Preparation process of degradable wear-resistant synthetic lubricating grease

A preparation process and technology of lubricating grease, applied in the directions of lubricating composition, dissolving, mixer, etc., can solve the problems of easy clogging of filtration structure, low degree of uniformity, single filtration treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

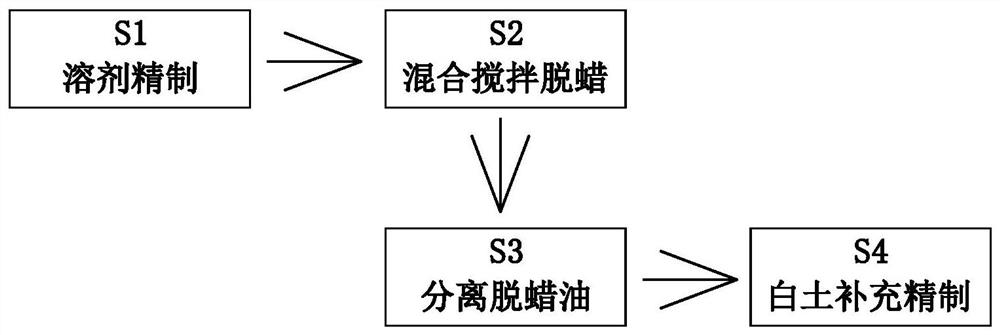

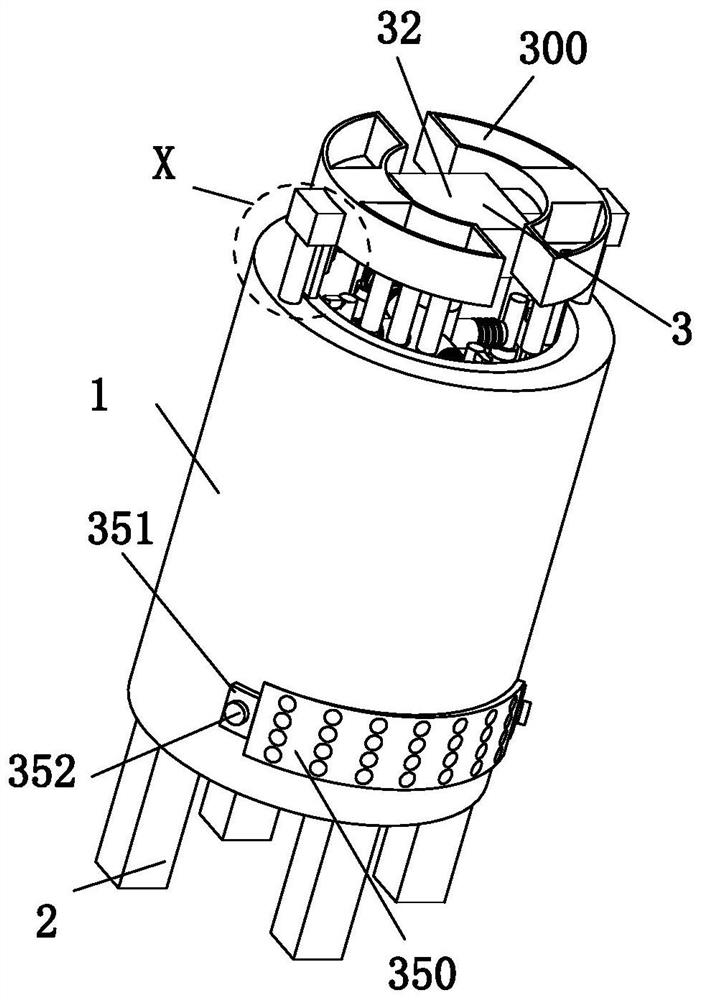

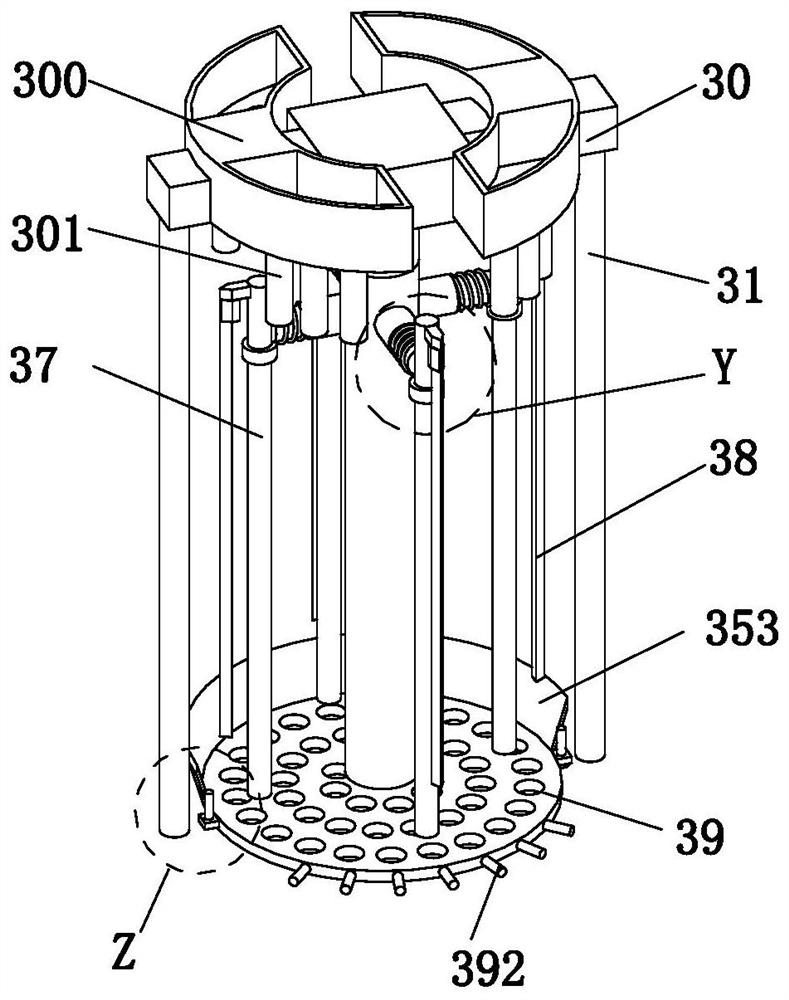

[0037] Such as Figure 1 to Figure 11 A degradable wear-resistant synthetic grease preparation process shown, which uses a degradable wear-resistant synthetic grease preparation device, the degradable wear-resistant synthetic grease preparation device includes a mixing tank 1, legs 2 and a mixing mechanism 3 , the specific preparation process for the preparation of degradable wear-resistant synthetic grease using a degradable wear-resistant synthetic grease preparation device is as follows:

[0038] S1. Solvent refining: use furfural solvent to remove colloid, asphalt, etc. in the oil, so that the oil can be refined;

[0039] S2. Mixing and stirring dewaxing: Pour the refined oil into the mixing tank 1, add benzene solvent at the same time, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com