Carding machine

A carding machine and cotton carding technology, which is applied in the field of carding machines, can solve the problems of different lengths of cotton fibers, material residues, and mixed cotton fibers in cotton fiber treatment, so as to avoid hooking damage, avoid mixing, and reduce cotton residues rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

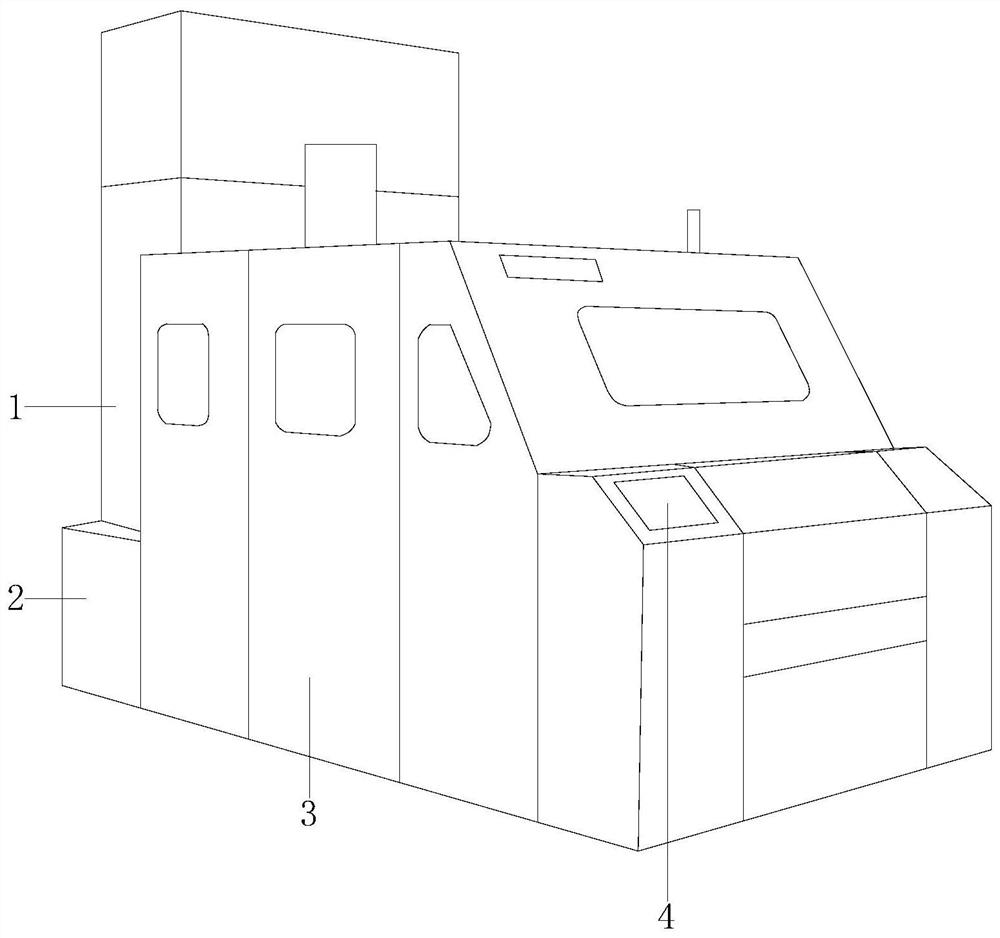

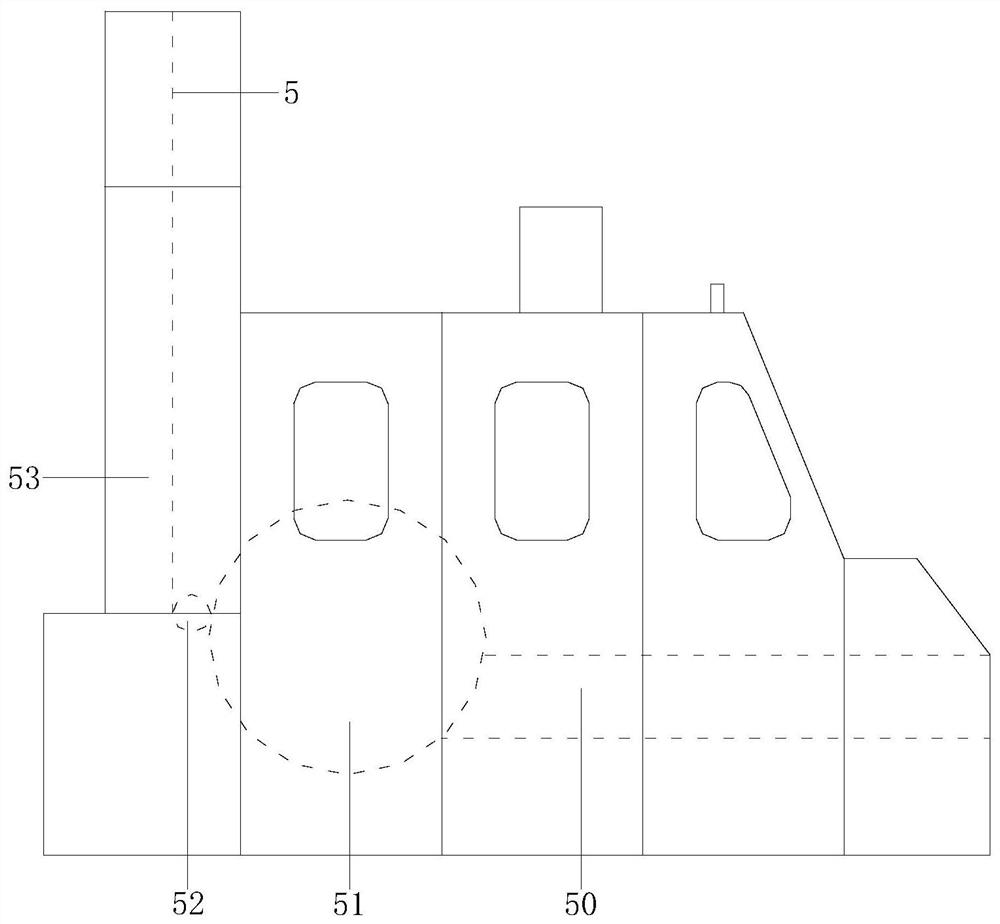

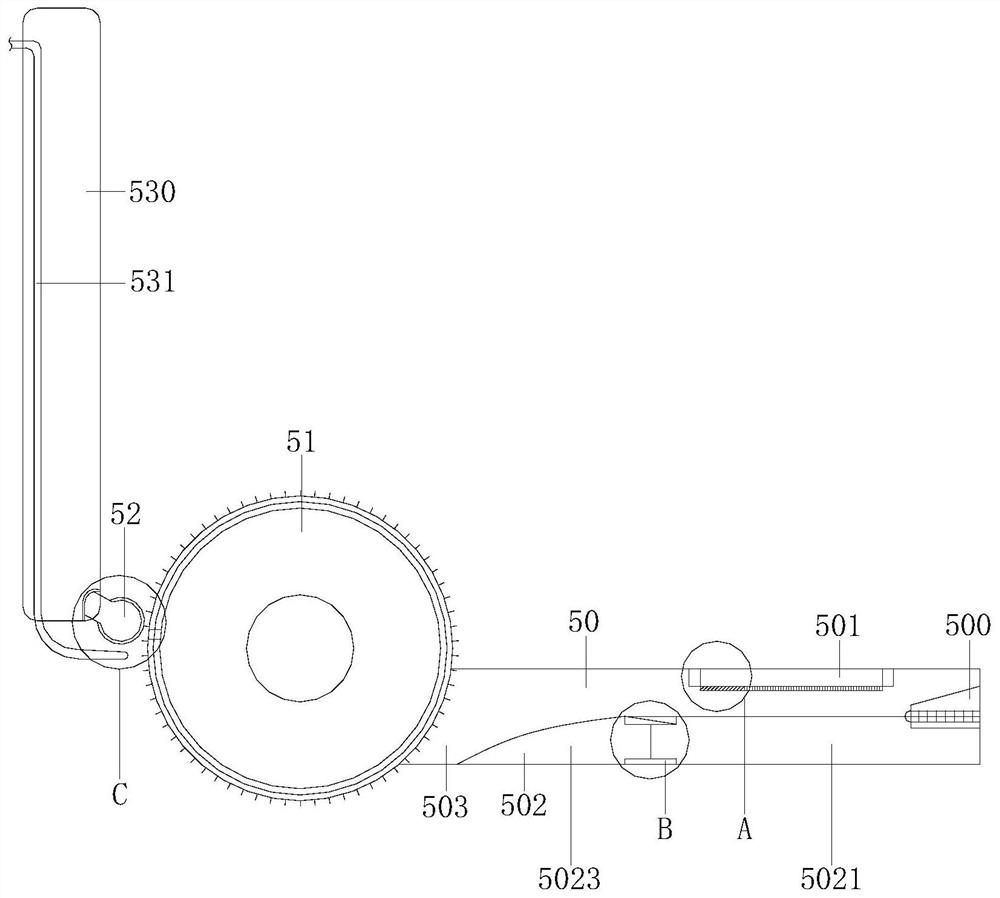

[0026] Example 1 see Figure 1-3 , the present invention provides a technical solution for a carding machine: its structure includes a conveyor 1, a frame 2, a cotton feeder 3, a control panel 4, and an internal device 5, the conveyor 1 is welded to the frame 2, and the conveyor Machine 1, frame 2 are installed and connected with cotton feeder 3, and described control board 4 is installed on the cotton feeder 3, and described cotton feeder 3 is installed and connected with internal device 5, and described internal device 5 is fed by feeder 50 , a carding roller 51, a jack 52, and an upper feeder 53, the feeder 50 is installed and connected with the carding roller 51, the carding roller 51 is attached to the jack 52, and the jack 52 is installed on On the feeder 53, the feeder 50 includes a blanking structure 500, a bulk material structure 501, a material transfer structure 502, and a feeder frame 503, and the blanking structure 500 is connected to the material transfer structu...

Embodiment 2

[0028] Example 2 see Figure 4-7 , the present invention provides a technical solution for a carding machine: the structure of the blanking structure 500 includes an inclined upper frame 5000, a mounting base frame 5001, an articulator 5002, and a reinforced sliding cover 5003, and the articulator 5002 is an articulation structure. The lifting transmission drives its own shaking, that is, it drives the shaking of the inclined upper frame 5000 to realize the shaking and sliding of cotton fibers. The inclined upper frame 5000 and the mounting base frame 5001 are installed and connected through the articulator 5002, and the reinforced sliding cover 5003 is installed on the inclined upper frame. 5000, the articulator 5002 is connected to the track of the installation chassis 5001, the reinforced sliding cover 5003 plays the role of protection, assists in fixing the articulator 5002, and reinforces its transmission, and the bulk material structure 501 includes a lifting bulk materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com