Patents

Literature

71results about How to "Increase precipitation speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Boiler coal combustion-improving desulfurizing and denitrifying agent composition and preparation method thereof

The invention provides a boiler coal combustion-improving desulfurizing and denitrifying agent composition. The composition comprises the following raw materials in parts by weight: 2-7 parts of sodium carbonate, 1-3 parts of alumina, 2-8 parts of aluminium hydroxide, 2-5 parts of ferric trichloride, 2-6 parts of ferric oxide, 3-10 parts of potassium permanganate, 3-10 parts of potassium chlorate, 10-35 parts of activated attapulgite clay, 15-30 parts of urea, 2-4 parts of ammonium formate, 2-4 parts of ammonium chloride, 6-23 parts of ammonium acetate, 3-9 parts of manganese oxide, 9-12 parts of copper chloride, 1-3 parts of copper oxide, 2-4 parts of zinc sulfate, 1-3 parts of zinc nitrate, 7-18 parts of potassium dichromate, 1.0-1.5 parts of titanium dioxide, 0.5-1.0 part of barium molybdate, 0.5-1.5 parts of cobalt sulfate, 0.5-1.5 parts of vanadium pentoxide, 0.3-0.7 part of cerium oxide, 0.1-0.2 part of sodium dodecyl benzene sulfonate and 0.1-0.2 part of alkyl glyceryl ether. The composition is convenient to use, has stable properties, plays roles of combustion improving, desulfurization and denitrification, has coal saving rate of 8-25% and can remove fixed sulfur by 50-70%.

Owner:兰州熙瑞化工科技有限公司

Method and system for transporting flows of fluid hydrocarbons containing wax, asphaltenes, and/or other precipitating solids

ActiveUS7261810B2Costly removalSimpler and steady operationRefining by heating/coolingWorking-up pitch/asphalt/bitumenWaxCrystallization temperature

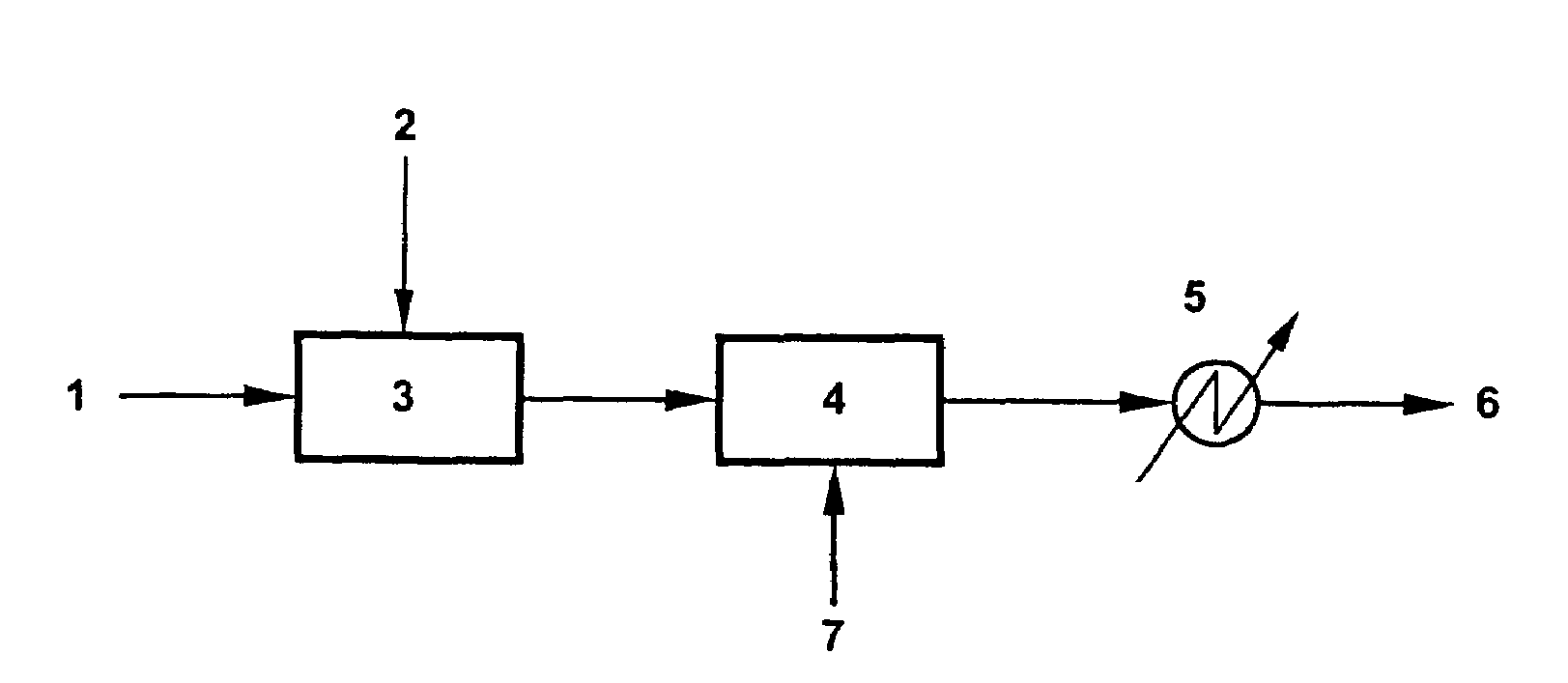

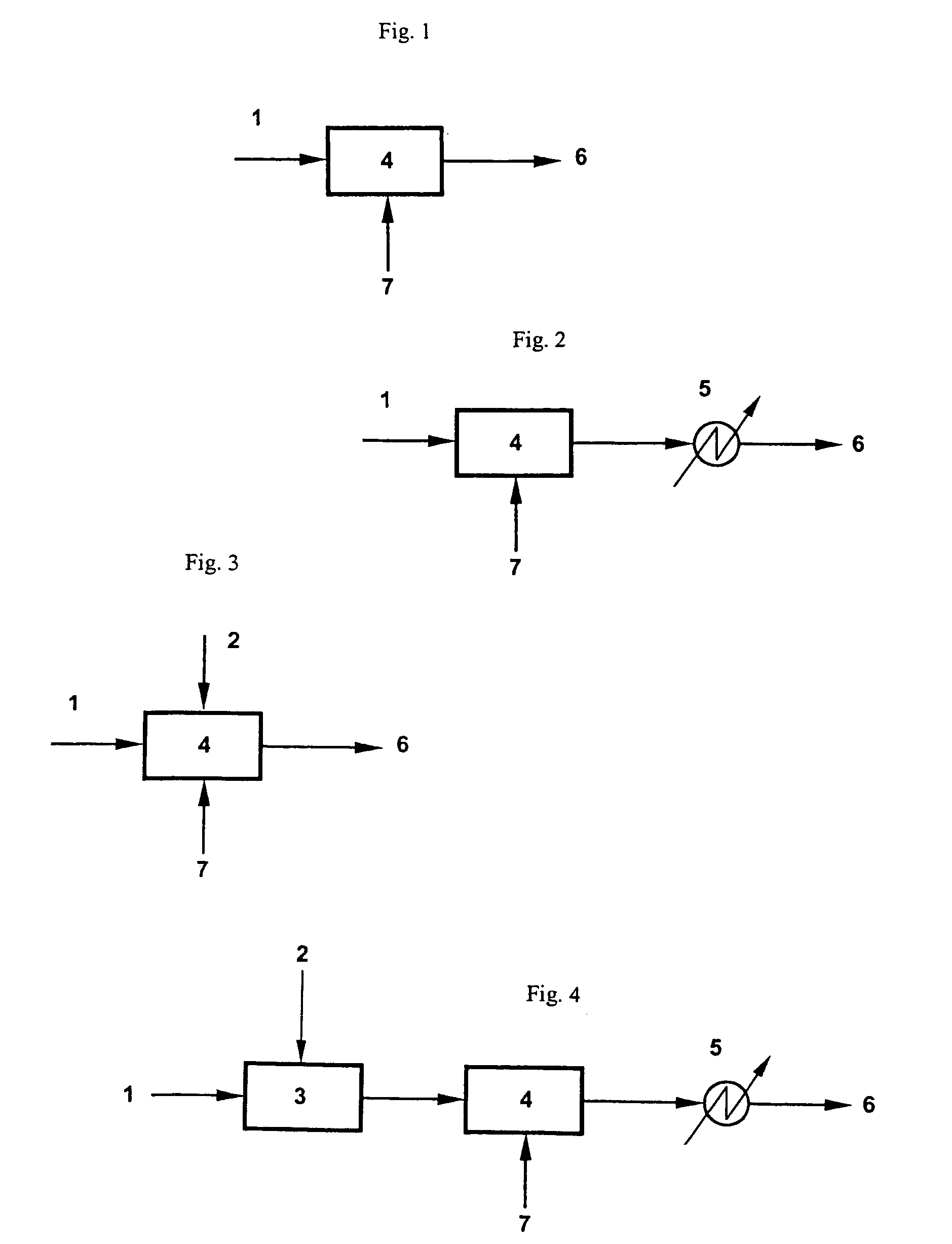

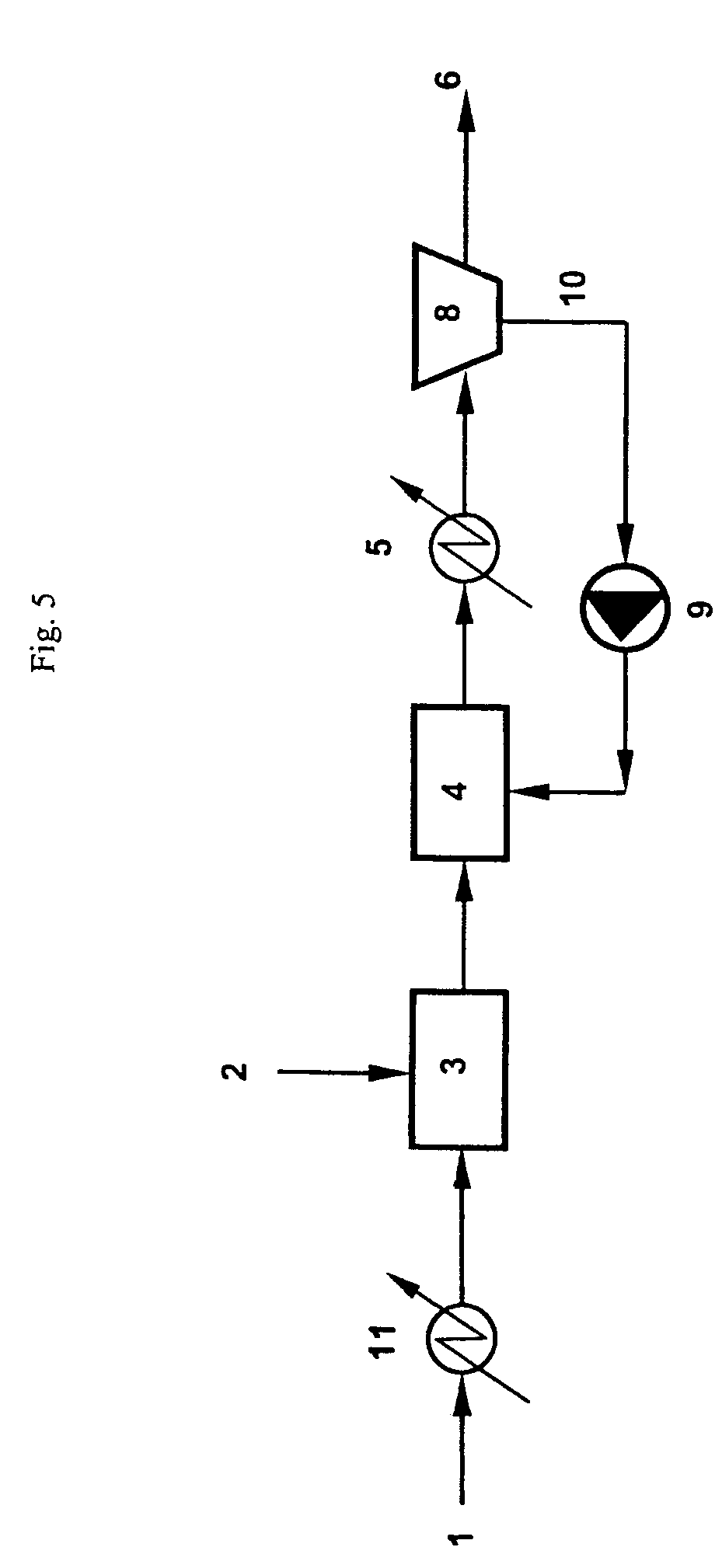

A method and a system for transporting a flow of fluid hydrocarbons containing wax and / or asphaltenes or any other precipitating solids through a treatment and transportation system including a pipeline are disclosed. The flow of fluid hydrocarbons is introduced into a reactor (4), where it is mixed with another fluid flow having a temperature below a crystallization temperature for the wax and / or asphaltenes or other solids and containing particles or crystals acting as nucleating and / or growth cores for the wax and / or asphaltenes or other solids, the mixing temperature providing precipitation of the wax and / or asphaltenes or other solids from the flow of fluid hydrocarbons, and the effluent flow of hydrocarbons and particles is conveyed from the reactor (4) to a pipeline (6) for transportation.

Owner:SINVENT AS +2

Method for recovering copper and cadmium from copper and cadmium slag and device for recovering cadmium from zinc sulfate solution rich in cadmium

ActiveCN103556180APromote leachingImprove leaching ratePhotography auxillary processesProcess efficiency improvementElectrolysisSlag

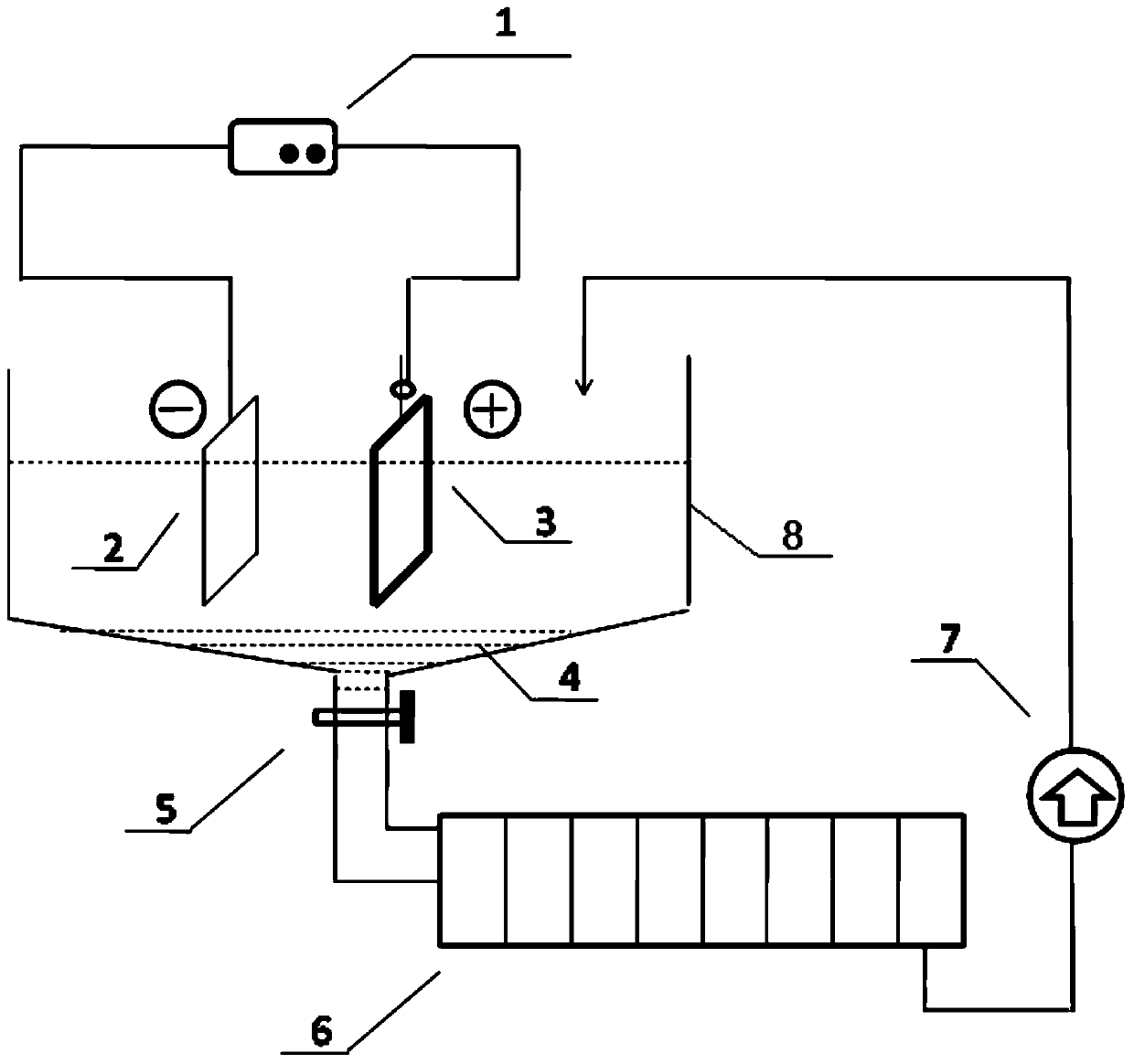

The invention discloses a method for recovering copper and cadmium from copper and cadmium slag and a device for recovering cadmium from a zinc sulfate solution rich in cadmium. The method comprises the following steps of firstly mixing copper and cadmium slag with a gas carrier substance uniformly; then using a sulfuric acid solution to carry out acid leaching on the copper and cadmium slag under certain conditions to leach all copper, cadmium and zinc in the copper and cadmium slag into the solution; then adopting zinc powder as a reducing agent to preferably reduce copper ions in the acid leachate into elemental copper to be precipitated under certain conditions, and adopting the device for recovering cadmium from a zinc sulfate solution rich in cadmium to selectively extract cadmium from the obtained zinc sulfate solution rich in cadmium, thus obtaining a high-grade sponge cadmium and zinc sulfate solution, wherein sponge cadmium can be directly subjected to casting-electrorefining or rectifying to obtain high-purity cadmium, and the zinc sulfate solution can be directly returned to an electrolytic zinc system to produce electrolytic zinc.

Owner:CENT SOUTH UNIV +1

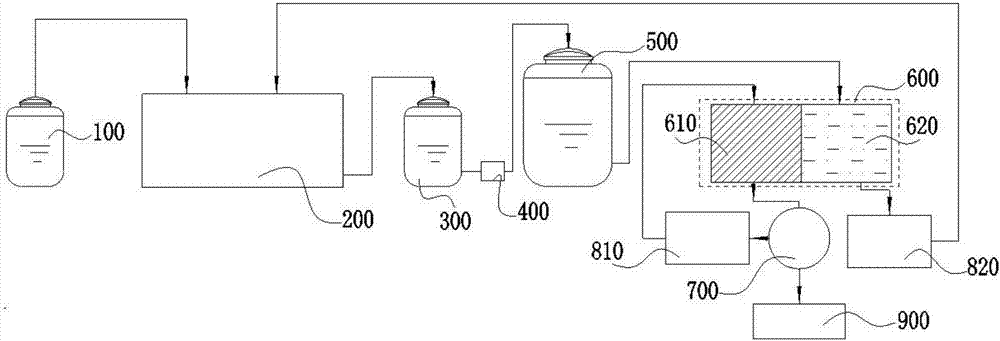

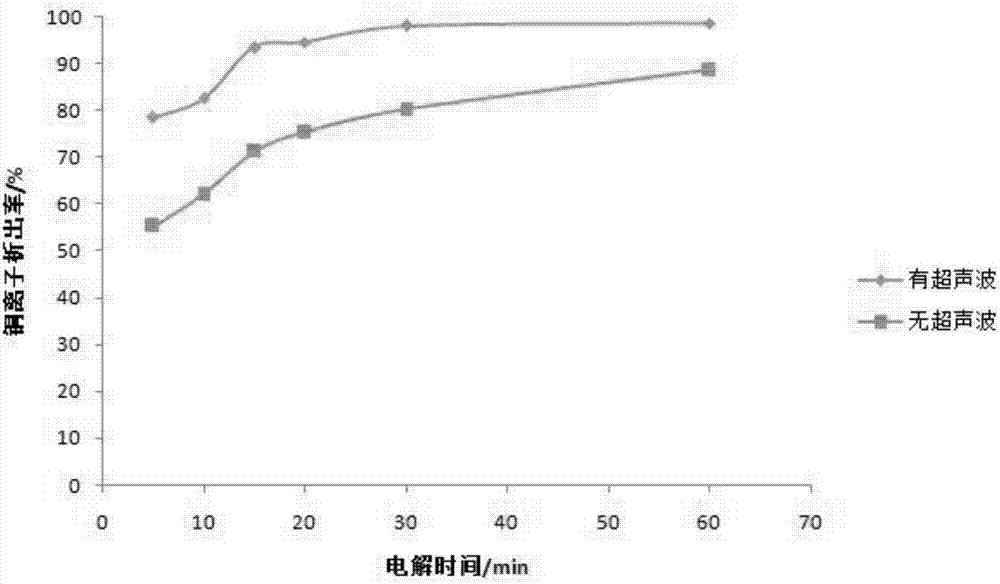

Acid etching liquid regenerative cycle method and system

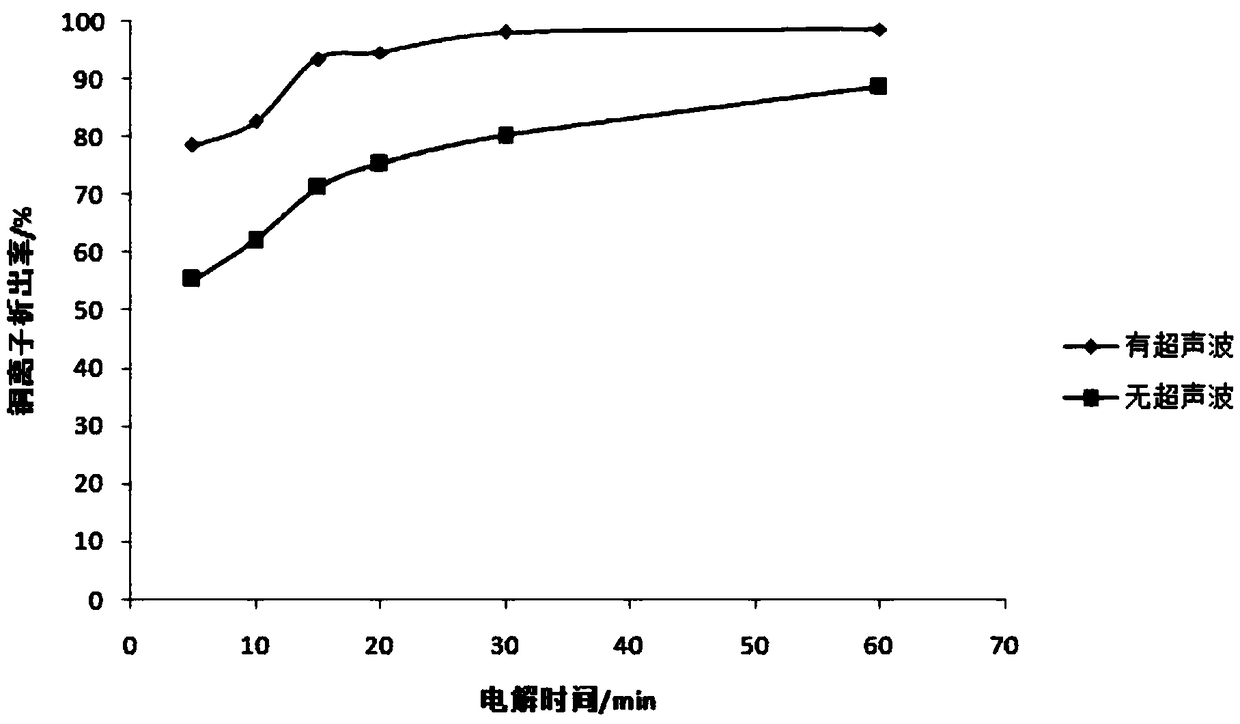

ActiveCN107012466APrecise etching effectIncrease precipitation speedPhotography auxillary processesAcid etchingElectrolysis

The invention provides an acid etching liquid regenerative cycle method. The method comprises the steps of collection of acid etching liquid, filtration and mixing of the acid etching liquid, ultrasonic-assisted electrolysis, copper sheet decomposition, anolyte cycle using and the like. According to the acid etching liquid regenerative cycle method, ultrasonic catalyzed electrolysis is adopted, the concentration of the acid etching electrolyte, the electrolytic current density and electrolytic temperature are precisely adjusted and controlled, copper ions in the acid etching liquid can be converted to be copper sheets with the purity reaching up to 99%, the separation-out speed of the copper ions is greatly improved, production efficiency is improved, and meanwhile production energy consumption is lowered. The invention further provides an acid etching liquid regenerative cycle system matched with the acid etching liquid regenerative cycle method. The ultrasonic technology is combined with the ion film technology, the copper ion separation-out speed can be increased, the copper ion separation-out purity can be further improved, and the high-purity copper sheets with the purity being 99.8% or above can be obtained.

Owner:丰顺佳丰电子有限公司

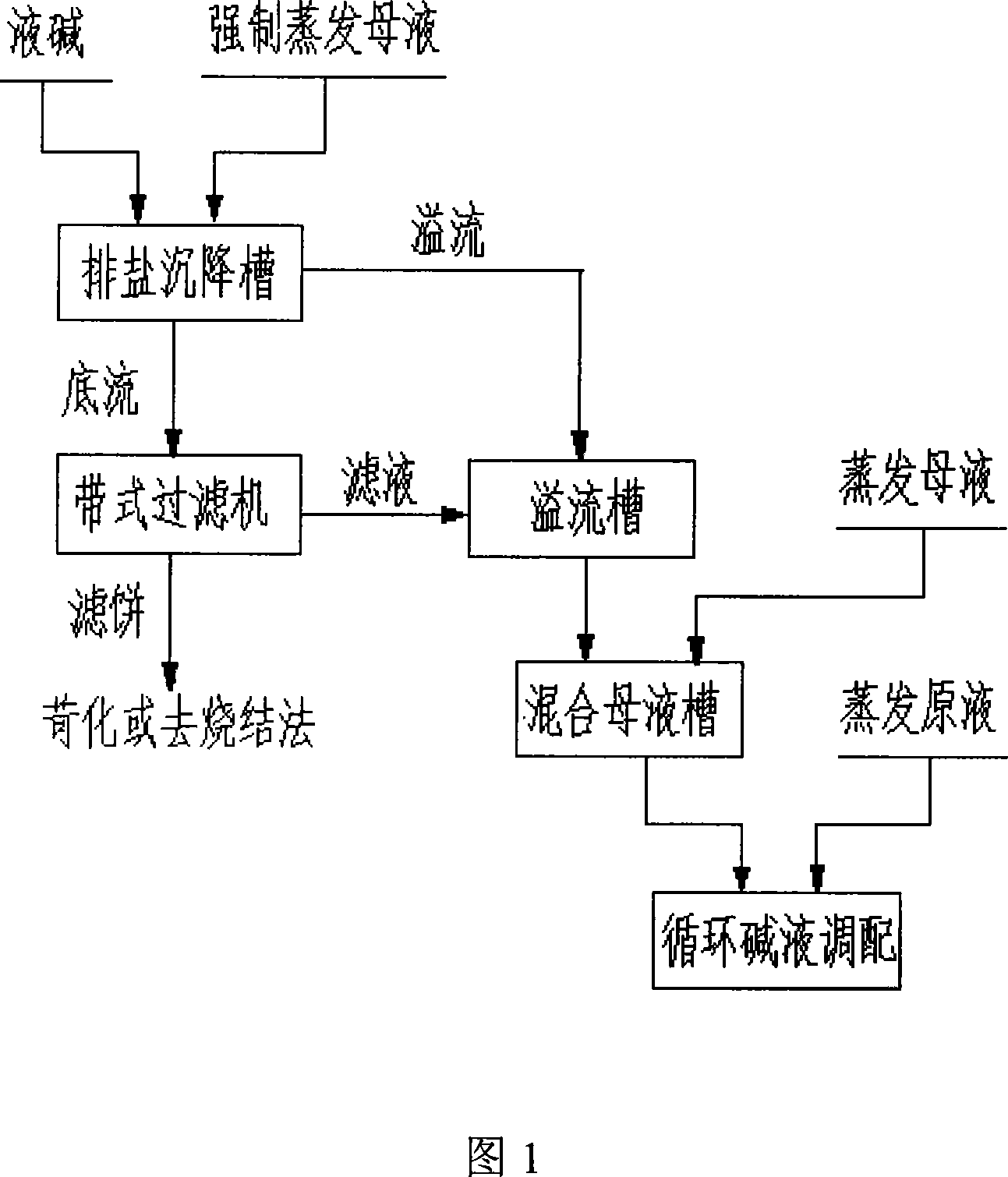

Method for expelling carbonate in production of aluminum oxide

ActiveCN101117226AEasy and accurate deployment operationIncrease supersaturationAluminium oxides/hydroxidesRoom temperatureEvaporation

The invention relates to a method to exclude carbonate in the production process of aluminum oxide, which relates to a technological method producing aluminum oxide with the Bayer process. The method is characterized in that: the liquid caustic which is required in the production process of aluminum oxide with the Bayer process is directly added into the salt draining settling tank, the settled bottom stream is solid-liquid separated into carbonate and the evaporation alkali liquor; the solid obtained by the separation is dealt with the causticizing process or the sintering process to produce aluminum oxide; the liquor obtained by the separation and the overflow of the settling tank are added into the mother liquor tank together, and then is circularly lye allocated. By using the invention, the liquid caustic with normal temperature high caustic sodium concentration is added into the salt draining settling tank, the temperature of the solution in the settling tank is reduced, the caustic sodium concentration of the solution is improved, and the separating speed for the carbonate crystallization is accelerated. The liquid caustic, the overflow of the settling tank and the evaporation mother liquor are mixed into the mother liquor tank, and during the circular lye allocation, only the flow of the evaporation stock solution and the mixed mother solution is calculated and regulated, ,the technological process by using the circular lye allocation with the Bayer process is simplified, the operation of the lye allocation is more convenient and exact.

Owner:中铝中州铝业有限公司

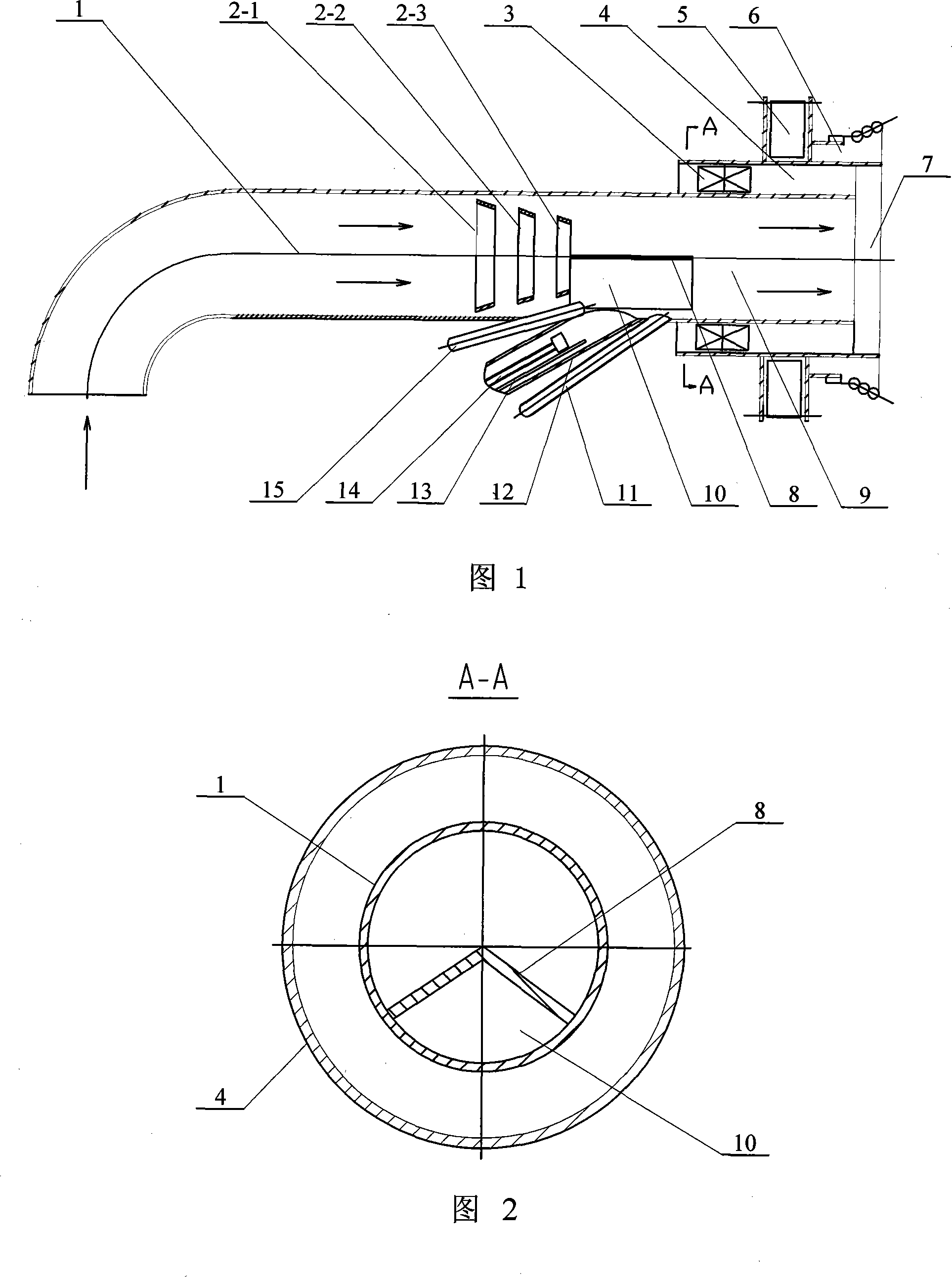

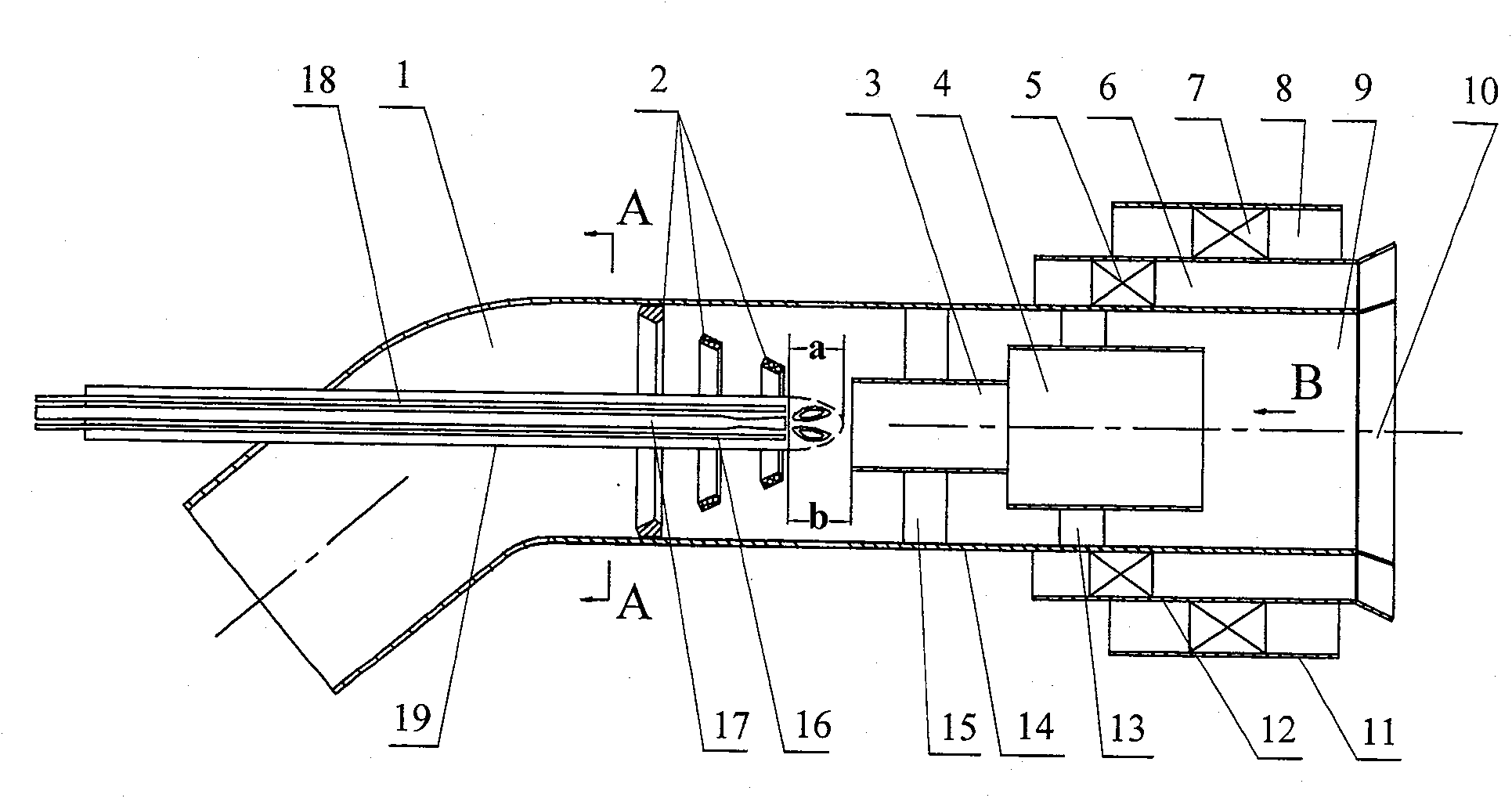

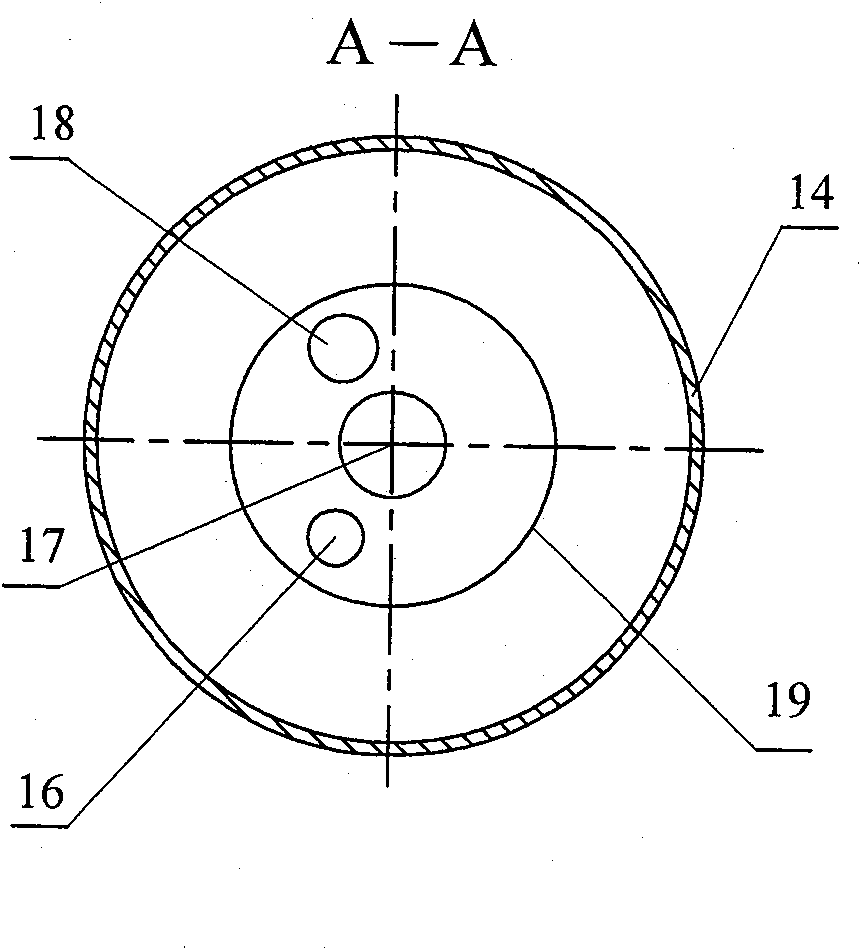

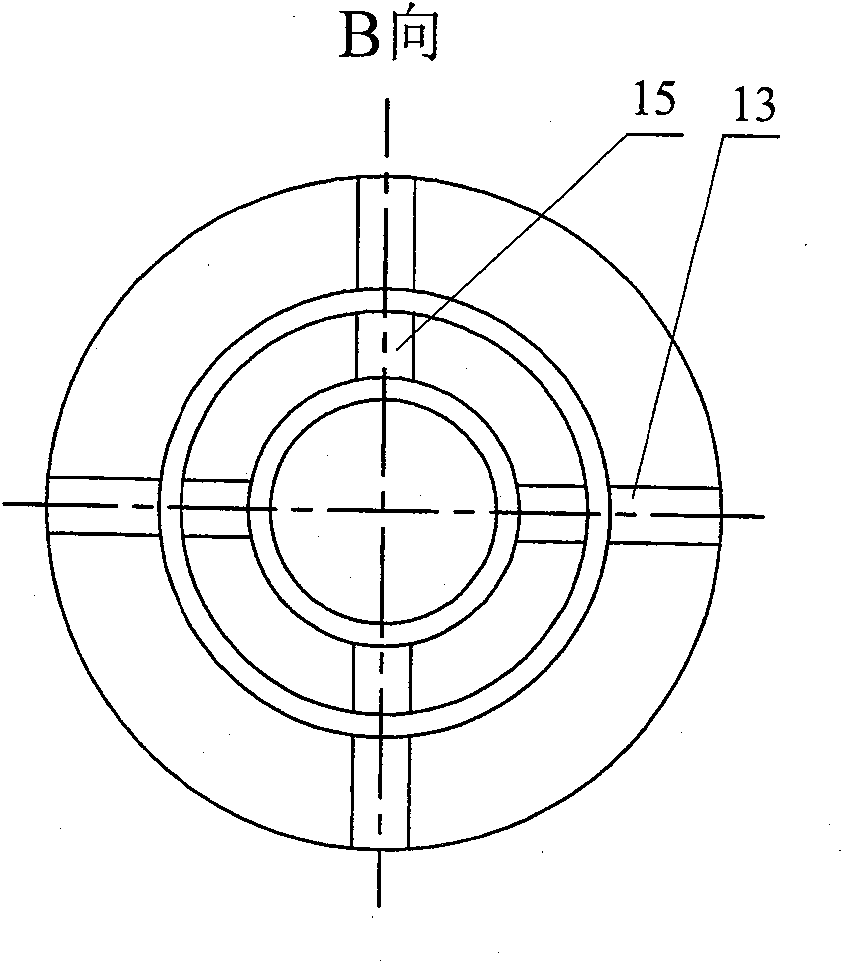

Little oil gasification and burning lateral-igniting center coal powder-feeding swirling burner

InactiveCN101101115ASolve the fuel saving problemSolve wear and tearCatalytic ignitersPulverulent fuel combustion burnersStart stopCombustor

The invention relates to swirl-flow burner. The first, second, and third truncated cone shape separating rings are orderly set at the middle of the burner primary flue in which the backward V shape separator is fixed at the right of the third truncated cone shape separating ring. The invention can greatly reduce initiation energy, satisfy the demands of start stop, and under load stable combustion for boiler, prolong coal dust residence time, control NOx production, form fractional combustion to combine with center feeding, realize NOx low discharge owing to secondary draft is divided into inner and outer two parts.

Owner:HARBIN INST OF TECH

Anti-corrosion glass silver mirror and production process thereof

The invention relates to the technical field of mirrors, and particularly discloses an anti-corrosion glass silver mirror and a production process thereof. The process comprises the following steps: polishing and cleaning the surface of glass; carrying out sensitization for the first time; plating palladium; then carrying out pretreatment; carrying out sensitization for the second time; performingsilver plating for the first time; performing silver plating for the second time; carrying out first passivation; carrying out secondary passivation; preheating; spraying paint for the first time; baking for the first time; spraying paint for the second time; carrying out secondary baking; cooling the surface of the glass to room temperature; cleaning the cooled surface of the glass; and air-drying the surface of the glass after cleaning. According to the production process, the binding power between a silver coating and the glass can be improved, so that the occurrence of edge corrosion is reduced, and the service lifetime of the glass silver mirror is prolonged.

Owner:苗东保

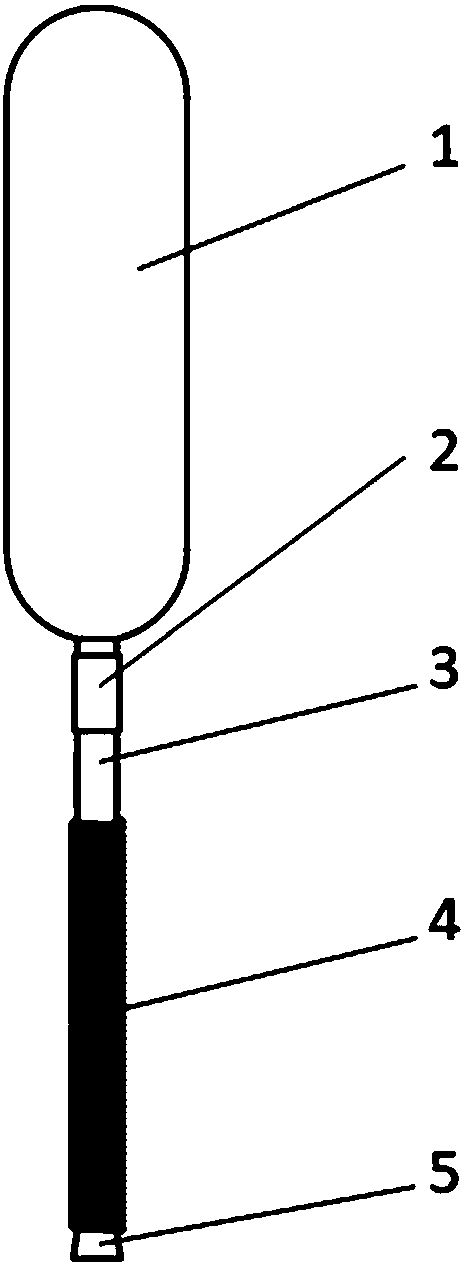

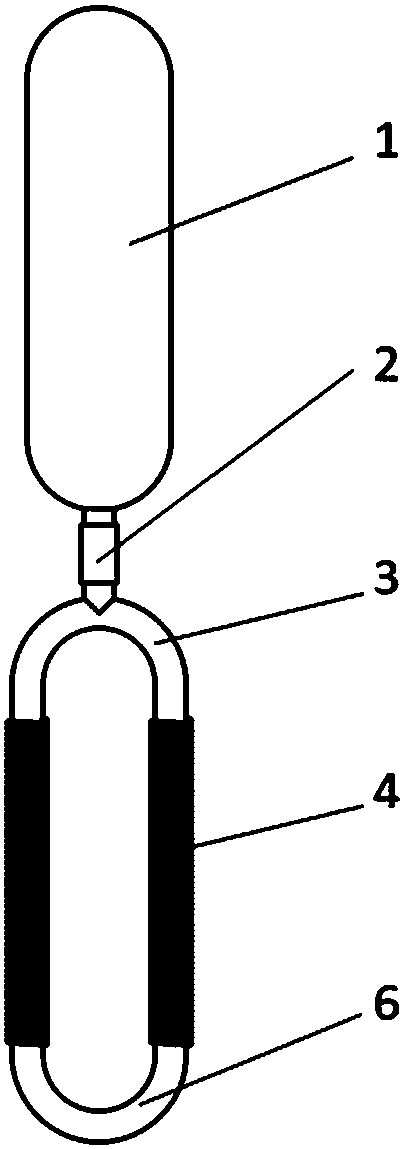

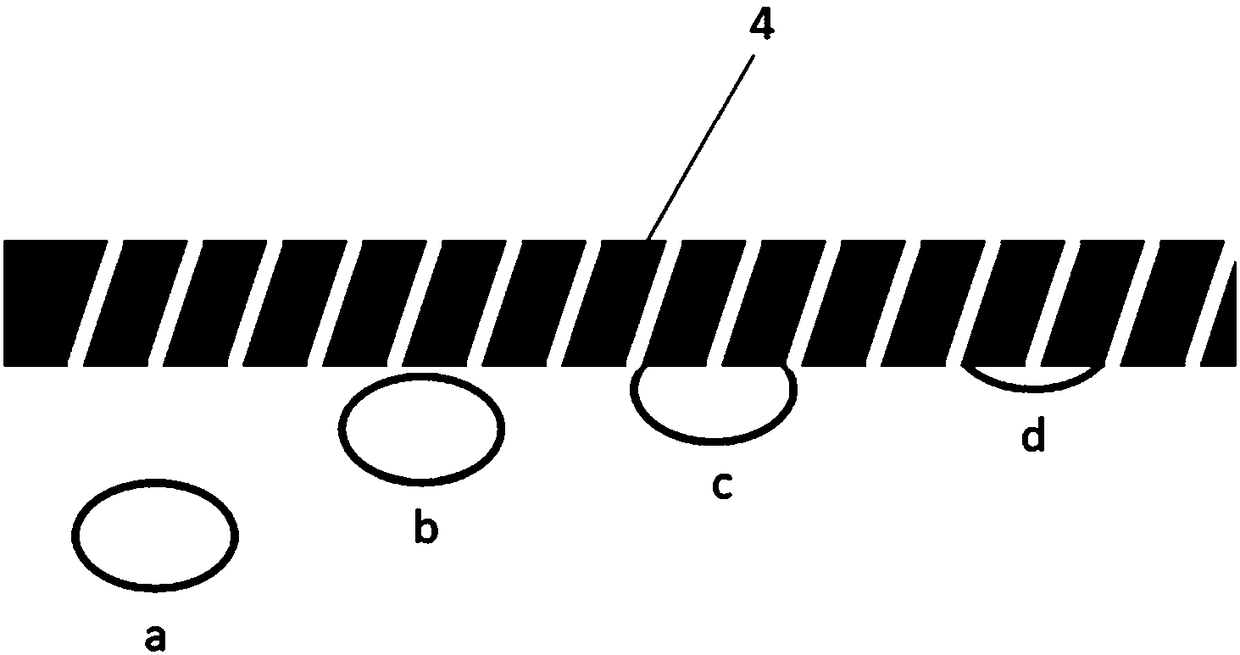

Method for recycling cadmium from metallurgical cadmium-contained dust and device for recycling cadmium from cadmium-ammonia solution

ActiveCN108220999AReduce cleaning burdenImprove qualityPhotography auxillary processesElectrolysis componentsDistillationImpurity ions

The invention discloses a method for recycling cadmium from metallurgical cadmium-contained dust and a device for recycling cadmium from a cadmium-ammonia solution. The metallurgical cadmium-containeddust is subject to ammoniacal circular leaching, when the lead / cadmium molar ratio in the solution is smaller than 0.01, the circular leaching process is ended; after leaching is finished, liquid solution separation is carried out, and the cadmium-ammonia solution is obtained; the proper amount of vulcanizing agent is added to enable impurity ions in the cadmium-ammonia solution to be subject tovulcanization precipitation separation. After impurity removal, liquid is placed in an ultrasonic enhancing electric strengthening replacement cadmium extraction key device to be subject to efficientcadmium extraction, and high-grade sponge cadmium and zinc-ammonia solution can be obtained. The sponge cadmium can be directly used for briquetting distillation or fusion casting-electrolytic refining to obtain high-purity cadmium. The zinc- ammonia solution can be directly turned into an electric zinc system to produce electric zinc.

Owner:CENT SOUTH UNIV

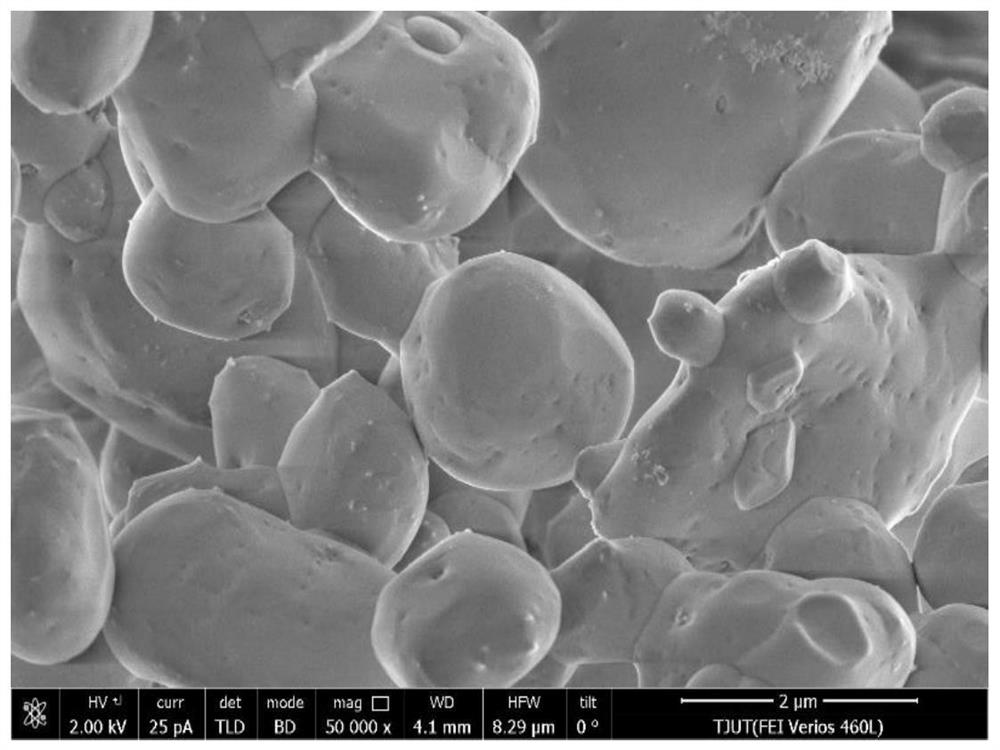

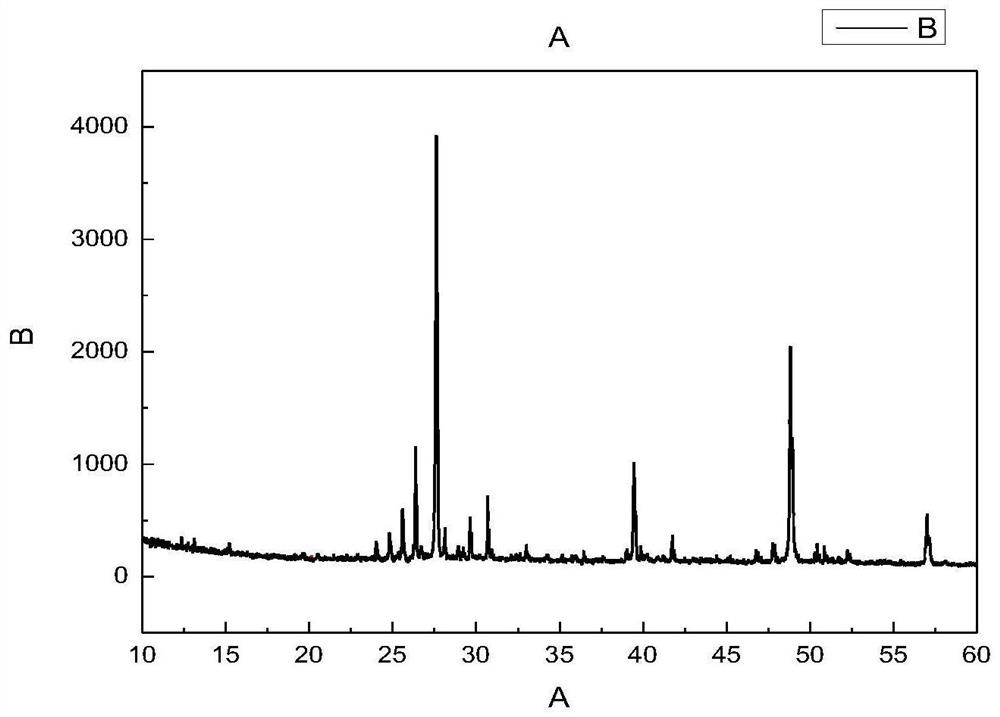

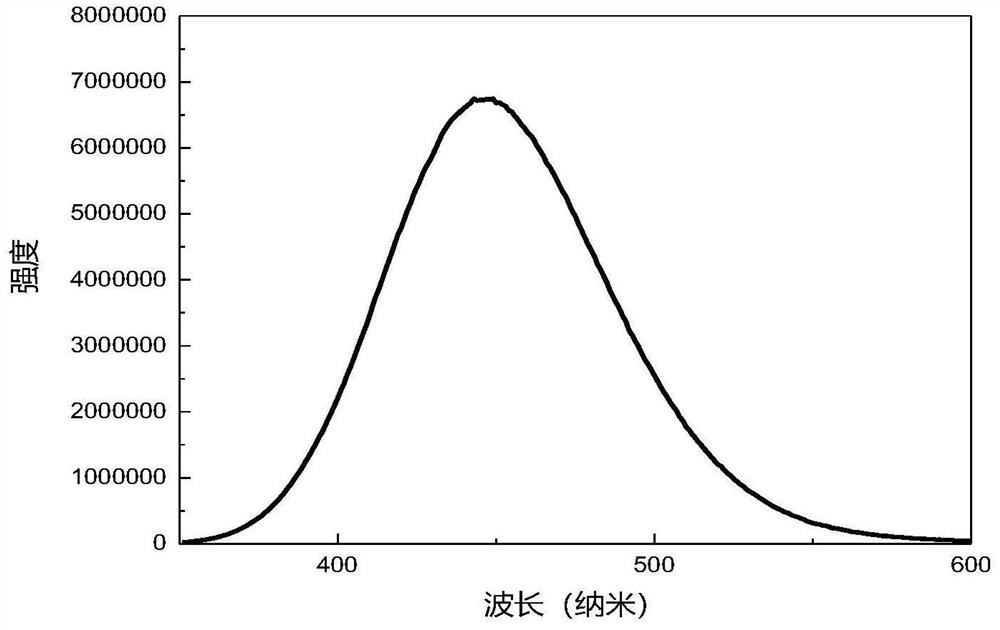

Method for synthesizing copper-based perovskite powder by low-temperature solvent method

InactiveCN112280555ALow costShort preparation cycleCopper compoundsLuminescent compositionsCupric bromideCopper chloride

The invention relates to a method for synthesizing copper-based perovskite powder by a low-temperature solvent method. The method comprises the following steps: adding CsX and CuX into a polar organicmixed solution, and stirring for 4-6 hours at 40-70 DEG C, wherein the polar organic mixed solution is a mixed solution of N, N-dimethylformamide (DMF)and dimethyl sulfoxide (DMSO), the CsX is cesiumchloride, cesium bromide or cesium iodide, and the CuX is copper chloride, copper bromide or copper iodide. According to the synthesis process, constant-temperature growth on a hot plate is not needed, synthesis is directly conducted on a magnetic stirrer, the synthesis process has the advantages of being short in manufacturing period, low in cost, simple in growth step, environmentally friendlyand the like, and Cs3Cu2X5 powder with high crystallization quality is separated out within 5 hours.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

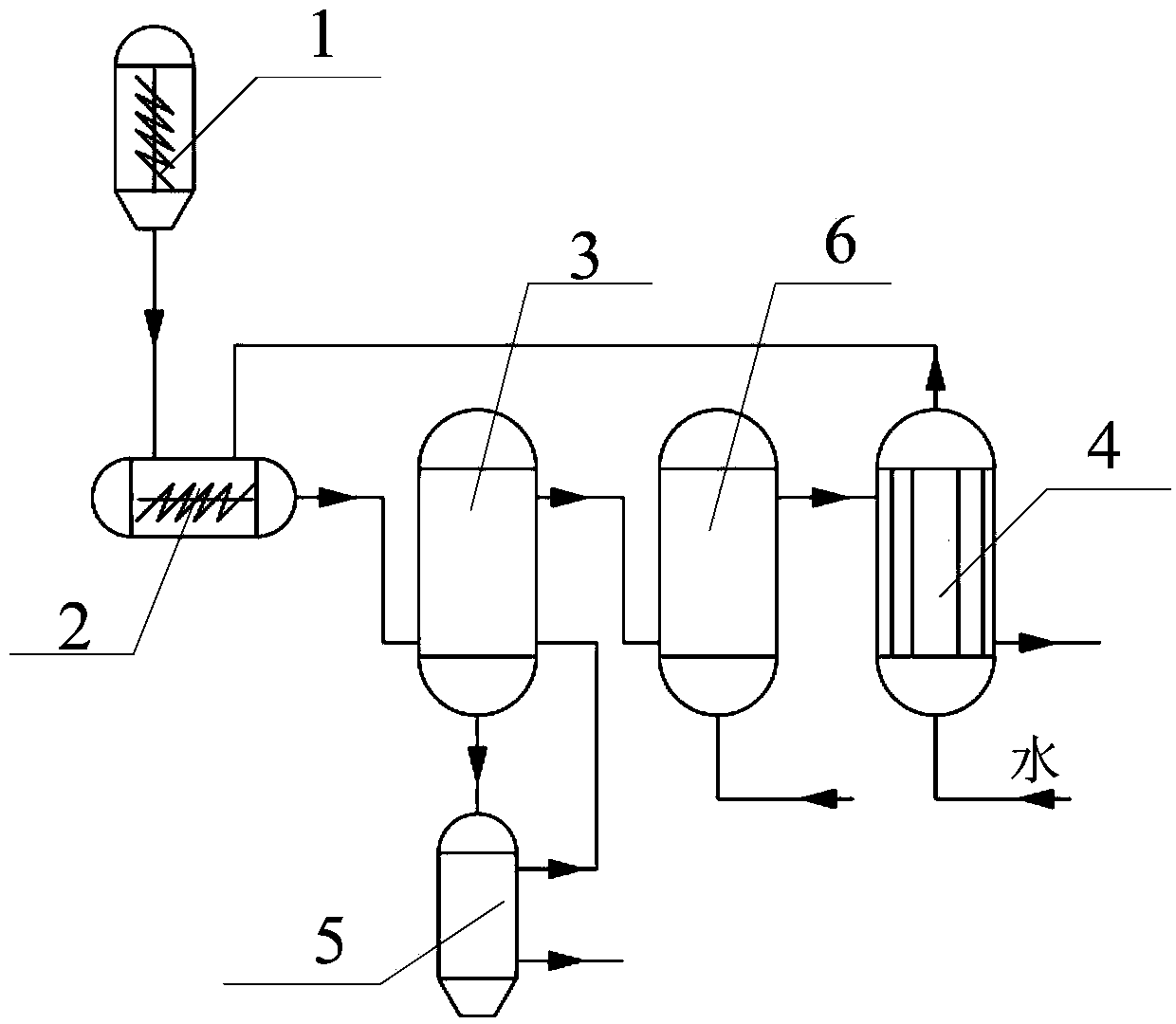

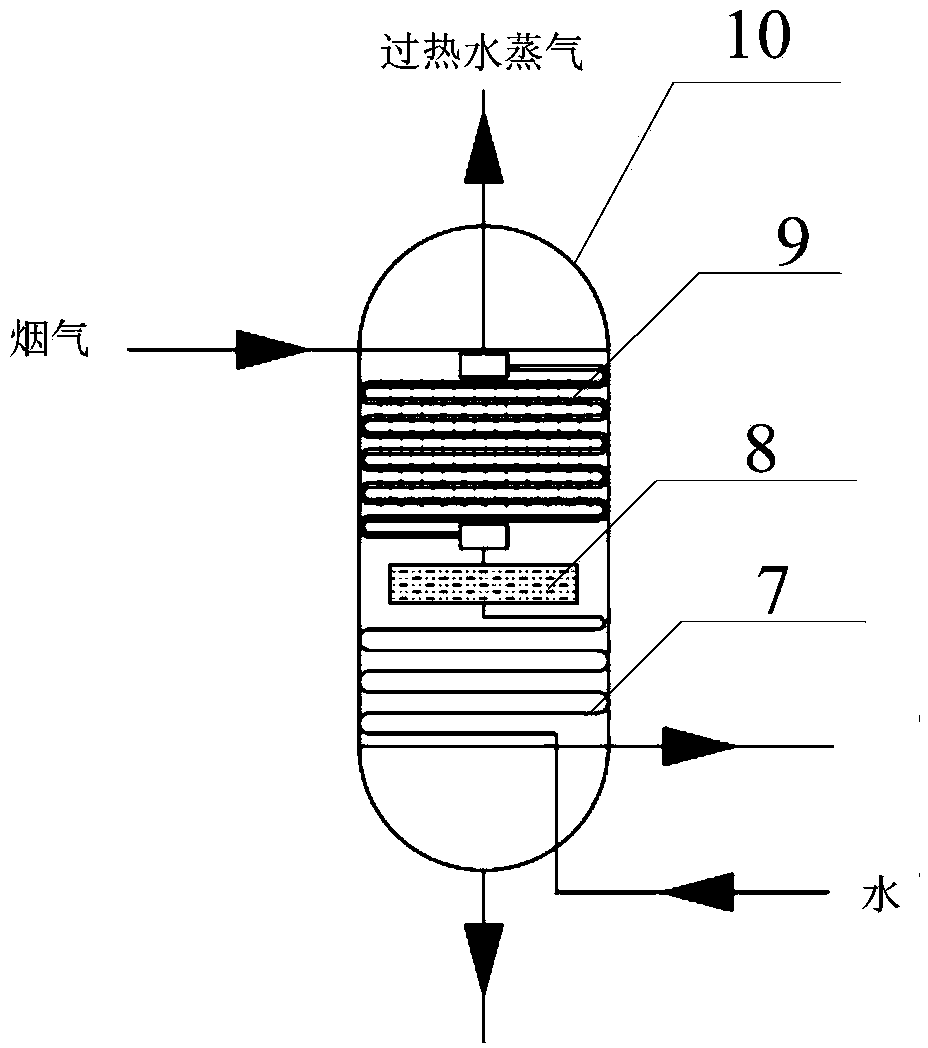

Device and method for accelerating gas generating speed by biomass pyrolysis and obtaining nanoscale carbon dioxide material

ActiveCN103695015ASolve the speed problemSolve efficiency problemsProductsSilicaWater vaporSilicon dioxide

The invention provides a device and method for accelerating gas generating speed by biomass pyrolysis and obtaining a nanoscale carbon dioxide material. The device comprises a spiral feeding device, a pre-treatment stirrer, a pyrolysing device, a combusting device, a steam generator and a calcining device. A biomass raw material is fed to the pre-treatment stirrer through the spiral feeding device, stirred biomass raw material and superheated water vapor generated by the steam generator are mixed and enter the pyrolysing device, a combustible gas separated out by the pyrolysing device combusts in the combusting device, hot smoke generated by the combusting device heats the superheated water vapor generated by the steam generator, and ash discharged from an ash opening at the lower part of the pyrolysing device combusts in the combusting device. The device provided by the invention uses superheated water vapor to heat and dry the biomass raw material, and the drying speed is high compared with that of a method in which biomass raw material is dried by synthermal hot air, so that a pyrolytic gas separating speed of the system is greatly improved compared with the pyrolytic gas separating speed and the gas generating heat value of the conventional system.

Owner:ZHONGYING CHANGJIANG INTERNATIONAL NEW ENERGY INVESTMENT CO LTD

Aging strengthening heat treatment method for nickel-based alloy GH4169

InactiveCN110747417AReduce heating defectsImprove plasticitySolution treatmentUltimate tensile strength

The invention discloses an aging strengthening heat treatment method for nickel-based alloy GH4169. The method comprises full solution treatment and a two-stage aging treatment process. A nickel-basedalloy GH4169 material is subjected to the full solution treatment by preserving the heat for 1 to 3 hours at 980 to 1,070 DEG C; the two-stage aging treatment process comprises first-stage aging treatment, namely, rising the temperature of the nickel-based alloy GH4169 material to 730 to 780 DEG C at the speed of 150 to 200 DEG C / h and preserving the heat for 12 to 18 hours; and second-stage aging treatment, namely, cooling the nickel-based alloy GH4169 material to 630 to 680 DEG C at the speed of 55 DEG C / h and preserving the heat for 18 to 25 hours, discharging the nickel-based alloy GH4169material out of a furnace, and performing air-cooling to room temperature. According to the aging strengthening heat treatment method for the nickel-based alloy GH4169, the tensile strength and yieldstrength of the nickel-based alloy GH4169 at room temperature can be remarkably improved; the hardness at the room temperature is obviously improved; the comprehensive performance of the material isobviously improved; and the service life of the material is obviously prolonged.

Owner:HEBEI IRON AND STEEL

Menthol extraction method

ActiveCN108002982AImprove decomposition effectImprove decomposition abilityOrganic compound preparationHydroxy compound separation/purificationMentholFreeze-drying

The invention discloses a menthol extraction method. The menthol extraction method comprises the following steps: adding a grinding fluid into mint leaves for grinding; then adding a decomposition liquor for decomposition; performing ultrasonic concussion; after that, filtering mint syrup by means of filtration under a reduced pressure; directly concentrating the filtrate; extracting filter residues by means of a Soxhlet extractor; concentrating the extract; after finish of concentration, merging the concentrated solutions; performing freeze drying on the merged concentrated solutions under avacuum condition; crushing the dry product; placing the crushed dry product into a supercritical extractor for supercritical extraction; after finish of extraction, performing fractional distillationon a crude product; and collecting fractions at 160-280 DEG C to obtain menthol. By adoption of the menthol extraction method, the technical problems of low purity, poor quality and low extraction ration of a menthol extraction product can be effectively solved, the menthol extraction ratio can reach 1.65% or above, and the product purity exceeds 92%.

Owner:SICHUAN JINSUIFANG PHARMA

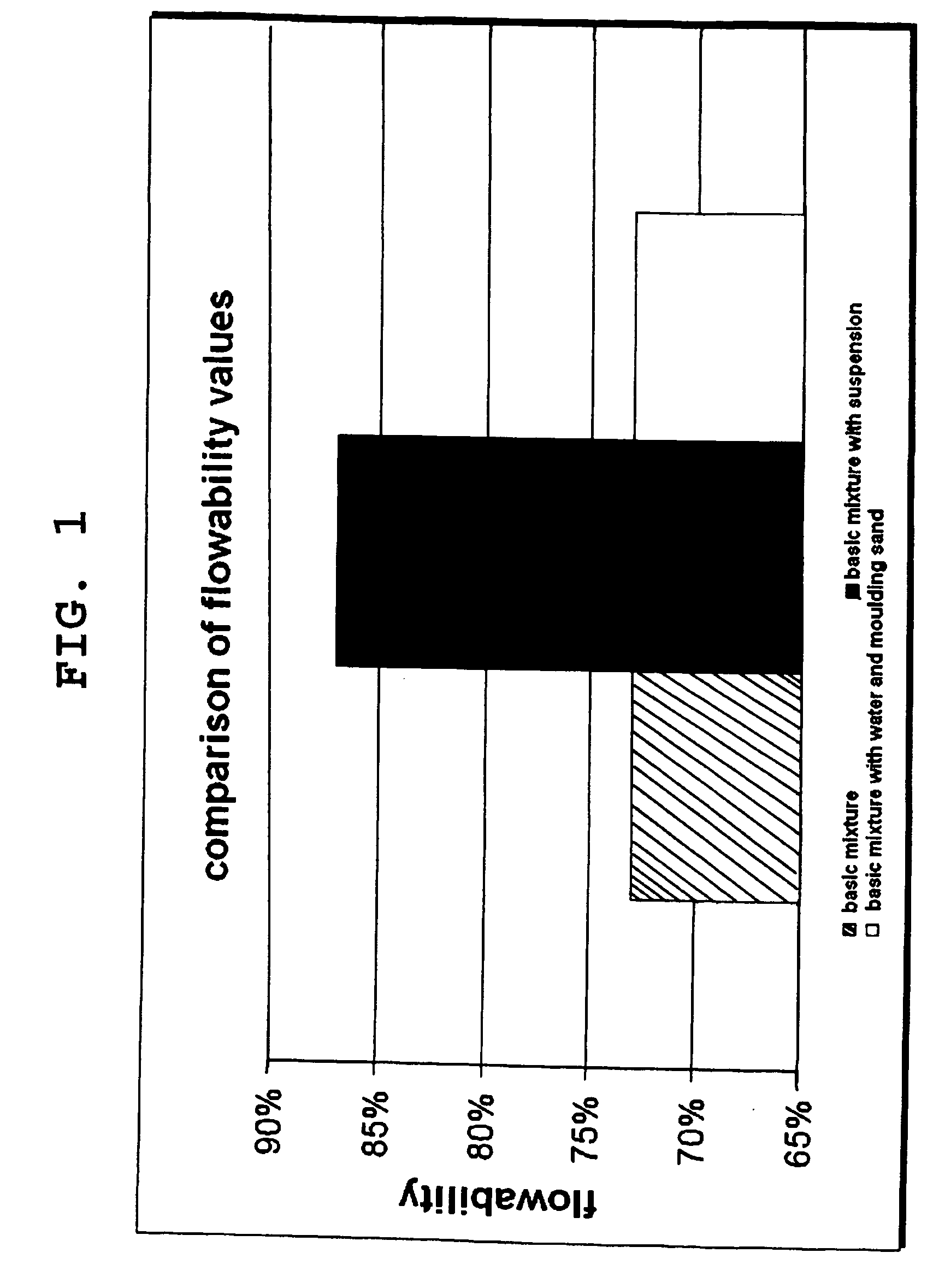

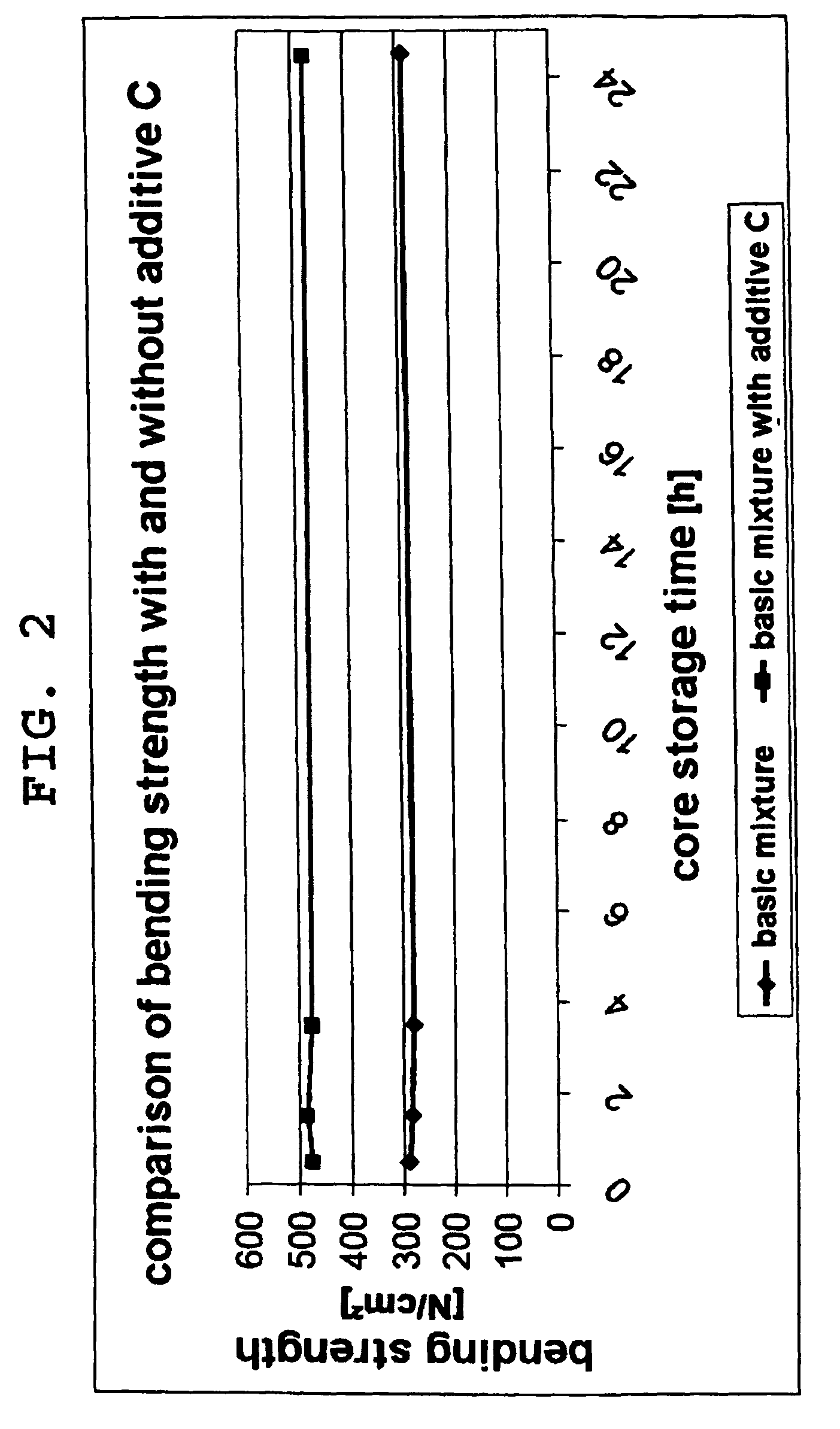

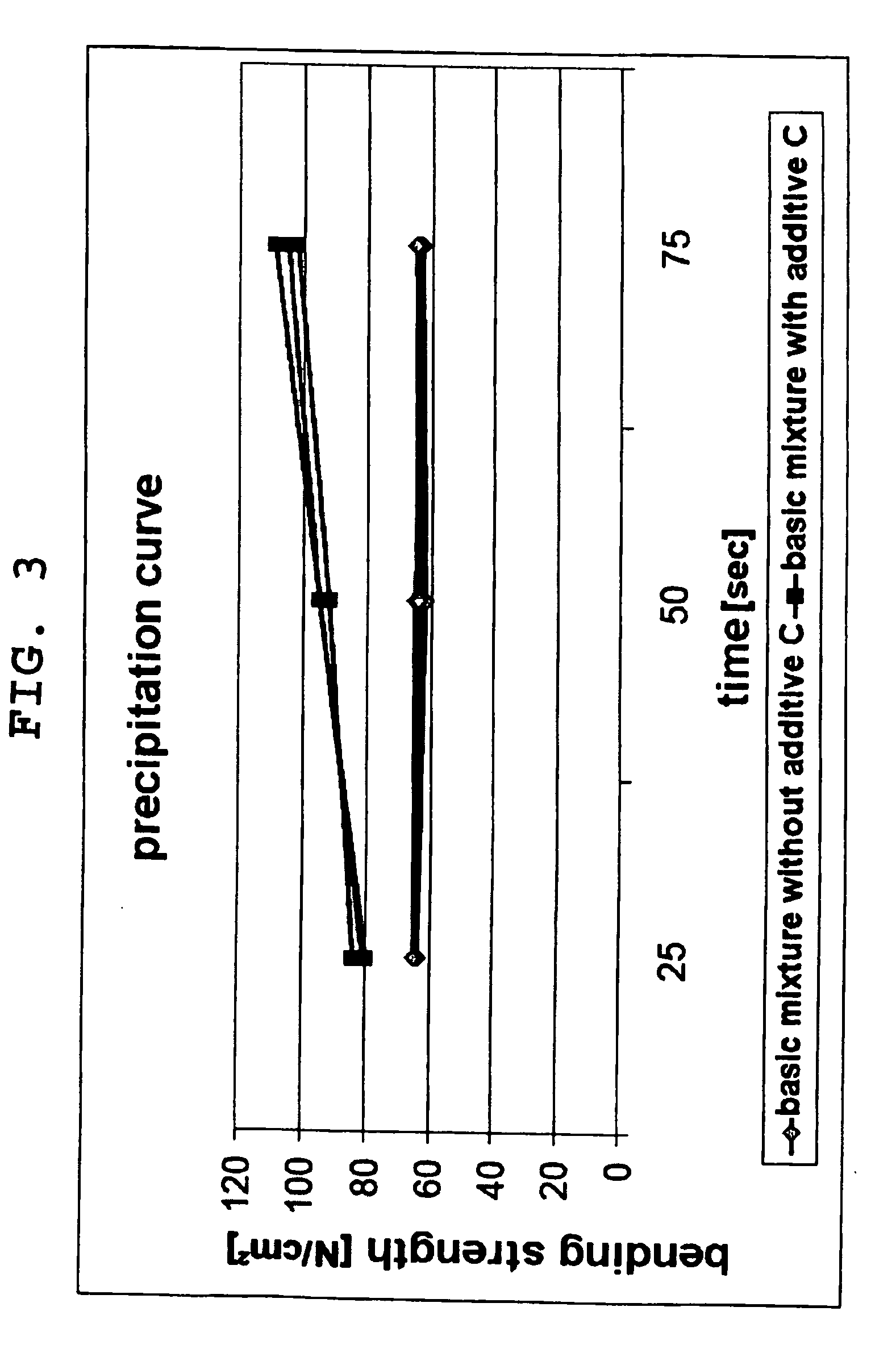

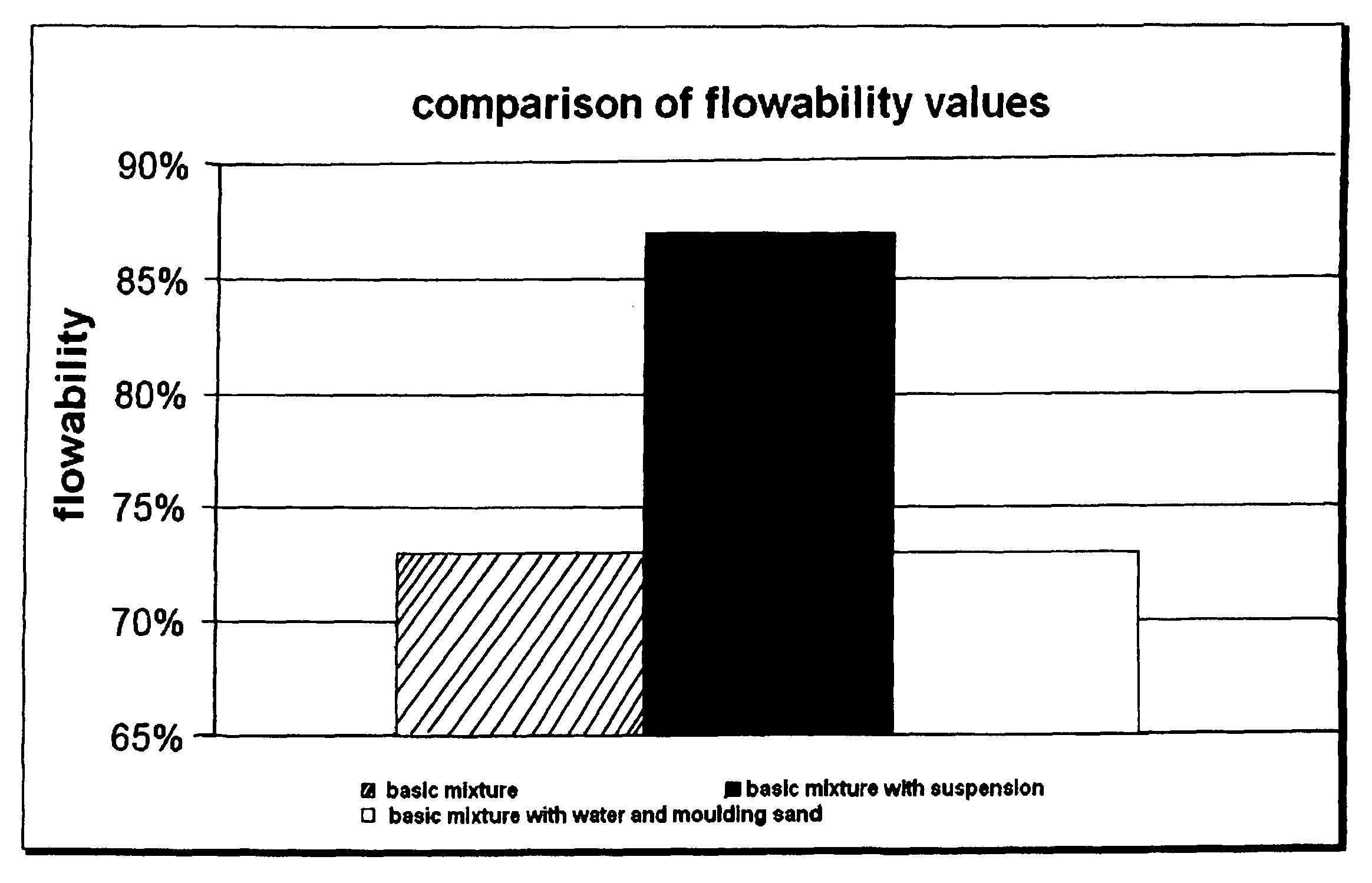

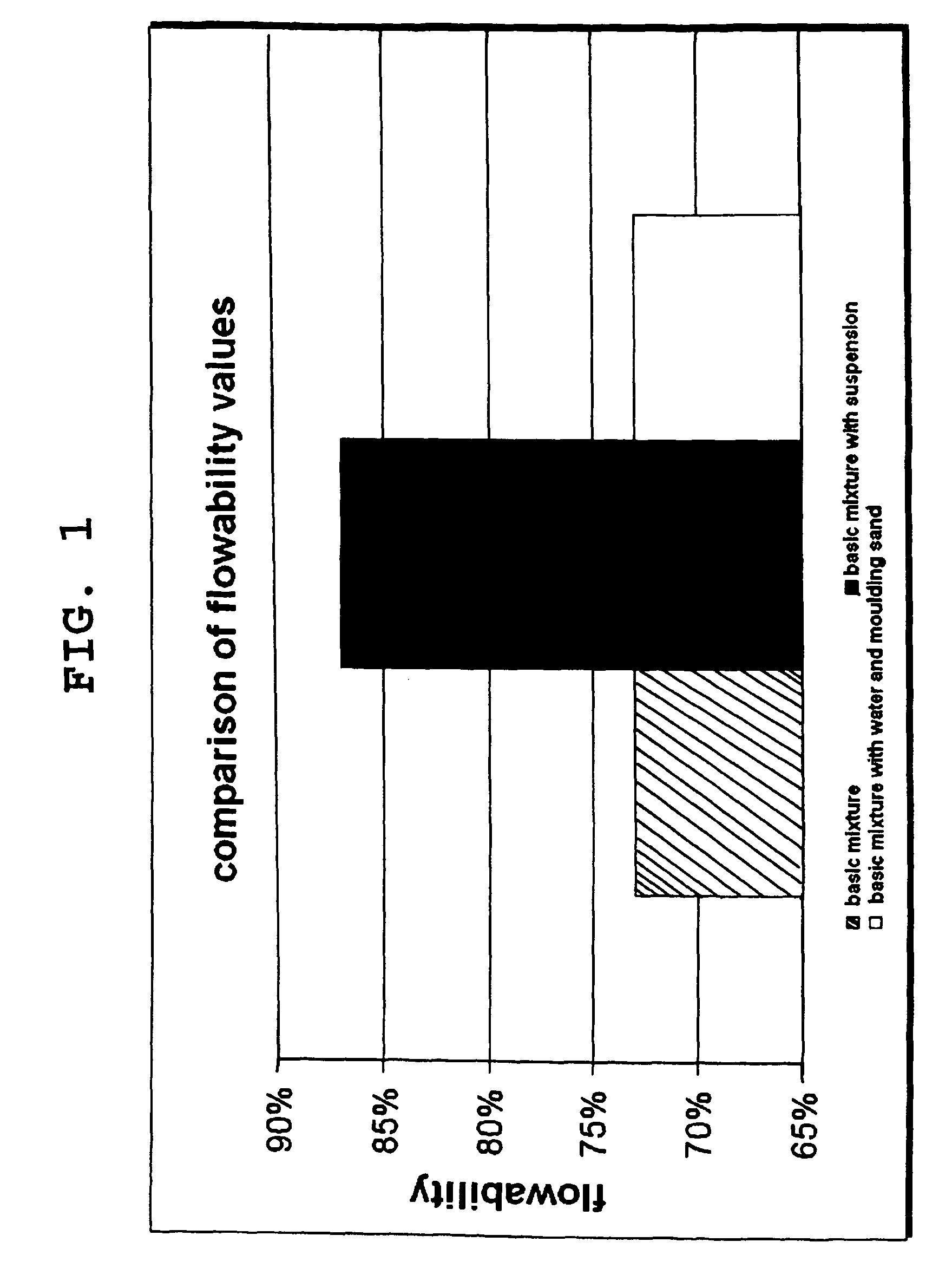

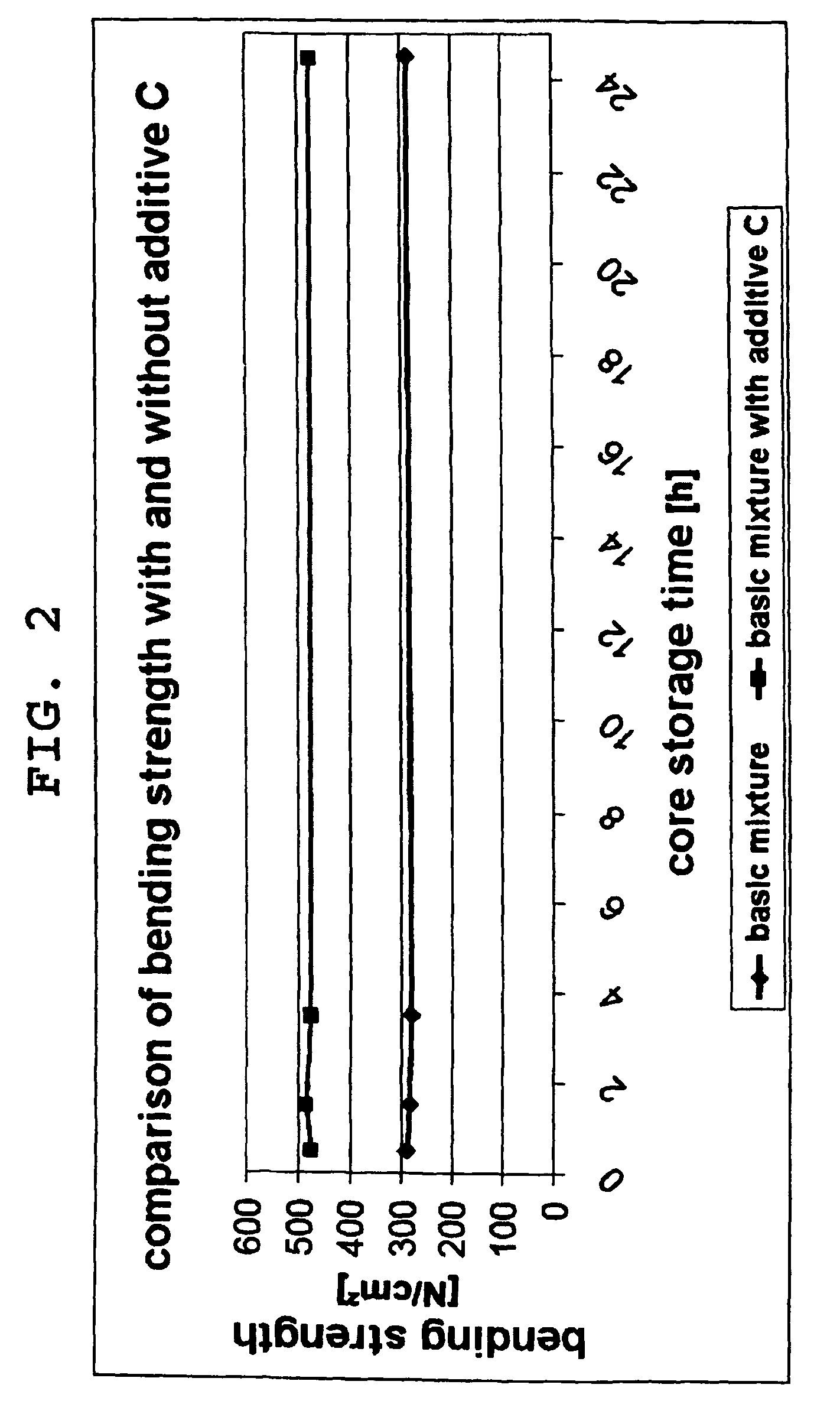

Molding material mixture, molded part for foundry purposes and process of producing a molded part

InactiveUS20080314549A1Evenly distributedImprove flow characteristicsAlkali metal silicate coatingsFoundry mouldsTrademarkShell molding

Molding material mixture, molded part for foundry purposes and process of producing a molded part. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:IMERYS METALCASTING GERMANY GMBH

Method for reducing concentration of lead ions in lead electrolyte

InactiveCN104264185AIncrease precipitation speedReduce the concentration of lead ionsElectrolysis componentsPhotography auxillary processesElectrolysisEnergy consumption

The invention discloses a method for reducing the concentration of lead ions in a lead electrolyte. The method is applied in an electrolytic refining process of lead and comprises the following steps: (1) casting by virtue of a vertical die to obtain anode plates of which sizes are 1210*810*27mm and preparing cathode starting sheets of which sizes are 1370*840*(0.85+ / -0.05) mm by virtue of a cathode sheet processing machine; (2) arranging pitches between the newly manufactured cathode starting sheets and the anode plates by virtue of an automatic pitch arranging machine, loading into a tank, switching the direct current on and electrolyzing for 3.5-4 days; and (3) taking the cathodes out, reloading the newly manufactured cathode starting sheets, continuously electrolyzing for 3.5-4 days and taking the cathodes and residual anodes out so that an electrolytic period is completed. The method disclosed by the invention has the characteristics that the effect of reducing the concentration of lead ions in a lead electrolyte is obvious and economic and technical indexes such as the current efficiency, the rate of residual anodes and energy consumption are significantly improved, and is economical, environmentally friendly and strong in operability.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

Making technology of cold-brewed Mingqian tea

The invention relates to a making technology of cold-brewed Mingqian tea. The making technology comprises the following steps of firstly, drying Mingqian Longjing green tea and Mingqian Xinyang tippy tea, performing refrigerating wall-breaking, performing air pressure wall-breaking, and then mixing the wall-broken Mingqian Longjing green tea with the wall-broken Mingqian Xinyang tippy tea for air pressure wall-breaking, so that nutrient components in the Mingqian Longjing green tea and the Mingqian Xinyang tippy tea are easily extracted and merged into cold water, the tea fragrance and the tea flavor of the Mingqian Longjing green tea and the Mingqian Xinyang tippy tea are merged, and the quality of tea soup of the cold-brewed Mingqian tea is improved.

Owner:福建省耕山队生态有机茶叶开发有限公司

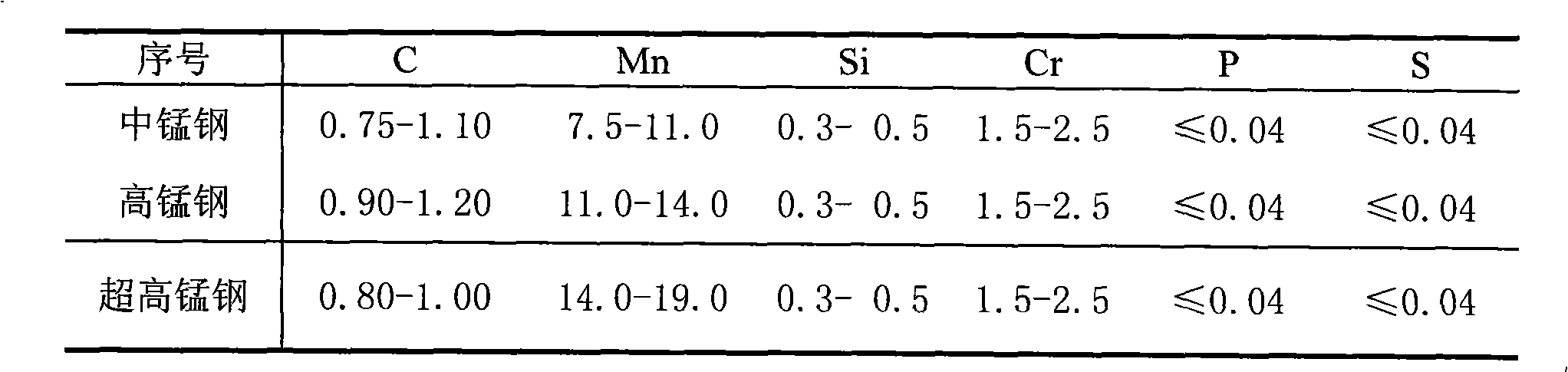

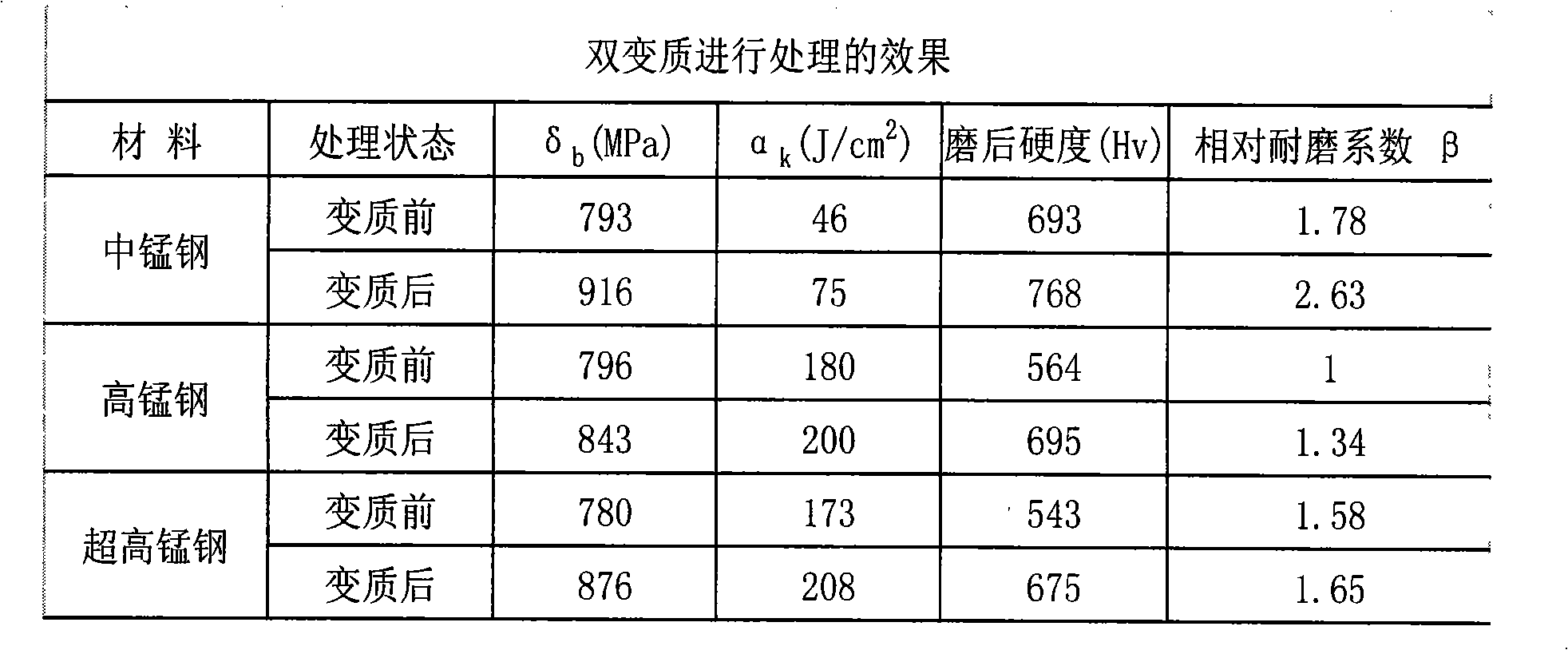

Double- modification method for advanced austenitic manganese steel

The invention discloses an advanced double-modification method for austenitic manganese steel. The method comprises the following steps that: after ferromanganese is added to molten steel for the fine adjustment of manganese content, Re-containing rare earth alloy accounting for 0.067-0.081 percent of the weight of the molten steel and vanadium slag accounting for 2.0-2.5 percent of the weight of the molten steel are orderly added to a molten pool; aluminum accounting for 0.15-0.20 percent of the weight of the molten steel is added in before the tapping of the molten steel; calcium silicon accounting for 0.04-0.06 percent of the weight of the molten steel, Re-containing rare earth alloy accounting for 0.133-0.169 percent of the weight of the molten steel, ferrotitanium accounting for 0.02-0.03 percent of the weight of the molten steel, as well as zinc accounting for 0.006-0.008 percent of the weight of the molten steel are added to a steel ladle outside a furnace. The comprehensive mechanical property and wear resistance of austenitic manganese steel are improved through double modification.

Owner:铜陵市大明玛钢有限责任公司

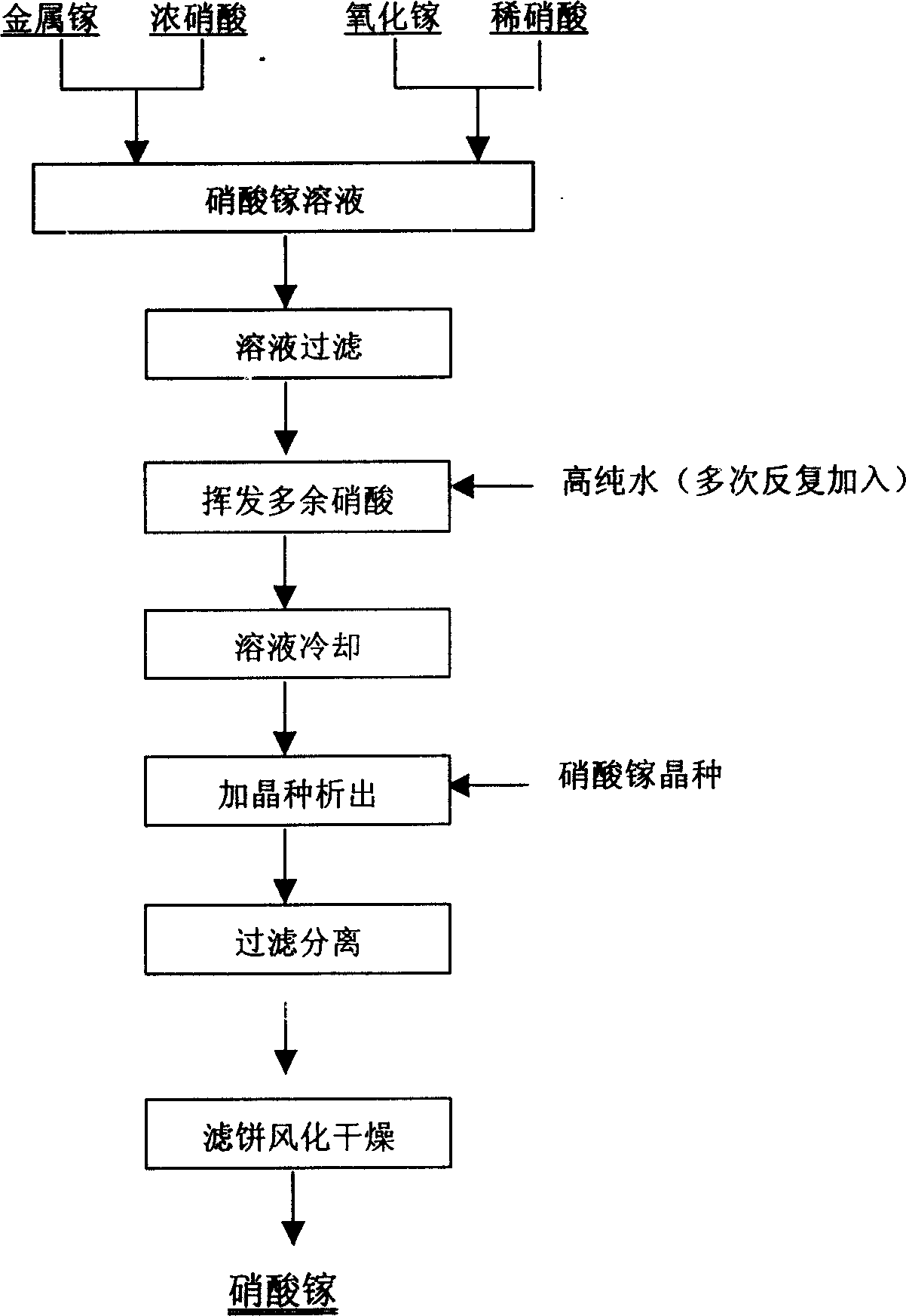

Gallium nitrate preparation method

InactiveCN1762825AShorten the induction periodAccelerate the speed of product precipitationGallium/indium/thallium compoundsChemistryAir drying

The present invention relates to gallium nitrate preparing process. The preparation process includes: dissolving 6N metal gallium in high purity nitric acid at 50-80 deg.c, evaporating the solution at 80-100 deg.c until no bad smell of nitric acid, cooling the solution to -20 deg.c to 0 deg.c, adding gallium nitrate crystal seed into the solution with the weight ratio between the added gallium nitrate crystal seed and gallium nitrate inside the solution being 0.01-0.1, separating crystal, filtering to separate gallium nitrate crystal hydrate, and air drying to obtain gallium nitrate crystal. Owing to the controlled acid dissolving and separation, the process has shortened acid dissolving time and crystal separating time, effectively raised production efficiency, simple operation and easy embodiment. Owing to the high purity of the material, the product has high purity up to 4N.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Cerium-doped iron hydroxide modifying foam titanium material and preparing method and application thereof in water treatment

ActiveCN109261140AIncrease precipitation speedGood application effectWater treatment parameter controlOther chemical processesPorosityControllability

The invention discloses a cerium-doped iron hydroxide modifying foam titanium material and a preparing method thereof. A three-electrode system is formed with a foam titanium plate serving as a working electrode, a platinum sheet serving as a counter electrode and a saturated calomel electrode serving as a reference electrode. An aqueous solution containing ferric chloride, cerium chloride, sodiumsulfate, polyvinylpyrrolidone and hydrogen peroxide serves as an electrolyte solution, cyclic voltammetry is adopted for cyclic circle sweeping, and then a working electrode is taken out, washed anddried to obtain the cerium-doped iron hydroxide modifying foam titanium material. The invention further discloses application of the cerium-doped iron hydroxide modifying foam titanium material in water treatment. According to the cerium-doped iron hydroxide modifying foam titanium material and the preparing method and application thereof, porous foam titanium serves as a matrix, cerium-doped ironhydroxide modifies the surface, and the applicability and activity of iron hydroxide are improved; the cerium-doped iron hydroxide modifying foam titanium material has high porosity and adsorption and oxidation capacity, can serve as adsorbing filler, filter elements or electrodes to be applied to water treatment, secondary pollution to the treated water cannot be caused, and the preparing process has high controllability and stability.

Owner:SHENGSHI LANDSCAPE GRP CO LTD

Gold nano membrane electrode preparation method and gold refining method

InactiveCN101768757AControl thicknessReduce dosagePhotography auxillary processesElectrodesHigh current densityElectrolysis

The invention discloses a gold nano membrane electrode preparation method and a gold refining method. The gold nano membrane electrode preparation method comprises the following steps: adding electrolyte into an electrolyzer, wherein the electrolyte is composed of AuCl3 solution and concentrated hydrochloric acid, and the amount of the concentrated hydrochloric acid is controlled to keep pH value of the electrolyte less than 1; putting the electrolyzer in ultrasonic wave with frequency of 20-30kHz; dipping a pure gold anode and a titanium sheet cathode in the electrolyte; and controlling the decomposition voltage to keep asymmetric current density of the electrolyte is within 600-1000A / m2 to enable gold to be separated out at the cathode to develop gold nano membrane to obtain gold nano membrane electrode. The gold nano membrane electrode can be used for asymmetric current high purity gold refining production; the characteristic of electro-catalysis of the gold nano membrane is used for reducing oxidation-reduction potential and improving current density, so as to speed up gold separation at the cathode, reduce the raw material amount of gold, decrease consumption, improve gold purity and the like, thereby realizing better economic and social benefits.

Owner:厦门紫金矿冶技术有限公司

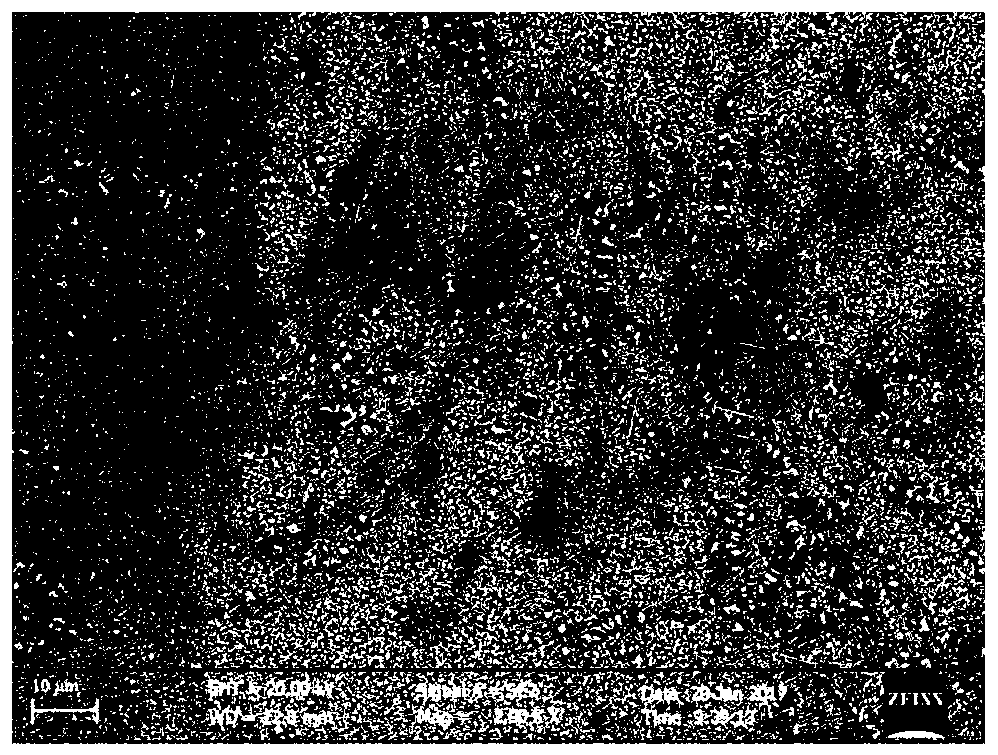

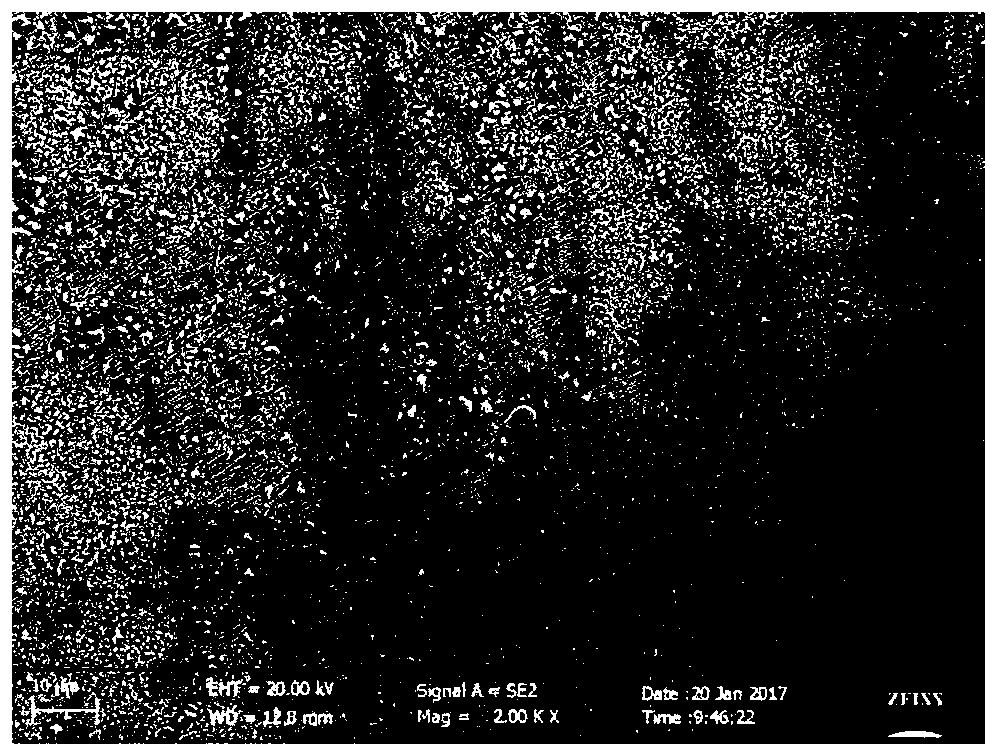

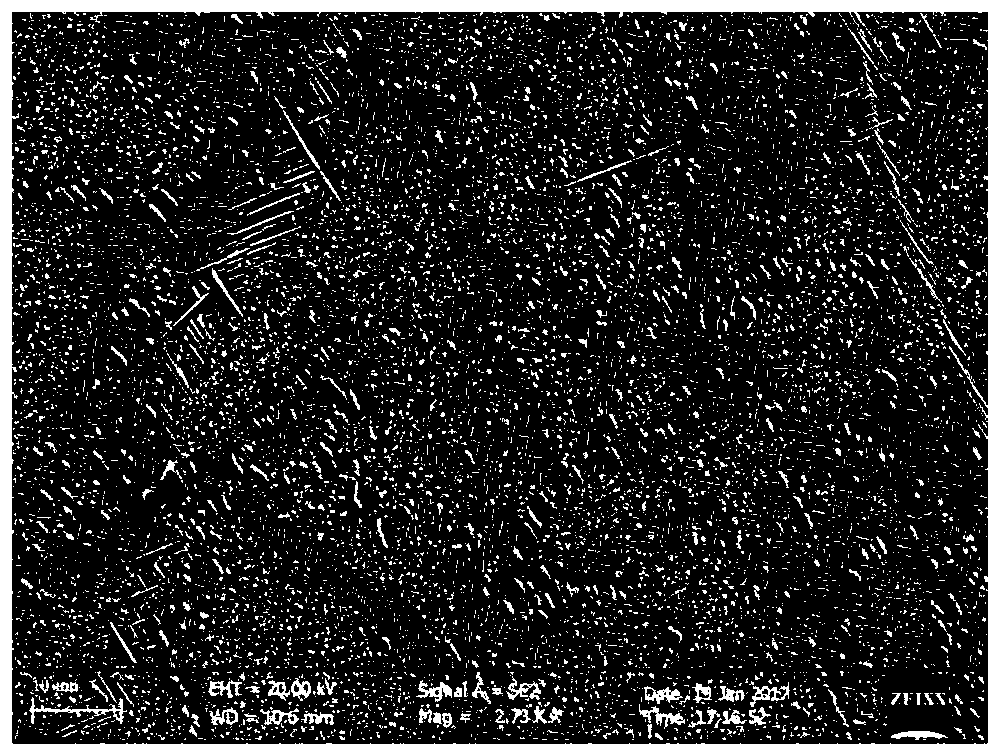

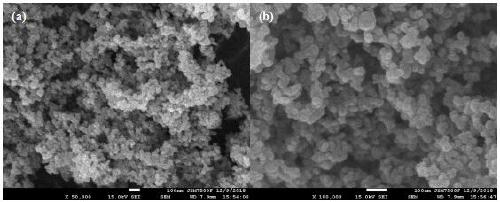

Molding material mixture, molded part for foundry purposes and process of producing a molded part

InactiveUS8006745B2Improve flow characteristicsImprove bending strengthFoundry mouldsFoundry coresShell moldingMicrometer

A molding material mixture for foundry purposes, comprising a mold sand, a sodium hydroxide solution, an alkali-silicate binding agent, and an additive suspension. The molding material mixture contains 0.1 to 10% by weight of sodium hydroxide solution with reference to the weight of the sand, 0.1 to 5% of binding agent with a solid matter percentage of 20 to 70%, and 0.1 to 3% by weight of the additive suspension. The additive suspension comprises 30 to 70% by volume of an amorphous, spherical SiO2 particles, which have a first grain size in the range of 1 to 5 micrometers, and a second grain size in the range of 0.01 to 0.05 micrometers.

Owner:IMERYS METALCASTING GERMANY GMBH

Rapid gas-liquid separation device for separating gas from liquid

ActiveCN108325240AFast separationGood effectLiquid degasification with auxillary substancesThree-phaseEngineering

The invention discloses a rapid gas-liquid separation device for separating gas from a liquid. At least one gas-liquid separation core is soaked in the liquid, and each gas-liquid separation core is of a net barrel type or spring type structure and is covered with a superhydrophobic material coating on the surface. Each gas-liquid separation core adopts an independent structure, and a gas-liquid separation core array can be formed by combining gas-liquid separation cores through connecting pipelines. By means of the superhydrophobic characteristic of the superhydrophobic material, a solid-gas-liquid three-phase interface is formed on the peripheral wall of each net barrel type or spring type gas-liquid separation core, gas is gathered in each gas-liquid separation core, the liquid is isolated outside each gas-liquid separation core, peripheral gas is rapidly separated from the liquid when making contact with the surface of each gas-liquid separation core, and the gas-liquid separationefficiency of gas in the liquid is improved.

Owner:ZHEJIANG UNIV

Method for extracting rutin from ilex latifolia thunb

InactiveCN107434816AShorten the production cycleEasy to operateSugar derivativesSugar derivatives preparationWater bathsFiltration

The invention relates to a method for extracting rutin from ilex latifolia thumb. The method comprises technical steps: performing continuous reflux treatment to dried pulverized ilex latifolia thumb with acetone in a water-bath at 50-60 DEG C for 2-4 h, recycling acetone, airing a sample, taking 70-80% of ethanol as an extraction medium with the weight volume ratio of material to liquid being 1:(20-30), performing ultrasonic extraction and filtering, carrying out pressure reduction to recycle ethanol, continuously performing ultrasonic treatment to mother liquor for 1 h, performing cooling and standing for crystallization, performing pumping filtration to obtain a crude rutin product, performing continuous reflux treatment to the crude rutin product with acetone for 0.5-1 h, recycling acetone, drying the sample, adding distilled water at a weight volume ratio of 1:100 for heating and dissolving the sample, performing filtering while the obtained product is hot, and performing cooling and standing for crystallization to obtain a fine rutin product. Through adoption of ultrasonic-assisted extraction technology, the extraction efficiency and yield are improved. The method is simple in operation process, allows ilex latifolia thumb resources which are abundant in the southwest region of China to be fully used, develops a new field of ilex latifolia thumb application, and solves the problem that a rutin raw material is tight.

Owner:LIAONING YAOLIAN PHARMA

Anti-ultraviolet and anti-fog polyethylene greenhouse film and preparation method thereof

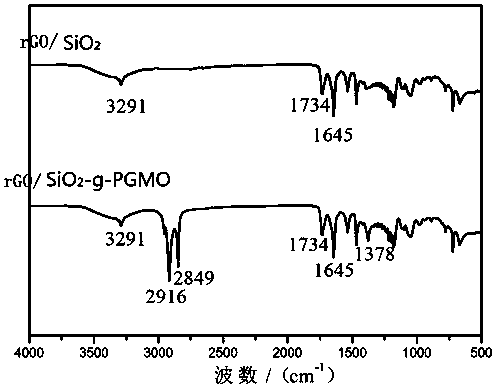

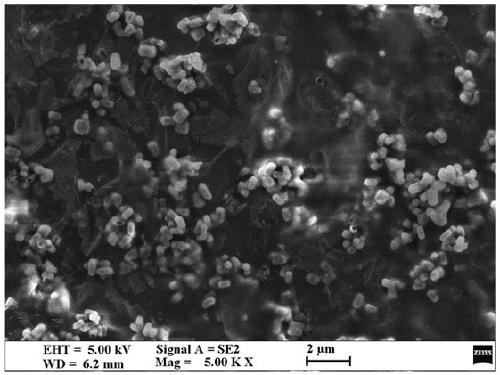

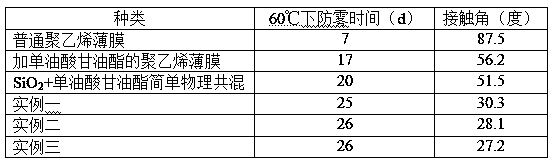

ActiveCN111234366AStrong Light Scattering FeaturesDoes not affect light transmissionCultivating equipmentsCarboxyl radicalChemical reaction

The invention discloses an anti-ultraviolet and anti-fog polyethylene greenhouse film and a preparation method thereof. The anti-ultraviolet and anti-fog polyethylene greenhouse film is prepared fromthe following raw materials: LLDPE resin, LDPE resin, EVA plastic and an anti-ultraviolet and anti-fog agent. The preparation method comprises the following steps: putting the raw materials into a high-speed mixing stirrer in proportion, mixing and stirring for 10 minutes at the speed of 300r / min and the temperature of 60 DEG C, extruding and granulating at the extrusion temperature of 170 DEG C,extruding and casting, cooling, trimming, pressurizing and rolling to obtain the anti-ultraviolet and anti-fog polyethylene greenhouse film. Glycerin monooleate is covalently grafted to the surface ofrGO / SiO2 throughfree radical reaction to obtain the anti-ultraviolet and anti-fogagent. Glycerin monooleate and active functional groups such as hydroxyl and carboxyl on the surface of the hybrid material rGO-SiO2 are subjected to a better chemical reaction, so that polyglycerol monooleate is not prone to moving to the surface of the film along with molecules to be continuously reduced; and the precipitation speed of adripping agent is further increased and the precipitation amount is further controlled through a method of combining inorganic matter grafting and grafting of the dripping agentandpolymer main chains.

Owner:FUZHOU UNIV

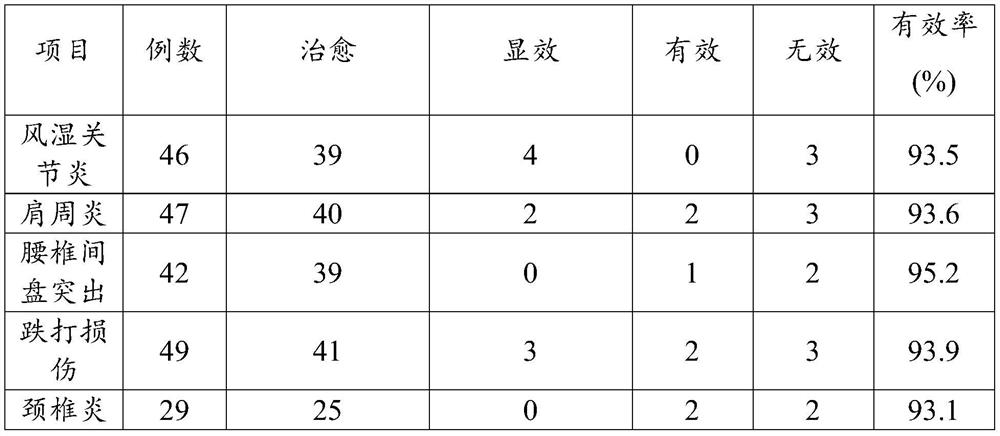

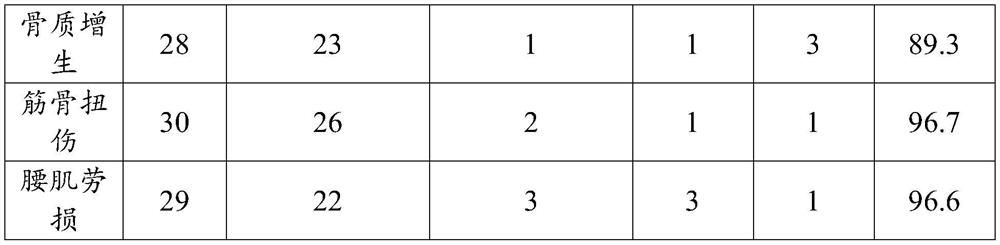

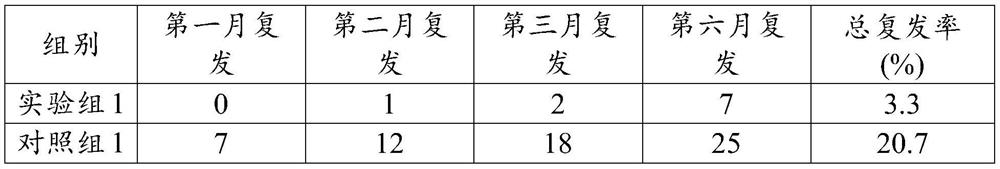

Traditional Chinese medicine composition for treating orthopedic diseases, preparation, preparation method and application

InactiveCN112915173AStrong muscleRelieve symptomsOrganic active ingredientsNervous disorderAristolochia mollissimaDisease

The invention provides a traditional Chinese medicine composition for treating orthopedic diseases, which is prepared from the following ingredients in parts by weight: 65 to 105 parts of snakes, 10 to 15 parts of scorpions, 50 to 80 parts of polygonum cuspidatum roots, 20 to 40 parts of bock greenbrier rhizomes, 20 to 30 parts of berba aristolochiae mollissimae, 20 to 30 parts of Chinese ardisia roots, 30 to 50 parts of creeper creeper roots, 20 to 30 parts of geranium wilfordii, 20 to 30 parts of manyprickle acanthopanax roots, 20 to 30 parts of aralia decaisneana, 30 to 50 parts of asiatic toddalia roots, 30 to 40 parts of vernonia gratifolia, 40 to 50 parts of caulis spatholobi, 20 to 30 parts of sarcandra glabra, 30-40 parts of alangium platanifolium, 30-50 parts of rhizoma drynariae, 40-50 parts of obscured homalomena rhizome, 30-40 parts of philippine flemingia root, 5-10 parts of hippocampus, 100 parts of camphor and white spirit, can be used for remarkably relieving various orthopedic diseases of patients, and is short in treatment course, quick in effect taking and free from toxic and side effects; The invention further provides a traditional Chinese medicine liquor prepared from the traditional Chinese medicine composition and a preparation method thereof, the medicine effect can be exerted to the maximum extent, and the positive effect of treating various orthopedic diseases is improved; and the invention also discloses application of the traditional Chinese medicine composition in preparation of medicines for treating various orthopedic diseases.

Owner:梁潇艺

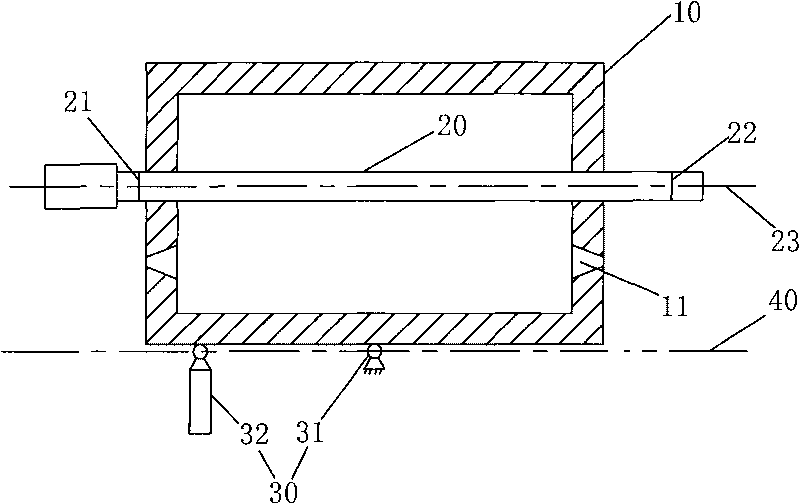

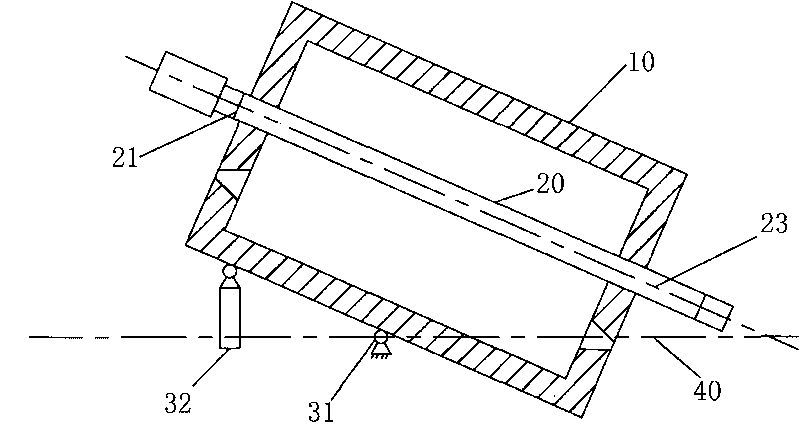

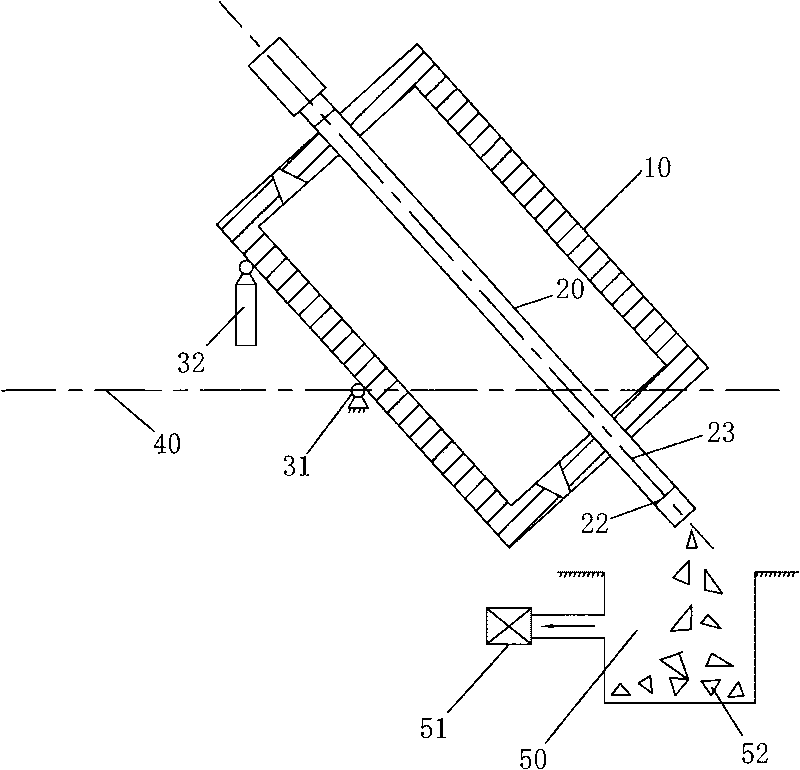

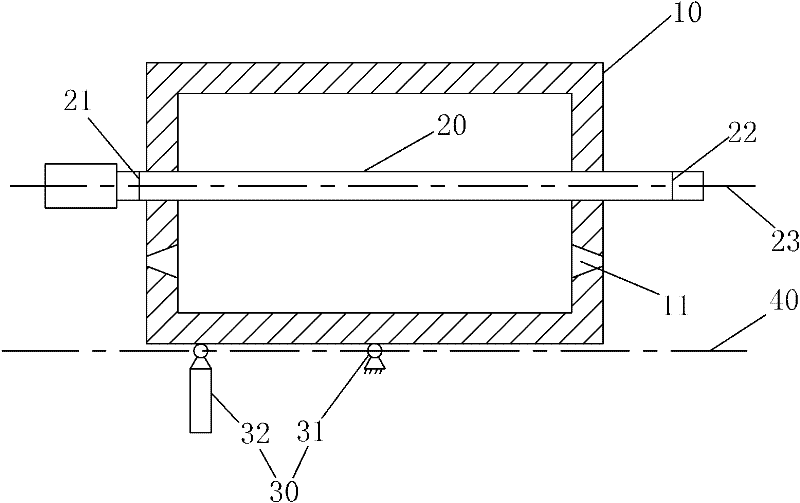

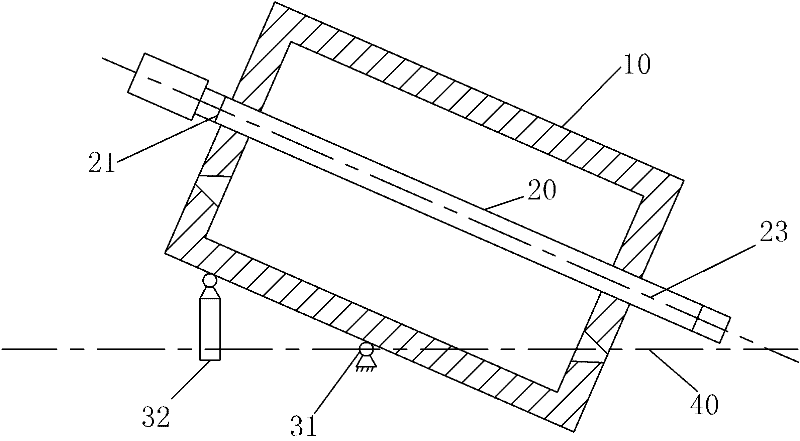

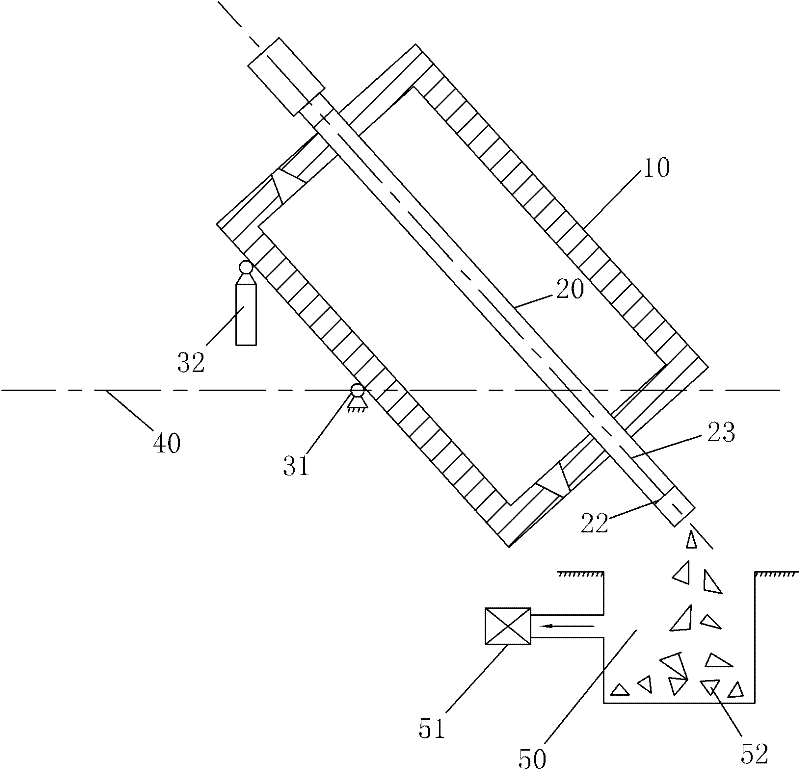

Tilting charge and discharge type reducing furnace and reducing method thereof

The invention relates to a tilting charge and discharge type reducing furnace and a reducing method thereof. The reducing furnace comprises a furnace body, a furnace tank and a furnace body tilting mechanism, wherein a combustion system is arranged in the furnace body for providing high temperature required for a reducing process; the reducing tank is arranged in the furnace body in a penetrating manner, and two ends thereof extend out of the furnace body, a charging hole is formed at one end of the reducing tank, and a dreg outlet is formed at the other end of the reducing tank; the furnace body tilting mechanism comprises a rotating shaft as a furnace body rotating and moving fulcrum and a lifting mechanism for driving the furnace body to rotate around the rotating shaft; and the rotating shaft is horizontally arranged; and the reducing tank at least can rotate between a horizontal position and an inclined position back and forth. The reducing tank of the tilting charge and discharge type reducing furnace is positioned in the horizontal position during the heating and reducing process and also positioned in the inclined position in a charging and dreg discharging process; and dregs can be automatically discharged by utilizing gravity, so that the production speed is improved, and the labor amount is reduced, thereby facilitating mechanical production.

Owner:青岛荣恒节能设备有限公司

Micro-oil ignition rotational flow breeze combustion device for preventing slag bonding of primary combustion chamber

InactiveCN101403497BBurn fullyStable concentrationPulverulent fuel combustion burnersCombustion chamberLow load

The invention discloses a micro-oil ignition swirling pulverized coal burning device for preventing slag formation in a first-class burning chamber, which relates to a swirling pulverized coal burning device for preventing slag formation in a first-class burning chamber, and aims at solving the problems of easy slag formation in the burning chamber during burning and large oil consumption for ignition under low-load stable burning of the existing micro-oil ignition swirling pulverized coal burner. A concentration ring is fixed in a first air channel pipe, a sleeve is fixedly arranged in the concentration ring, the first-class burning chamber and a second-class burning chamber are fixed in the first air channel pipe at the front end of the sleeve, one end of a main oil gun is fixed in the sleeve, a second air channel pipe is fixedly sheathed on the first air channel pipe, an inner swirler is fixed in an inner secondary air channel, a third air channel pipe is fixedly sheathed on the second air channel pipe, an outer swirler is fixed on an outer secondary air channel, the axial distance between the sleeve and the first-class burning chamber is b, a backflow area is generated at the front end of the sleeve, the axial distance between the front border of the backflow area and the mouth of the sleeve is a, and b is more than a. The burning device has the advantages of having no slag formation in the first-class burning chamber during burning and small oil consumption for ignition.

Owner:HARBIN INST OF TECH

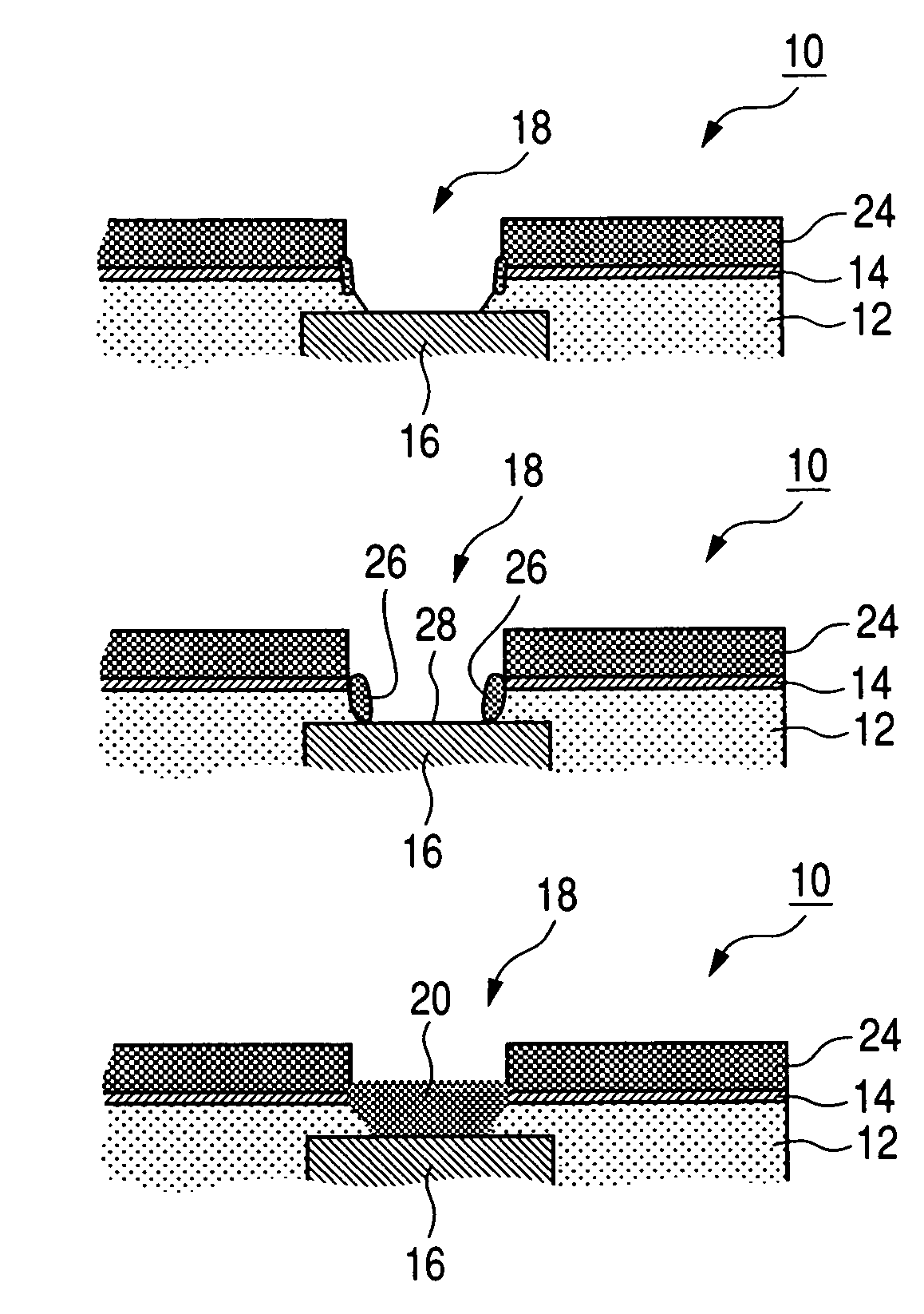

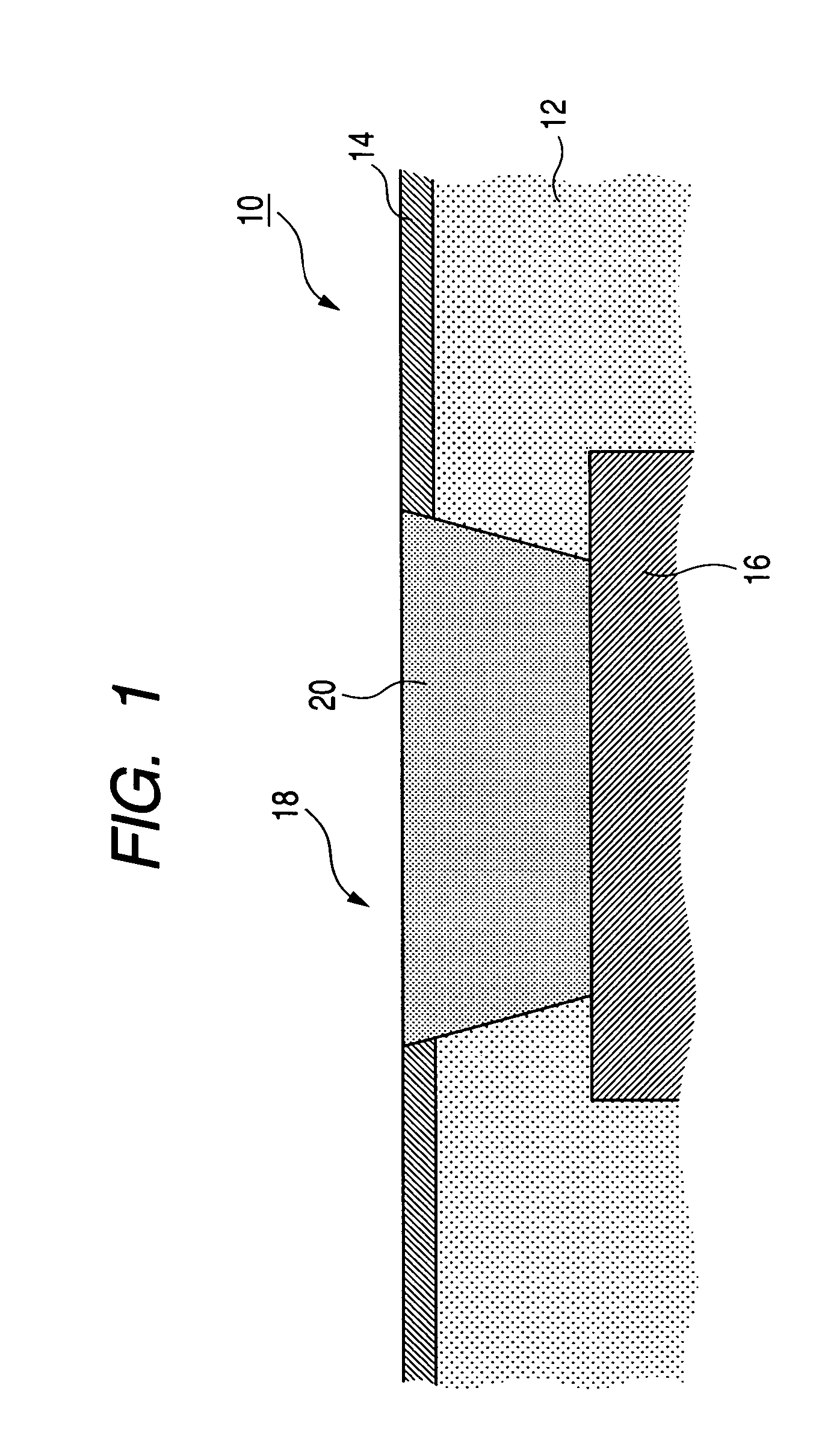

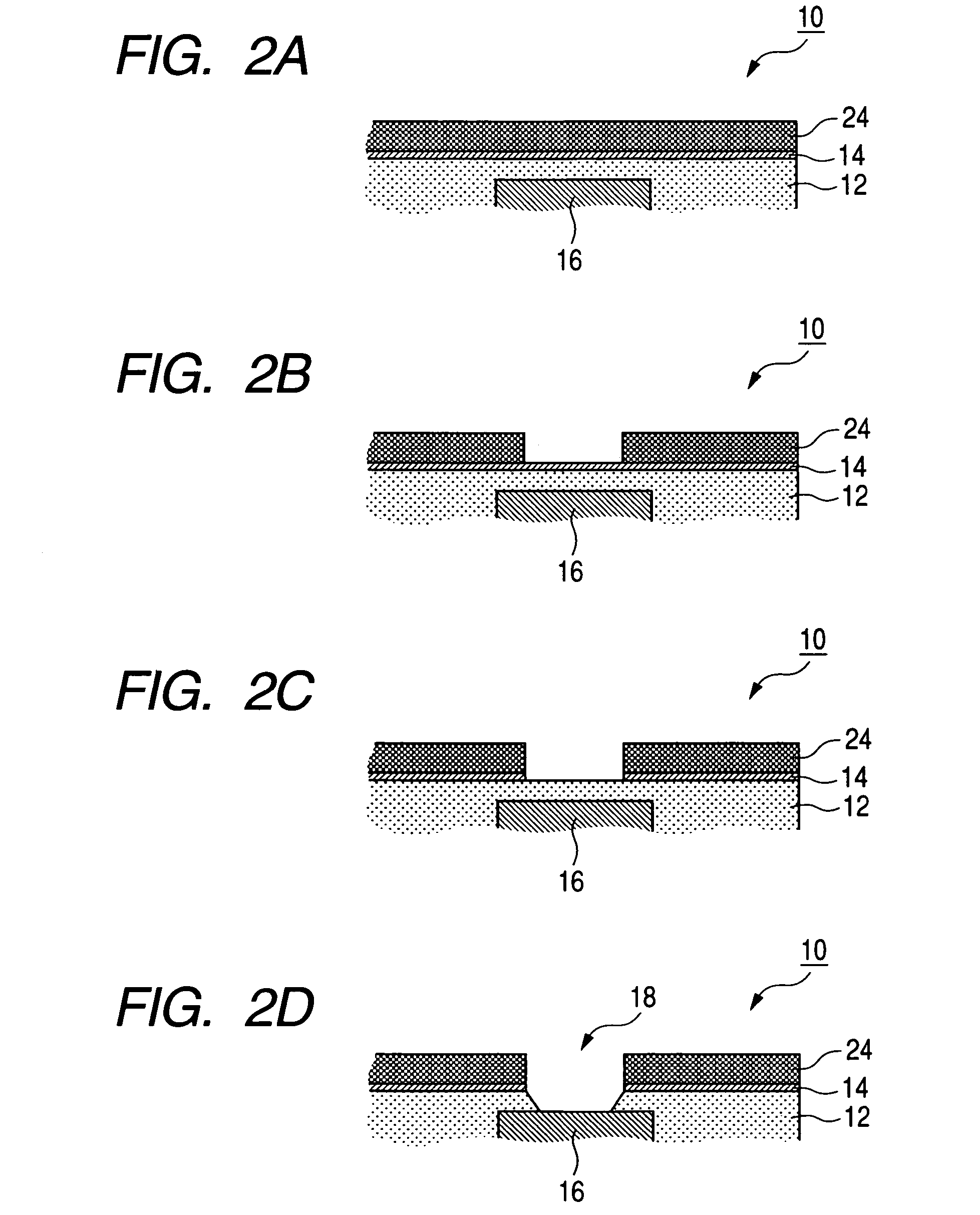

Production method for electronic component and electronic component

ActiveUS7371682B2Simple stepsImprovement in electrical reliancePrinted circuit aspectsSemiconductor/solid-state device manufacturingElectrical conductorEngineering

A method of manufacturing an electronic part in which on the upper surface of an insulating member covering lower layer wiring, a conductor portion connected from the lower layer wiring is exposed. In this method, electric power supplying film is formed on the upper surface of the insulating member, whereafter an opening portion having the lower layer wiring as a bottom is formed from the electric power supplying film side. Then metal plating is grown from the edge portion of the electric power supplying film from the opening portion with the electric power supplying film as an electrode, and the opening portion is filled with the metal plating closely contacting with the lower layer wiring to thereby form a conductor portion.

Owner:TDK CORPARATION

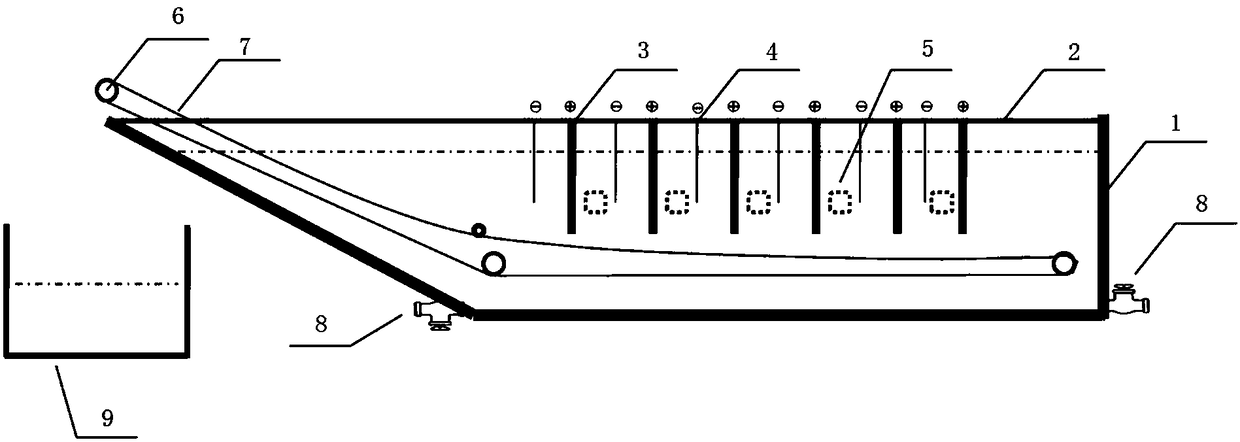

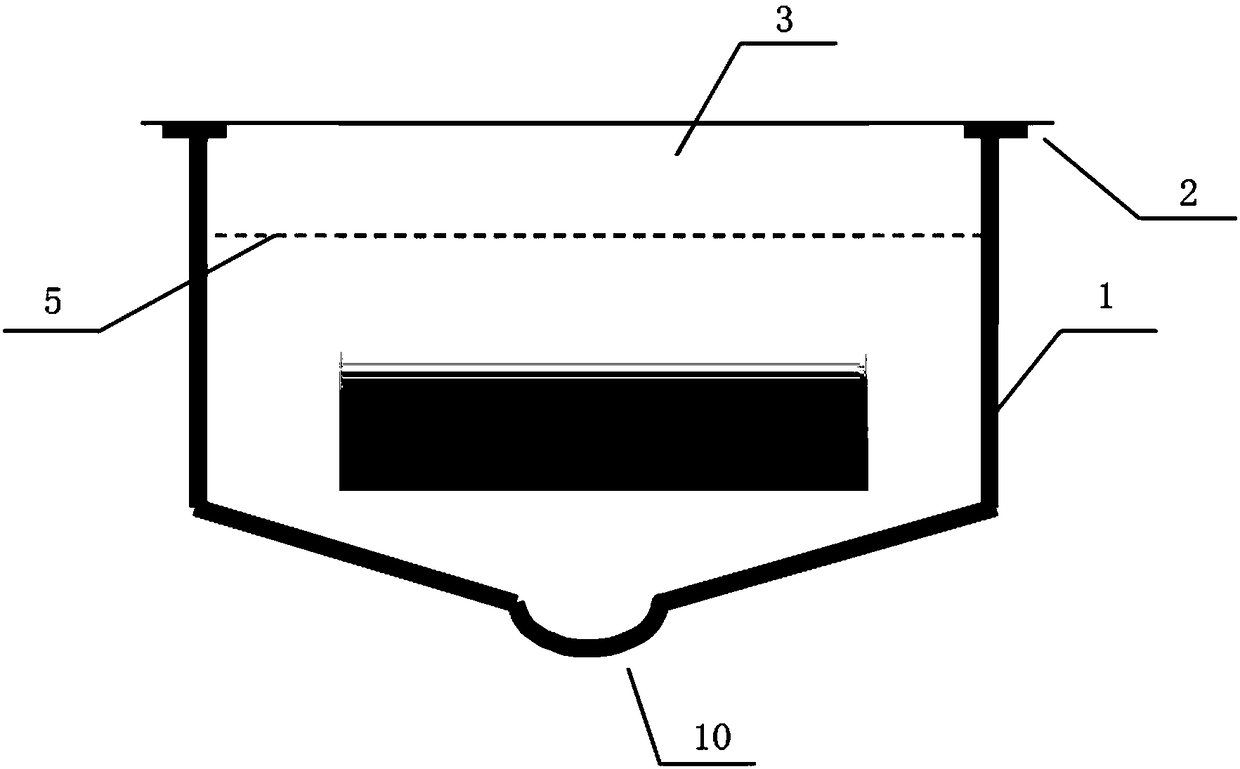

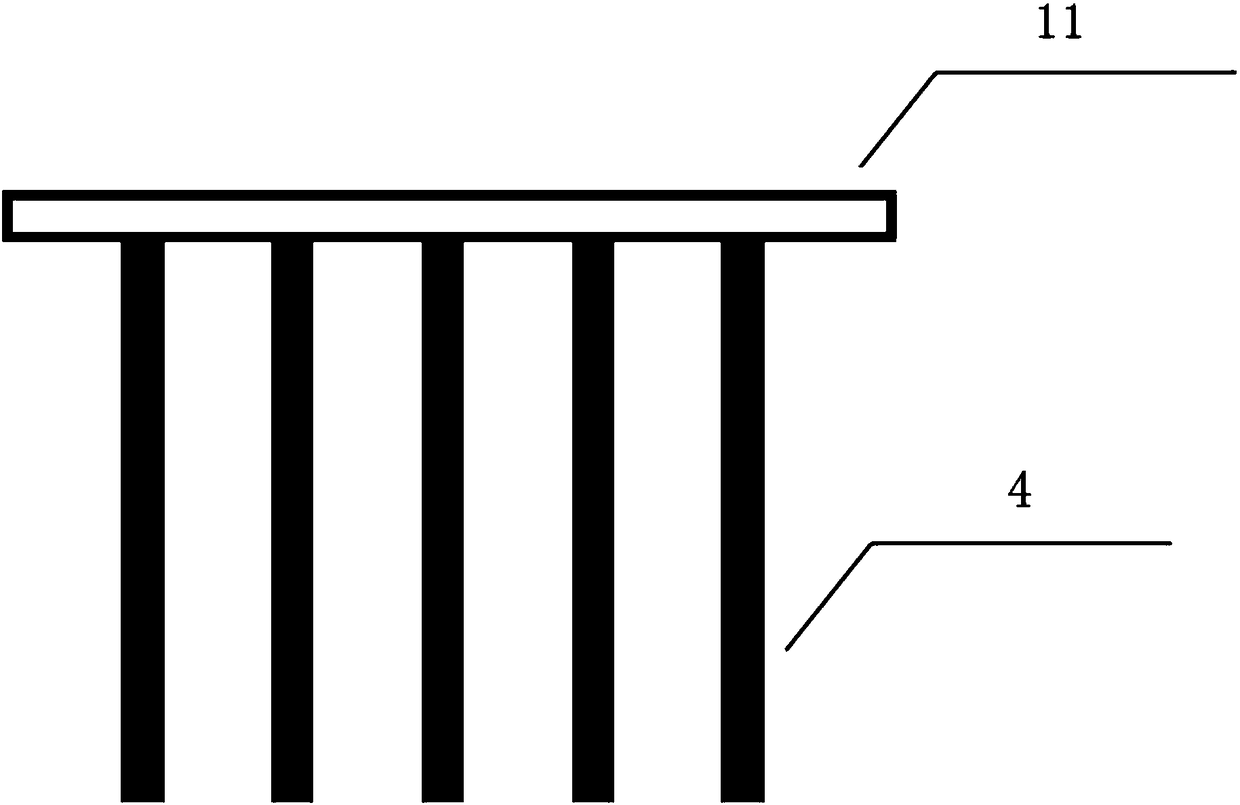

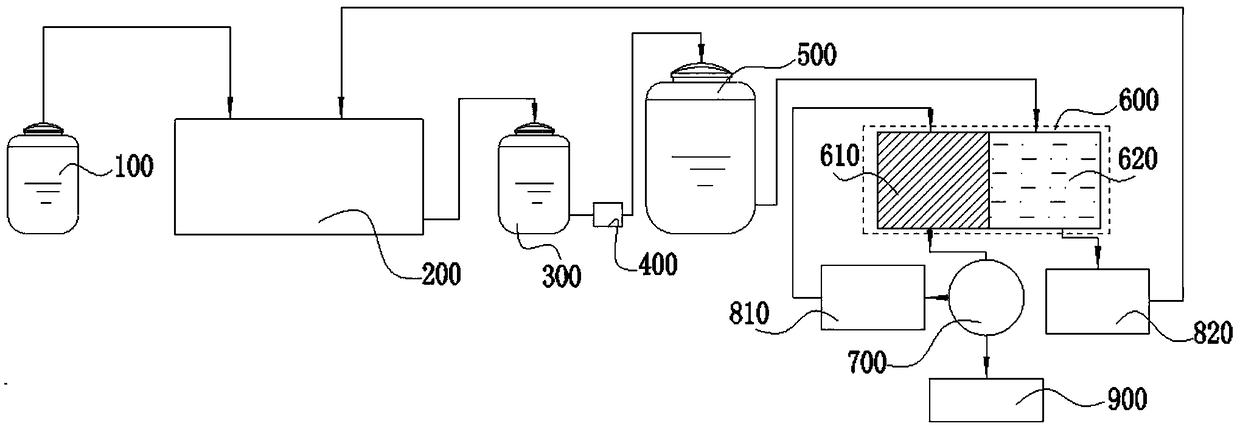

A method and system for recycling acidic etching solution

ActiveCN107012466BPrecise etching effectIncrease precipitation speedPhotography auxillary processesAcid etchingElectrolysis

The invention provides an acid etching liquid regenerative cycle method. The method comprises the steps of collection of acid etching liquid, filtration and mixing of the acid etching liquid, ultrasonic-assisted electrolysis, copper sheet decomposition, anolyte cycle using and the like. According to the acid etching liquid regenerative cycle method, ultrasonic catalyzed electrolysis is adopted, the concentration of the acid etching electrolyte, the electrolytic current density and electrolytic temperature are precisely adjusted and controlled, copper ions in the acid etching liquid can be converted to be copper sheets with the purity reaching up to 99%, the separation-out speed of the copper ions is greatly improved, production efficiency is improved, and meanwhile production energy consumption is lowered. The invention further provides an acid etching liquid regenerative cycle system matched with the acid etching liquid regenerative cycle method. The ultrasonic technology is combined with the ion film technology, the copper ion separation-out speed can be increased, the copper ion separation-out purity can be further improved, and the high-purity copper sheets with the purity being 99.8% or above can be obtained.

Owner:丰顺佳丰电子有限公司

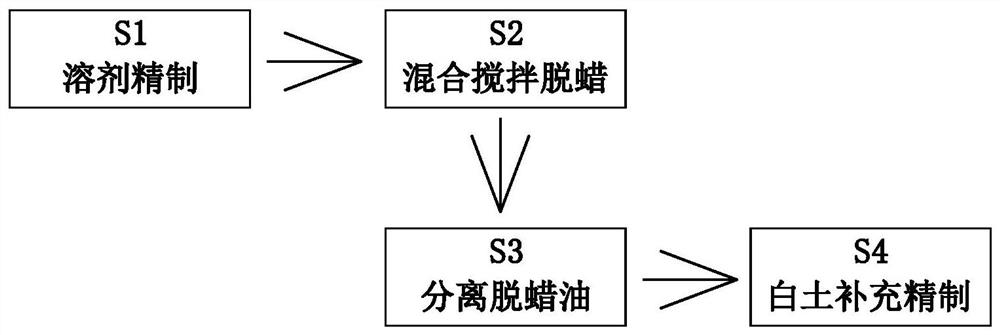

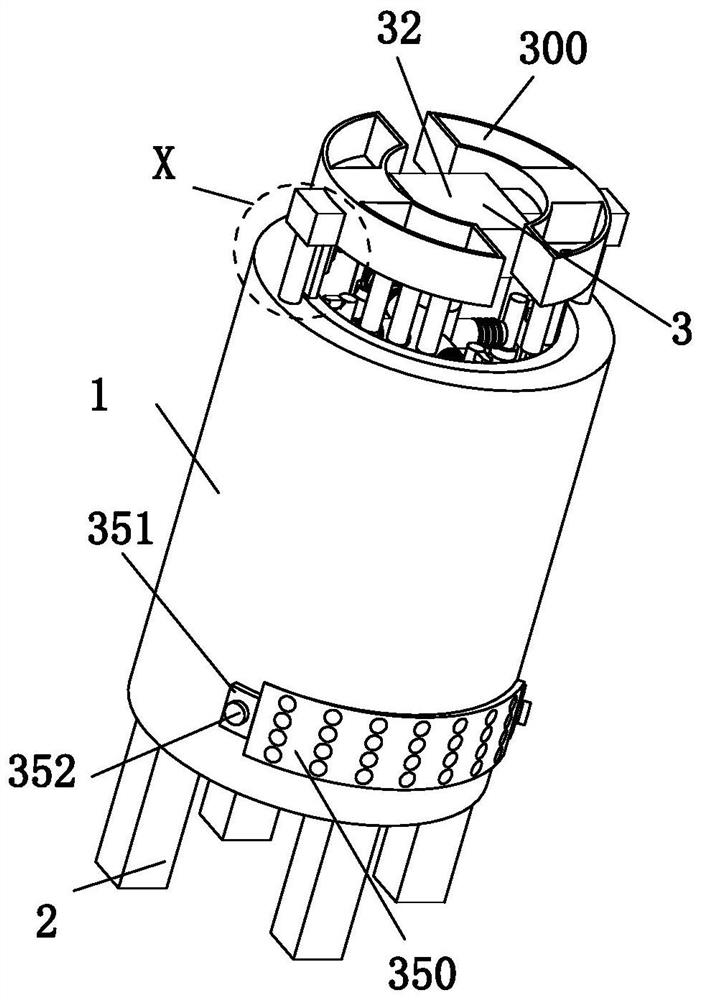

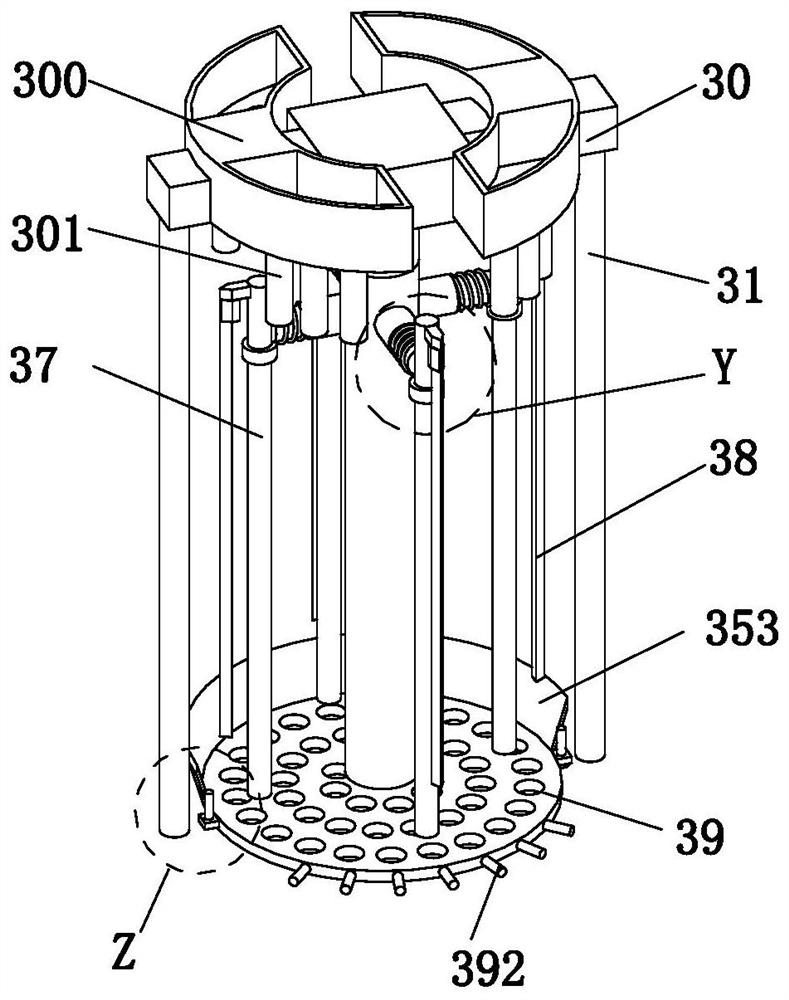

Preparation process of degradable wear-resistant synthetic lubricating grease

InactiveCN112920885AIncrease precipitation speedAccelerated precipitationRotary stirring mixersTransportation and packagingPolymer sciencePolymer chemistry

The invention relates to a preparation process of degradable wear-resistant synthetic lubricating grease. The process uses a degradable wear-resistant synthetic lubricating grease preparation device. The degradable wear-resistant synthetic lubricating grease preparation device comprises a stirring barrel, supporting legs and a mixing mechanism, the supporting legs are installed on the lower end face of the stirring barrel, the supporting legs are evenly distributed in the circumferential direction of the stirring barrel, the lower ends of the supporting legs are connected to the existing ground, and the mixing mechanism is arranged inside the stirring barrel. According to the invention, degradable wear-resistant synthetic lubricating grease is prepared by adopting the design concept of multiple cleaning structures, and the arranged mixing mechanism has the cleaning effect of scraping an adhered wax layer on the basis of the function of mixing an oil product and a benzene solvent, so that the wax content of the subsequent prepared degreasing oil is reduced. Meanwhile, a structure capable of realizing multi-point uniform addition of the benzene solvent is arranged, and the structure can be used for improving the full mixing degree between the benzene solvent and a refined oil product, so that the precipitation speed and the precipitation amount of wax are both improved.

Owner:杨根超

Tilting charging and discharging type reduction furnace and reduction method thereof

The present invention relates to a reduction furnace with tilting loading and discharging and its reduction method. The reduction furnace includes a furnace body, a reduction tank and a furnace body tilting mechanism. high temperature; the reduction tank is installed in the furnace body, both ends of which extend out of the furnace body, one end of the reduction tank is provided with a charging port, and the other end is provided with a slag discharge port; the furnace body tilting mechanism includes : the rotating shaft as the fulcrum of the rotary motion of the furnace body and the lifting mechanism driving the furnace body to rotate around the rotating shaft, the rotating shaft is arranged horizontally, and the reduction tank can at least rotate back and forth between a horizontal position and an inclined position. In the heating reduction process of the present invention, the reduction tank of the tilting charging and discharging type reduction furnace is in a horizontal position, and in the process of charging and slag removal, the reduction tank is in an inclined position, since the slag removal can be carried out automatically by utilizing the gravity of the earth, The production speed is improved, the amount of manual labor is reduced, and it is beneficial to realize the mechanization of production.

Owner:辛卫亚

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com