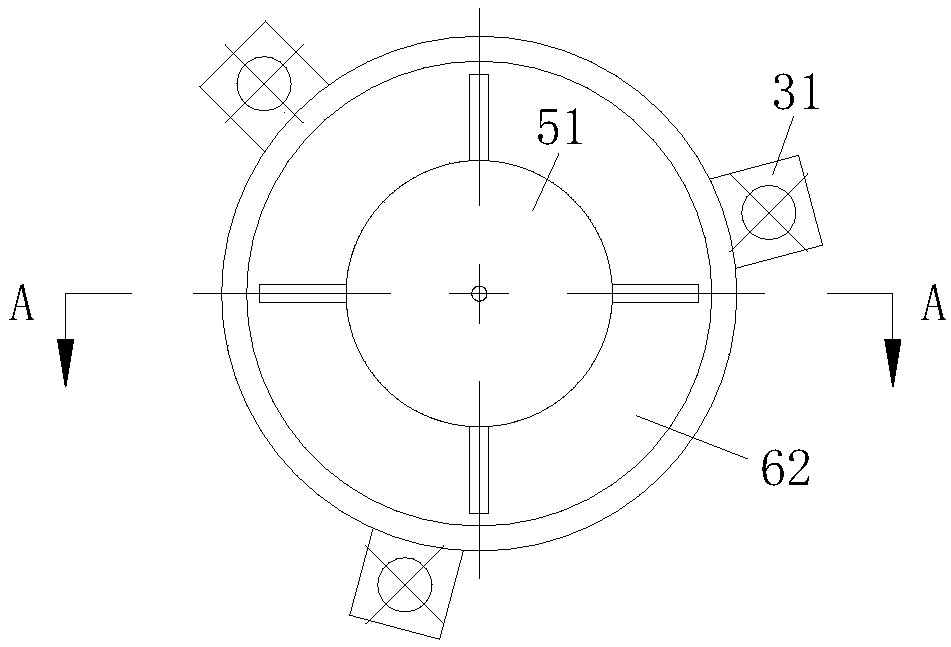

The invention relates to the technical field of organic solid waste treatment, in particular to a closed silo composting reactor. The closed silo composting reactor comprises a composting silo, a stirring device, a hydraulic drive device and a discharge screw conveyor, wherein a feed port and an exhaust port are formed in the top of the composting silo; a discharge port is formed in the bottom of the composting silo; the discharge screw conveyor corresponds to the discharge port; the stirring device is arranged in the composting silo; the hydraulic drive device drives the stirring device to rotate and stir. The composting silo adopts vertical closed design, has high effective volume and can increase fermentation temperature, so that the fermentation period is greatly shortened; the stirring device performs continuous dynamic stirring, thereby having stirring, mixing and loosening effects and avoiding material compaction; with the adoption of rotating aeration, effectiveness and uniformity of aeration are improved.

Owner:北京沃土天地生物科技股份有限公司

Novel cotton cultivation method

InactiveCN102783345AImprove labor productivityReduce labor intensityHorticultureUltimate tensile strengthBiology

Seedling raising and transplanting in protected areas can prolong growth period by 30-40 days and promote increase of cotton yield. Traditional seedling raising and transplanting use soil nutrition pots. Manufacturing and transplanting of the soil nutrition pots are labor-consuming, high in labor intensity and low in efficiency. Paper-tube combined filled lightweight substrate and industrially made nutrition pots are used, mechanical seeding and mechanical transplanting are carried out and are development trends of cotton industry in China.

Owner:操宇琳

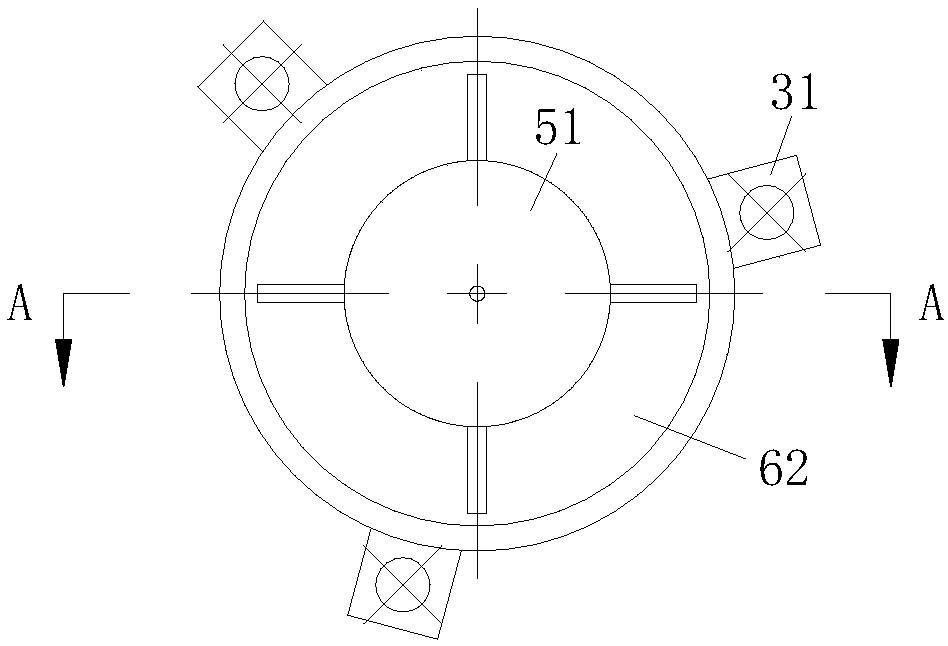

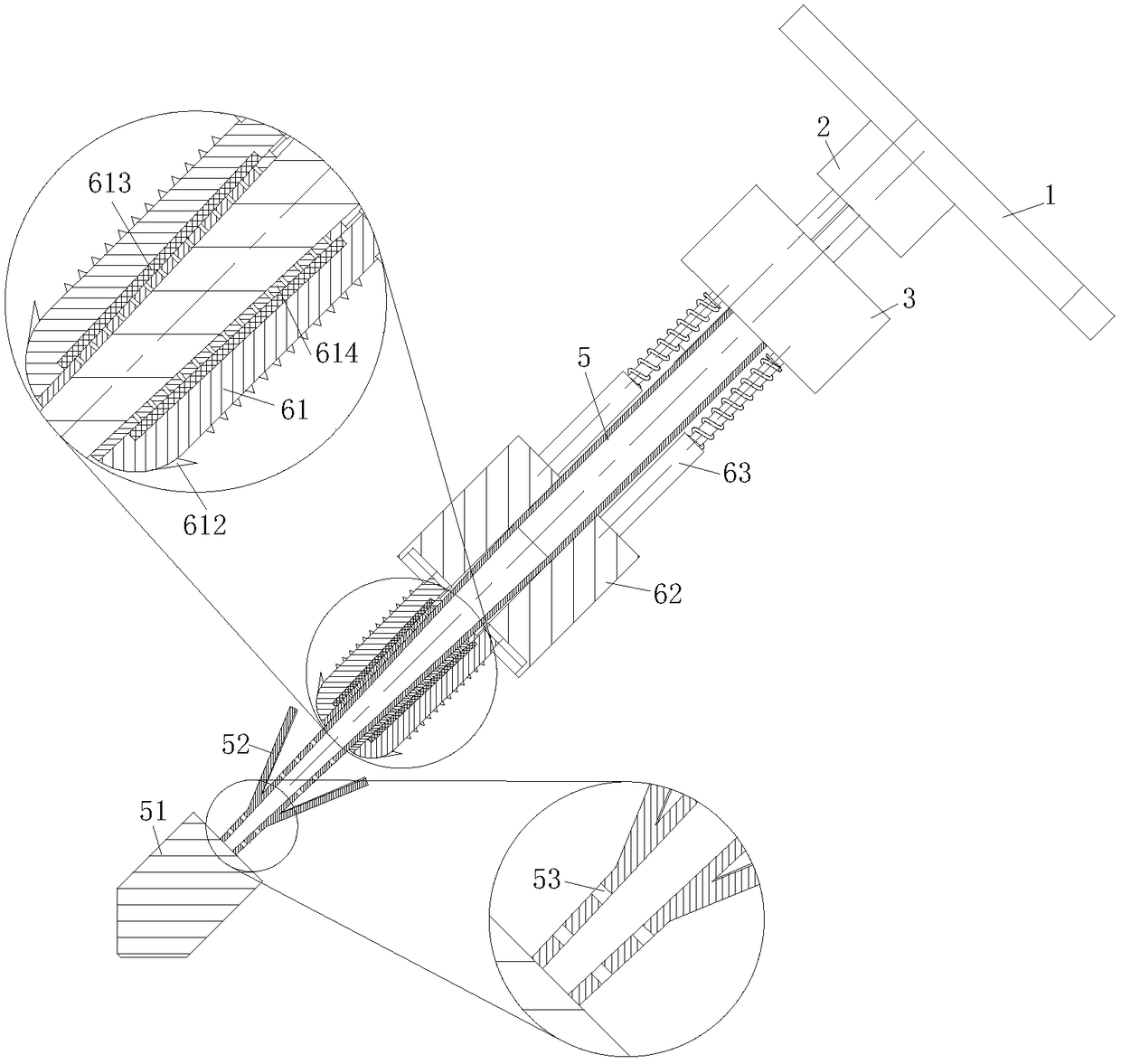

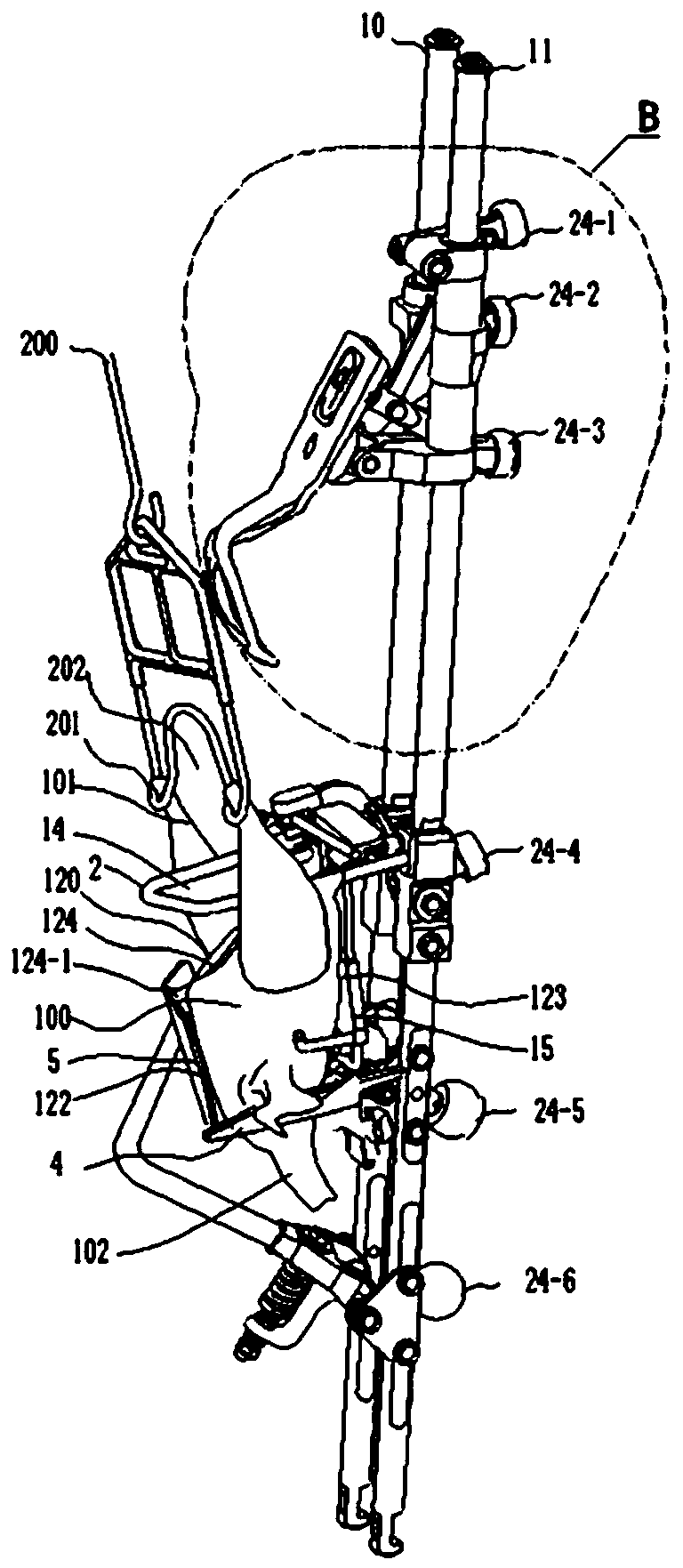

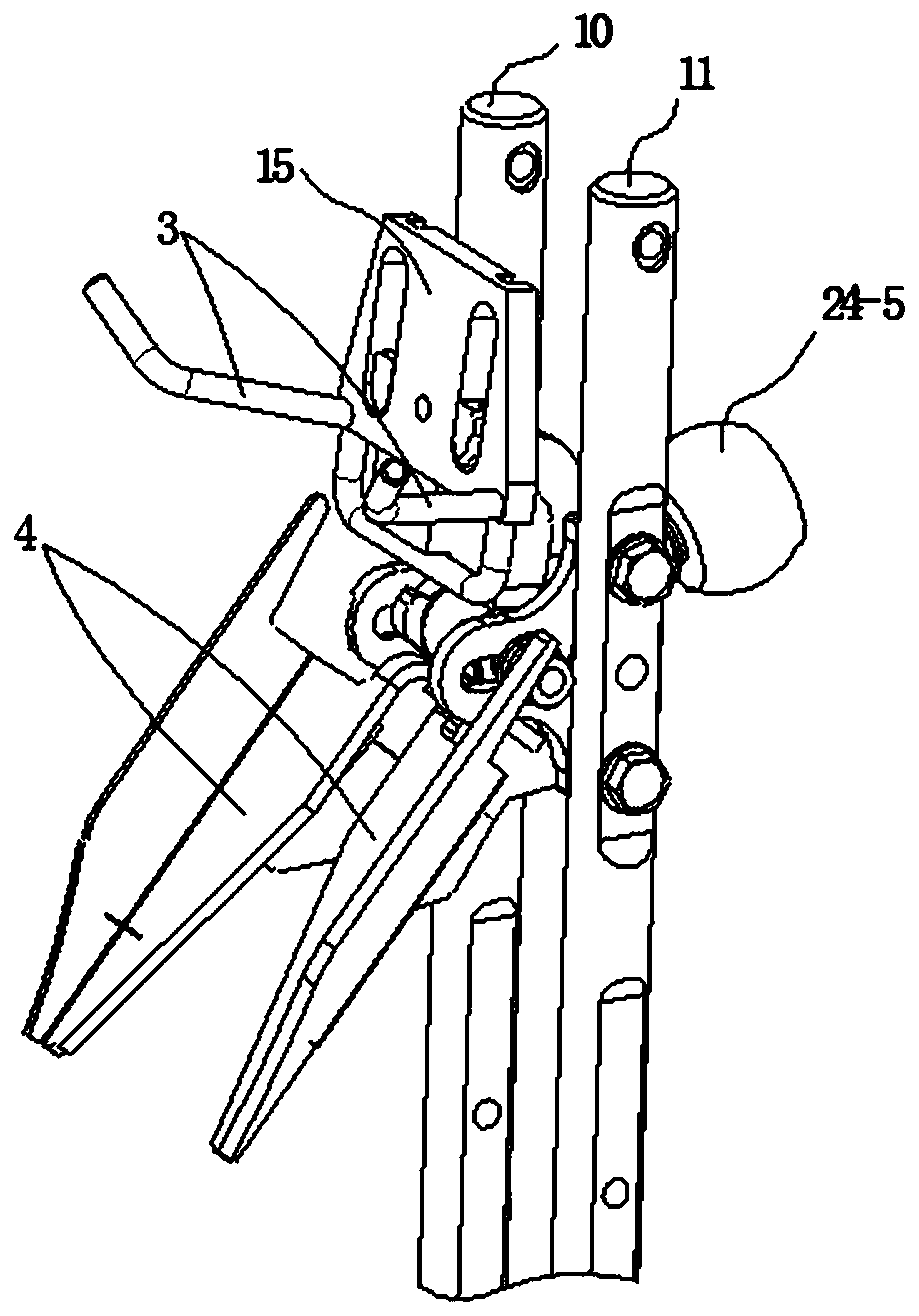

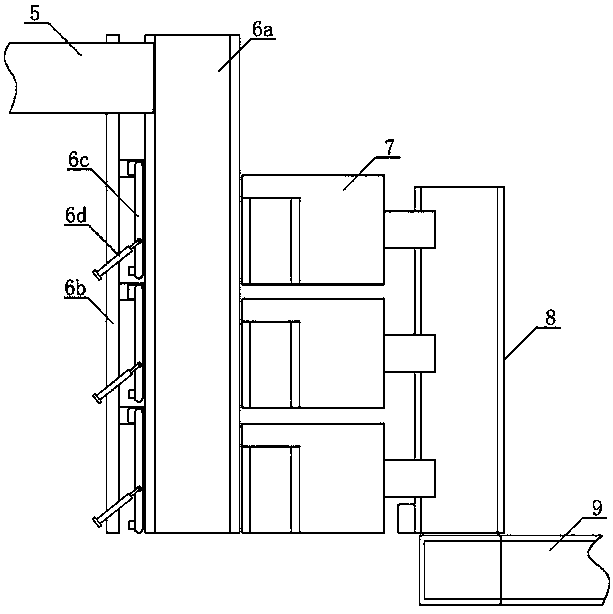

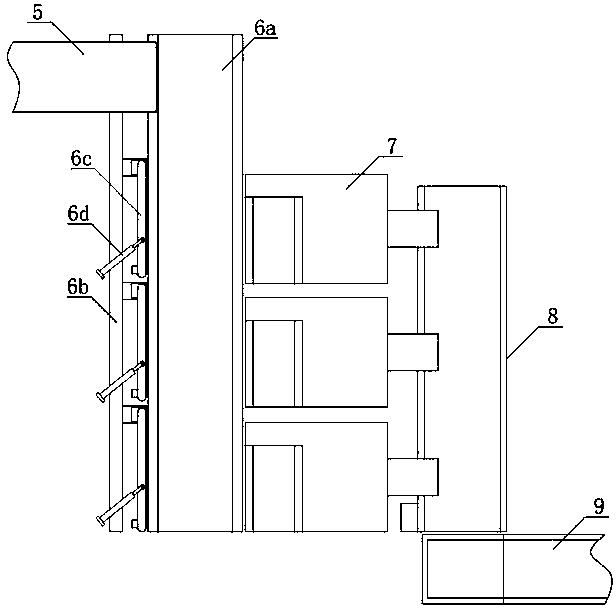

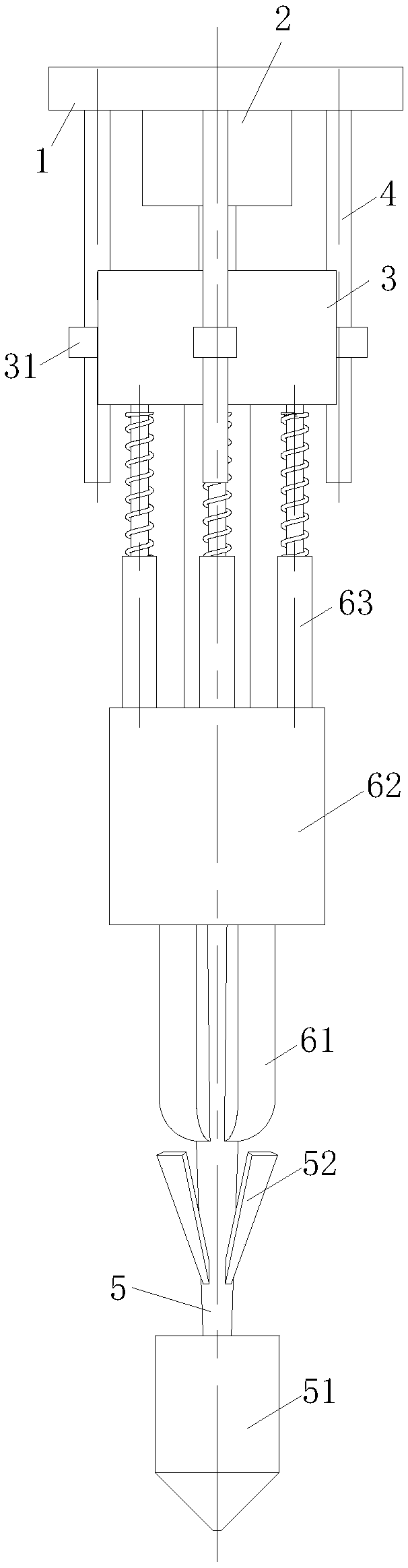

Rock drilling and braking integrated machine

ActiveCN108222931AAchieve brokenAvoid repositioningConstructionsSlitting machinesEngineeringDrill bit

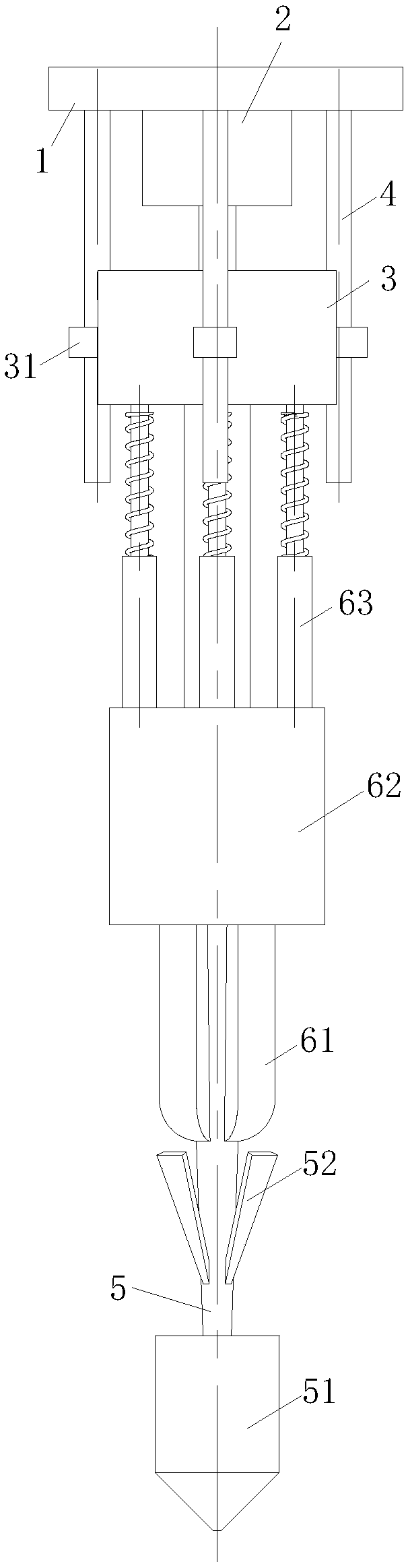

The invention belongs to the field of drilling and splitting devices, and particularly discloses a rock drilling and braking integrated machine. The rock drilling and braking integrated machine comprises a fixed plate, an oil cylinder, a motor, a guide pillar, a pushing ram and a crushing module. The oil cylinder is fixed on the fixed plate, the end head of the oil cylinder is fixedly connected with the motor, a group of sliding blocks are fixedly arranged on the periphery of the motor, and the sliding blocks are connected to the guide pillar in a sleeving mode. The guide pillar is arranged onthe fixed plate, the oil cylinder can push the motor to move up and down along the guide pillar, and a rotating shaft of the motor is fixedly connected with the pushing ram, and the periphery of thepushing ram is connected with the crushing module in a fit mode. The crushing module comprises a wedge block, an installation disk and an expansion link, and the end head of the pushing ram is fixedlyconnected with a drill. When the rock drilling and braking integrated machine is drilled to the design depth, under the action of the pushing ram, the crushing module expands the hole to the surrounding area to achieve rock breaking. The rock drilling and braking integrated machine integrates drilling and splitting to avoid secondary positioning of a crushing rod, so that the drilling and splitting work is carried out in a coherent mode, the working process is simplified, and the working efficiency is improved.

Owner:淮北通鸣矿业有限公司

Preparation method of lipid lowering monascus purpureus powder

The present invention provides a preparation method of lipid lowering monascus purpureus powder. The method comprises the steps of liquid seed preparing, solid fermentation medium preparing, fermentation culturing, drying and crushing. At the same time, the lipid lowering monascus purpureus powder contains two lipid-lowering ingredients of Monacolin k and phytosterol. In a fermentation for 18 days, content of the Monacolin k is up to 15.9 mg / g and content of the phytosterol is up to 11.3 mg / g, and content of citrinin is in line with safety standards. The lipid lowering monascus purpureus powder is simple in preparation method, free of rice soaking, rice steaming and water spraying processes, low in costs, short in fermentation period, low in risks of micro-organism infections, and suitable to be used as raw materials for health-care food or medicines.

Owner:JIANGSU SHENHUA PHARMA

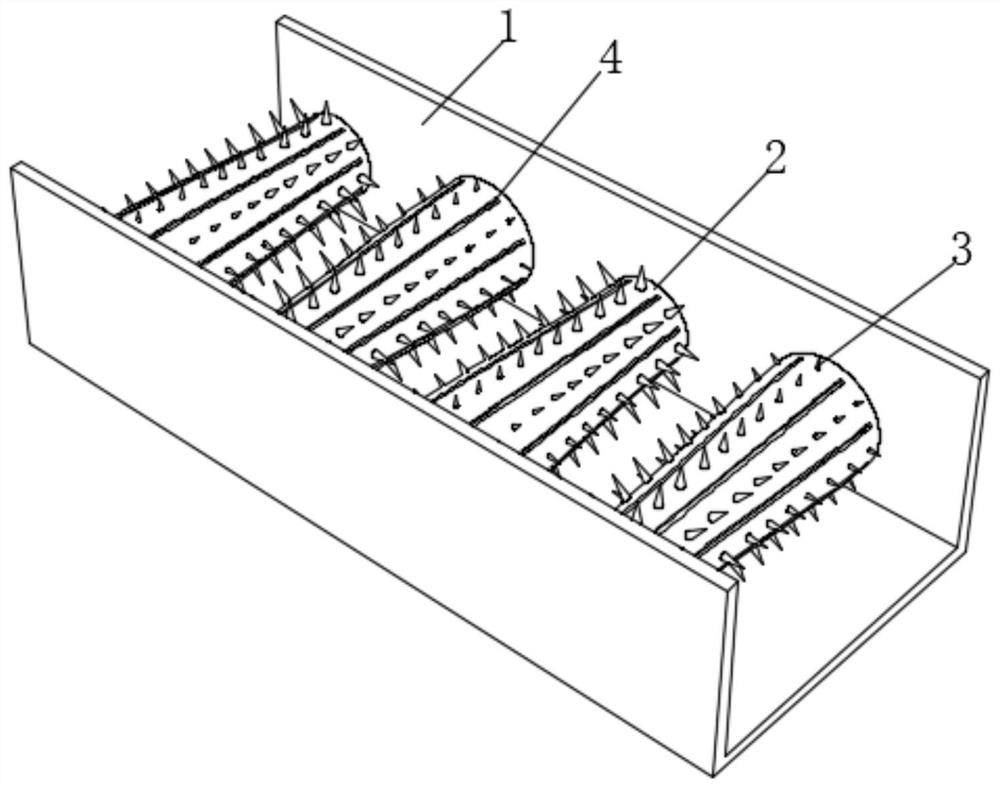

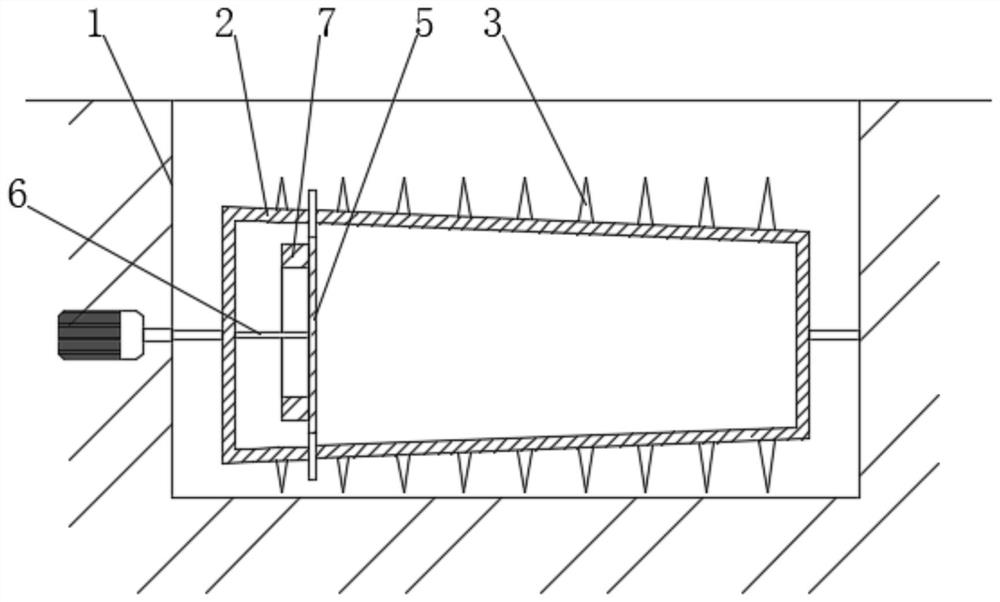

Impurity removal device for wool processing

InactiveCN112813507APlay a role in looseningAvoid clumpingDrying gas arrangementsWool fibre washing/scouringThermodynamicsElectric machinery

The invention discloses an impurity removal device for wool processing. The impurity removal device comprises a base, wherein an impurity removal box is arranged above the base, a crushing barrel is arranged on the left side of the impurity removal box, a first motor is arranged on the left side of the interior of the crushing barrel, a first rotating rod is arranged at the output end of the first motor, a rotating blade is arranged on the first rotating rod, stirring rods are arranged in the impurity removal box, a filter screen plate is arranged below the stirring rods, the filter screen plate is in sliding connection with the impurity removal box, a water tank is arranged on the left side of the impurity removal box, a water pump is arranged at the top of the water tank, a water outlet pipe is arranged at the water inlet end of the water pump, a water inlet pipe is arranged at the water outlet end of the water pump, and the tail end of the water inlet pipe is in communication with the impurity removal box. During working, wool is poured into the crushing barrel from the feeding hopper, the wool is opened through the arrangement of the rotating blades, and the phenomenon of wool caking is fully avoided; meanwhile, a water pump injects water into the impurity removal box, a second motor drives the stirring rods to rotate, and thus the wool is cleaned.

Owner:苏州开江纺织品有限公司

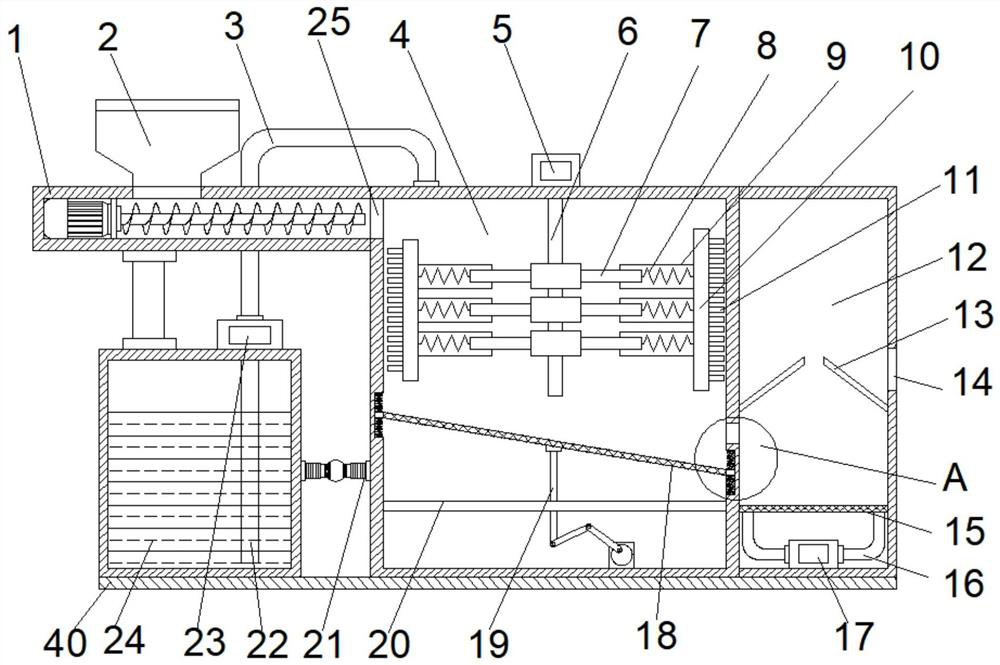

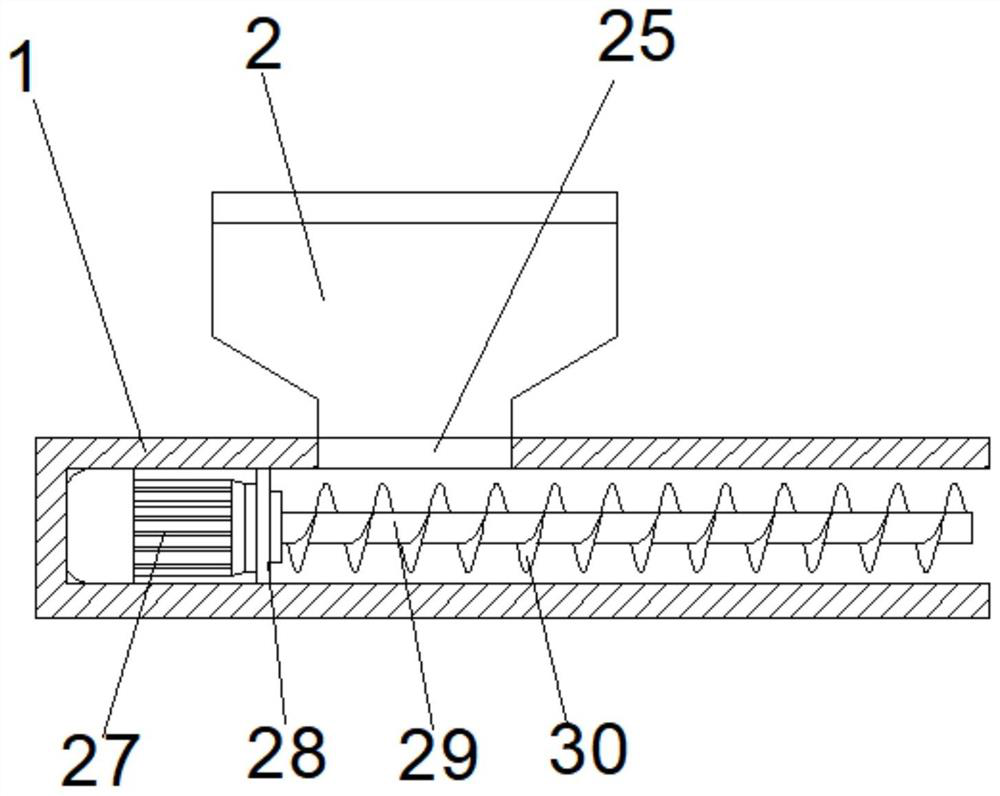

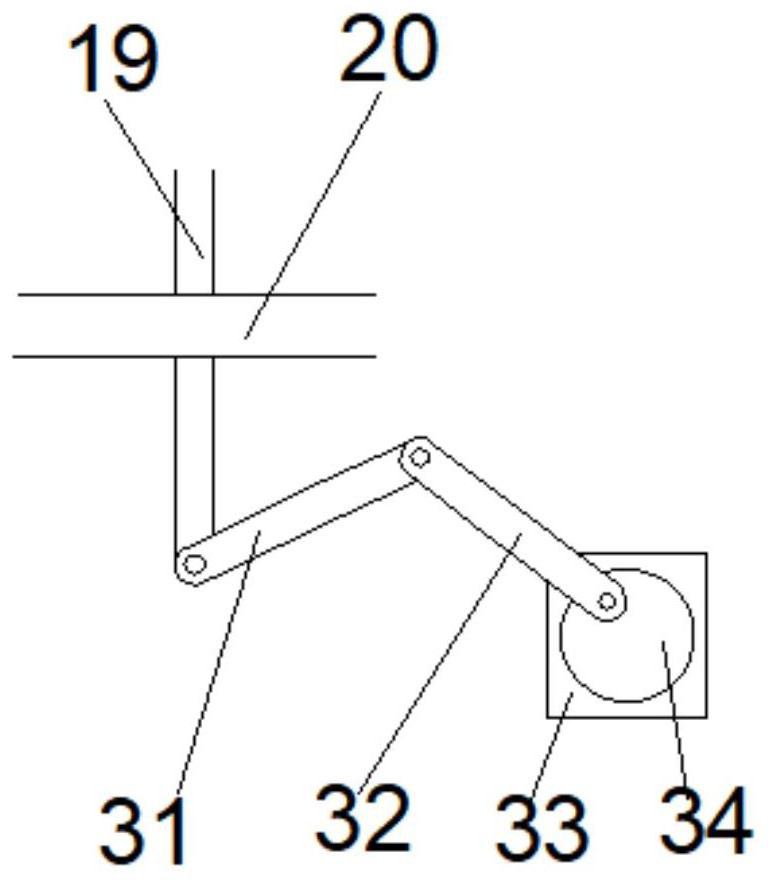

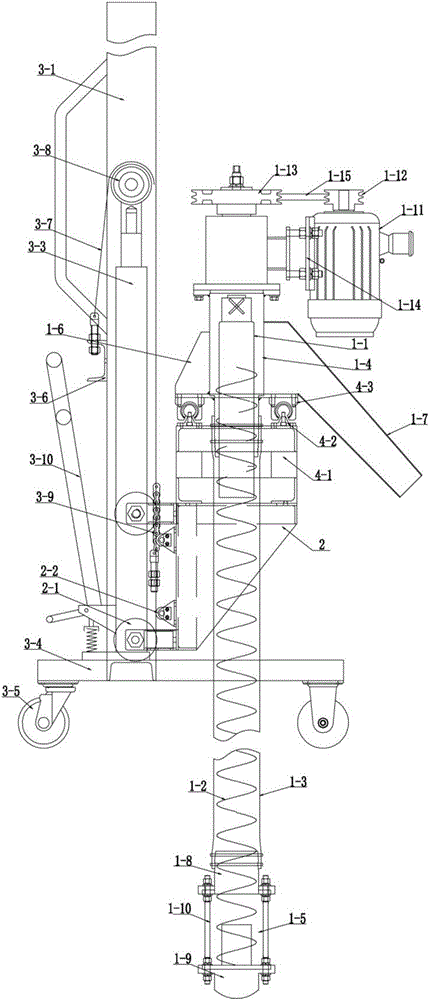

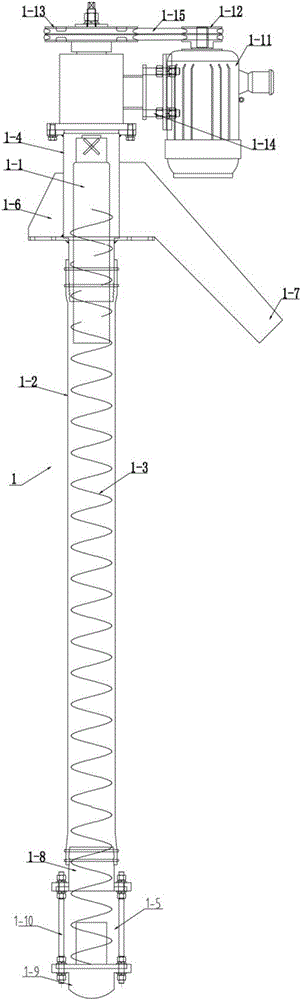

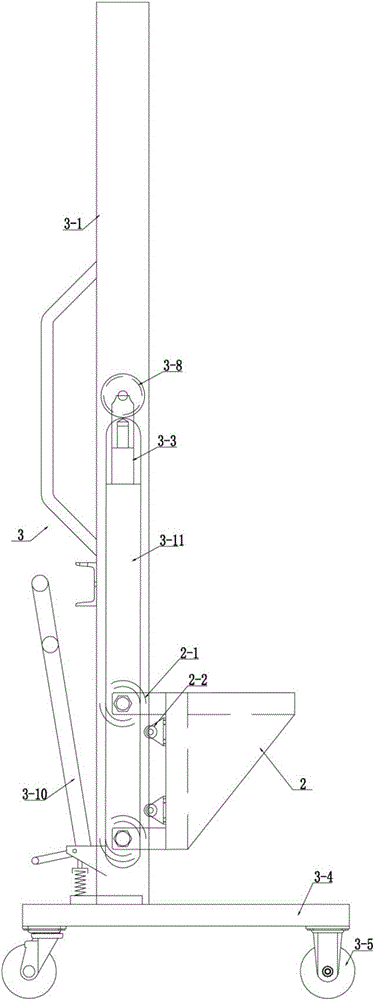

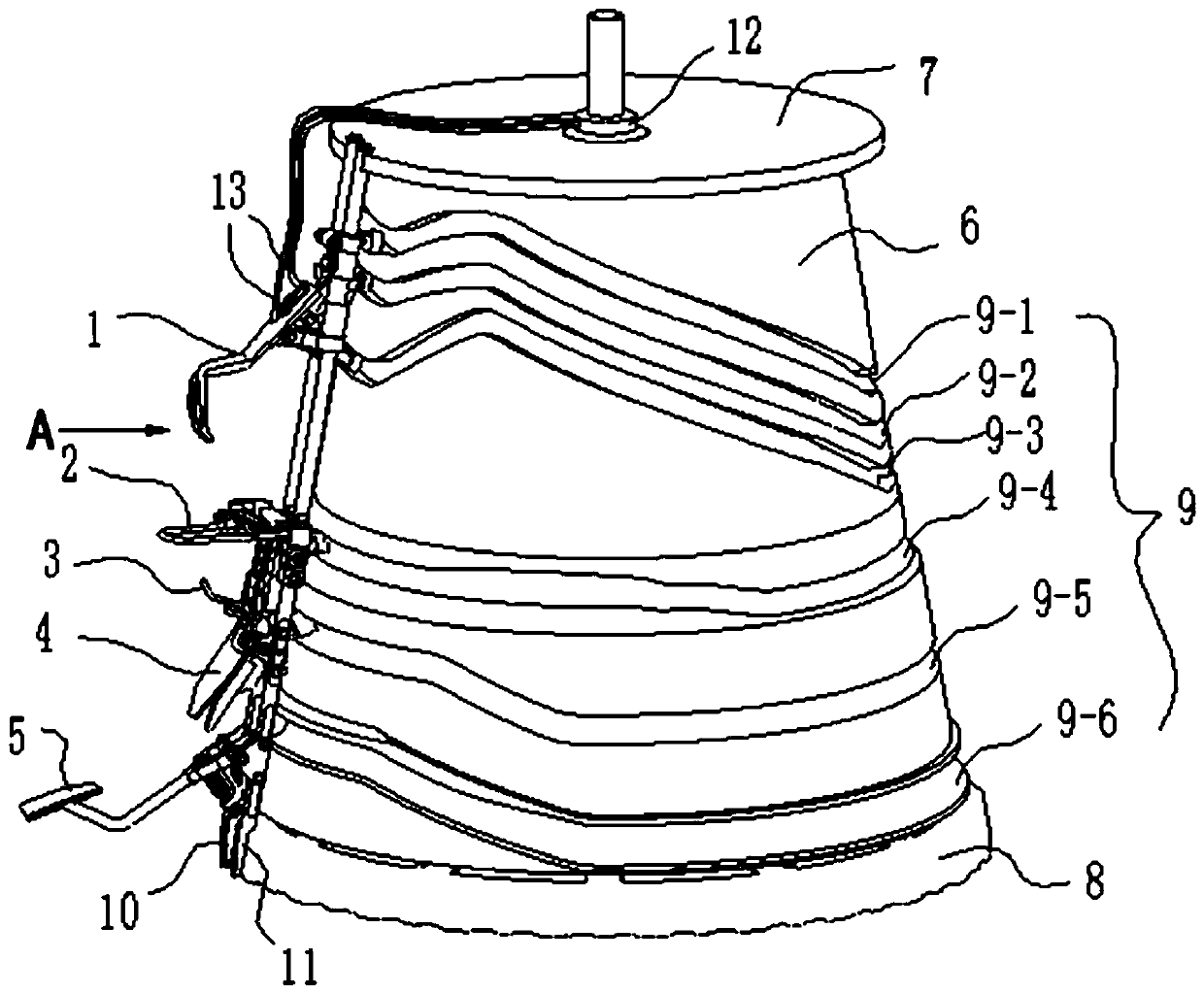

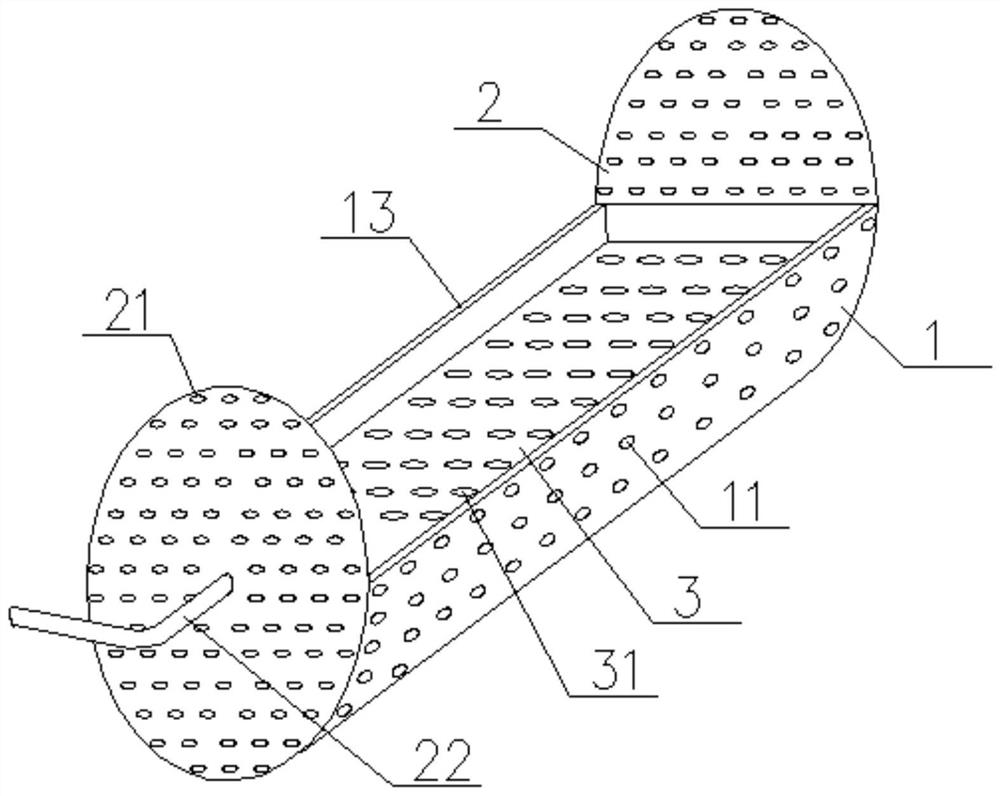

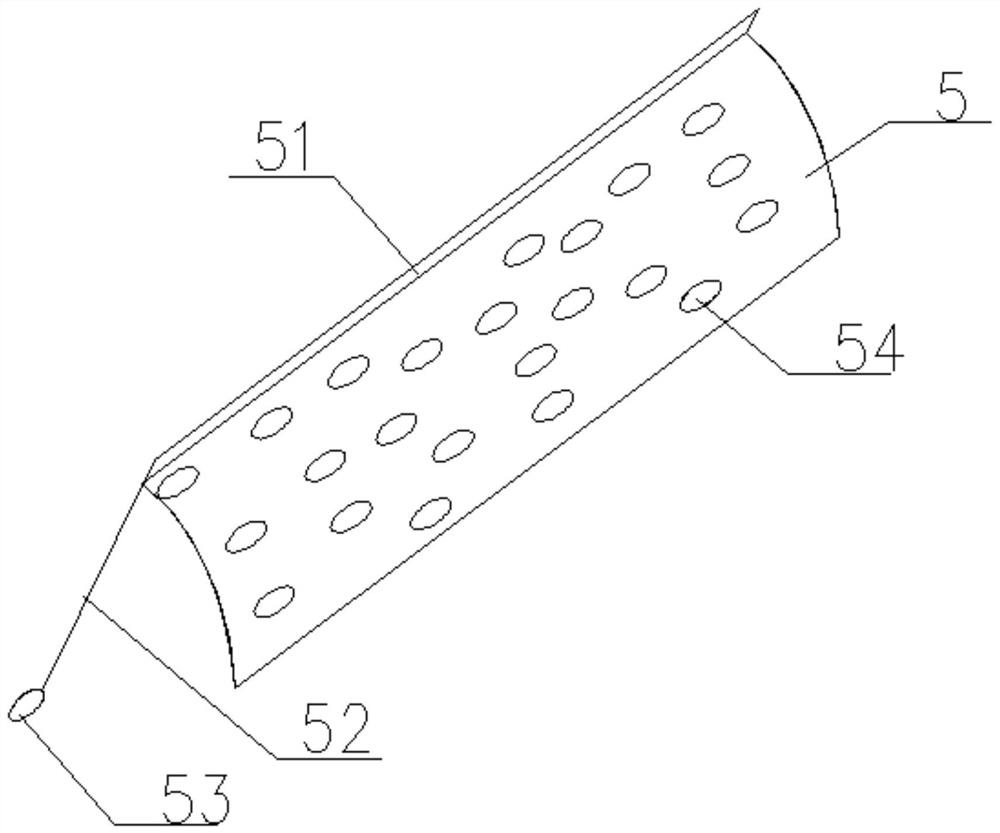

Elevating machine for fermented grains

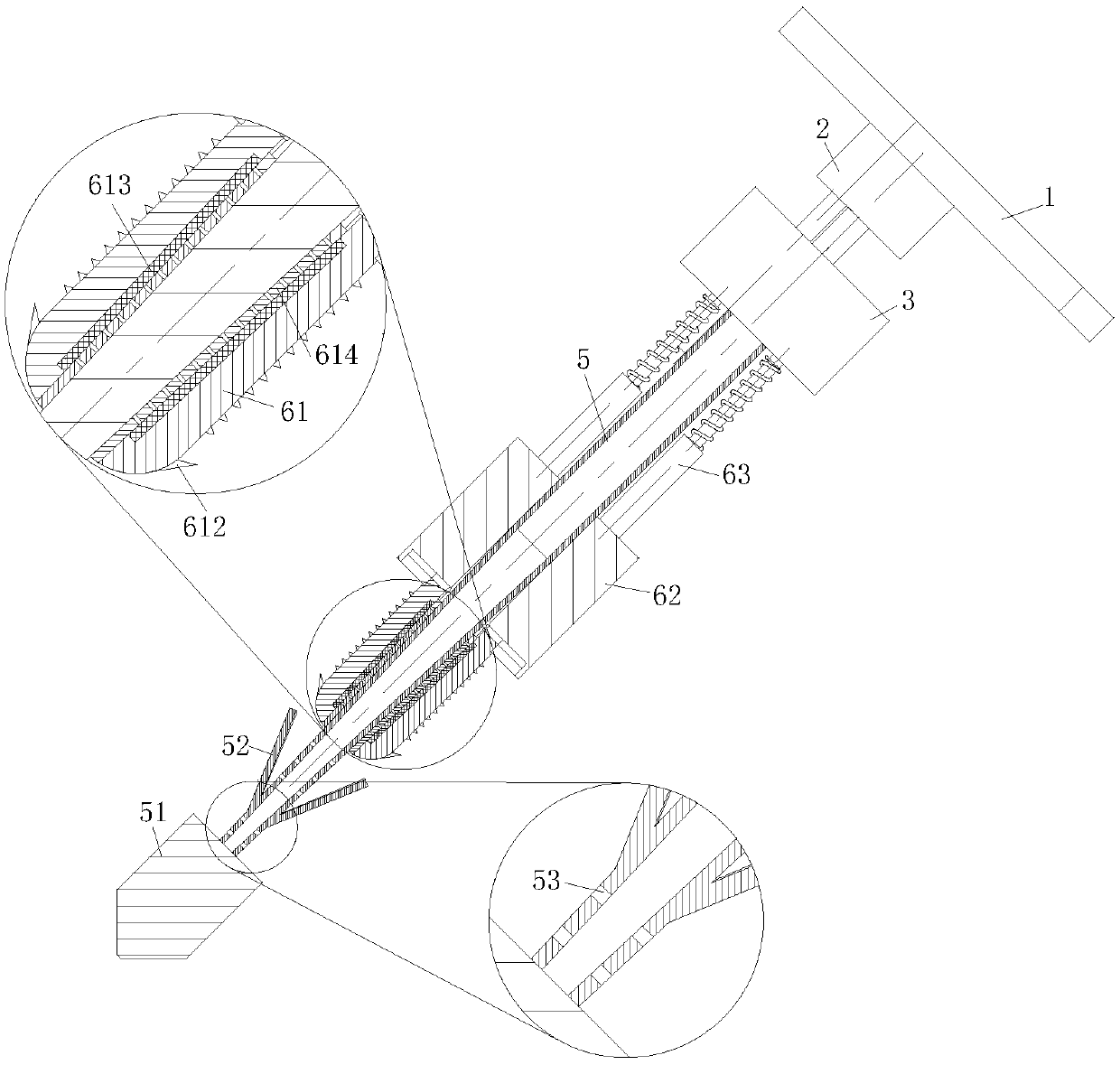

The invention discloses an elevating machine for fermented grains, and belongs to the technical field of wine-making equipment. The elevating machine comprises a lifting platform and an elevating mechanism, wherein the lifting platform is capable of moving up and down along a vertical direction under the action of a hydraulic lifting truck; the elevating mechanism comprises a rotary shaft, an outer sleeve, an auger and a power mechanism used for driving the rotary shaft to rotate; the auger is a spiral blade; an auger housing is installed outside the auger in a sleeving manner; the auger housing is made of a hose; the auger and the auger housing form a flexible conveying pipeline; the outer sleeve is installed at the outer side of the rotary shaft in a sleeving manner; the auger housing is connected with the lower end of the outer sleeve; the upper end of the auger is connected with the rotary shaft; a charge port is arranged in the lower end of the auger housing; a fixed seat is arranged on the outer sleeve and a discharge port is arranged in the outer sleeve; a discharge tube corresponding to the discharge port is arranged on the fixed seat; and the fixed seat is installed on the lifting platform. The elevating machine disclosed by the invention is simple in structure, convenient to operate, time-saving and labour-saving, low in the labour intensity of workers, and high in elevating efficiency for the fermented grains; and the whole process of elevating, transferring and storing the fermented grains is sanitary and environment-friendly.

Owner:烟台良荣机械精业有限公司

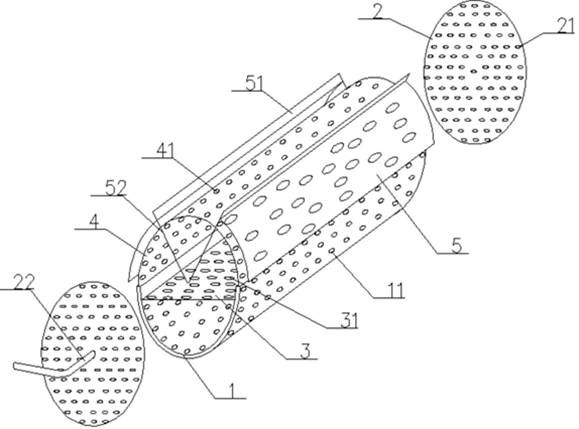

Peanut planting method capable of rapidly harvesting

InactiveCN109429969AGuaranteed moisture contentIncrease moisture contentFabaceae cultivationDigger harvestersEmbryoDisease free

The invention discloses a peanut planting method capable of rapidly harvesting, which comprises the following steps: I, selecting plump disease-free peanut seeds for accelerating germination; II, taking out the peanut seeds after embryo roots of the peanut seeds are exposed to white, and after sequentially soaking the peanut seeds in cold water and dressing seeds, obtaining the peanuts to be sown;III, digging a plurality of planting holes in a peanut planting field, and placing one peanut planting device in one planting hole; IV, covering soil and sowing in the planting device; V, harvestingpeanut straws and peanut pods. According to the method, the peanut seeds are directly planted into the planting device, and when the peanuts are ripe, the planting device is taken out from the land, so that the recovery ratio of the peanut pods and the integrity rate of the pods are ensured and the working hours required by harvesting the peanuts are shortened. The method saves time and effort inthe process of taking out the planting device. The planting device is simple in structure and low in manufacturing cost. The method can be widely popularized in the market and is suitable for the national conditions of China as a large agricultural country.

Owner:林芝

High-nutrient organic compound fertilizer

InactiveCN104892312AImprove fertilityPromotes Nutritional BalanceFertilizer mixturesSimple Organic CompoundsSoil quality

The invention discloses a high-nutrient organic compound fertilizer which is prepared from bamboo charcoal, glucose, bamboo vinegar and amino acids. The high-nutrient organic compound fertilizer is prepared by the following steps: pulverizing the bamboo charcoal, and mixing the pulverized bamboo charcoal with a mixed solution formed by the bamboo vinegar, glucose and amino acids. The high-nutrient organic compound fertilizer can obviously improve the soil quality structure and soil environment and improve the crop planting environment, has high and favorable fertilizer efficiency, and is capable of greatly enhancing the yield and lowering the labor cost and production cost.

Owner:张焕东 +1

Poultry offal taking out device

PendingCN111567604AImprove fitImprove the success rate of clampingPoultry eviscerating devicesEngineeringPhysical therapy

Owner:JILIN SSK MASCH&ELECTRON CO LTD

High-nutrient organic granular fertilizer

InactiveCN107721726AImprove fertilityPromote growthExcrement fertilisersBioloigcal waste fertilisersNutrient solutionSoil texture

The invention discloses a high-nutrient organic granular fertilizer. The high-nutrient organic granular fertilizer comprises, by weight, 30 to 65% of dried cake-shaped rape seed dreg powder, 20 to 45%of bamboo charcoal particle, and 5 to 30% of a nutrient solution. The high-nutrient organic granular fertilizer is capable of improving soil texture structure and soil environment obviously, improving crop plantation environment, and providing crops with needed nutrients; the fertilizer efficiency is high; preparation cost is low; crop yield can be increased greatly; and the high-nutrient organicgranular fertilizer is friendly to the environment.

Owner:江西科农沃科技有限责任公司

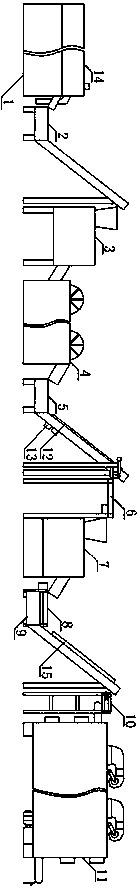

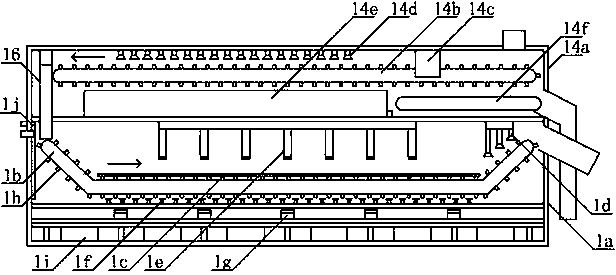

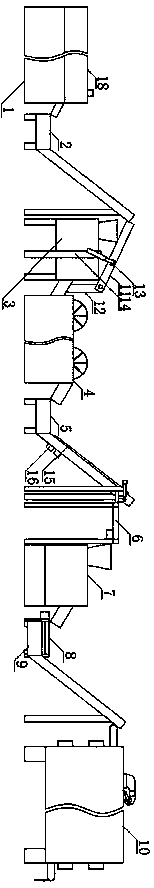

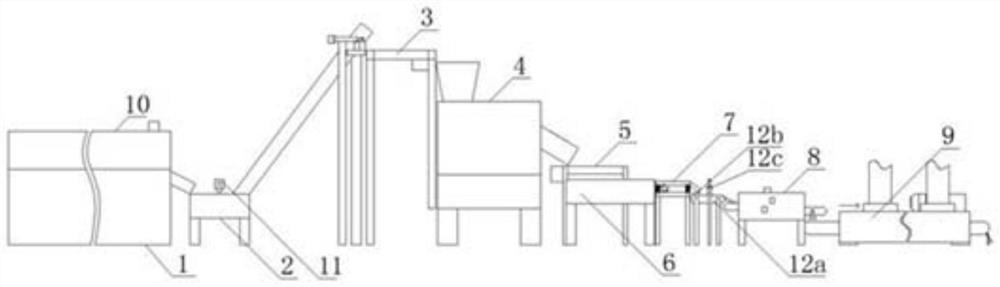

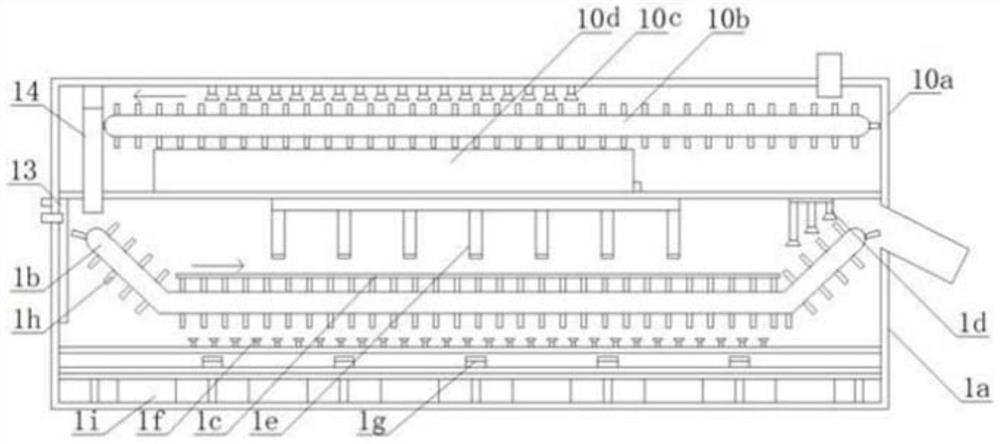

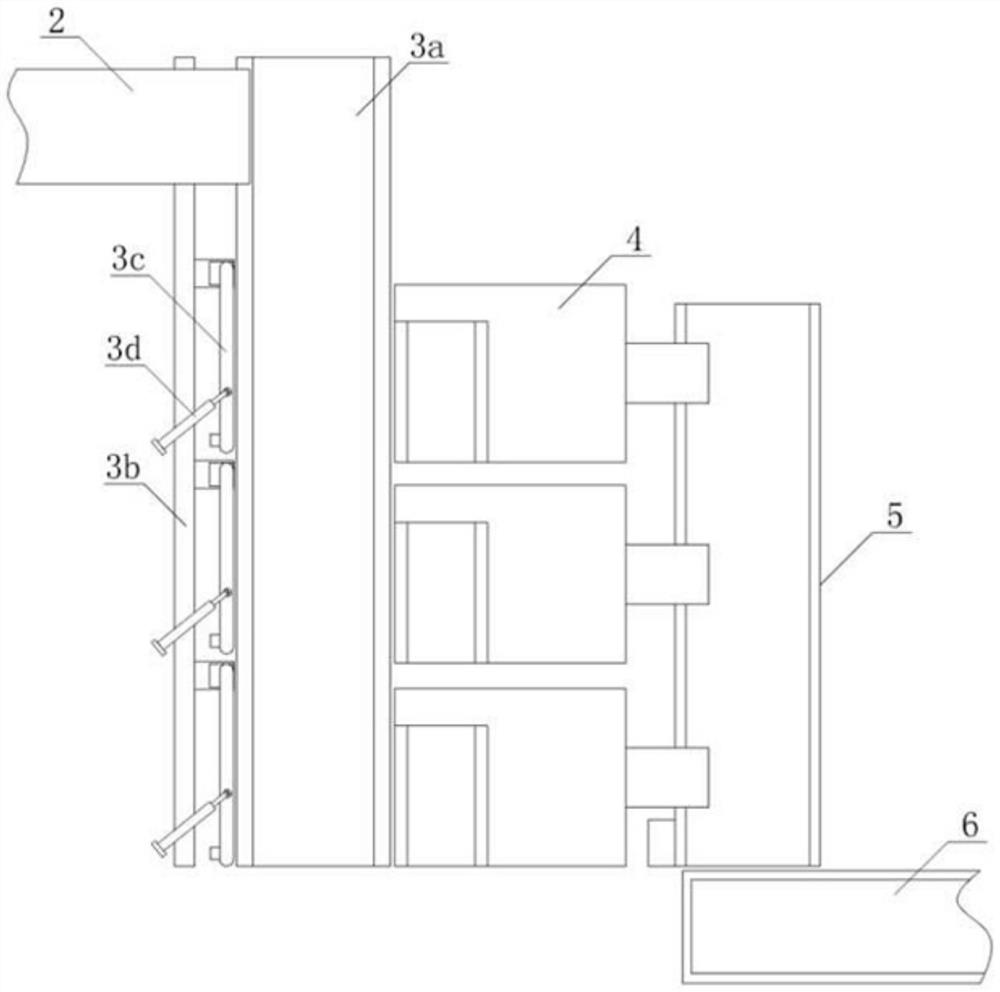

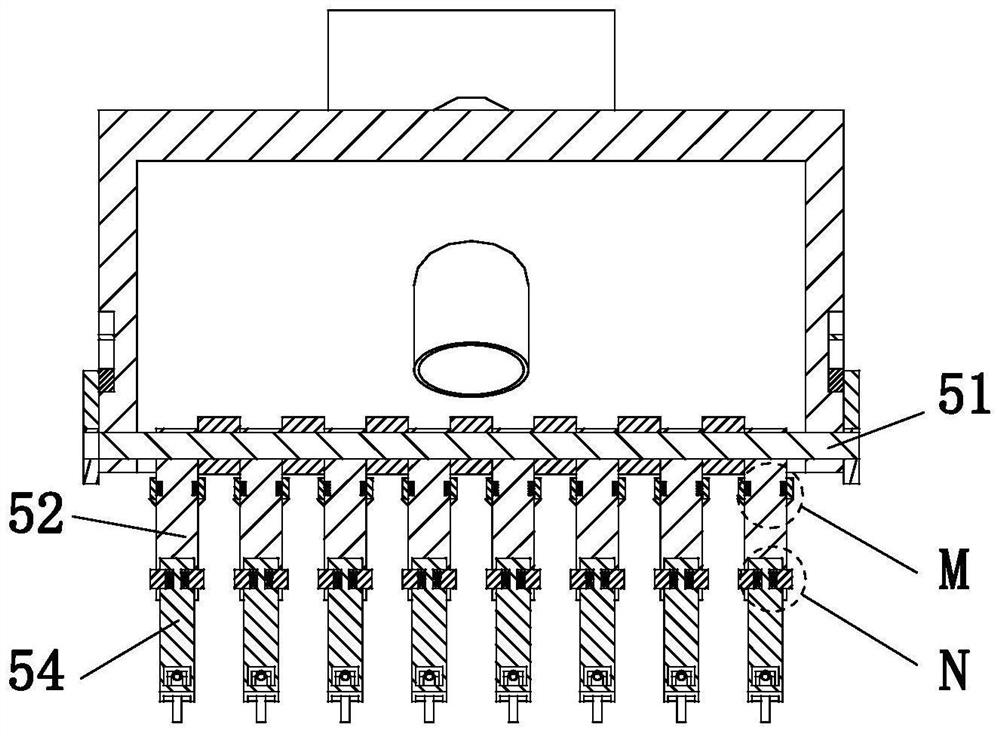

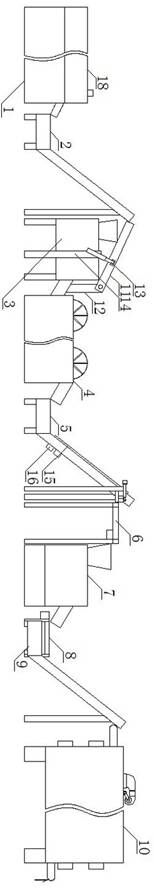

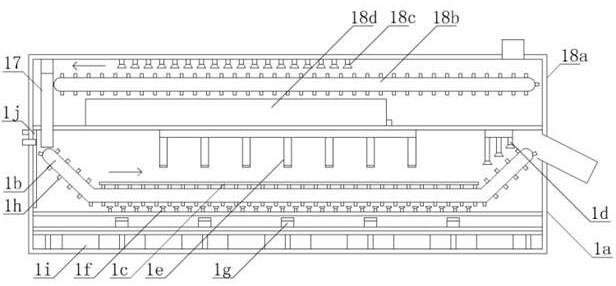

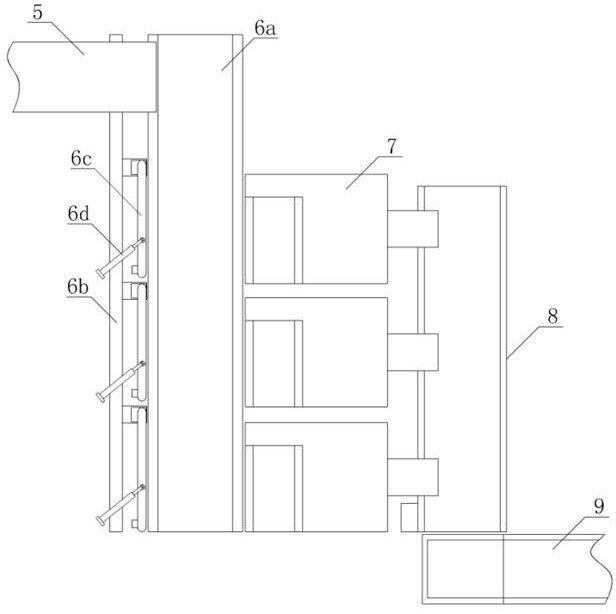

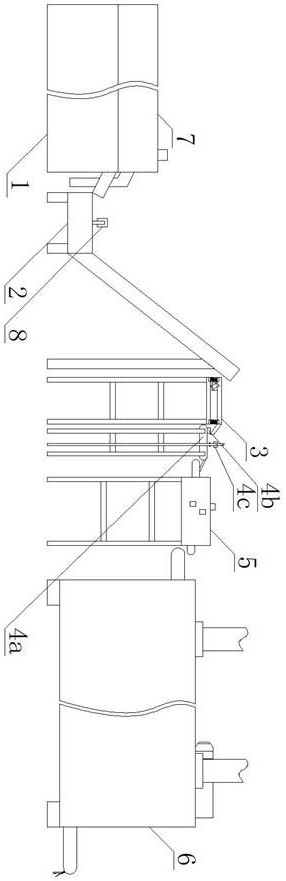

Production system for dewatered chives and production method of system

InactiveCN109770286ARealize non-stop transportationHigh degree of automationFruits/vegetable preservation by dehydrationFood treatmentSodium hypochlorite solutionProcess engineering

The invention discloses a production system for dewatered chives. The system comprises a cleaning device, a first lifting conveying device, a cutting device, a sterilization rinsing device, a second lifting conveying device, a material distribution device, a centrifugal dewatering device, a material guide conveying device, a third lifting conveying device, a vibration cloth device and a conveyingdrying device which are arranged in sequence. The production system has the advantages of being high in automation degree and processing treatment amount. The invention further discloses a productionmethod of the production system for the dewatered chives. The method comprises the steps that firstly, the chives are cleaned and then cut into chive particles, the chive particles are put into a sodium hypochlorite solution for sterilization and rinsing, the sterilized chive particles are blown with air and pre-dewatered, then centrifugal dewatering is conducted, the centrifuged and dewatered chive particles are preheated, after preheating, the chive particles are flat laid and dried, and the dewatered chives are obtained. According to the production method, the food hygiene and safety of thefinished product dewatered chives are guaranteed, which helps to shorten the production time.

Owner:YUNNAN LONGYUN DAYOU IND CO LTD

Strong rust remover

The invention discloses a strong rust remover. The strong rust remover is prepared from the following raw materials in parts by volume: 15-20 parts of sulfamic acid, 15-20 parts of boric acid, 2-13 parts of sodium silicate, 12-20 parts of phosphoric acid, 1-10 parts of sodium dodecyl sulfate, 20-25 parts of calcium hypophosphite, 2-15 parts of potassium tetraborate and 400-500 parts of deionized water. The strong rust remover has very strong decontamination ability and erosion ability, and can quickly penetrate into fastened threaded connectors to corrode rust so as to play a loosening role.

Owner:长沙丰畅车辆工程技术有限公司

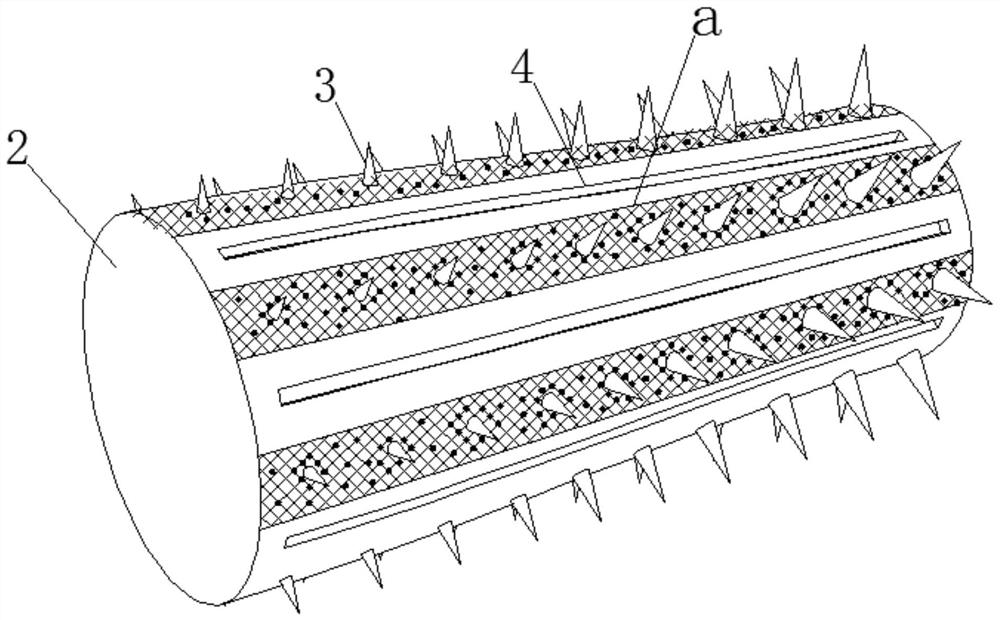

A wall-attached undulating textile wastewater fiber interception and crushing device

ActiveCN111659496BReduce entanglementPlay a role in looseningSpecific water treatment objectivesWater/sewage treatmentEngineeringPulp and paper industry

The invention discloses a wall-adhering undulating textile wastewater fiber intercepting and crushing device, which belongs to the field of textile wastewater treatment. A wall-adhering and undulating textile wastewater fiber intercepting and crushing device passes through the transverse crushing blade inside the uneven crushing cylinder. The setting of the uneven crushing cylinder can cut the wool fibers intercepted on its surface transversely along the direction of the uneven crushing cylinder, thereby effectively reducing the degree of entanglement between the wool fibers. At the same time, during the cutting and crushing process, due to the undulating magnetic ring Mutual repulsion with the magnetic point makes the ups and downs control magnetic ring continuously lift up the wall-adhering loosening piece from the inside when moving to the right with the transverse crushing knife, so that the wall-attaching helping loosening piece carries the wool fiber Continuous undulations can effectively loosen the wool fibers, effectively reduce the adhesion between the wool fibers and the uneven crushing cylinder, and then effectively reduce the difficulty of cleaning the wool fibers entangled on the uneven crushing cylinder.

Owner:山东西盟罗盾服饰有限公司

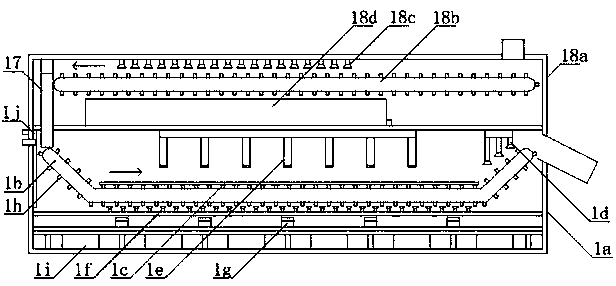

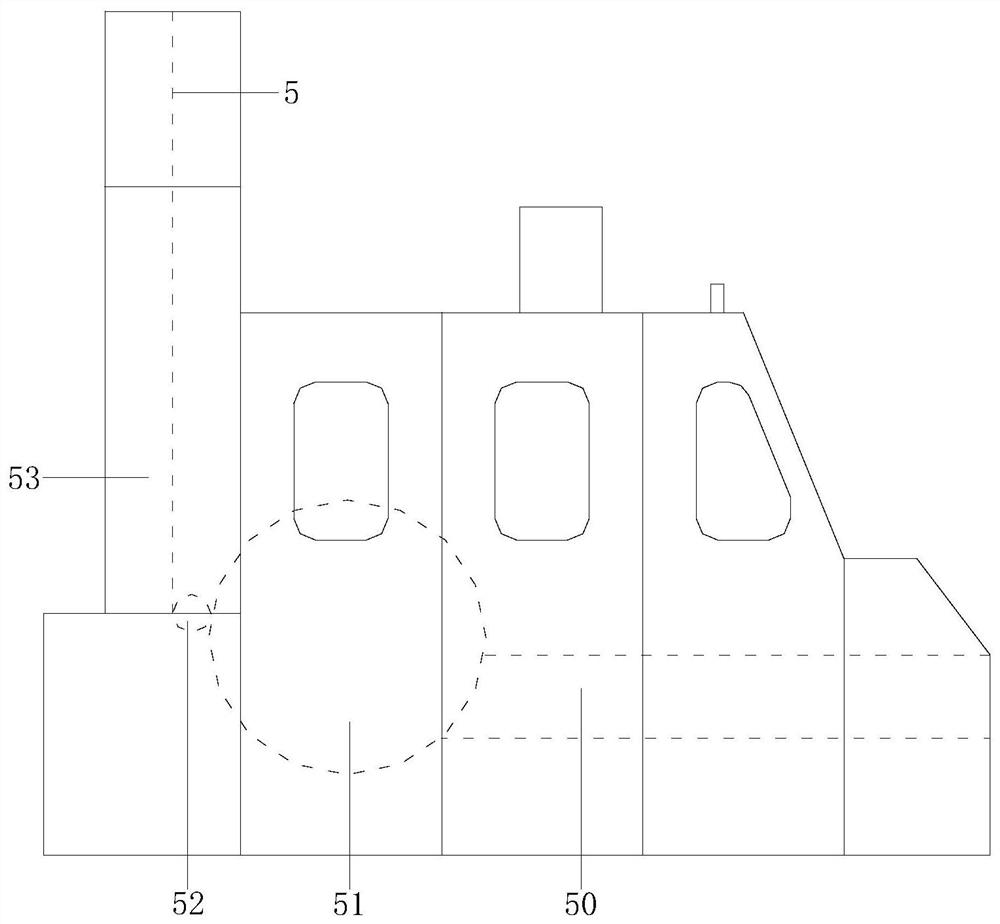

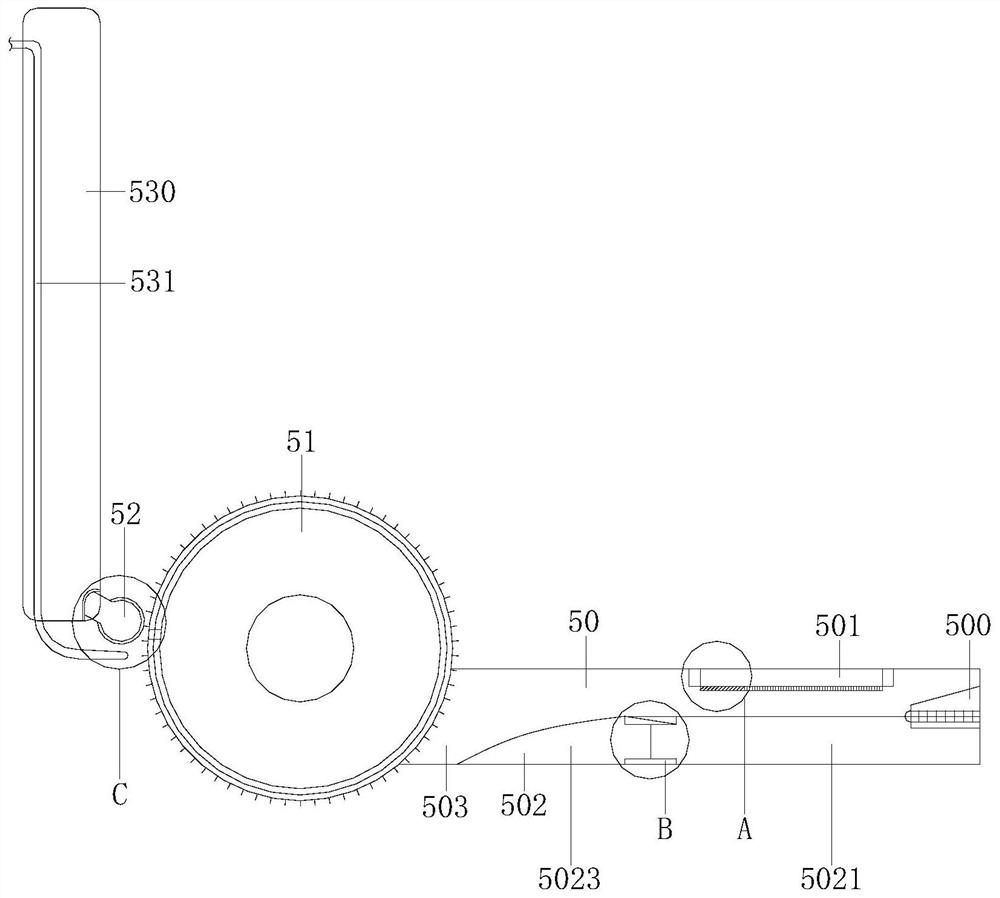

Production system of dehydrated edible fungi and production method of production system

ActiveCN109805356ARealize non-stop transportationHigh degree of automationMetal working apparatusFood treatmentProcess engineeringSodium hypochlorite solution

The invention discloses a production system of dehydrated edible fungi. The production system comprises a washing device, a first lifting and conveying device, a slicing device, a disinfection and rinsing device, a second lifting and conveying device, a material distribution device, a centrifuging and dehydration device, a material guide and conveying device, a third lifting and conveying device and a drying device, which are arranged in sequence. The production system disclosed by the invention has the advantages of high automation degree and large treatment amount. The invention further discloses a production method of the production system of the dehydrated edible fungi; the production method comprises the following steps: firstly, washing edible fungi; then putting the edible fungi into a sodium hypochlorite solution and disinfecting and rinsing; blowing air to the disinfected edible fungi and carrying out pre-dehydration treatment; then centrifuging and dehydrating; then drying the edible fungi through hot air to obtain the dehydrated edible fungi. The production method disclosed by the invention ensures the food sanitation and safety of finished-product dehydrated edible fungi and the production time is easy to shorten.

Owner:YUNNAN LONGYUN DAYOU IND CO LTD

Special blueberry fertilizer

InactiveCN107840745AImprove soil structureImprove soil environmental characteristicsAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersHydrogen phosphateRapeseed

The invention discloses a special blueberry fertilizer which contains the following components in parts by weight: 25-50 parts of plant charcoal, 15-45 parts of red soil, 18-25 parts of rapeseed cakes, 2-3 parts of amino acid, 3-5 parts of potassium sulfate and 2-3 parts of diammonium hydrogen phosphate. The special blueberry fertilizer is capable of remarkably improving soil texture structures and soil environments, improving planting environments and meeting expected nutrients and soil environments, and in addition, is high in fertilizer efficiency, low in preparation cost, high in yield andorganic and environment-friendly.

Owner:江西科农沃科技有限责任公司

How to grow peanuts for a quick harvest

InactiveCN109429969BGuaranteed moisture contentIncrease moisture contentFabaceae cultivationDigger harvestersRadicleHorticulture

The invention discloses a peanut planting method capable of rapidly harvesting, which comprises the following steps: I, selecting plump disease-free peanut seeds for accelerating germination; II, taking out the peanut seeds after embryo roots of the peanut seeds are exposed to white, and after sequentially soaking the peanut seeds in cold water and dressing seeds, obtaining the peanuts to be sown;III, digging a plurality of planting holes in a peanut planting field, and placing one peanut planting device in one planting hole; IV, covering soil and sowing in the planting device; V, harvestingpeanut straws and peanut pods. According to the method, the peanut seeds are directly planted into the planting device, and when the peanuts are ripe, the planting device is taken out from the land, so that the recovery ratio of the peanut pods and the integrity rate of the pods are ensured and the working hours required by harvesting the peanuts are shortened. The method saves time and effort inthe process of taking out the planting device. The planting device is simple in structure and low in manufacturing cost. The method can be widely popularized in the market and is suitable for the national conditions of China as a large agricultural country.

Owner:林芝

Granules for treating hyperplasia of mammary glands and preparation method of granules

InactiveCN109350650AEffective treatmentPlay a role in reducing swellingAlgae medical ingredientsMammal material medical ingredientsSide effectPalmitates

The invention discloses granules for treating hyperplasia of mammary glands, and relates to the field of medical treatment. The problem that when traditional medicine is used for treating hyperplasiaof mammary glands, the recurrence rate is high is mainly solved. The granules are prepared from, by weight, 7-12 parts of cetostearyl alcohol, 4-9 parts of aprylic capric triglyceride, 3-8 parts of oysters, 2.5-4.1 parts of isooctyl palmitate, 6.4-8.3 parts of seaweed, 2.5-3.9 parts of corydalis tubers, 08-1.6 parts of human placenta and 0.5-0.9 part of a catalyst. According to the granules, a reasonable formula is adopted, hyperplasia of mammary glands can be effectively treated, the functions of detumescence, stasis removal and pain relieving can be achieved on a patient, and no toxic or side effect exists. The form of granules is adopted, the patient can take the granules easily, the effect is remarkable, and the recurrence rate is low.

Owner:何凤姣

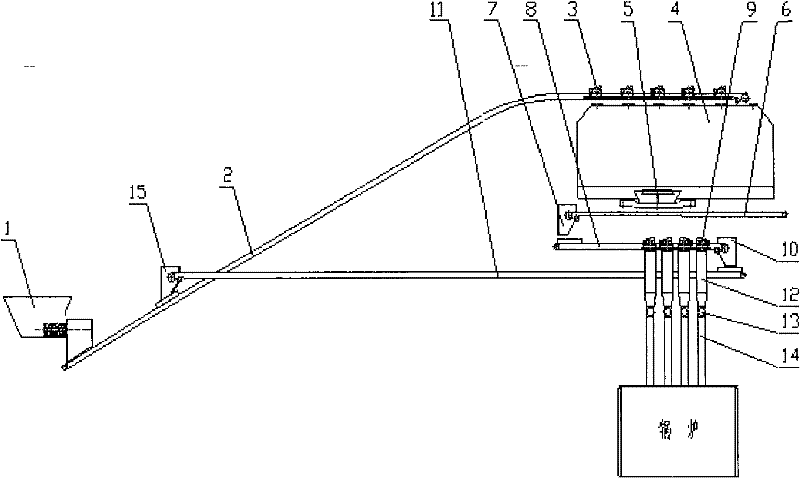

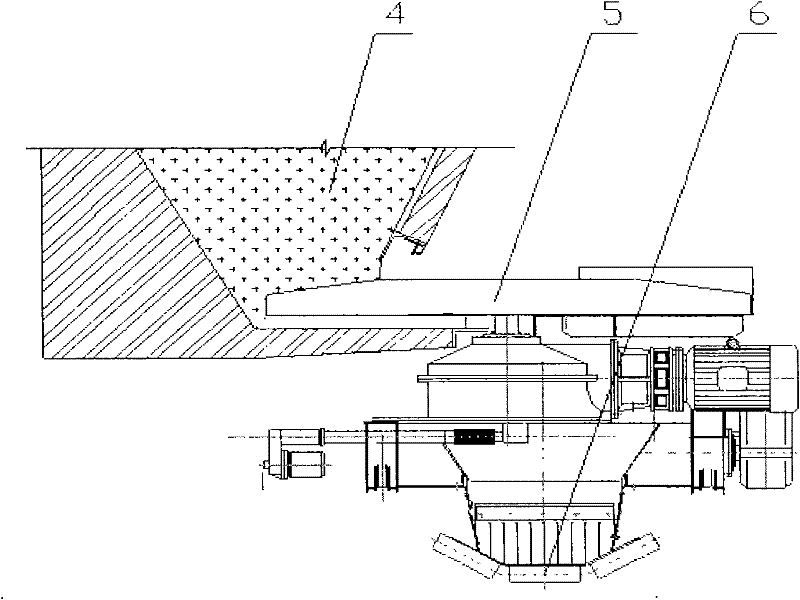

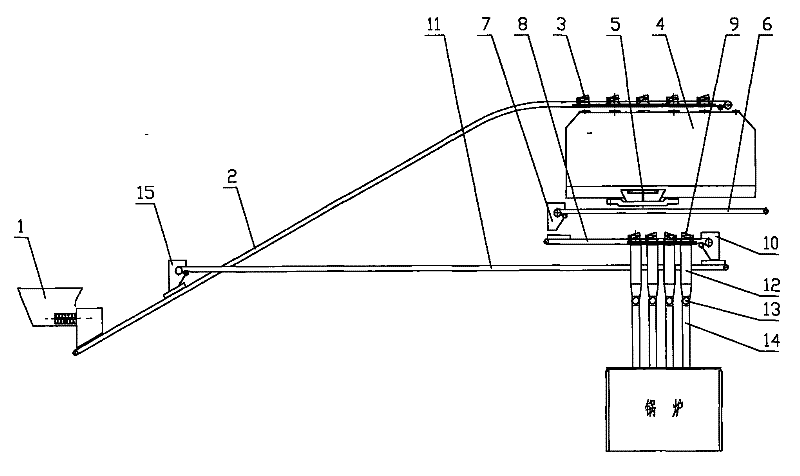

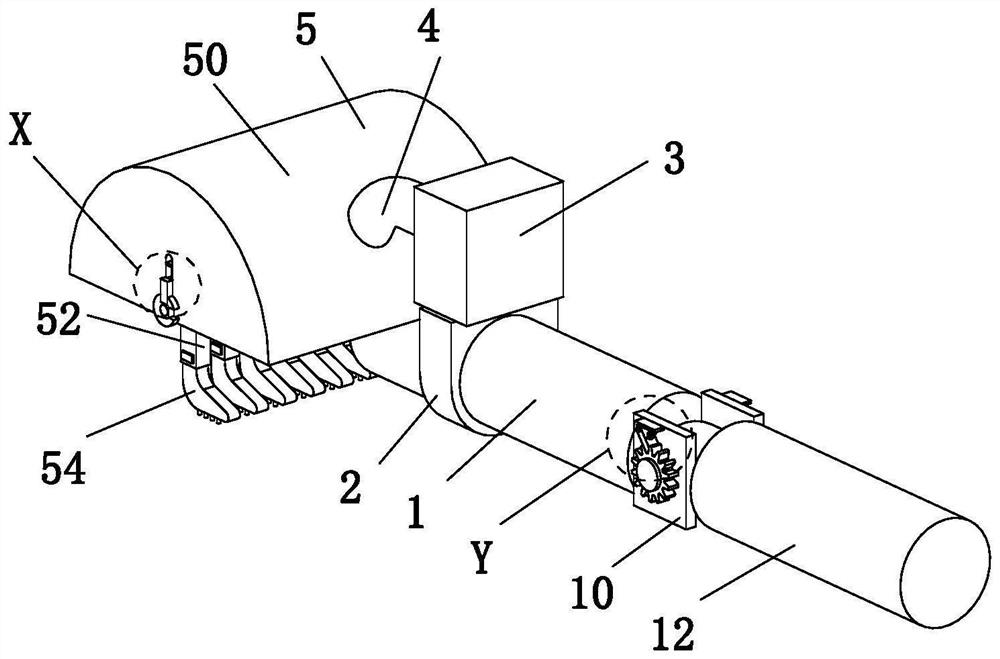

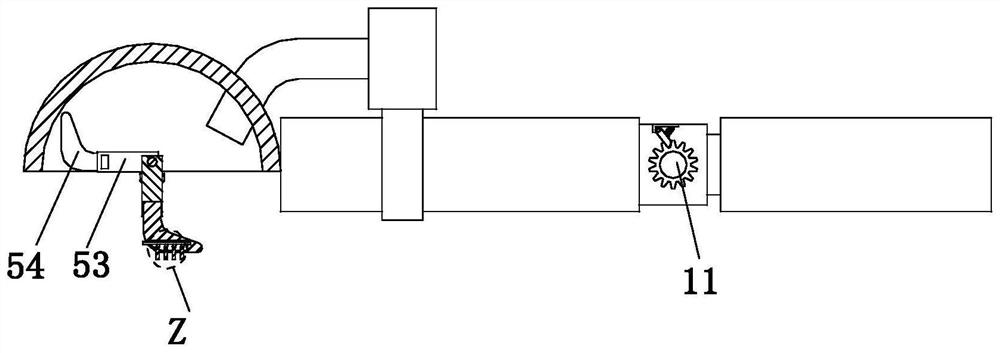

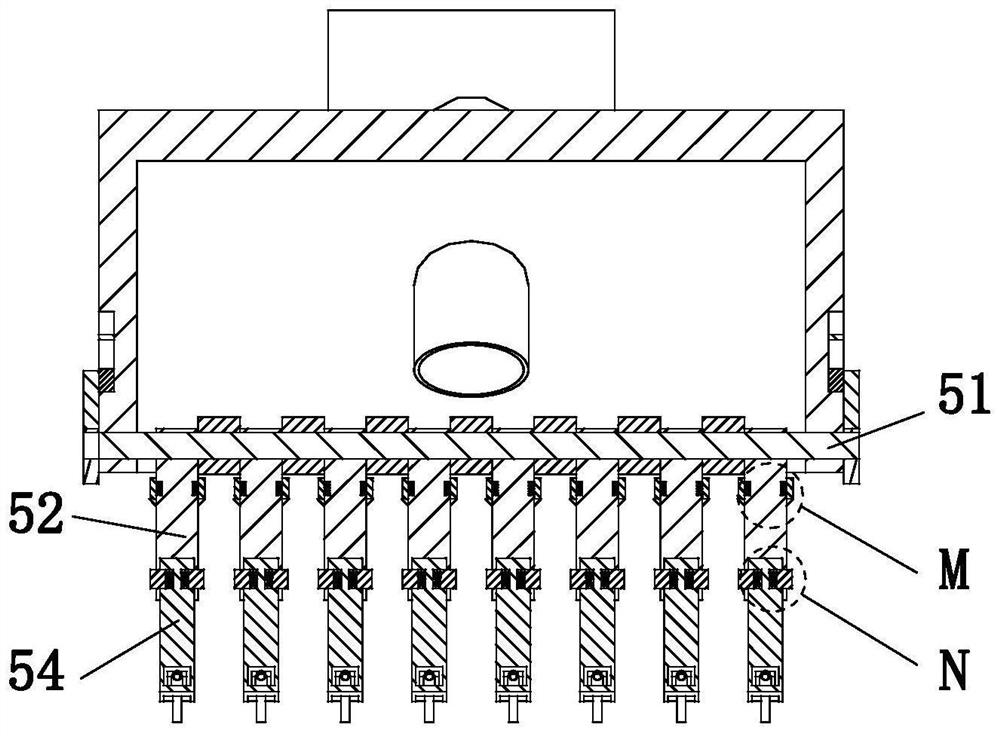

Fuel conveying method and equipment of boiler for burning crop straws

ActiveCN101713545BReduce processing costsLow costLump/pulverulent fuel feeder/distributionImpellerCombustor

Owner:CHINA LIGHT IND NANNING DESIGN ENG

Orchid cultivation substrate and preparation method thereof

InactiveCN110089394APromote growthThere will be no phenomena such as root rot and burning seedlingsGrowth substratesCulture mediaFlowering seasonDisease

The invention discloses an orchid cultivation substrate and a preparation method thereof and belongs to the technical field of plant cultivation substrates. The orchid cultivation substrate is prepared from, by weight percentage, 60-67% of oil tea seed shells, 25-32% of crushed stone, 5-10% of moss and 3-5% of enzyme bacteria. The invention also discloses the preparation method of the orchid cultivation substrate. Raw materials of the orchid cultivation substrate are easy to obtain and low in cost, the orchid cultivation substrate has the advantage of good ventilation performance, great softness, high drainage performance and the like, the growth of orchids can be promoted, and phenomena such as root rotting and seedling burning cannot occur; there are many flowers in the flower season every year, flower buds are plump, the flowers send out a rich flower flavor and have few pests and diseases, the yield of the orchids is significantly increased, and the quality of the orchids is significantly improved.

Owner:桂林市林业科学研究所

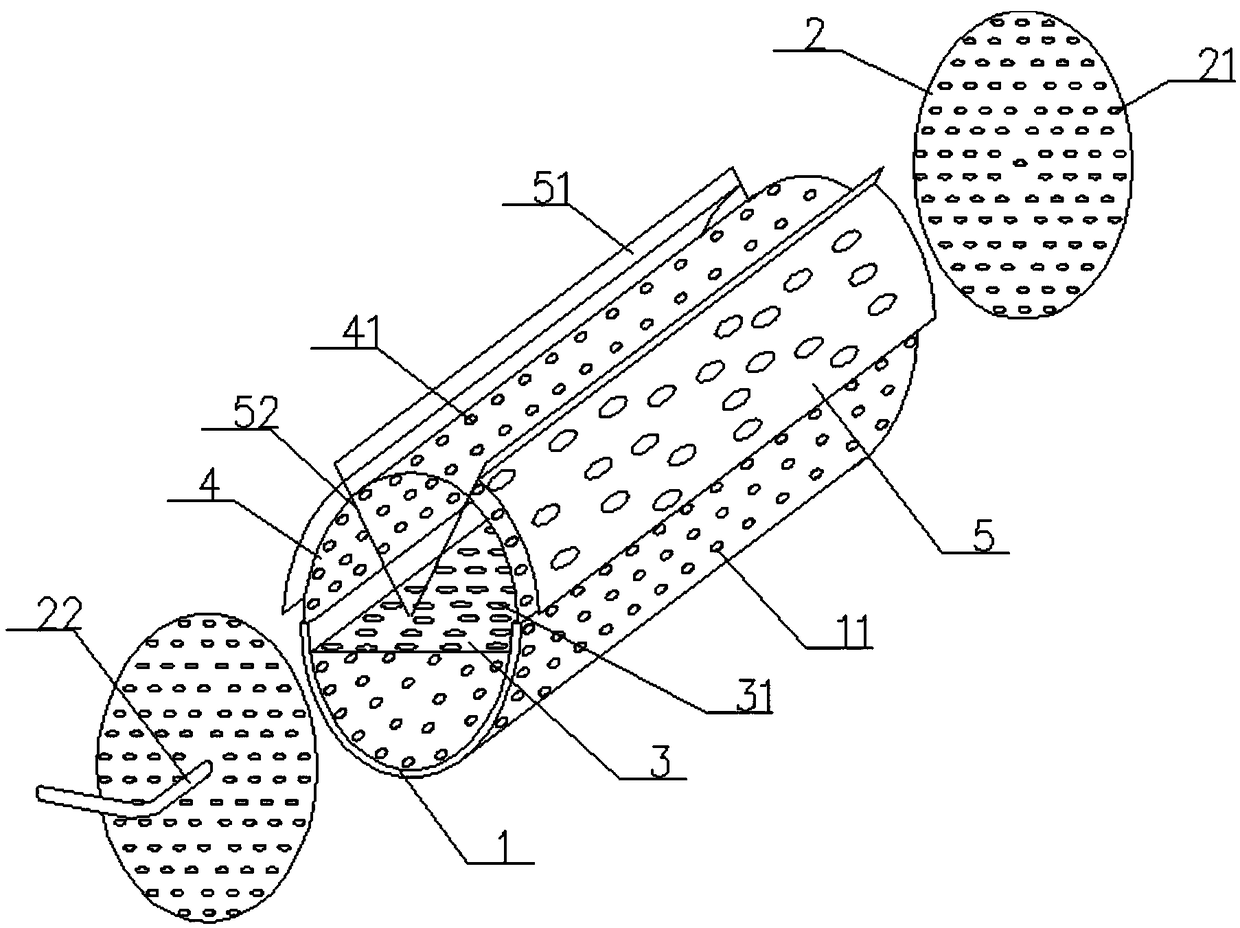

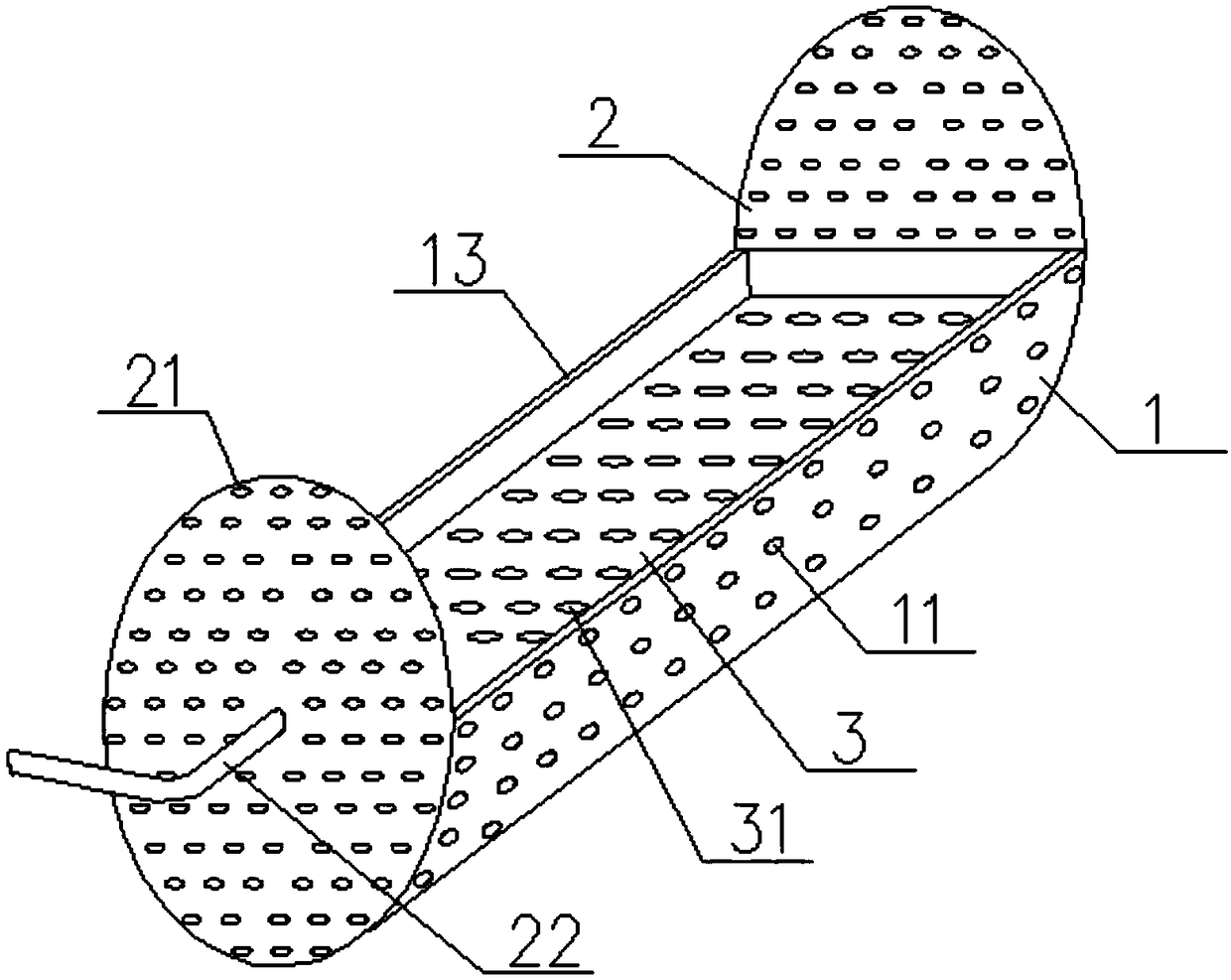

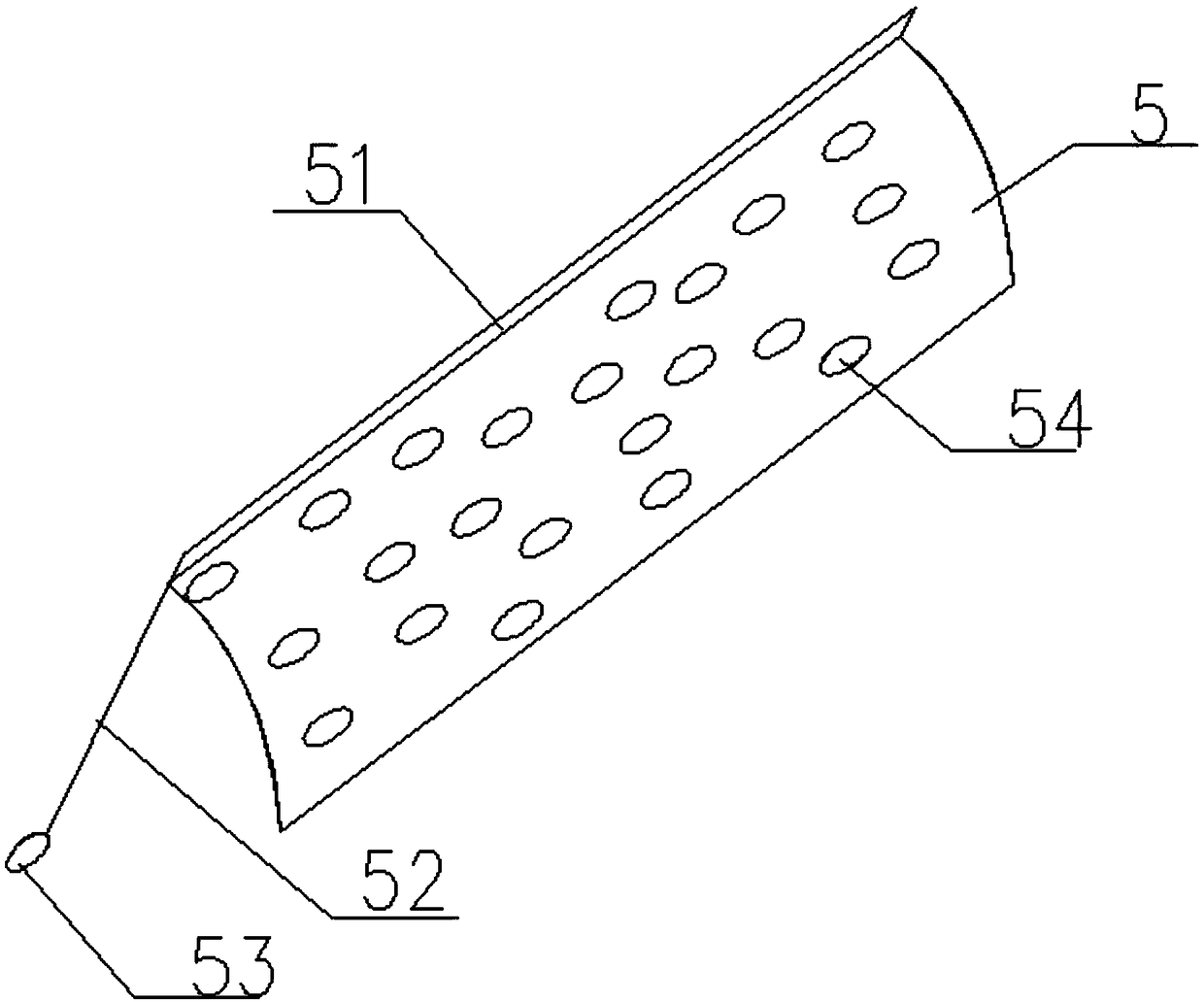

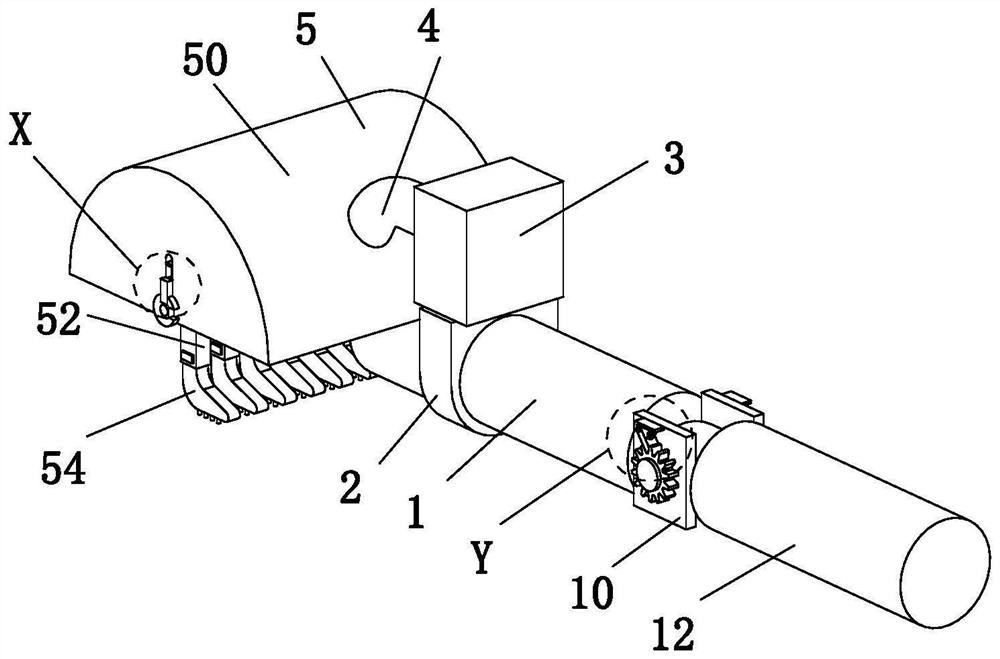

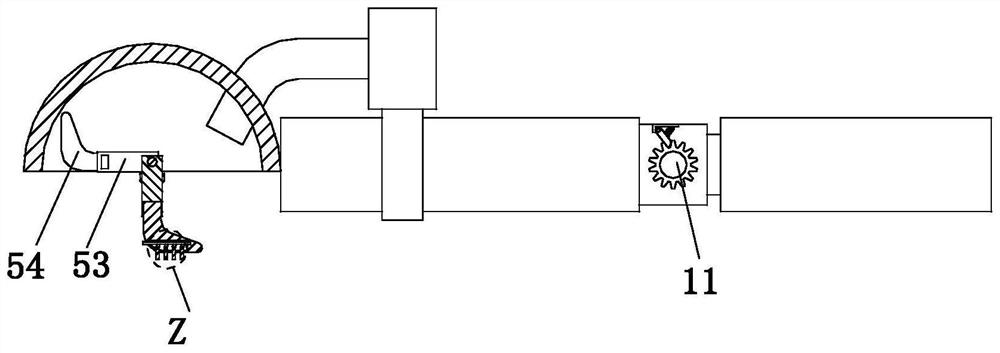

Animal hair carding and size-dividing treatment equipment

The invention relates to animal hair carding and size-dividing treatment equipment. The equipment comprises a handle, a clamping sleeve, a suction machine, a connecting pipe and a carding mechanism, the clamping sleeve is mounted at the left middle end of the handle; the suction machine is mounted at the upper end of the clamping sleeve; the connecting pipe is mounted in the middle of the left endof the suction machine; the left lower end of the connecting pipe is connected with the right upper end of the carding mechanism; and the right end of the carding mechanism is connected with the leftend surface of the handle. The design concept of a convertible combing structure is adopted for animal hair combing treatment; the arranged carding mechanism can enable workers to carry out forward and reverse multiple carding treatment on animal hair while keeping a fixed position, so that the situation that the workers frequently change directions to increase the working time and labor intensity is avoided, the carding degree of the animal hair is improved, and meanwhile, the carding mechanism can also timely carry out centralized cleaning on fallen hair generated by carding.

Owner:太和县瑞伟鬃尾有限责任公司

a carding machine

ActiveCN112410938BReduce residual rateAvoid confusionCarding machinesCotton fibreMechanical engineering

The invention discloses a cotton carding machine, the structure of which comprises a conveyor, a frame, a cotton feeding machine, a control panel, an internal device, the conveyor and the frame are welded, the conveyor, the frame and the cotton feeding machine are installed and connected, the control panel Installed on the cotton feeding machine, the cotton feeding machine is installed and connected with the internal device. The internal device is composed of a material feeder, a carding roller, an ejector, and an upper feeder. The material feeder is installed and connected with the carding roller, and the carding roller is connected with the ejector. Fitting, the ejector is installed on the feeder, the feeder includes a blanking structure, a bulk material structure, a material transfer structure, and a feeder frame, and the blanking structure and the transfer structure are installed and connected. 1. Carding roller carding, and then feeding from the upper feeding machine through the top device, the roller needle moves on the rotating roller to loosen the cotton and reduce the cotton residual rate. The fine and short fibers are thoroughly extracted to avoid the mixing of cotton fibers, and there is no need to increase the lifting process to process them when receiving materials, so as to avoid damage to parts due to lifting.

Owner:浙江奥佳纺织有限公司

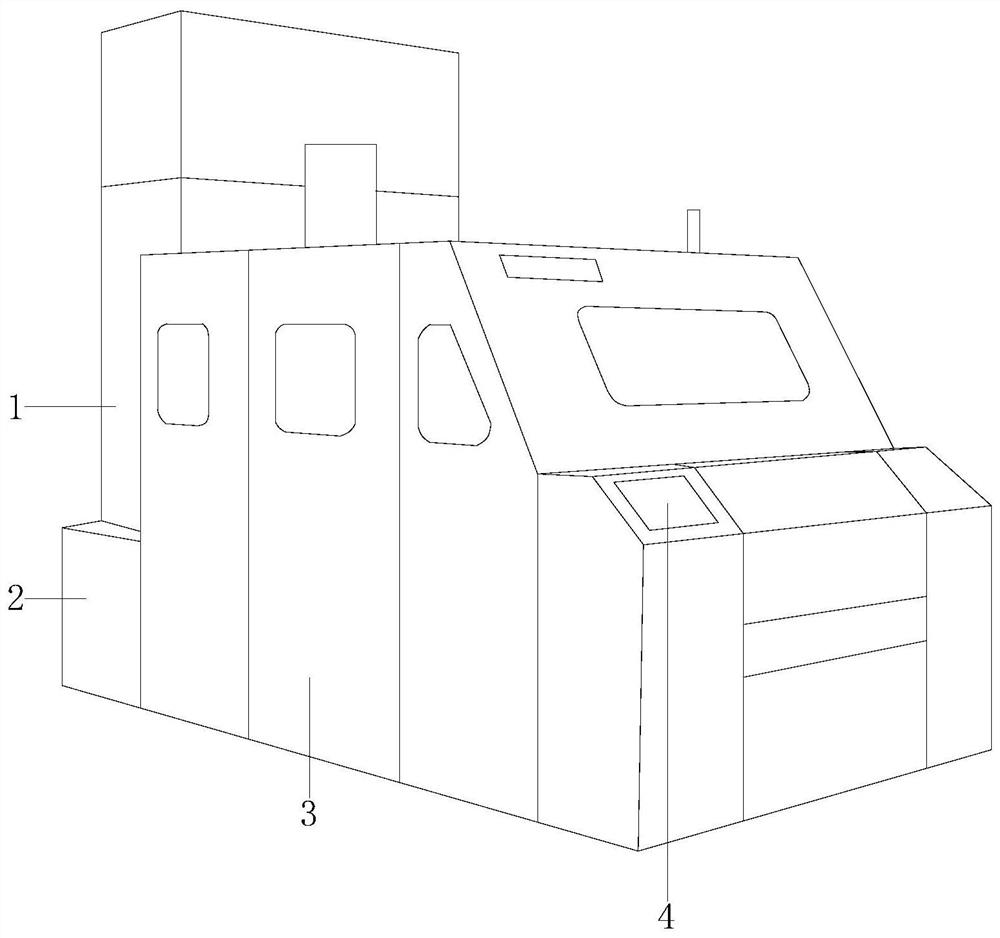

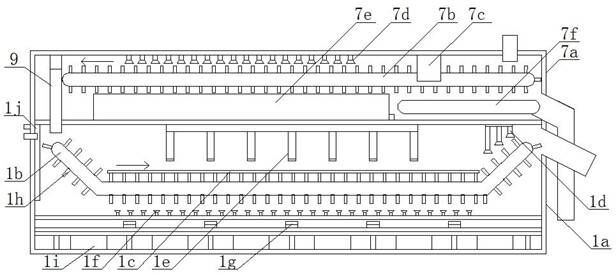

An automatic frying and roasting production system of eggplant food materials and its production method

ActiveCN109601918BUniform brandingHigh degree of automationOil/fat bakingFood shapingProcess engineeringEdible oil

The invention discloses an automatic frying and roasting production system for eggplant food materials, which comprises a cleaning device, a lifting conveying device, a food material distributing device, a material cutting device, a first material guiding and conveying device, a second material guiding and conveying device, a vibrating cloth device, double-sided oiling device, branding device, and frying device; the production system of the present invention has the advantages of high degree of automation and large processing capacity. The invention also discloses a production method of an automatic frying and roasting production system for eggplant ingredients. The eggplant ingredients are pre-cleaned first, then cleaned, and then cut into long slices, round slices or strips, and then both sides of the ingredients are cleaned. Spray edible oil, then brand the ingredients on one or both sides, and then fry and roast the ingredients; the production method of the present invention performs branding on one or both sides of the ingredients, which not only enhances the roasted flavor, but also improves the quality of the finished product. The visual aesthetics of the finished product; and, while ensuring the roasted quality of the finished product, the finished product can form a unique roasted flavor.

Owner:YUNNAN LONGYUN DAYOU IND CO LTD

A kind of equipment for combing and dividing animal hair

Owner:太和县瑞伟鬃尾有限责任公司

Carding machine

ActiveCN112410938AReduce residual rateAvoid confusionCarding machinesCardingAgricultural engineering

The invention discloses a carding machine which structurally comprises a conveyor, a frame base, a cotton conveying machine, a control panel, and an internal device; the conveyor is welded to the frame base; the conveyor, the frame base, and the cotton conveying machine are installed and connected; the control panel is installed on the cotton conveying machine; the cotton conveying machine is installed and connected with the internal device; the internal device is composed of a feeding machine, a cotton carding roller, an ejector and an upper feeding machine; the feeding machine is connected with the cotton carding roller in an installation mode; the cotton carding roller is attached to the ejector; the ejector is installed on the feeding machine; the feeding machine comprises a discharging structure, a material scattering structure, a material moving structure, and a feeding machine frame; and the discharging structure is connected with the material moving structure in an installationmode. According to the carding machine, through the cotton paving of the feeding machine, the cotton carding of the cotton carding roller, and the upward pushing of the ejector from the upper feedingmachine, roller needles move on rotating rollers to loosen cotton, so that the cotton residue rate is reduced; and fine staple fibers can be thoroughly extracted through extraction type material taking of a material extracting pipe, so that cotton fibers are prevented from being mixed, the cotton fibers do not need to be treated by adding a hooking procedure during material collecting, and partsare prevented from being damaged due to hooking.

Owner:浙江奥佳纺织有限公司

A production system and production method for dehydrated edible mushrooms

ActiveCN109805356BRealize non-stop transportationHigh degree of automationMetal working apparatusFood treatmentBiotechnologyPulp and paper industry

The invention discloses a production system for dehydrated edible fungus, which comprises a cleaning device, a first lifting and conveying device, a slicing device, a disinfection and rinsing device, a second lifting and conveying device, a material distribution device, a centrifugal dehydration device, and a material guiding and conveying device arranged in sequence. device, a third lifting conveying device, and a drying device; the production system of the present invention has the advantages of high degree of automation and large processing capacity. The invention also discloses a production method of a production system for dehydrating edible fungi. The edible fungi are cleaned first, then put into a sodium hypochlorite solution for disinfection and rinsing, and the sterilized edible fungi are pre-dehydrated by air blowing, and then centrifuged. Dehydration, and then drying the edible fungi with hot air; the production method of the invention ensures the hygiene and safety of the finished dehydrated edible fungi, and is beneficial to shorten the production time.

Owner:YUNNAN LONGYUN DAYOU IND CO LTD

Novel cotton cultivation method

Owner:操宇琳

A kind of rock drilling and cracking machine

ActiveCN108222931BAchieve brokenAvoid repositioningConstructionsSlitting machinesEngineeringDrill bit

The invention belongs to the field of drilling and splitting devices, and particularly discloses a rock drilling and braking integrated machine. The rock drilling and braking integrated machine comprises a fixed plate, an oil cylinder, a motor, a guide pillar, a pushing ram and a crushing module. The oil cylinder is fixed on the fixed plate, the end head of the oil cylinder is fixedly connected with the motor, a group of sliding blocks are fixedly arranged on the periphery of the motor, and the sliding blocks are connected to the guide pillar in a sleeving mode. The guide pillar is arranged onthe fixed plate, the oil cylinder can push the motor to move up and down along the guide pillar, and a rotating shaft of the motor is fixedly connected with the pushing ram, and the periphery of thepushing ram is connected with the crushing module in a fit mode. The crushing module comprises a wedge block, an installation disk and an expansion link, and the end head of the pushing ram is fixedlyconnected with a drill. When the rock drilling and braking integrated machine is drilled to the design depth, under the action of the pushing ram, the crushing module expands the hole to the surrounding area to achieve rock breaking. The rock drilling and braking integrated machine integrates drilling and splitting to avoid secondary positioning of a crushing rod, so that the drilling and splitting work is carried out in a coherent mode, the working process is simplified, and the working efficiency is improved.

Owner:淮北通鸣矿业有限公司

A kind of automatic frying and roasting production system and production method of green leafy food materials

The invention discloses an automatic frying and roasting production system for green leafy food materials, which includes a cleaning device, a lifting conveying device, a vibrating material distribution device, a double-sided oiling device, a branding device, and a three-dimensional conveying frying and roasting device arranged in sequence; the production system of the present invention It has the advantages of high degree of automation and large processing capacity. The invention also discloses a production method of an automatic frying and roasting production system for green leafy ingredients. First, the roots of the green leafy ingredients are cut off, then cleaned, and then edible oil is sprayed on both sides of the ingredients, and then one or both sides of the ingredients are branded. Then fry and roast the ingredients; the production method of the present invention imprints one or both sides of the ingredients, which not only enhances the roasted flavor, but also improves the visual aesthetics of the finished product; At the same time, the finished product has a unique roasted flavor.

Owner:YUNNAN LONGYUN DAYOU IND CO LTD

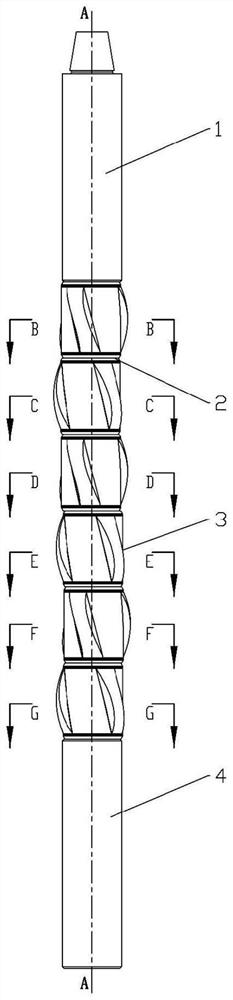

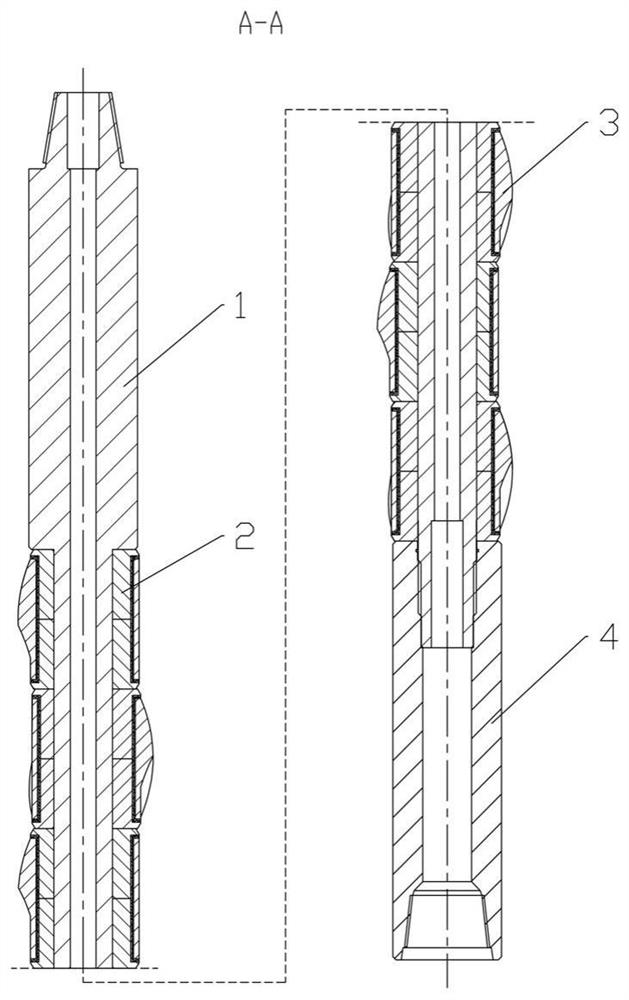

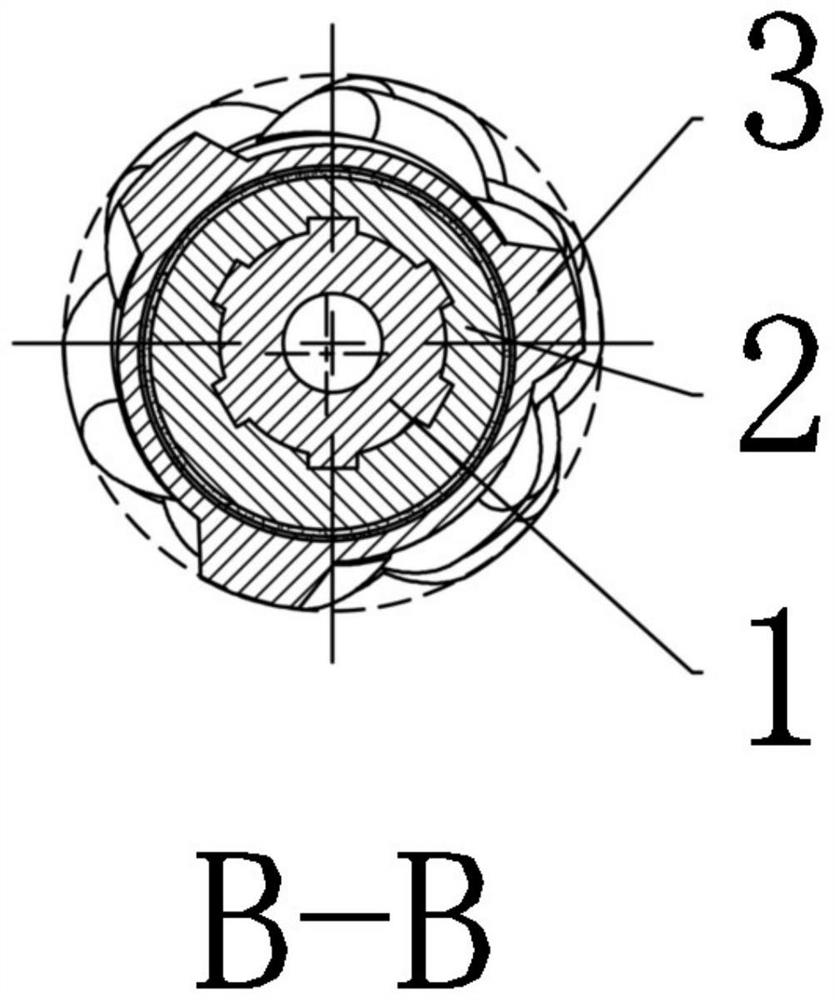

Rotary traction short section

PendingCN112523701APositive technical effectReduce frictionDrilling rodsFlushingClassical mechanicsWell engineering

The invention discloses a rotary traction short section, and belongs to the field of drilling engineering equipment. The rotary traction short section comprises centralizers and a mandrel. Two ends ofthe centralizers are correspondingly and fixedly connected with one ends of two centralizer bushings, the other ends of the two centralizer bushings are correspondingly and fixedly connected with themandrel, and the centralizer bushings are connected with the mandrel through splines. The lower part of the mandrel is in threaded connection with a lower joint; the lower part of the lower joint isin threaded connection with a drill string; radial bosses are correspondingly arranged at the left ends and the right ends of the centralizer bushings; and the centralizer bushings are divided into upper parts and lower parts along an axial symmetrical surface, and the upper parts and the lower parts are correspondingly connected with two centralizers. According to the rotary traction short section, the assembling relation between a conventional centralizer and the mandrel can be changed, sliding friction resistance between the centralizers and the well wall is changed into rotating friction resistance, and the effect of reducing friction resistance can be achieved; and the eccentric centralizer can be used for unclamping during clamping and burying.

Owner:成都希能能源科技有限公司

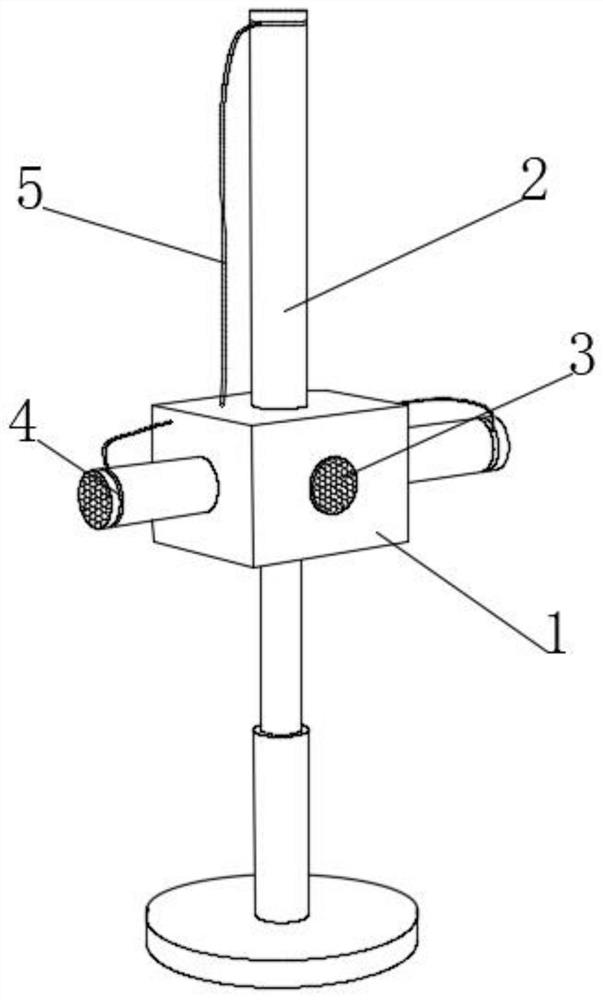

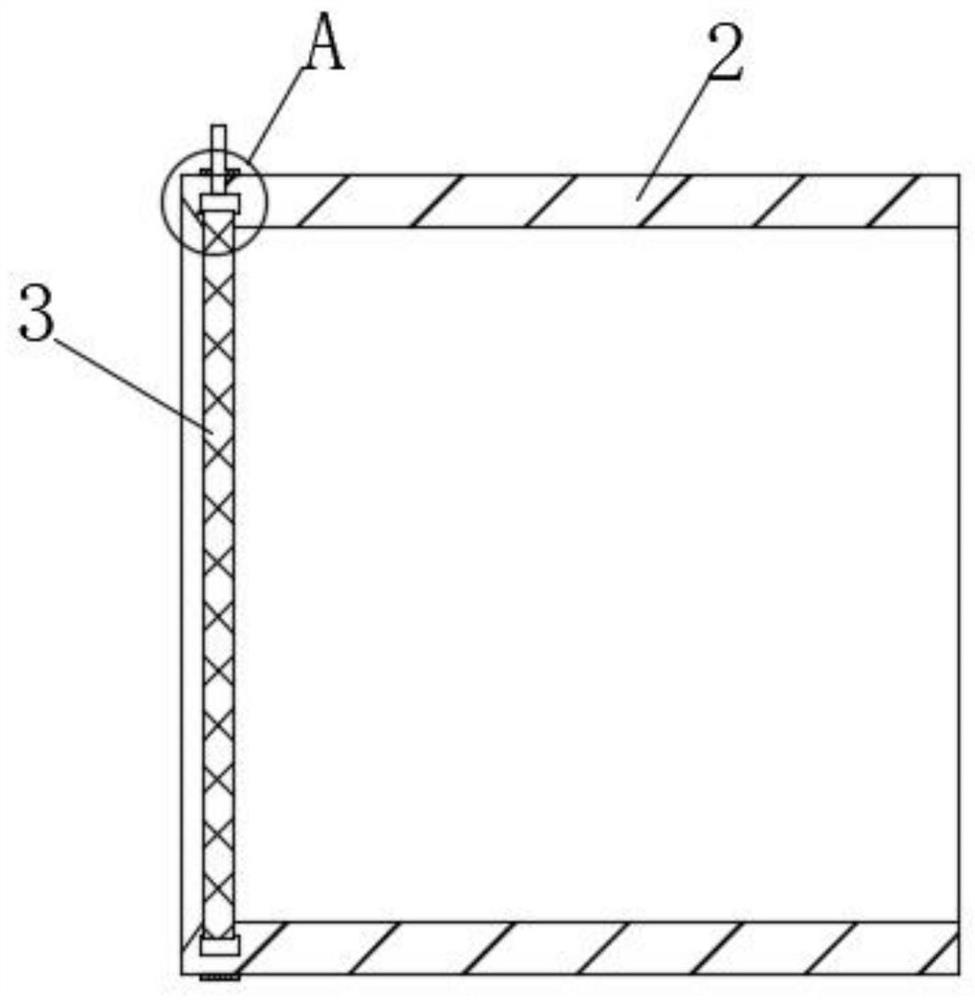

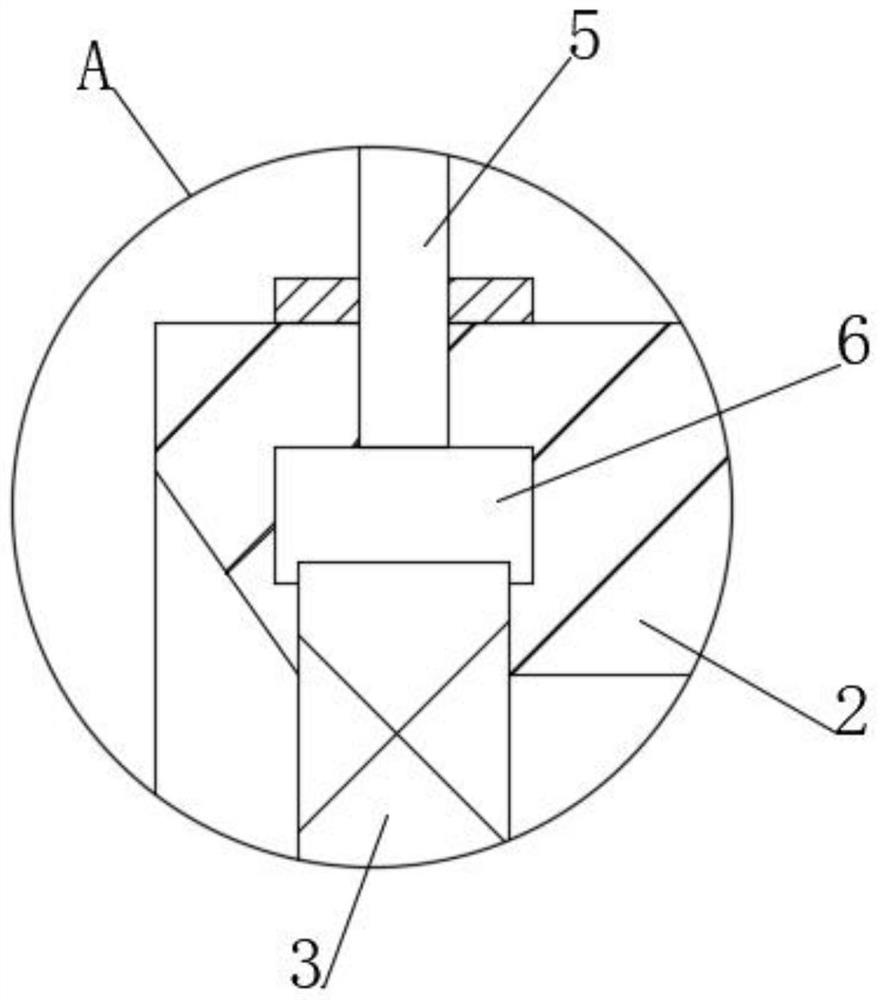

Atmospheric haze detection device based on Internet of things

InactiveCN111812280APrevent deviationAvoidance of circumstancesDispersed particle filtrationTransportation and packagingThe InternetEngineering

The invention discloses an atmospheric haze detection device based on the Internet of things and belongs to the field of haze detection. According to the atmospheric haze detection device based on theInternet of things, firstly, under the action of a plurality of air suction channels with the same length in different directions, a deviation of a detection result caused by one-way sampling is effectively avoided; secondly, a pneumatic net is arranged, after each sampling is finished, a gas can be controlled to be introduced into the device so that an air support deformation wire is expanded; at the moment, an external fixed multi-ball rod is not in contact with the air support deformation wire; and then, air bleeding is controlled so that the air support deformation wire is shrunk and restored to an original shape. Therefore, in an outer portion of a multi-bulging point wrapping the outer fixed multi-ball rod, by continuously repeating the process, dust in the air adhered to the outersurface of the air support deformation wire can be effectively loosened so that a situation that an air detection result is influenced by residual air impurities on the air support deformation wire iseffectively avoided, and accuracy of an atmospheric haze detection result is remarkably improved.

Owner:四川淼垚森环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com