Tilting charging and discharging type reduction furnace and reduction method thereof

A technology for charging and discharging materials and reducing furnaces is applied in the field of metal vacuum smelting and reducing furnaces, which can solve problems such as low efficiency and environmental pollution, and achieve the effects of protecting the environment, reducing dust pollution and shortening the production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

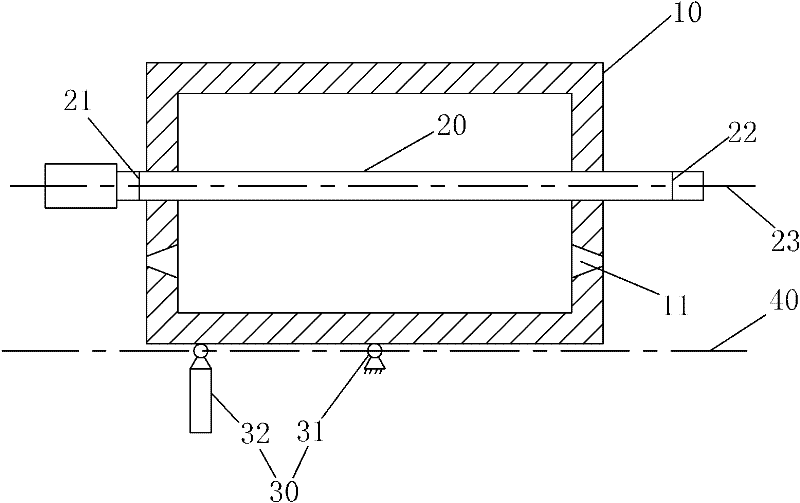

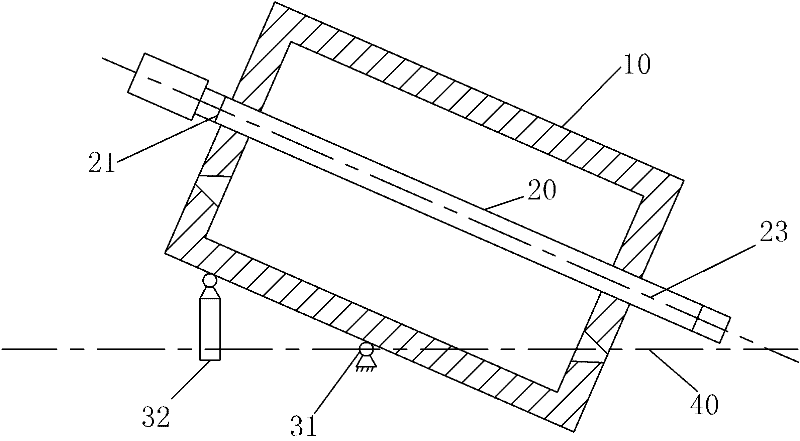

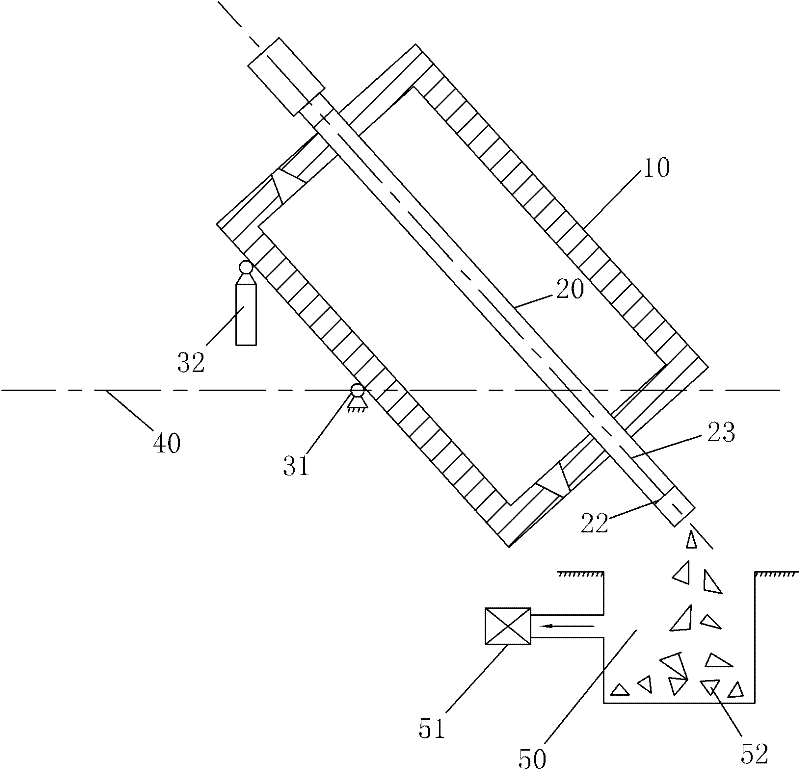

[0044] like figure 1 , figure 2 , image 3 As shown, it is a tilting charging and discharging type reduction furnace, which includes a furnace body 10, a reduction tank 20 and a furnace body tilting mechanism 30, wherein:

[0045] The furnace body 10 is provided with a combustion system 11 to provide the high temperature required in the reduction process;

[0046] The reduction tank 20 is installed and fixed in the furnace body 10, both ends of which protrude out of the furnace body 10, one end of the reduction tank 20 is provided with a charging port 21, and the other end is provided with a slag discharge port 22;

[0047] The furnace body tilting mechanism 30 includes: a rotating shaft 31 as a fulcrum of the rotating motion of the furnace body 10 and a lifting mechanism 32 (such as a hydraulic cylinder or an electric screw mandrel) that drives the furnace body 10 to rotate around the rotating shaft 31 . The rotating shaft 31 is arranged horizontally, so that the reductio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com