Micro-oil ignition rotational flow breeze combustion device for preventing slag bonding of primary combustion chamber

A technology of micro-oil ignition and pulverized coal combustion, which is applied to burners, burners, combustion methods and other directions of burning powder fuels, can solve problems such as the amount of ignition oil that is prone to slagging, and is conducive to ignition, full combustion, and combustion. Good effect of stable combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

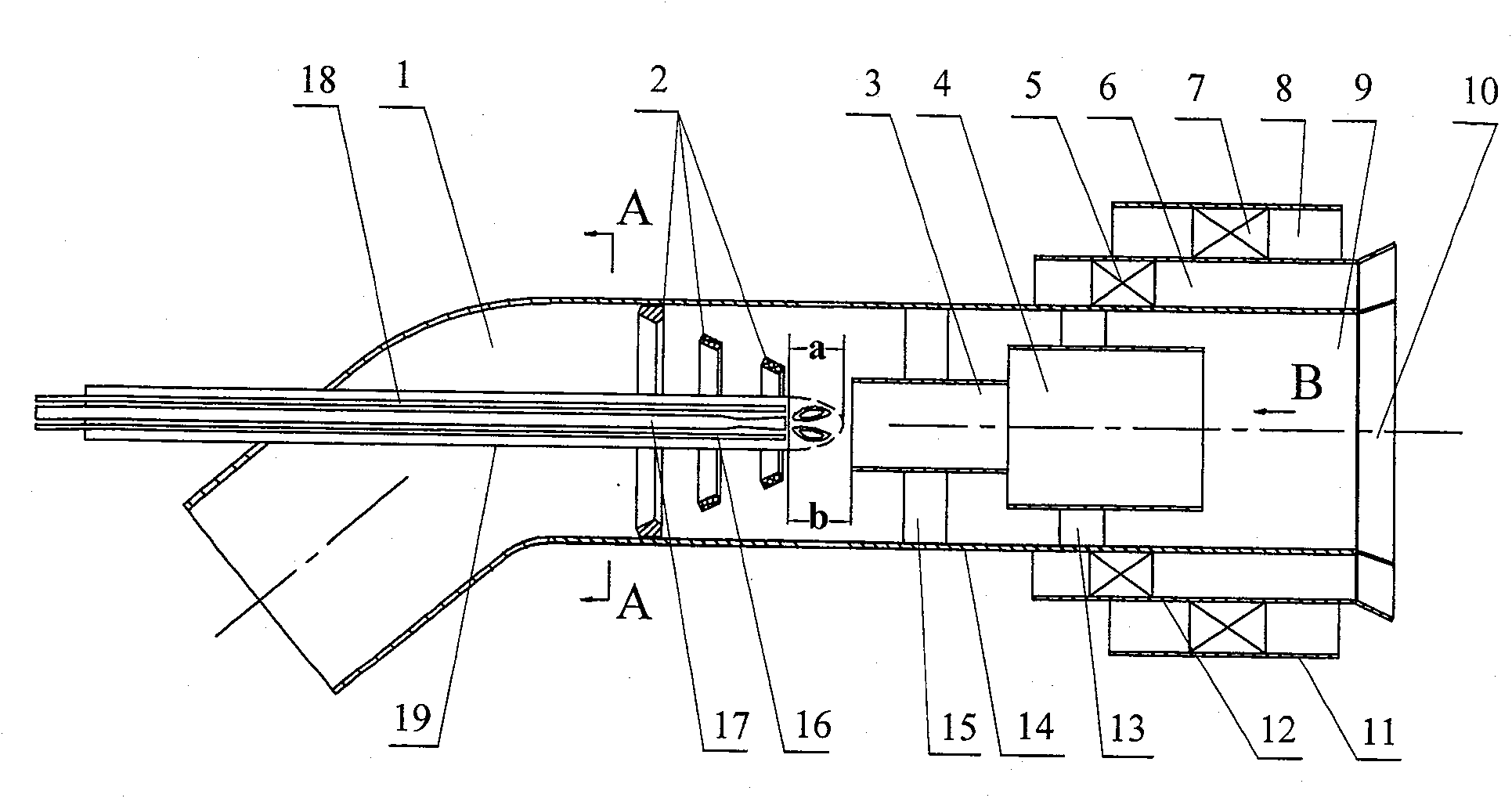

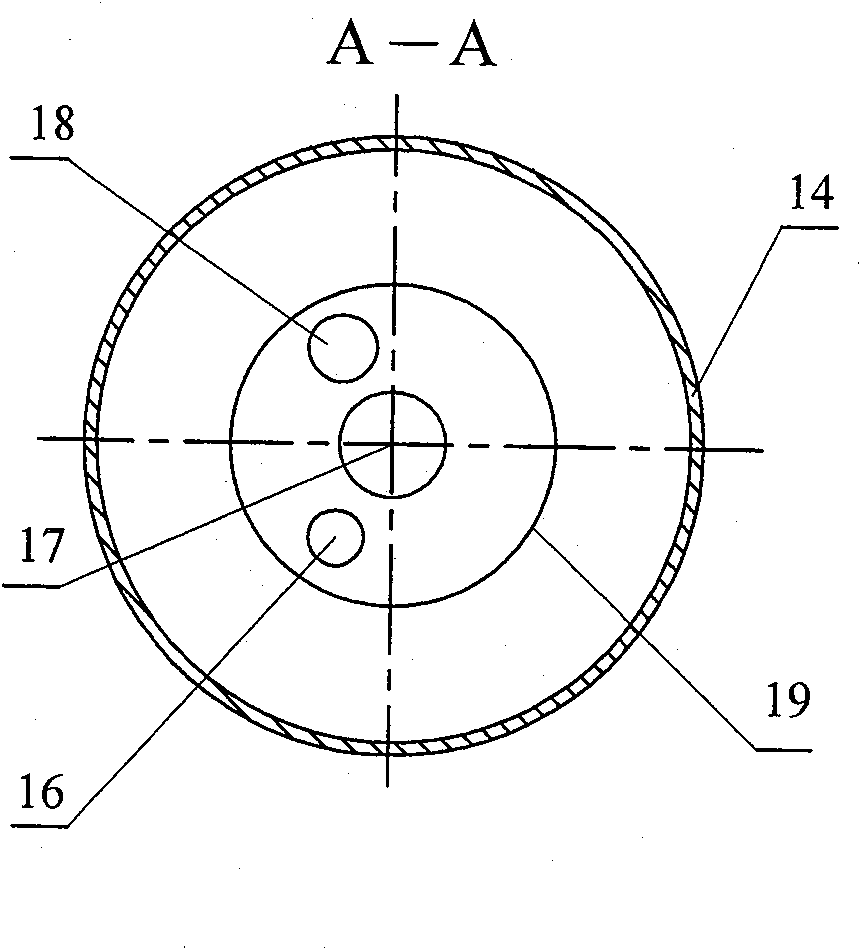

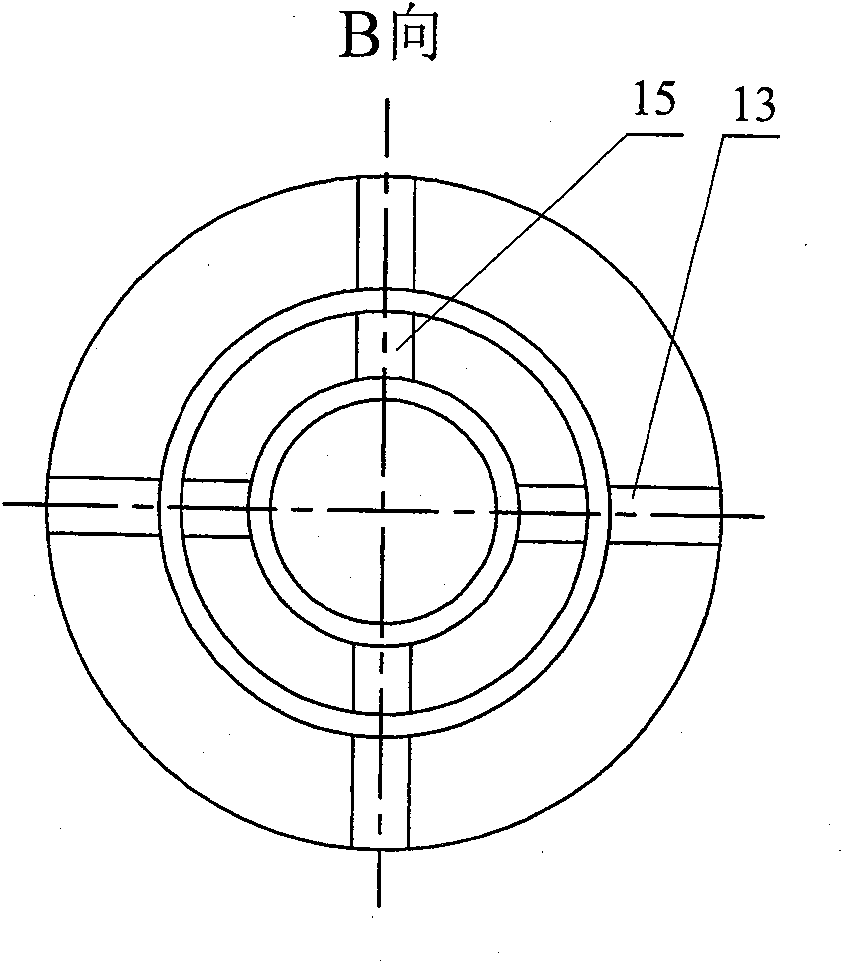

[0008] Specific implementation mode one: combine Figure 1~3 Describe this embodiment. This embodiment includes a primary air duct 1, a concentration ring 2, a primary combustion chamber 3, a secondary combustion chamber 4, an inner swirler 5, an inner secondary air duct 6, and an outer secondary air duct 8. The burner 10, the third air duct pipe 11, the second air duct pipe 12, the first air duct pipe 14 and the main oil gun 17; the combustion device also includes an outer swirler 7, a three-stage combustion chamber 9, The second support plate 13, the first support plate 15 and the casing 19; the primary air duct 1 is inside the first air duct pipe 14, and the outlet end of the first air duct pipe 14 is fixed with a burner 10, and the concentration ring 2 It is fixed in the first air duct pipe 14, and the diameter of the concentration ring 2 gradually decreases along the direction of the concentration ring 2 toward the burner 10. The front end of the sleeve 19 is an open end,...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1 Describe this embodiment, the difference between this embodiment and specific embodiment one is: the combustion device of this embodiment also includes an auxiliary oil gun 18; one end of the auxiliary oil gun 18 passes through the rear end of the casing 19 and is fixed on the The pipe 19 is arranged parallel to the main oil gun 17 , and the outlet end of the auxiliary oil gun 18 corresponds to the inlet end of the primary combustion chamber 3 . When the flame was unstable, the auxiliary oil gun 18 could be enabled in time to help the pulverized coal to burn.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 1 Describe this embodiment, the difference between this embodiment and the second embodiment is: the combustion device of this embodiment also includes a flame detection tube 16; one end of the flame detection tube 16 passes through the rear end of the sleeve 19 and is fixed on the sleeve In the pipe 19 , the outlet end of the flame detection pipe 16 corresponds to the inlet end of the primary combustion chamber 3 . So set, can detect at any time after main oil gun 17 is ignited, surrounding flame stability, when flame is unstable, can enable auxiliary oil gun 18 in time, helps pulverized coal to burn.

[0011] The working principle is: after the pulverized coal and air sent from the primary air pulverized pipeline flow into the concentration ring 2 in the primary air duct 1, a relatively high concentration of pulverized coal is formed in the central area of the primary air duct 1. In chamber 3, the pulverized co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com