Patents

Literature

79 results about "Pidgeon process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

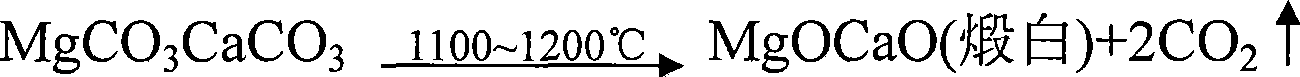

The Pidgeon process is one of the methods of magnesium metal production, via a silicothermic reduction. Practical production requires roughly 35–40 MWh/ton of metal produced, which is on par with the molten salt electrolytic methods of production, though above the 7 MWh/ton theoretical minimum.

Process for smelting magnesium by microwave heating Pidgeon process

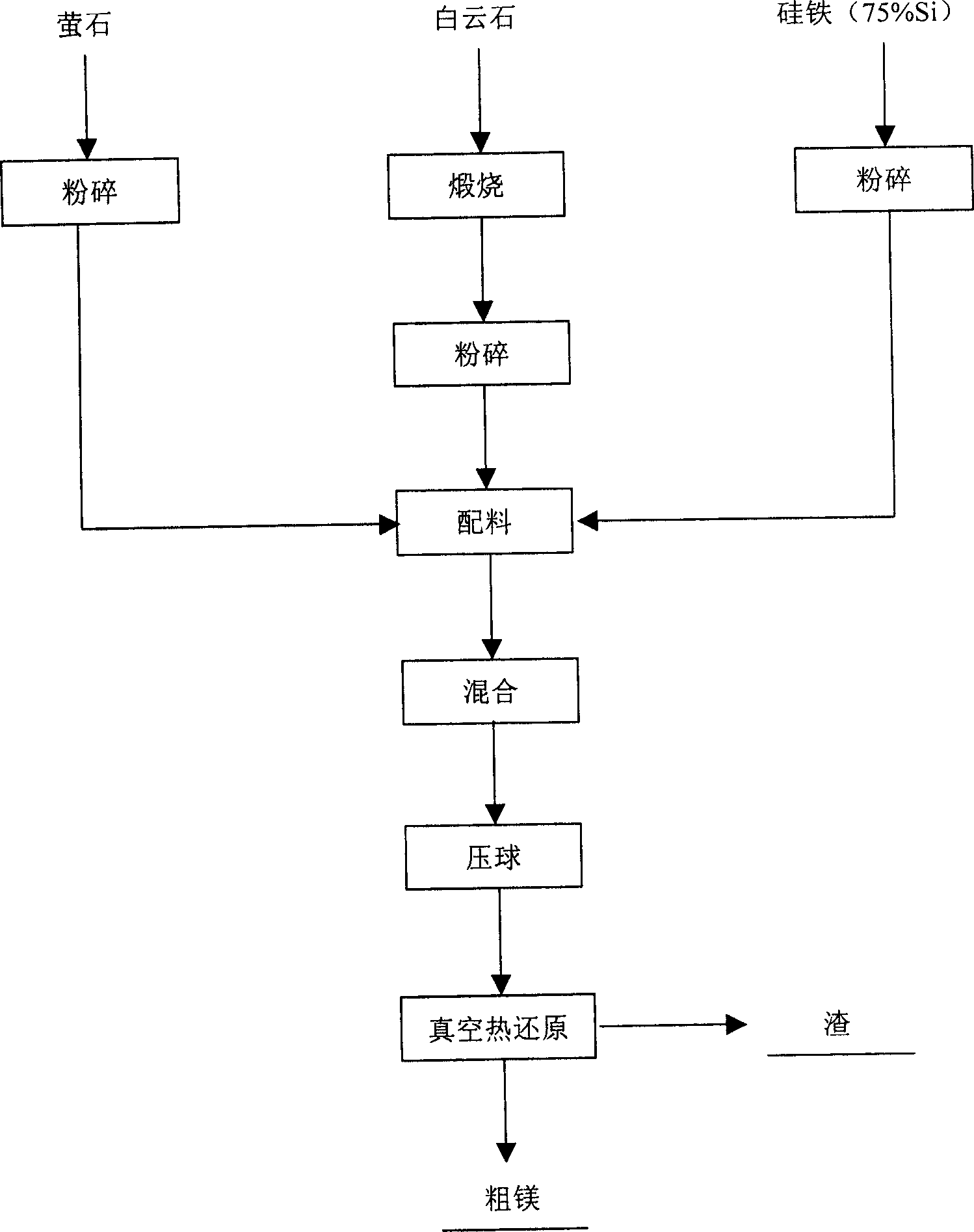

The invention discloses a magnesium reduction process through a micro-wave heating silicothermic method; the process comprises the following steps: 1. dolomite calcinations: the dolomite is heated to 1100 DEG C to 1200 DEG C and becomes calcined dolomite; 2. the calcined dolomite, silicon nitride powder and fluorite powder are weighed, mixed, milled and then pressed into a ball which meets technological requirements; 3. the ball is put into a closed non-metal reduction tank of a micro-wave heating oven to be heated under 1000 DEG C to 1200 DEG C, so that the magnesium compound in the ball reacts with the silicon nitride powder; 4. the vacuum degree of the closed non-metal reduction tank is kept to be 13.3Pa or higher for 4h to 6h; magnesium vapor is condensed in a condenser and becomes crude magnesium; 5. the crude magnesium is heated, melted and refined by solvent, to obtain refined magnesium; 6. acid washing and the like. The method evenly and quickly heats in the principle of micro-wave heating with high heating efficiency, is easy to be controlled, saves production cost, is safe, environment protective and harmless.

Owner:重庆科健冶金材料有限公司

Magnesium slag baking-free brick and preparation method thereof

The invention provides an environment friendly preparation method for a magnesium slag baking-free brick, aiming to solve the problems that the existing baking-free brick is long in maintenance time, severe in maintenance condition, slow in watering speed of C2S of raw material in aging reaction process, slow in strength increasing, and large in difference of structure and performance of formed hydration products. The raw material of the magnesium slag baking-free brick comprises the following components in percentage: 30-50 percent of reduced magnesium slag, 12-30 percent of fly ash, 24-28 percent of river sand, 4 percent of plaster and 6-10 percent of clinker; the preparation method comprises the following steps of adding water with 6-10 percent of the total gross of the raw material, mixing and press forming the mixture, naturally curing and naturally drying the mixture, and then obtaining the magnesium slag baking-free brick. The magnesium slag baking-free brick provided by the invention uses a large amount of reduced magnesium slag, produced in the magnesium smelting process by adopting a pidgeon process, as main raw material, thus, the pollution of the industrial waste slag to the environment is reduced, and new material is added for the building engineering. The method provided by the invention has the characteristics of simple manufacturing method, easiness in obtaining raw material, short production period and high finished-product brick strength.

Owner:SHANXI UNIV

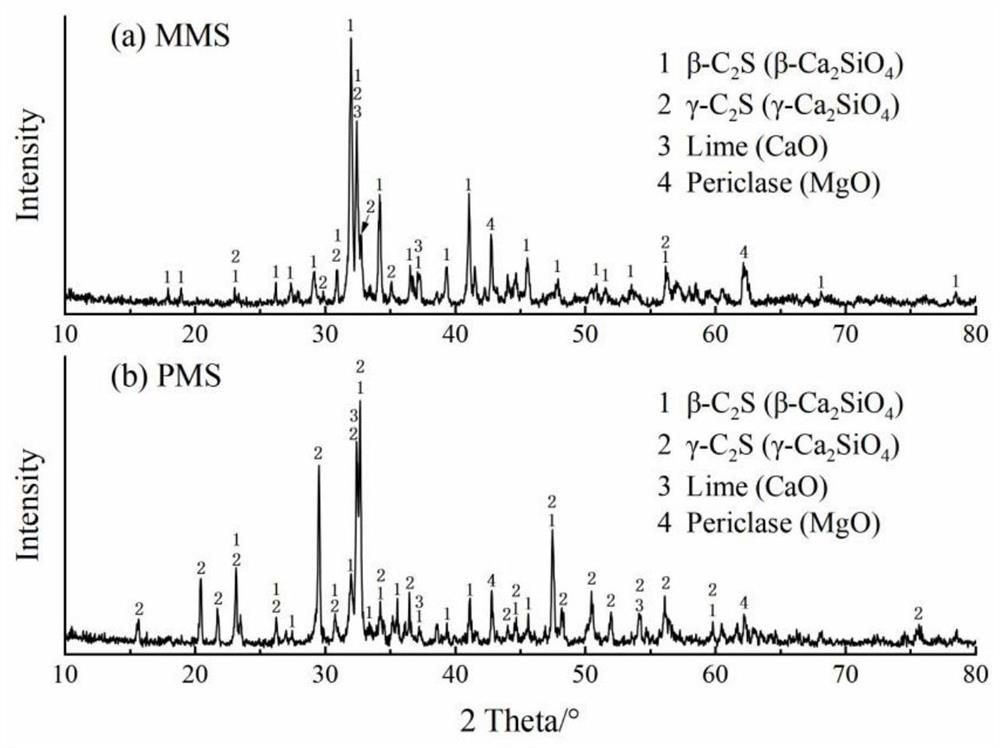

Waste residue modification method for preparing magnesium metal by pidgeon process

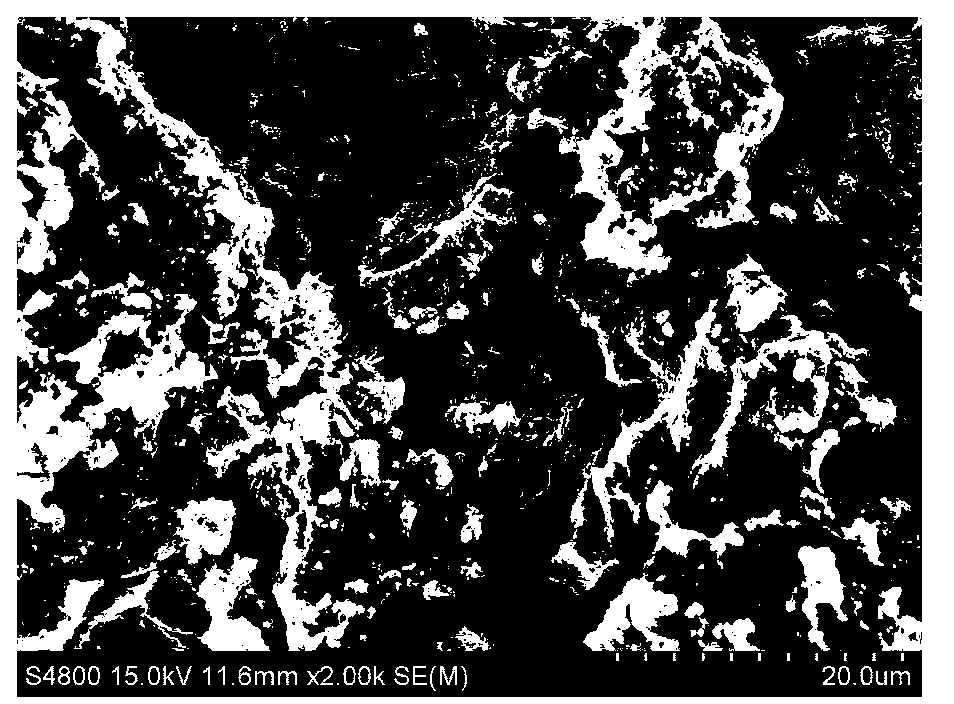

InactiveCN101457306AIncrease profitSimple processProcess efficiency improvementCement compositesGranularity

The invention provides a method for preparing modified magnesium metal waste residue by a Pidgeon process. The method comprises the following steps: adding an additive containing an aluminum raw material during mixing and milling a magnesium metal raw material for production to obtain an evenly mixed magnesium metal reduction material; allowing the added additive to react with the magnesium residue during the process of reducing the magnesium metal under a high-temperature vacuum condition to form gel mineral; collecting the magnesium metal and then quickly cooling the obtained modified magnesium residue; performing ball milling on the modified magnesium residue obtained by quick cooling to obtain modified magnesium residue mineral powder with the granularity of 45mum and the screen residue less than 12wt%; and taking the obtained powder as a high-activity magnesium residue concrete admixture or a cement composite material. The method has the advantages of simple process, wide variation range of additive amount, less effect on magnesium metal smelting production and low cost; furthermore, the magnesium residue modification process is adopted in the method, which causes the magnesium residue to be widely applied to the cement or the concrete, and causes high utilization rate of the magnesium residue, wide application, energy saving and environmental protection.

Owner:CHANGAN UNIV

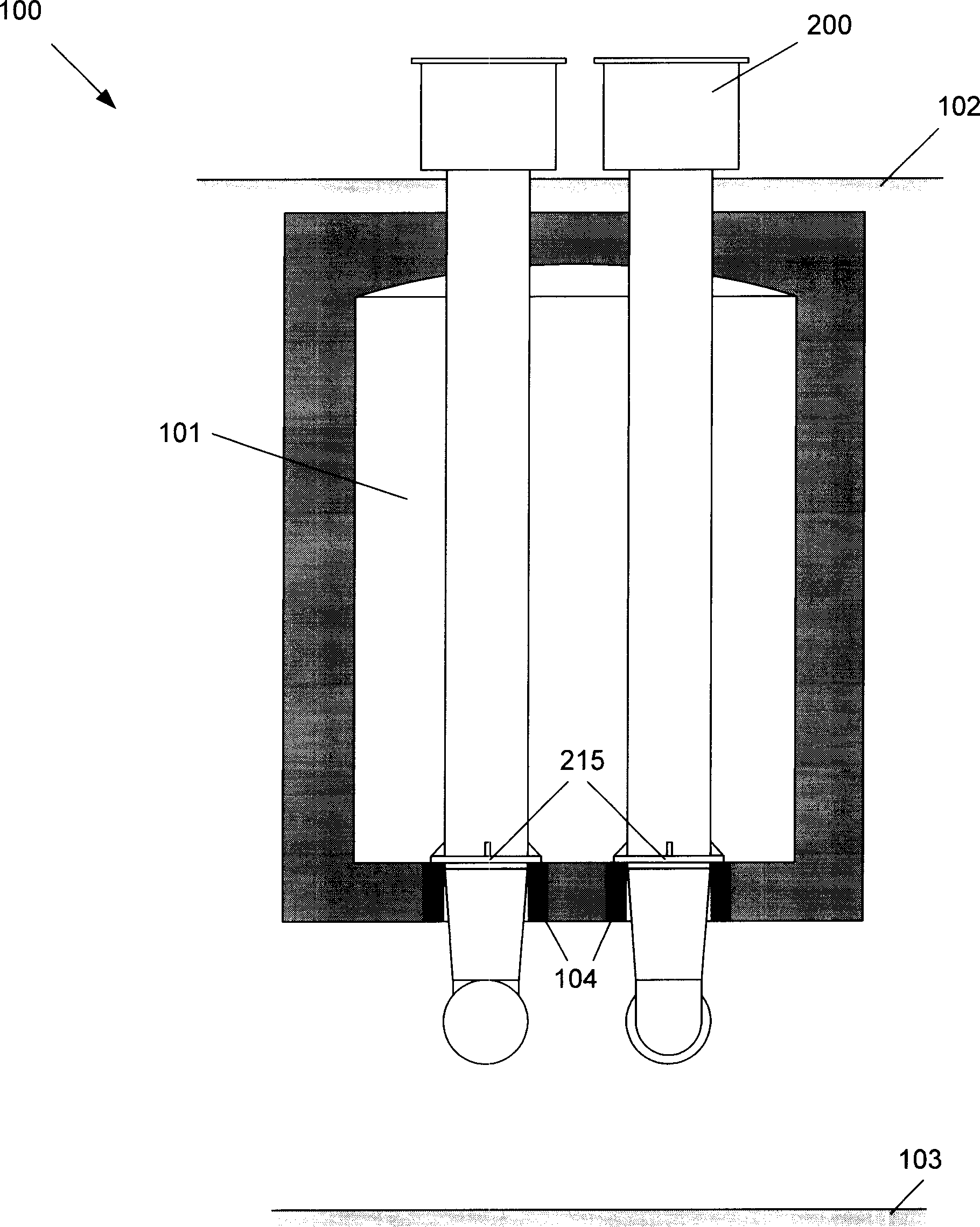

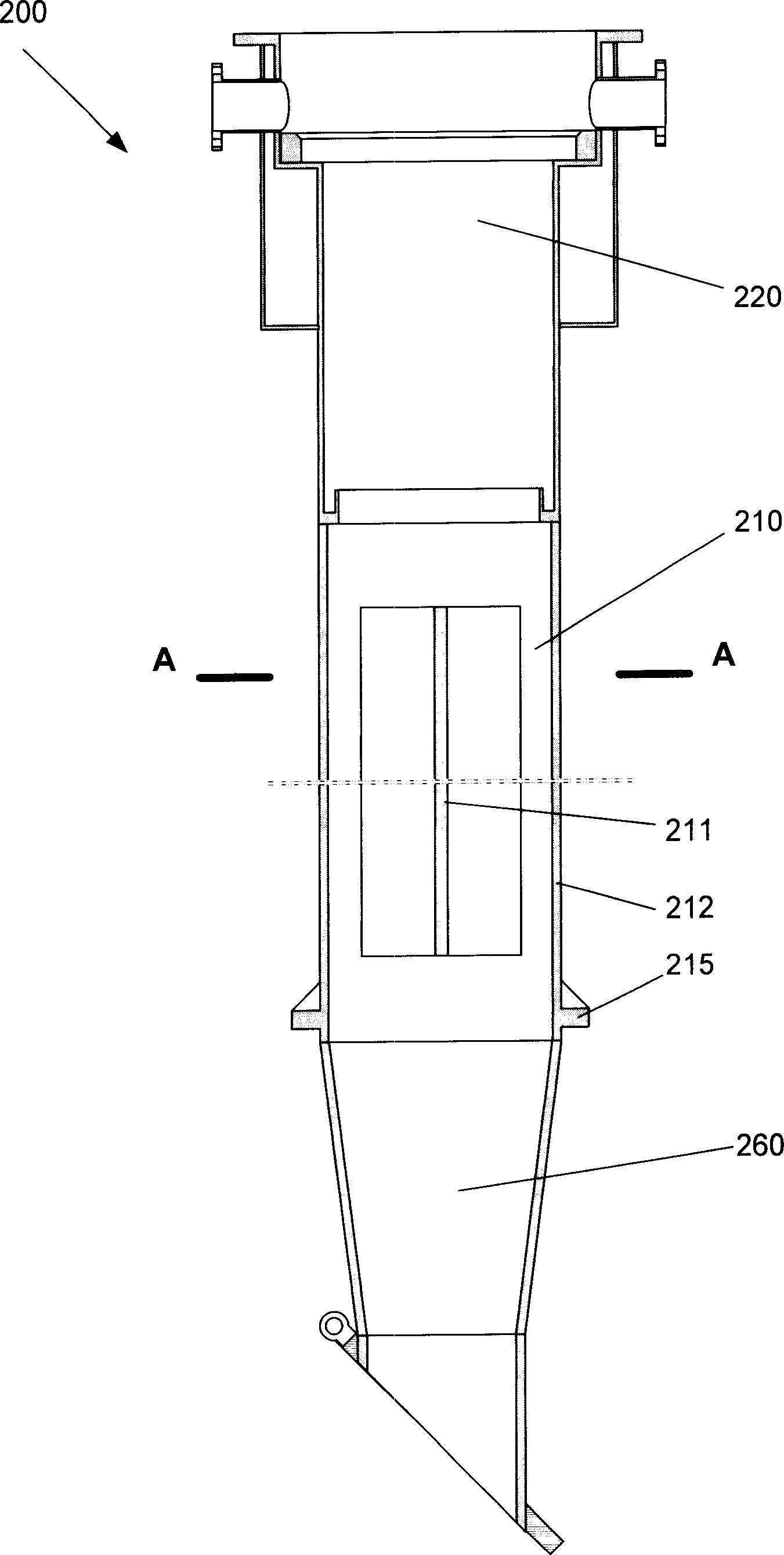

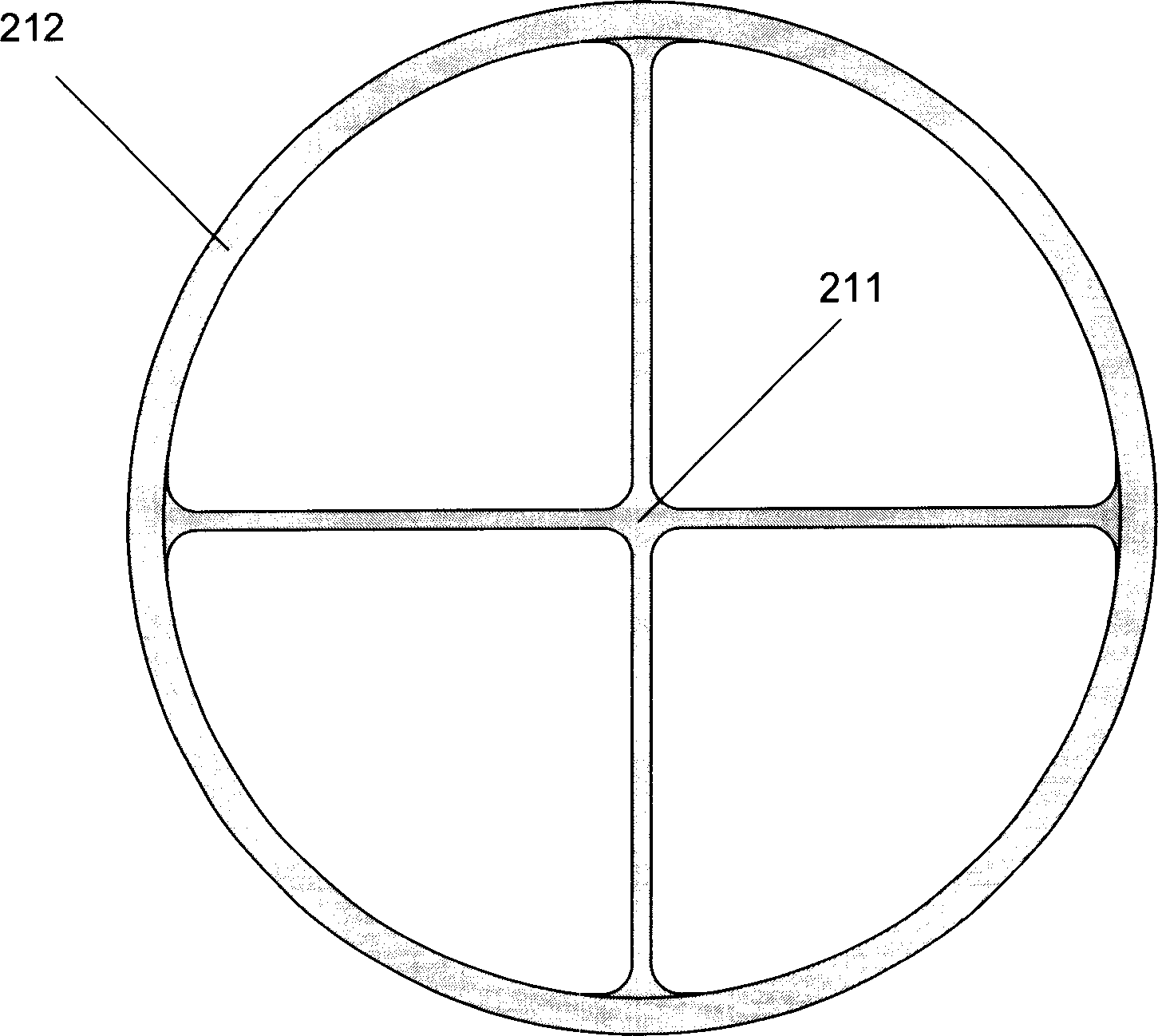

Pijiang metal refining method and device

InactiveCN1704489AImprove creep resistanceExtended service lifeReduction procedureHeat transfer efficiency

The invention discloses a method for reinforcing the heat transfer efficiency and creep-resistance for pidgeon process reduction tanks, a method for realizing pidgeon process reduction tank automatic charging and discharging, a method for continuous monitoring the pidgeon metal reduction procedure, a method for reclaiming reaction by-product base metals, a vertical reduction tank employing the methods and a pidgeon process reduction furnace constructed by employing the vertical reduction tank.

Owner:刘伟杰

Method for preparing metal magnesium by silicothermic process

InactiveCN101698907AAvoiding the Difficulties of Preparing Anhydrous Magnesium ChlorideLow equipment requirementsPotassiumPidgeon process

The invention provides a new method for preparing metal magnesium by a silicothermic process and by using bischofite from the seawater salt making or salt lake brine salt and potassium chloride making as a raw material. The method comprises the steps of: reacting lime and solution of magnesium chloride to generate a calcium-magnesium mixed hydroxide; calcining the calcium-magnesium mixed hydroxide to obtain a calcium-magnesium mixed oxide; finely grinding the mixture of calcium-magnesium mixed oxide, silicon iron and fluorite in a ball mill, pressing the ground mixture into a walnut shape or a sheet shape on a forming press, and reducing the walnut-shape or sheet-shape mixture under vacuum in a magnesium smelting reduction pot to obtain the magnesium crystalline; and finally refining the magnesium crystalline, casting the refined magnesium crystalline into ingot, and performing surface treatment to obtain a magnesium metal ingot. The method overcomes the defect that a great amount of carbon dioxide greenhouse gas is exhausted in the Pidgeon process for calcining dolomite, avoids the problem of preparing anhydrous magnesium chloride by an electrolytic process, overcomes the defect that the direct calcining of bischofite gives corrosive and toxichydrogen chloride gas, has low requirements on equipment and is clean, environmentally-friendly and safe in production. The method can also be applied to the field of alkaline waste liquor treatment and comprehensive utilization.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

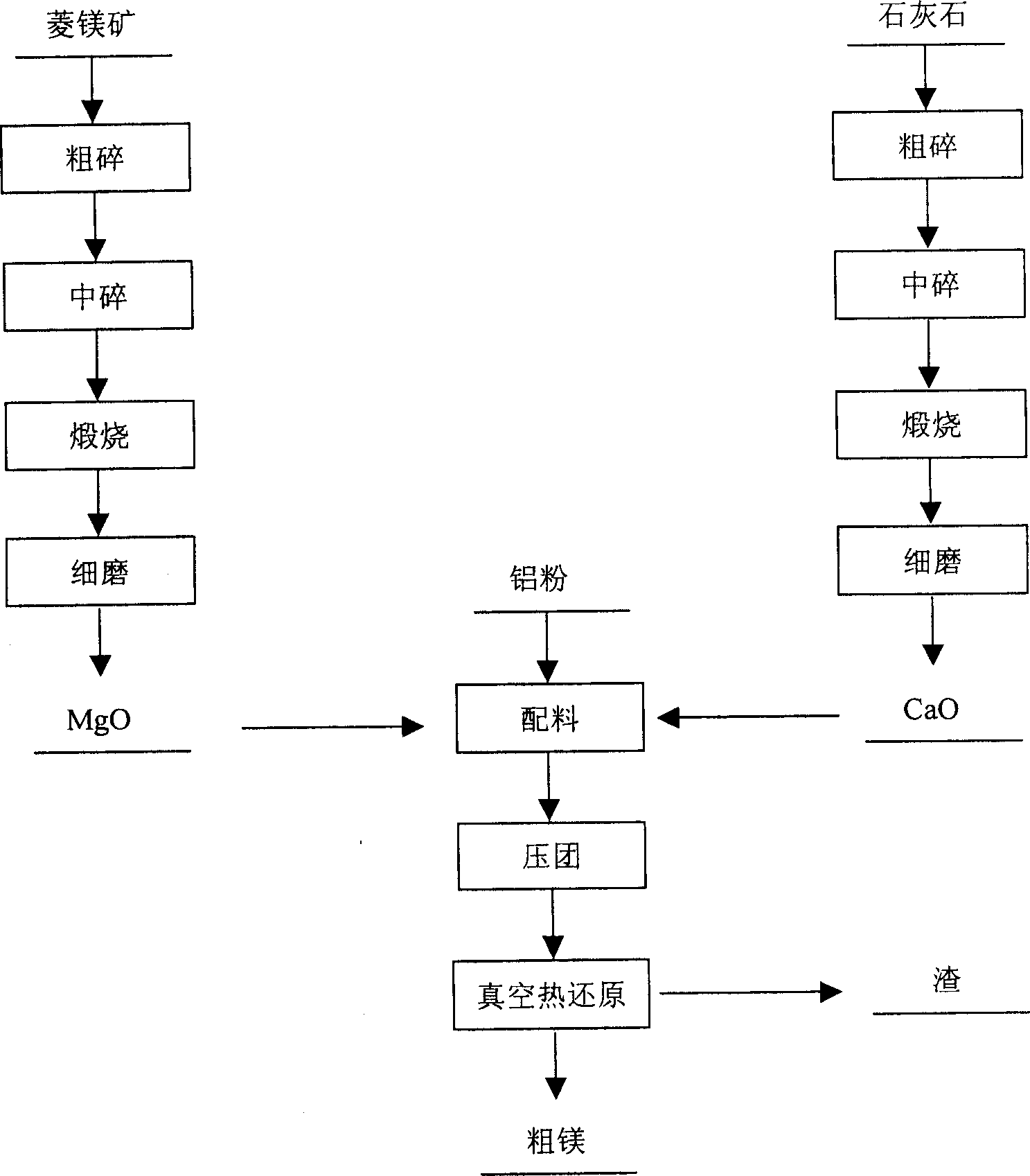

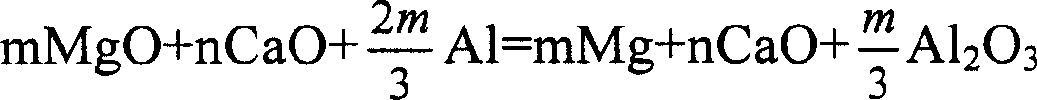

Aluminothermic reduction method and technology of giobertite calcination to produce magnesium

Disclosed is an aluminothermic reduction method and technology of giobertite calcination to produce magnesium which comprises using magnesite powder as raw material, aluminum powder as reducing agent, the invention is characterized in that, (1) charging 5-15 wt% calcined limestone powder (CaO) as adjuvant, (2) calcining magnesite powder at 700-1000 deg C for 1 hour to prepare active MgO, (3) mixing magnesite powder, limestone powder and aluminum powder by the weight ratio of 35-80:5-15:15-54, making into blocks under 40-450MPa, (4) loading the block into retort, evacuating and heating in reducing furnace, reducing 4-8 hours at 1050-1170 deg. C to obtain crude magnesium. The invention also discloses the optimum parameter for the process.

Owner:路忠胜

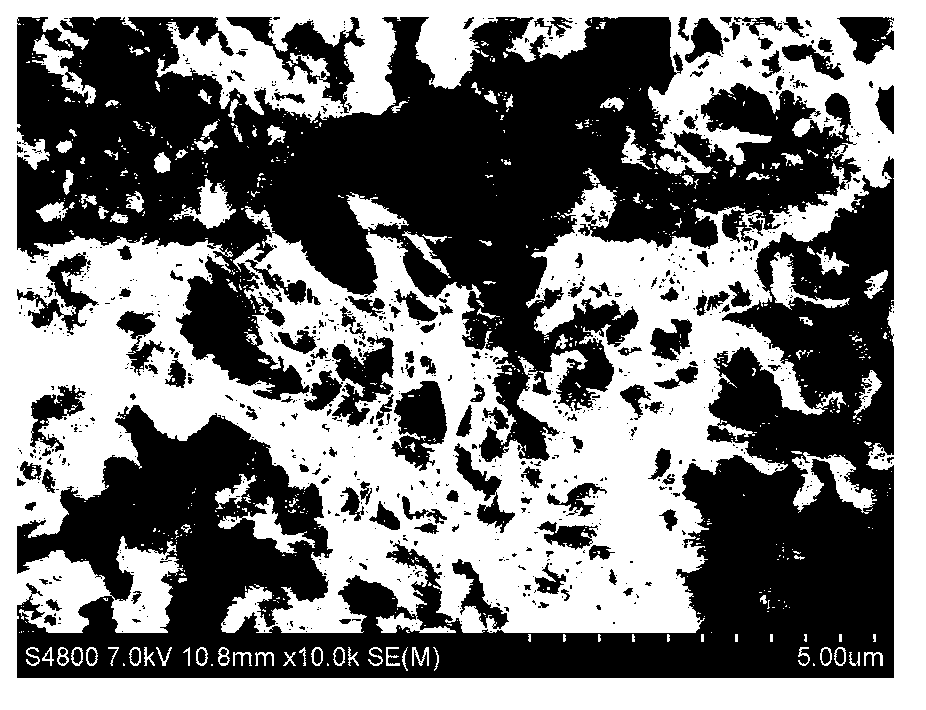

Magnesium slag modifier and magnesium slag modification method

The invention discloses a magnesium slag modifier and a magnesium slag modification method. The method comprises the following steps of: uniformly mixing magnesium slag and boric acid according to a weight ratio of 1:(200-340) to prepare a sample; and calcining at the temperature of between 1,150 and 1,300 DEG C for 3 to 6 hours. Beta-dicalcium silicate is prevented from being converted into gamma-dicalcium silicate in Pidgion process magnesium-smelting magnesium slag through a chemical method, and the magnesium slag can be prevented from being pulverized by adding a small amount of boric acid and calcining at high temperature; moreover, the cycle range of the magnesium slag can be widened, and the additional value of utilizing the magnesium slag is improved.

Owner:BEIFANG UNIV OF NATITIES

Preparation method of choline chloride type magnesium eutectic solvent

The invention relates to a preparation method of a choline chloride type magnesium eutectic solvent, which comprises the following steps of: mixing aqueous magnesium chloride and a ligand according to the mol ratio of 1:5-1:20, heating for melting at the temperature of 100-200 DEG C, and distilling for 0-3 hours at the temperature to obtain a completely dehydrated magnesium chloride-ligand solution; and then mixing the completely dehydrated magnesium chloride-ligand solution and choline chloride, stirring for 1-3 hours at the temperature of 70-90 DEG C, and finally sealing at room temperature to obtain a liquid magnesium eutectic solvent, wherein the mol ratio of the ligand to the choline chloride is 1:1-3:1. The invention has simple process and low cost, can eliminate the moisture influence problem in the electrodeposition process and is superior to traditionally operated magnesium smelting by a pidgeon process and metallic magnesium production by an electrolytic process in the aspects of reducing the energy source and resource consumption, reducing the environment pollution and the like.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Process for preparing calcined dolomite from magnesium chloride of chloride type by-product of potassium-extracting from salt lake

The invention provides a method for preparing a composed calcined dolomite by taking the byproduct of brine ( a saturated liquor which is mainly magnesium chloride ) after potassium extraction or the bischofite separated out from the brine by naturally evaporating as the materials to react with excess lime to prepare the floccule mixture of magnesium hydrate and calcium hydroxide; then the mixture is calcined and dehydrated under the temperature of 400 to 1200 DEG C after the mixture is deposited, filtered, washed, dried and cracked. The materials of the invention are easily obtained and cheap; the production process is simply and easily controlled; no carbon dioxide is discharged; besides, the invention basically has no corrosion to a device. The mol ratio of MgO to CaO in the composed calcined dolomite is within the range of 1:0.8 to 1:1.2; the activity of water is 25 to 36 percent; the composed calcined dolomite is applicable for the areas rich in the resource of magnesium chloride to use a Pidgeon process to produce the metal of magnesium.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

High strength ceramsite oil proppant using magnesium slag as mineralizer and preparation method thereof

The invention achieves the reuse of magnesium slag discharged when magnesium metal is produced through Pidgeon process, and discloses a high strength ceramsite oil proppant using magnesium slag as mineralizer and a preparation method of the high strength ceramsite oil proppant using the magnesium slag as the mineralizers. In terms of raw materials, the ceramsite oil proppant comprises, by weight, 100 parts of light roasting bauxite, 2-6 parts of the magnesium slag, 1-3 parts of auxiliary materials, and 0.3-0.5 part of binding agent. The preparation method includes the following steps: mixing the light roasting bauxite, the magnesium slag, the auxiliary materials and the binding agent proportionally, making ball materials, and sintering the dried ball materials to obtain products. The sintering temperature is 1300-1400 DEG C, the heat preservation time is 0.5-1 hour, and the products naturally cool down to the room temperature. The crushing rate of the high strength ceramsite oil proppant produced by the preparation method of the high strength ceramsite oil proppant using the magnesium slag as the mineralizers is smaller than or equal to 5% under a closing pressure of 86 megapascals, the volume intensity is smaller than or equal to 1.8 grams per cubic centimeter, and the apparent intensity is smaller than or equal to 3.35 grams per cubic centimeter. The preparation method is simple and low in production cost.

Owner:SHANXI FANGXING REFRACTORIES CO LTD

Method for making brick with slag form smelting magnesium by Pidgeon process

A process for preparing Mg-slag brick includes collecting Mg slag from reducing reactor, natural cooling, mixing with water, still standing for 7 days, shaping, and carbnifying the brick blank by CO2 fume generated by calcining dolomite during smelting Mg. It can decrease environment pollution of smelting Mg.

Owner:朱广东

Method for smelting magnesium by decomposition in vacuum through microwaves

The invention relates to a method for smelting magnesium by decomposition in vacuum through microwaves, and belongs to the field of magnesium smelting. The method comprises the following steps: firstly, crushing raw materials of magnesia, lime and ferrosilicon, then evenly mixing the crushed materials according to the proportions, pressing into balls, carrying out microwave-heating in a microwavevacuum reactor to resolve the magnesia into gaseous magnesium, and condensing to obtain crude magnesium. The invention is characterized in that the technical parameters are as follows: the reaction temperature in the microwave vacuum reactor is 1250-1450 DEG C, and the vacuum degree is 20-1000 Pa; the proportion of the lime to the magnesia is 0.5:1-1.5:1, and the proportion of ferrosilicon to themagnesia is 0.44-0.65:1; and the heating time is 1-5 hours. Compared with the prior Pidgeon process for smelting magnesium, the invention has the characteristics of high efficiency, low energy consumption, low pollution, low production cost, low fixed investment and the like.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD +1

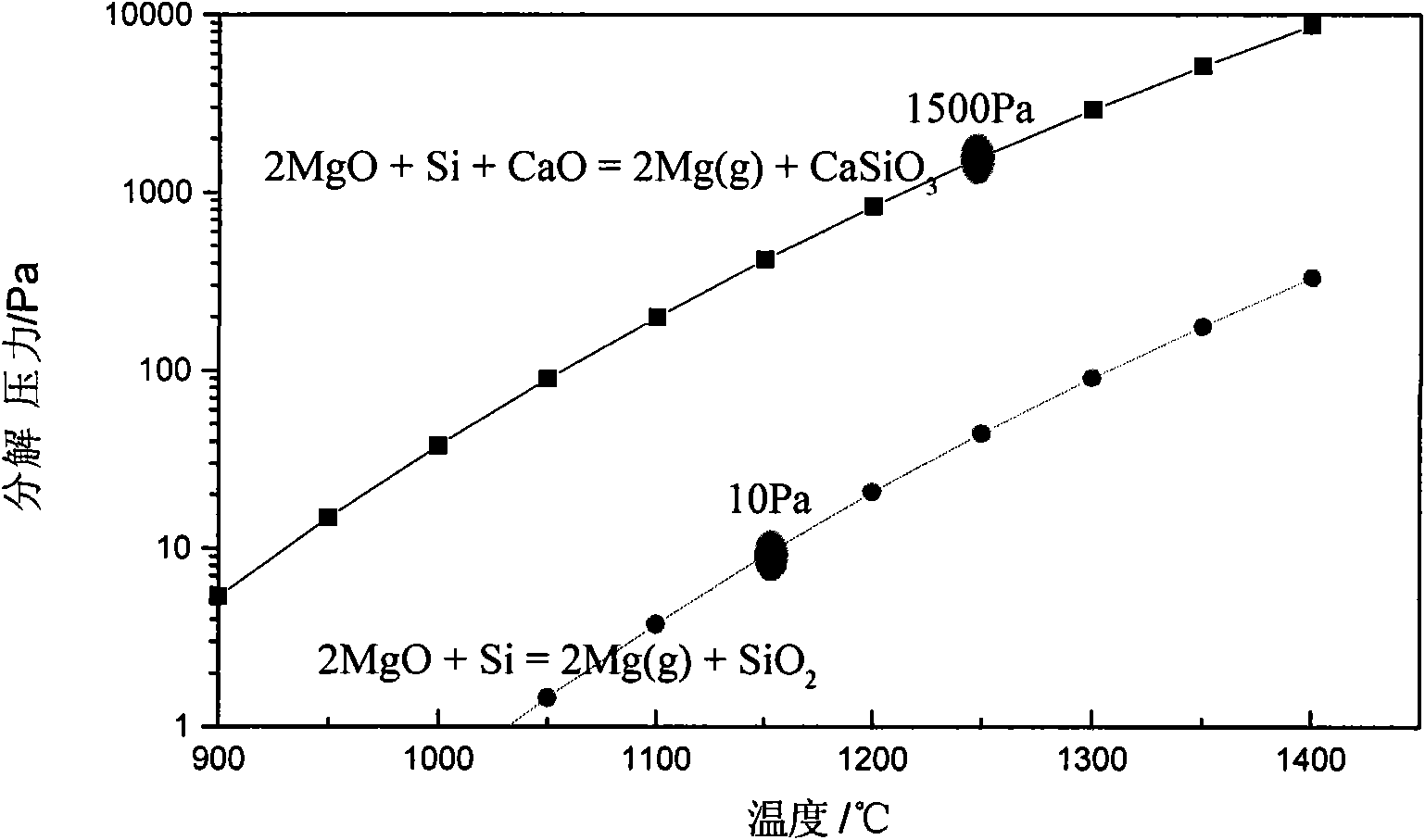

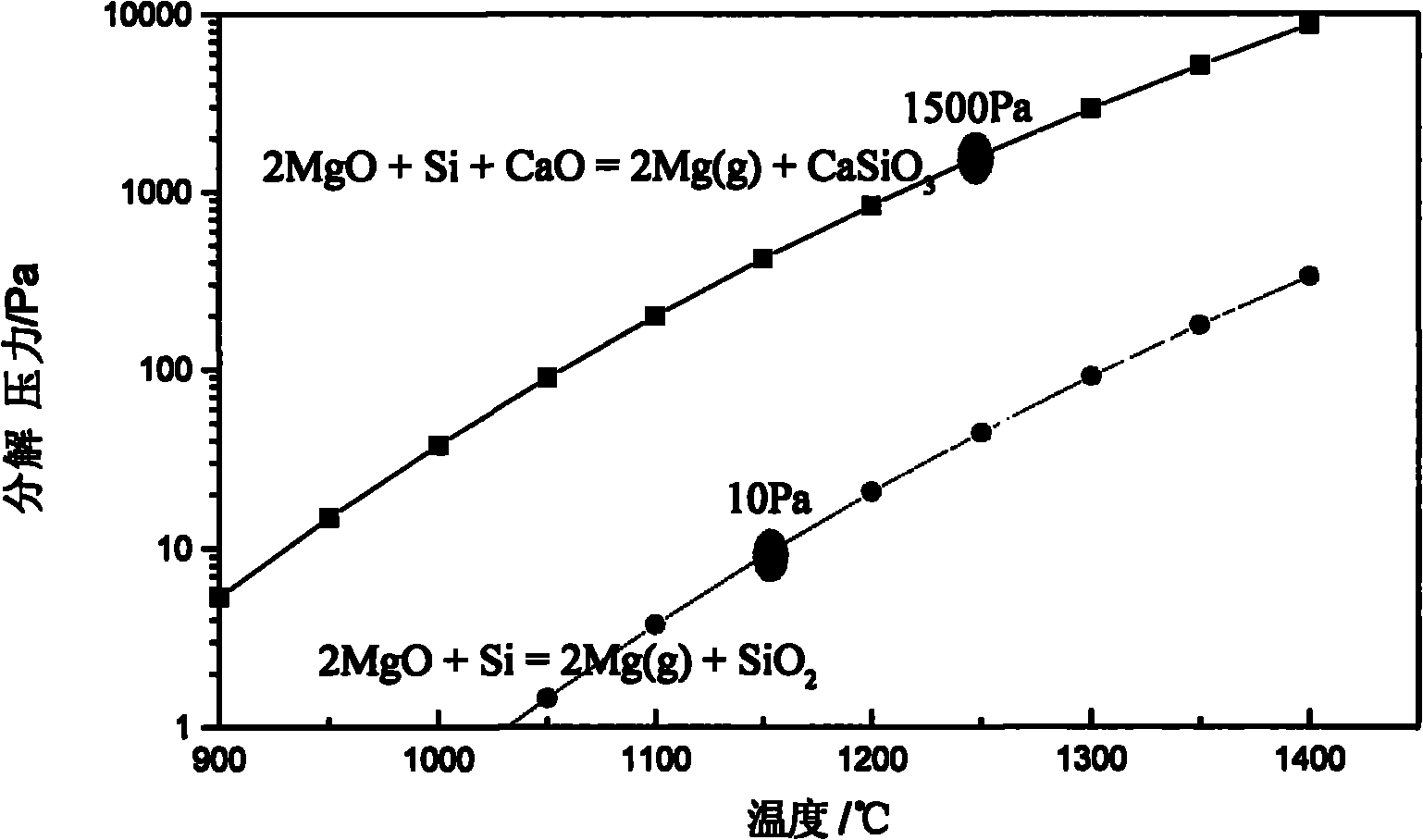

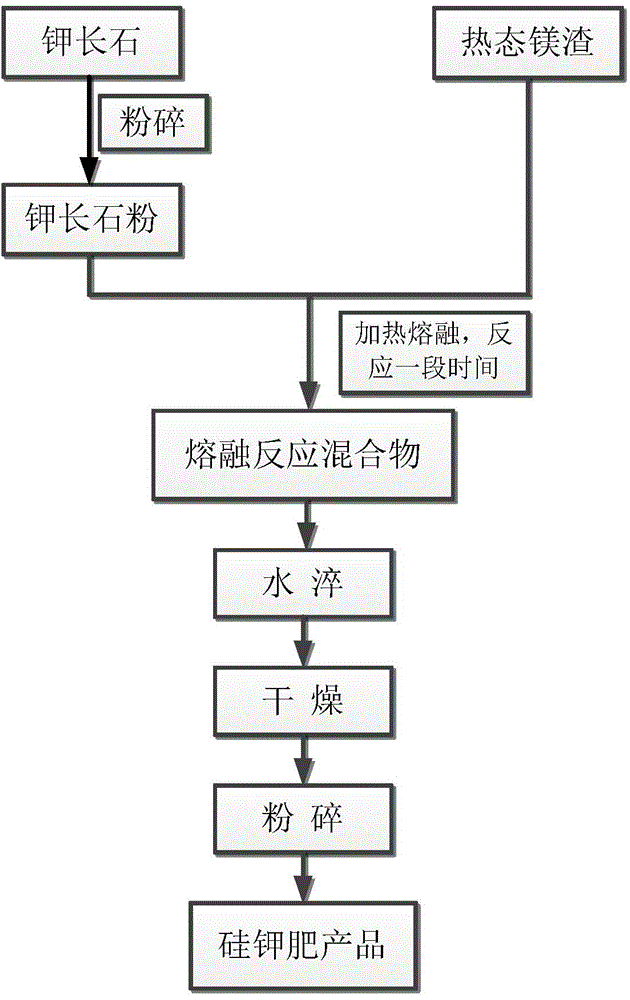

Method for preparing silicon-potash fertilizer based on magnesium slag

The invention provides a method for preparing a silicon-potash fertilizer based on magnesium slag and relates to a method for preparing the silicon-potash fertilizer by utilizing magnesium slag. The method comprises the following steps: carrying out high-temperature mixed melting by taking Pidgeon process thermal state reducing magnesium slag as a basic raw material, utilizing Si, Ca, Mg and Fe in thermal state magnesium slag and other beneficial components needed by multiple crops, adding potassium feldspar enriched in K2O, SiO2 and other plant nutrients, thereby preparing the silicon-potash fertilizer which is enriched in multiple plant growth nutrients and has a sustained release function. The method disclosed by the invention has the advantages that the raw material cost is low, the processing technology is relatively simple, and large-scale industrial production is easily realized. Moreover, the method has the comprehensive advantages that the energy consumption is saved, the environment is protected, and high-efficiency resource utilization of the magnesium slag is realized.

Owner:SHANXI UNIV

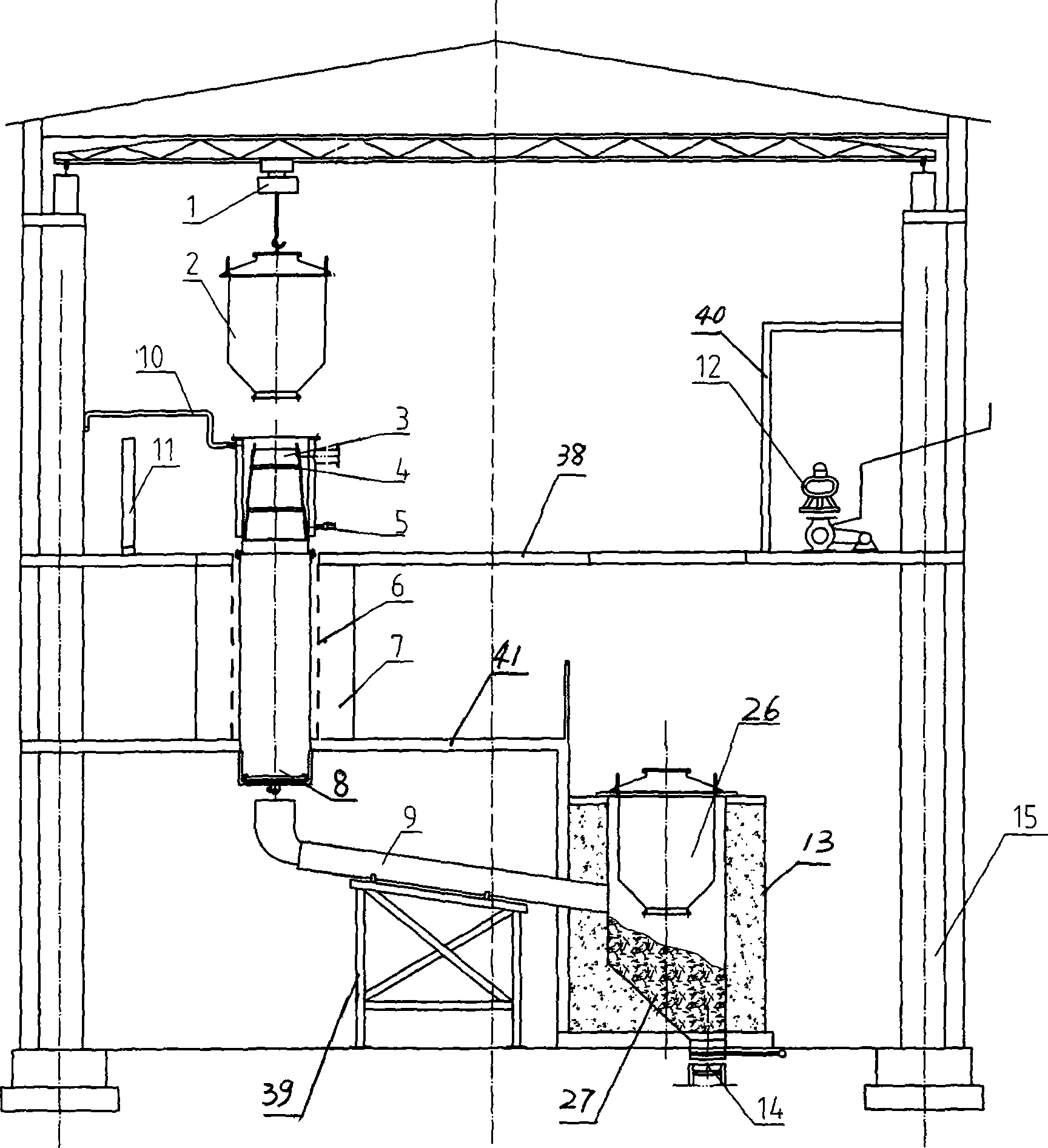

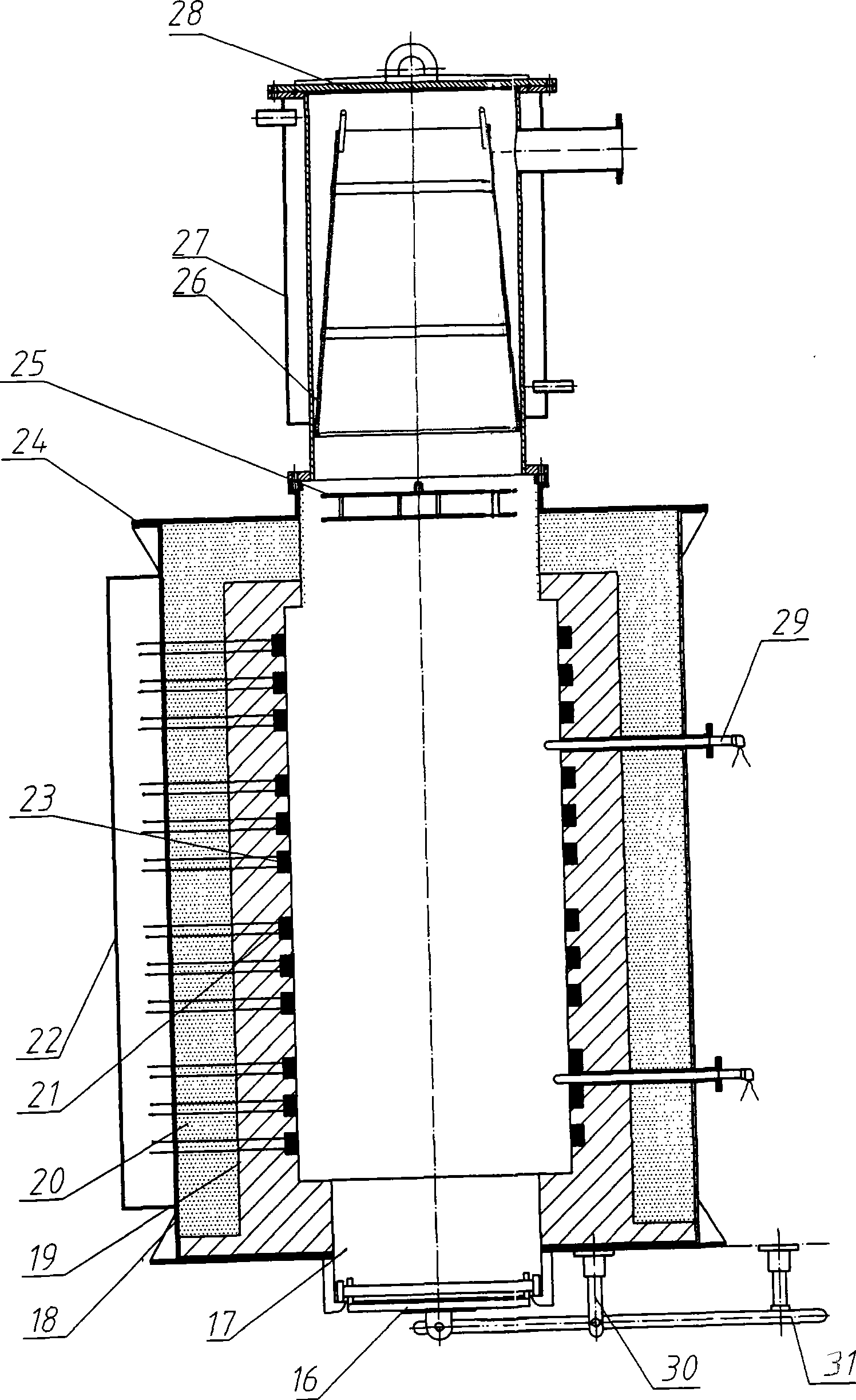

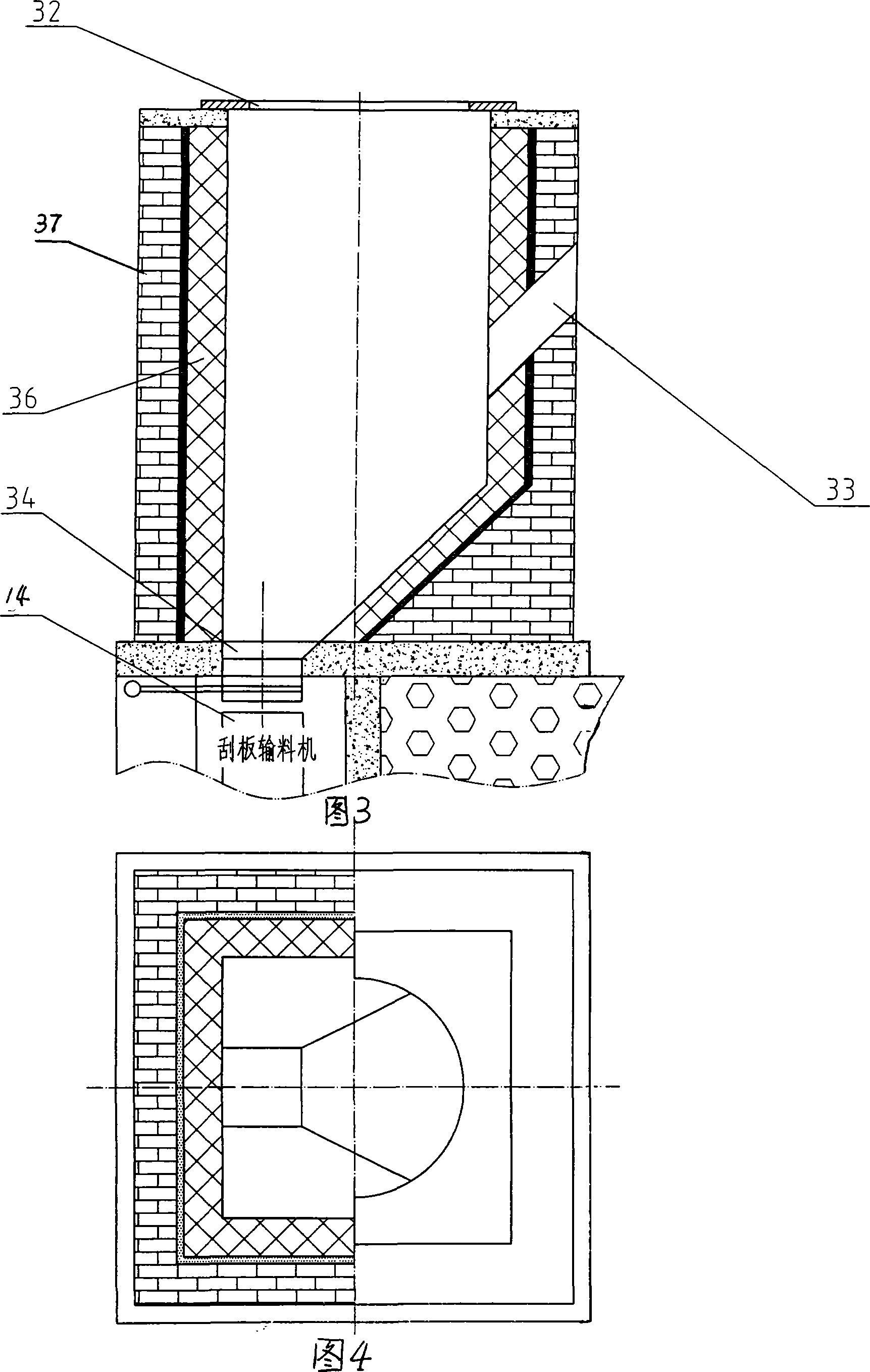

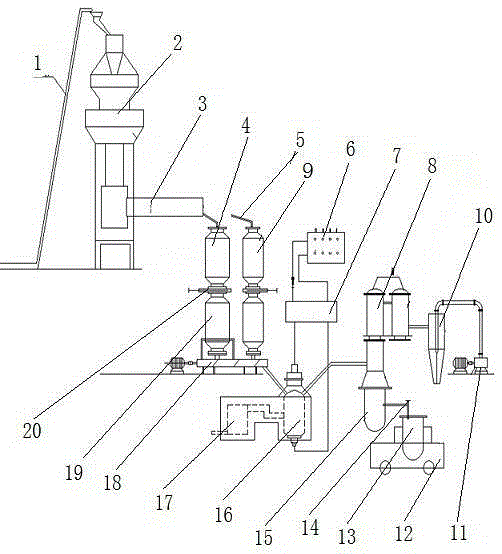

Nontank shaft type electric resistance furnace smelting magnesium apparatus and smelting magnesium method thereof

The invention discloses a pot free vertical shaft type resistance furnace magnesium smelting device, which comprises a charge can. The device is characterized in that a crystallizer is arranged on the lower end of the charge can; a vertical shaft type resistance furnace is arranged on the lower end of the crystallizer; a pipeline is arranged on the bottom of the vertical shaft type resistance furnace; and a furnace charge preheating furnace is connected with one end of the pipe. A pot free vertical shaft type resistance furnace magnesium smelting method comprises the following steps: mixing 84.5 weight percent of calcined dolomite and 15.5 weight percent of ferrosilicon and putting the calcined dolomite and the ferrosilicon into the charge can; pouring the mixed material in the charge can into a furnace cavity through a crane; turning on a power supply to heat the furnace cavity through resistance wire; when the temperature reaches 1,260 to 1,300 DEG C, gasifying the magnesium metal which rises into the crystallizer; and introducing cooling water into the crystallizer to crystallize the magnesium metal into solid magnesium metal when the temperature in the crystallizer is reduced to 400 to 450 DEG C. The greatest difference between the invention and the prior pidgeon process is as follows: the invention disuses an expensive reduction pot made of high alloy refractory steel. The smelting thermal efficiency can be as high as above 90 percent. The pot free vertical shaft type resistance furnace magnesium smelting device has less thermal loss, environmental protection, energy conservation, and less environmental pollution. The device facilitates mechanized production, and can reduce the labor intensity and improve the working environment.

Owner:孙克本 +1

Method for preparing calcined dolomite for silicothermic process magnesium production by aid of carbide slag and bischofite

The invention relates to a method for preparing calcined dolomite for silicothermic process magnesium production by the aid of carbide slag and bischofite. The method includes the steps: firstly, placing magnesium chloride and the carbide slag into water, performing stirring reaction for 0.5-3h at the normal temperature and generating mixed slurry of calcium hydroxide and magnesium hydroxide after sufficient reaction; secondly, performing solid-liquid separation for the slurry to obtain sediment; thirdly, washing the solid sediment, drying the solid sediment to reach constant weight and obtaining dried solid powder; and finally, calcining the dried solid powder for 0.5-3h at the temperature of 600-1000 DEG C to obtain the calcined dolomite. The carbide slag serving as raw materials is turned from harm into good and turned from waste into wealth, and the whole technical process is simple, easily controlled, non-corrosive to equipment and applicable to metallic magnesium production by the aid of a Pidgeon process for regions with high carbide slag byproduct yield or rich magnesium chloride resources.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Calcium hexaluminate/gehlenite diphase heat-insulation refractory material and preparation method thereof

The invention relates to a calcium hexaluminate (CA6) / gehlenite (C2AS) diphase heat-insulation refractory material and a preparation method thereof, and belongs to the technical field of refractory materials. In the invention, the raw materials of the refractory material comprise 20-50wt% of an industrial waste magnesium residue generated through Pidgeon process industrial magnesium making, 0-24wt% of kaolin and 26-80wt% of industrial alumina, and the sum of the above proportions of the raw materials is 100%. The preparation method comprises the following steps: burdening the raw materials according to the above proportions, uniformly mixing the raw materials, adding certain amounts of a binder and a pore forming agent, carrying out compression molding, and carrying out high temperature sintering in the air atmosphere to prepare the diphase heat-insulation refractory material with the CA6 and the C2AS as the principal crystalline phases. The main chemical components of the refractory material comprise CaO, Al2O3 and SiO2. The refractory material has the characteristics of low production cost, small density, good heat shock resistance, good heat insulation effect, high mechanical strength, good wear resistance and the like, and can be used in high temperature containers and kilns as a liner high temperature material.

Owner:田玉明 +2

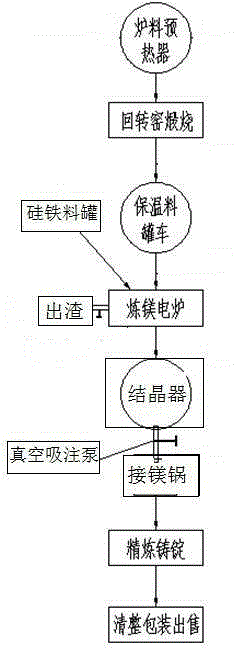

Novel process for continuously smelting magnesium metal with electric furnace

InactiveCN105420516ASave heatImprove the degree of continuous automation productionElectric arc furnacePidgeon process

The invention relates to a novel process for continuously smelting magnesium metal with an electric furnace. The novel process is characterized by comprising the following steps: feeding with a calcination rotary kiln, receiving materials and discharging with an insulated material tank, quantitatively sealed feeding, and smelting with the electric furnace; reducing magnesium vapor at 1550-1600 DEG C, wherein magnesium cooled by a magnesium vapor crystallizer is liquid magnesium; sucking and pouring the liquid magnesium to a magnesium receiving pot by using a vacuum suction pouring pump, and transporting the liquid magnesium in the magnesium receiving pot to a refining workshop for refining by using a battery cart; deslagging by using a forehearth which is positioned in front of the electric furnace and communicated with the electric furnace, and thus ensuring continuous deslagging in vacuum. According to the novel process, the whole production process can realize mechanization, and the main production part realizes automation control; in the whole production process, materials do not fall to the ground, the human consumption is reduced, the production efficiency is improved, powder pollution can be thoroughly removed, and the environment is improved. 7150 kilowatts are consumed per ton of magnesium, and the power consumption per ton of magnesium is reduced by 40 percent compared with the current French and American Malina method. Compared with the Pidgeon process, CO2 and SO2 emission can be reduced by 80 percent. The production efficiency is improved by 25 percent, the energy consumption is reduced by 50 percent, and the production cost is reduced by 30 percent.

Owner:孙克本 +2

Method for Al-Si-Fe alloy preparation and magnesium reduction in Pidgeon-process magnesium reduction process

InactiveCN107090547AAchieve reduction efficiencyLow costProcess efficiency improvementSmelting processReaction temperature

The invention discloses a method for Al-Si-Fe alloy preparation and magnesium reduction in a Pidgeon-process magnesium reduction process. The method comprises the following steps: (1) mixing calcined dolomite, powdered aluminium, silicon iron and calcium fluoride, pressing the mixture into balls to obtain mixed balls, then filling a magnesium reduction tank with the mixed balls, and enabling heating reaction; and (2) performing cooling after finish of reaction, performing vacuum breaking, and collecting volatilized magnesium in the format of elemental magnesium, wherein the mass percents of calcined dolomite, powdered aluminium, silicon iron and calcium fluoride in the mixed balls in the step (1) are 80-85%, 1-12%, 4-15% and 1-3%; and the reaction temperature in the step (1) is 1,000-1,300 DEG C, and the heat preservation reaction time is 1-12 h. According to the method, in the Pidgeon-process magnesium reduction process, aluminum and silicon iron react to produce Al-Si-Fe alloy, and the Al-Si-Fe alloy serves as a reductant in the traditional Pidgeon-process magnesium smelting process to reduce magnesium oxide in calcined dolomite; and the cost caused by using the Al-Si-Fe alloy in the magnesium reduction process is lowered.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

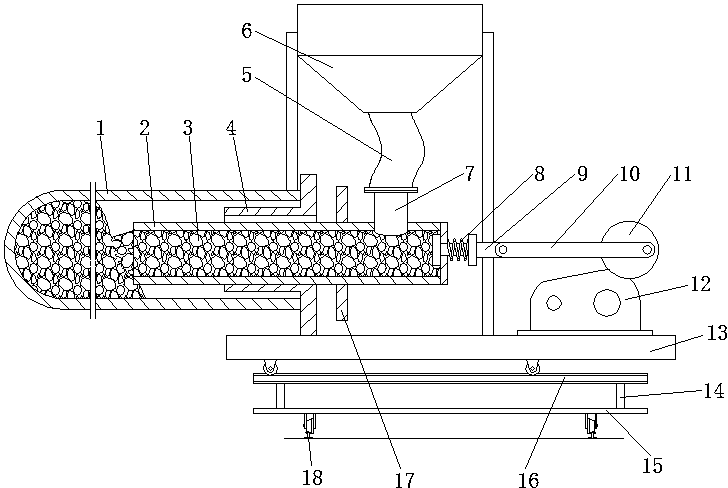

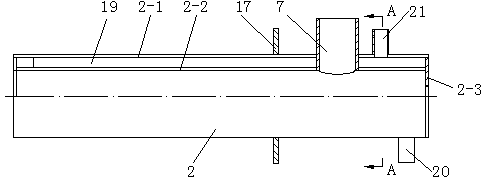

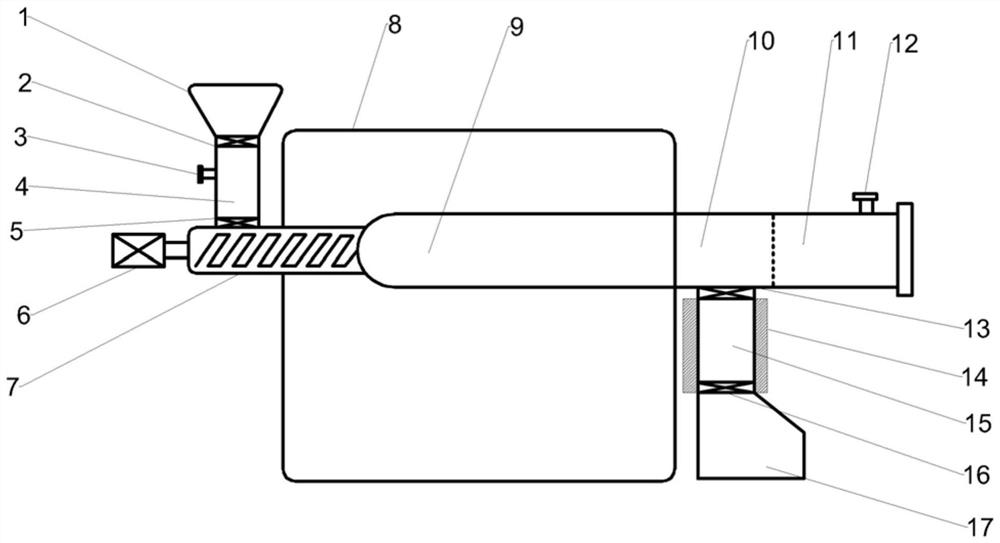

Loading device for smelting magnesium by Pidgeon process

The invention relates to equipment for smelting magnesium by Pidgeon process and particularly relates to a loading device for smelting magnesium by Pidgeon process. The device comprises a transverse moving trolley and a longitudinal moving trolley which is installed on the transverse moving trolley, wherein the longitudinal moving trolley is connected with the transverse moving trolley by virtue of a lifting device. The device is characterized in that the longitudinal moving trolley is provided with a cabin, the discharge opening of which is communicated with a feeding pipe; a guide supporting pipe is fixedly installed on the longitudinal moving trolley, the feeding pipe is arranged in the guide supporting pipe in a sleeving manner, a sealing plate with a hole is fixedly arranged on the rear end face of the feeding pipe, a power device is installed on the longitudinal moving trolley, a crankshaft of a crankshaft slide block mechanism is connected with the power device, the cross section of a slide block in the crankshaft slide block mechanism is a stepped shaft which is shaped like a Chinese character 'Gan', and a circular groove on the slide block can be movably arranged in the hole of the sealing plate at the rear end of the feeding pipe in a sleeving. The device is reasonable in structure and high in loading efficiency, and the production cost of the magnesium smelting industry and the labor intensity of workers can be effectively lowered.

Owner:宁夏创特机械制造有限公司

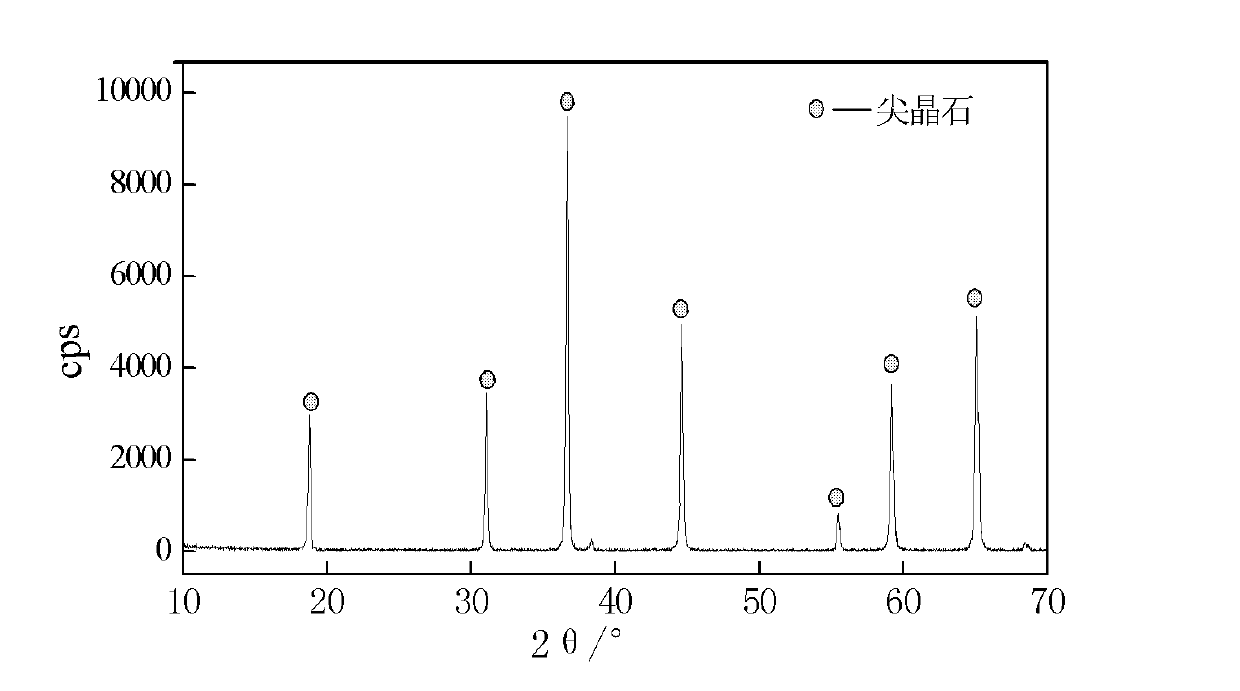

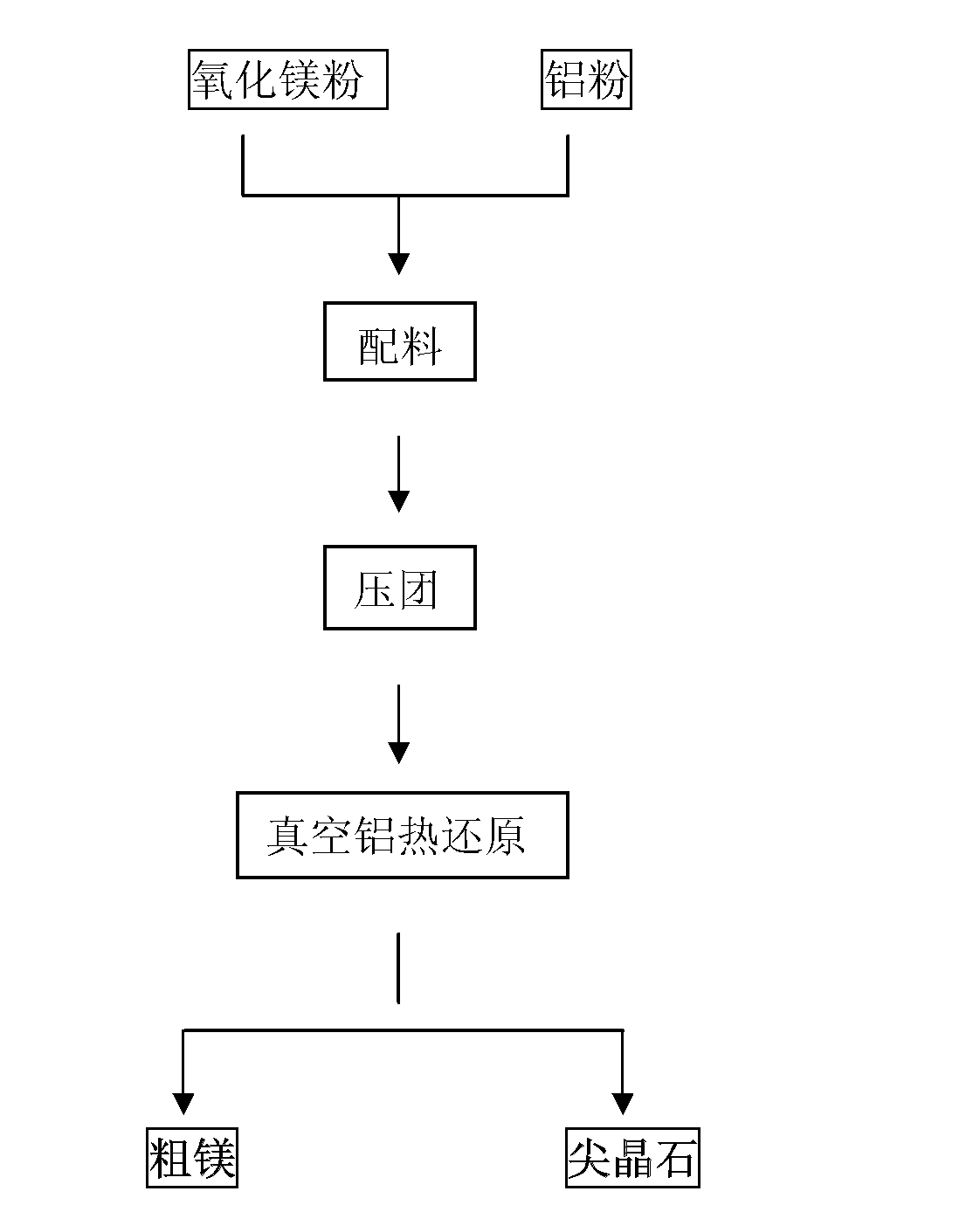

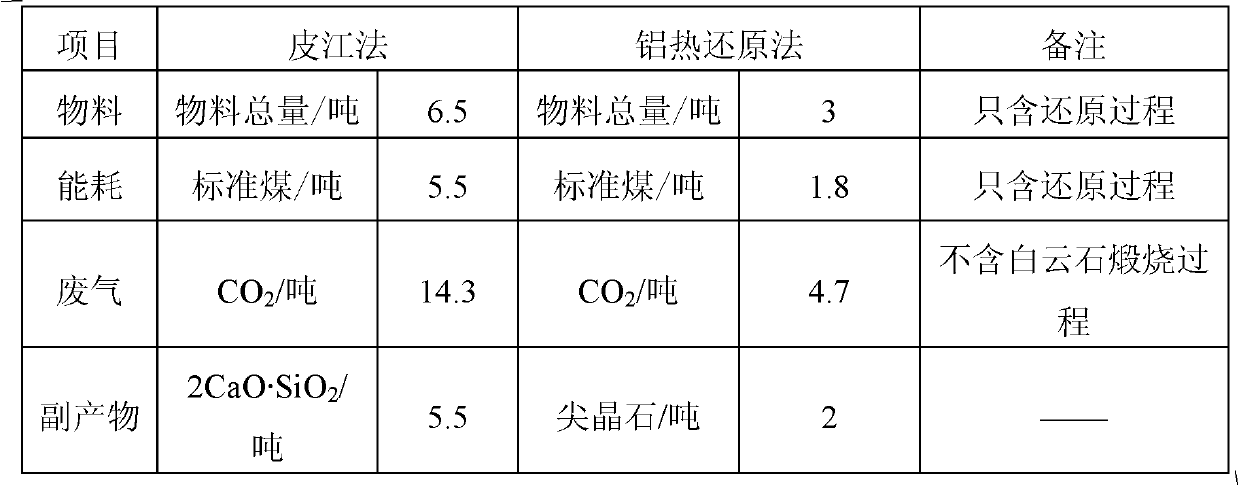

Technology for preparing magnesium metal by magnesium oxide aluminothermic reduction method

The invention relates to a method for preparing magnesium metal by taking magnesium oxide as a raw material and aluminum powder as a reducing agent through vacuum thermal reduction. The method for preparing magnesium metal comprises the following steps of: firstly, weighing and mixing magnesium oxide powder and aluminum powder according to the mole ratio of 2: (0.8-1.2); briquetting under the pressure of 20-35 MPa; putting into a reduction furnace; reducing under the conditions of the temperature of 1050-1150 DEG C and the vacuum degree of 1-13.3MPa for 3-6 hours. Compared with the pidgeon process, the total weight of the reduced and reacted materials in the prior art is reduced by above 50%; the energy consumption is reduced by about 54%; the CO2 tail gas emission is reduced by above 60%; a byproduct spinel powder body can be sold as a product, has no generated waste slag, and the whole process corresponds to the efficient and energy-saving requirements.

Owner:昊青薪材(北京)技术有限公司

Novel reduction method in pidgeon magnesium refining process

InactiveCN102409185AComplete restorationBreak the working condition of high reaction vapor pressurePidgeon processMagnesium

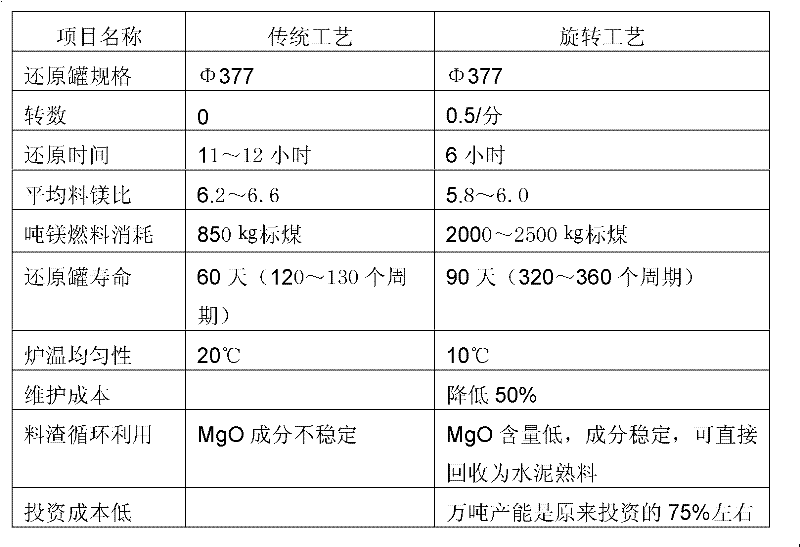

The invention relates to reduction steps in a pidgeon magnesium refining process, in particular to a novel reduction method in the pidgeon magnesium refining process. The method comprises the following steps of: heating a reduction tank filled with pellets to the temperature of between 1,100 and 1,300 DEG C; keeping the temperature under vacuum; and performing a reduction reaction. The method is characterized by comprising the following step of: rotating the reduction tank in the heating process. By the reduction method, materials in the reduction tank can be stirred by rotating the reduction tank, so that the materials in the middle of the reduction tank can acquire heat in time; simultaneously, the working condition of high reaction vapor pressure of the materials in the middle is broken through, so that the materials can be fully reduced, reduction time is shortened, and reduction temperatures are reduced; and preset reduction time can be shortened to 6 hours, the average ratio of the materials to magnesium reaches 5.8 to 6.0, and standard fuels for reducing each ton of magnesium are reduced by 1,000kg.

Owner:宁夏华亿镁业股份有限公司

Pidgeon magnesium smelting process and applications by taking rare earth oxide (REO) as mineralizer

The invention relates to a pidgeon magnesium smelting process and applications by taking rare earth oxide (REO) as a mineralizer. The pidgeon magnesium smelting process is characterized by comprising the following steps: carrying out metering and compounding by taking calcined dolomite as raw materials and silicon iron as a reducing agent together with mineralizer, wherein the mineralizer comprises rare earth oxide accounting for 0.25-3% total weight of pellet, the silicon iron accounts for 12-18% total weight of pellet, and the balance is the calcined dolomite; and grinding and then briquetting to be packed into a reducing tank, heating to be 1150-1250 DEG C, vacuumizing the interior, preserving temperature, cooling and collecting rough magnetism. According to the technical scheme, fluorite is entirely replaced by the rare earth oxide, so that the pollution of fluorine to the environment is reduced, and the existing equipment and process conditions are not required for changing; secondly, the modified magnesium slag has better gelatinization activity, the addition proportion of the magnesium slag applied in the cement and concrete building blocks can be increased, the magnesium slag utilization rate is high, the prepared building materials has high later strength, and the dual effects of being energy-saving and environment-friendly can be achieved.

Owner:BEIFANG UNIV OF NATITIES

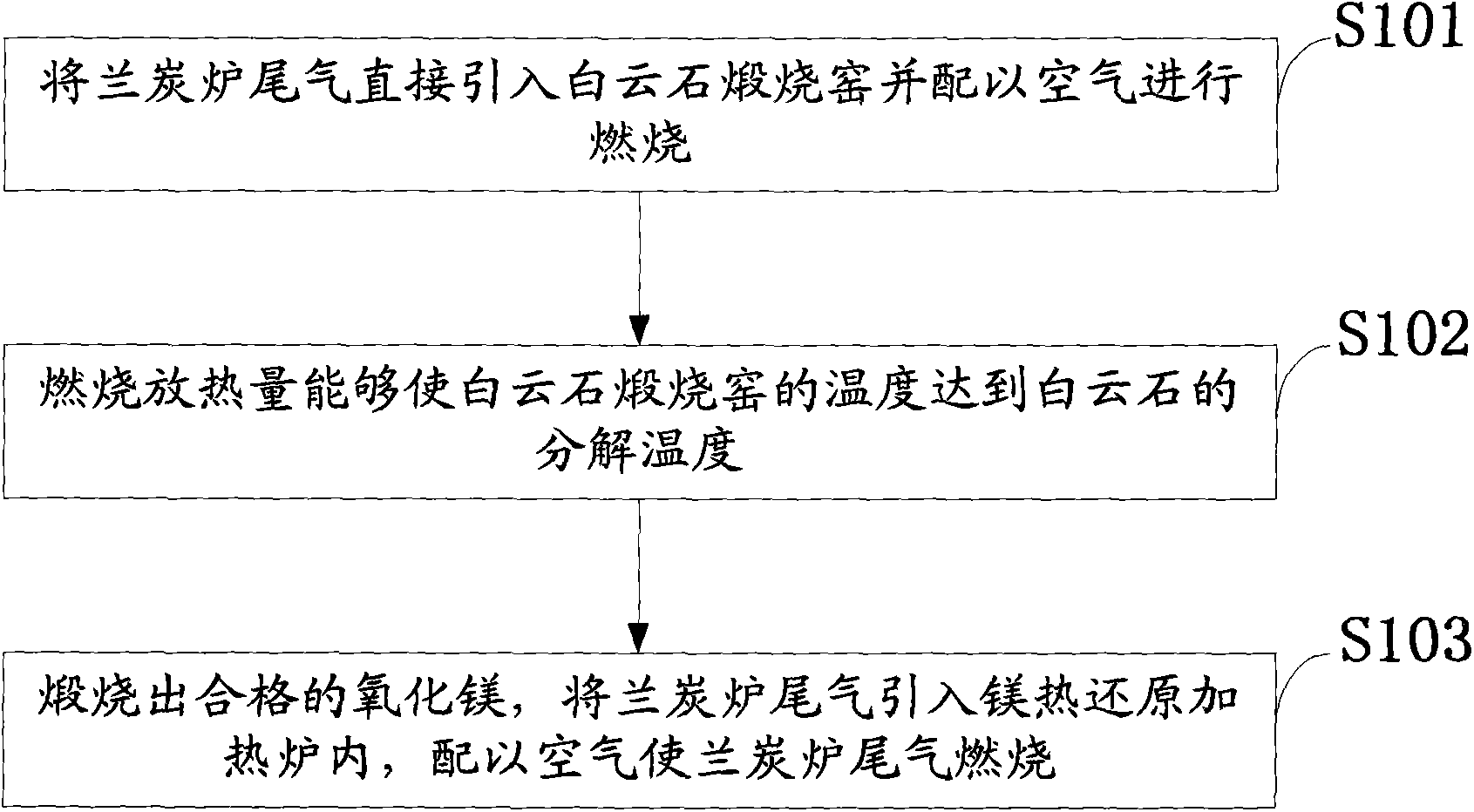

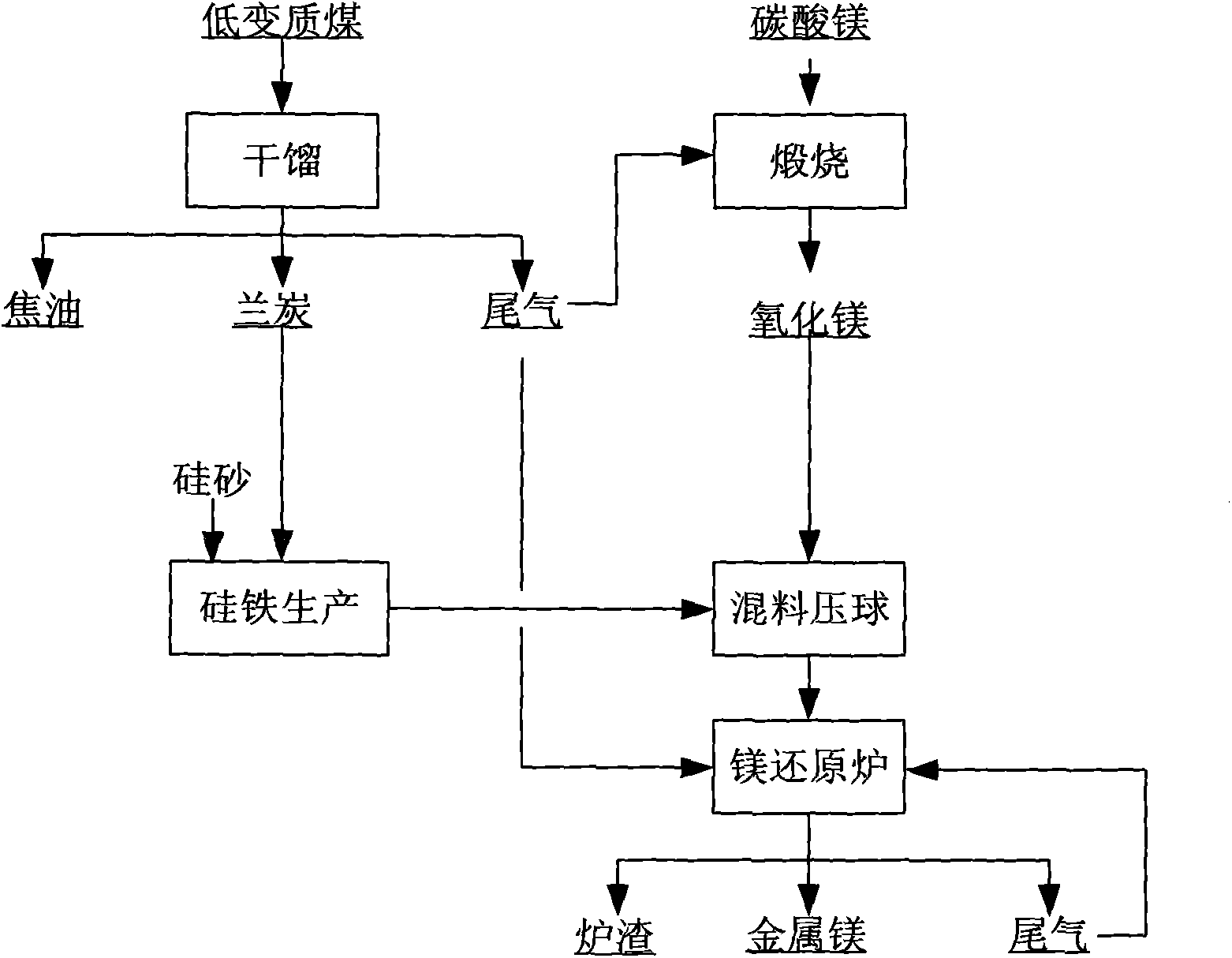

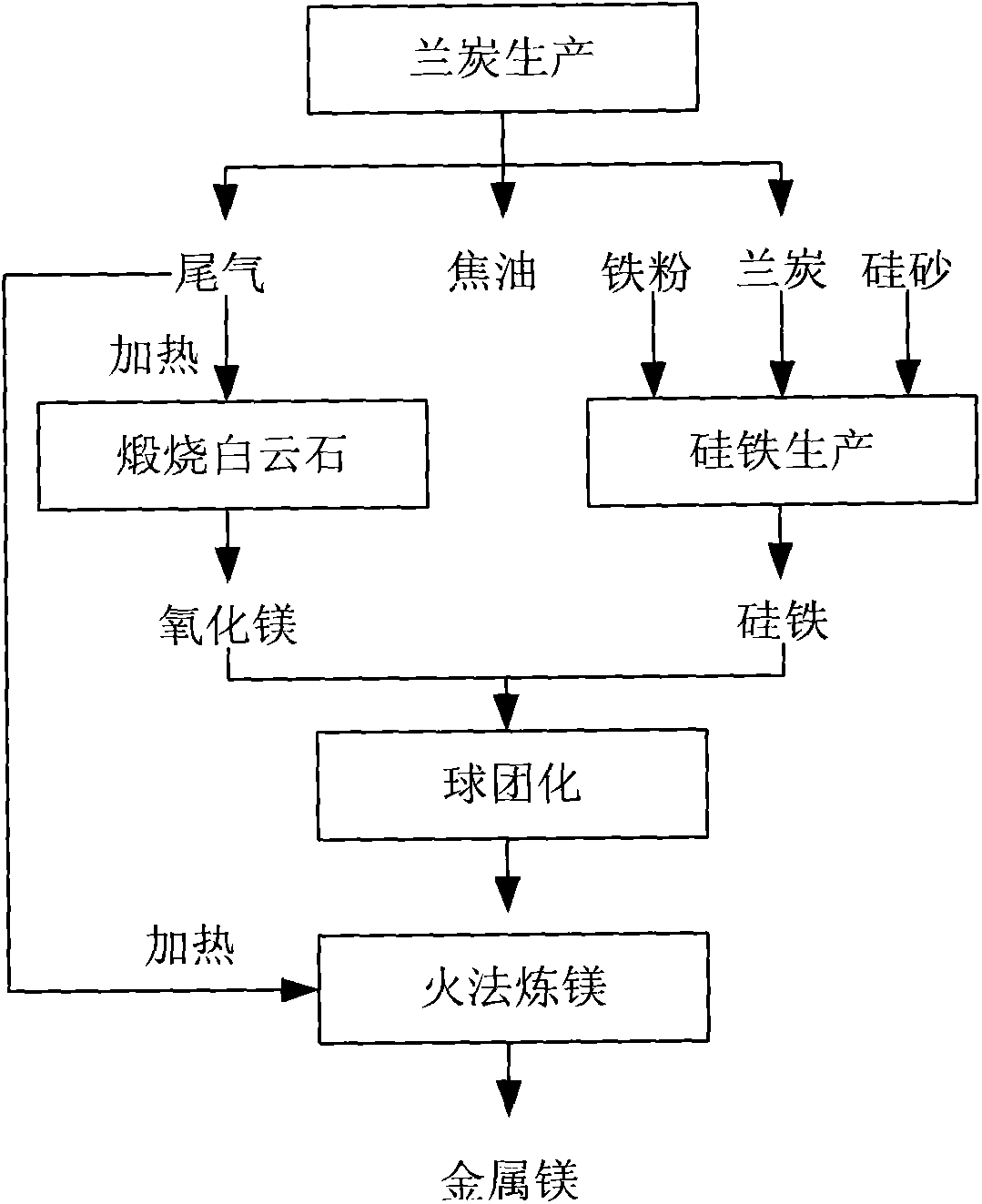

Method for poly-generation and large-scale coupling production based on semi coke and magnesium

The invention discloses a method for poly-generation and large-scale coupling production based on semi coke and magnesium. The method comprises the following steps: producing semi coke by using low metamorphic coal on a large scale, producing silicon iron by the semi coke instead of coke; reducing magnesium oxide by using the silicon iron to produce a reducing agent of magnesium metal through employing a pidgeon process, a ferrosilicon process or a pyrogenic process; directly leading semi coke furnace exhaust to a dolomite calcining kiln, and burning in combination with a proper volume of air, wherein the heat from combustion can enable the temperature of the dolomite calcining kiln to achieve the decomposition temperature of dolomite; calcining to produce magnesium oxide; mixing magnesium oxide with the silicon iron and pressing into a ball to be loaded to a magnesium reduction furnace; leading semi coke furnace exhaust to a heating furnace system produced in the process of reducing magnesium by the ferrosilicon process; reducing and producing magnesium metal by a heating reduction tank at a high temperature; and recycling afterheat and combustible marketable components after semi coke exhaust is burnt. The clean and large-scale development of magnesium smelting industry of smelting magnesium employing a silicon reduction process is facilitated, grading purification of coal and clean utilization are facilitated, and collaborative innovation and development of a coupling poly-generation industry chain and an industrial cluster of the semi coke and the magnesium metal are facilitated.

Owner:兰新哲 +1

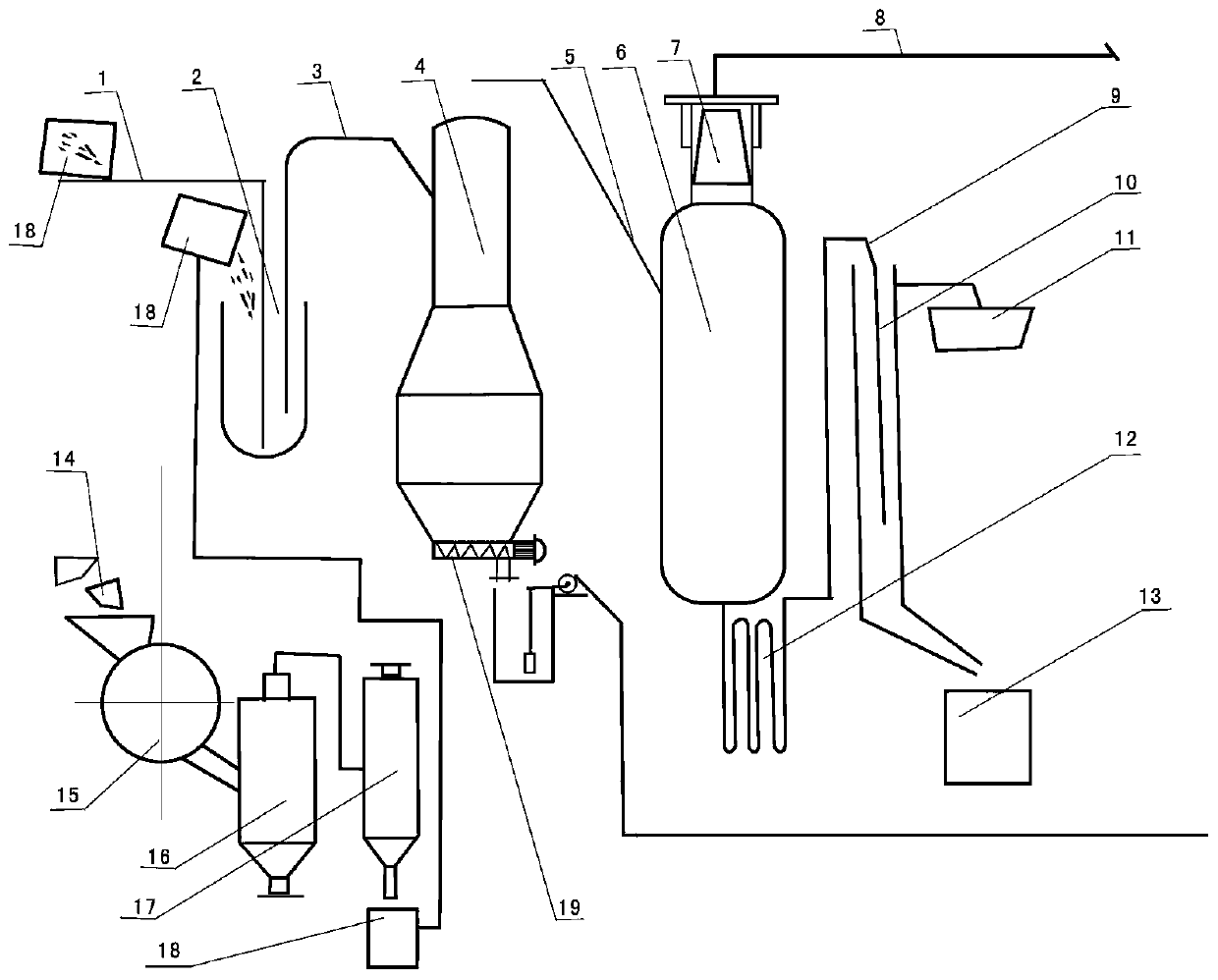

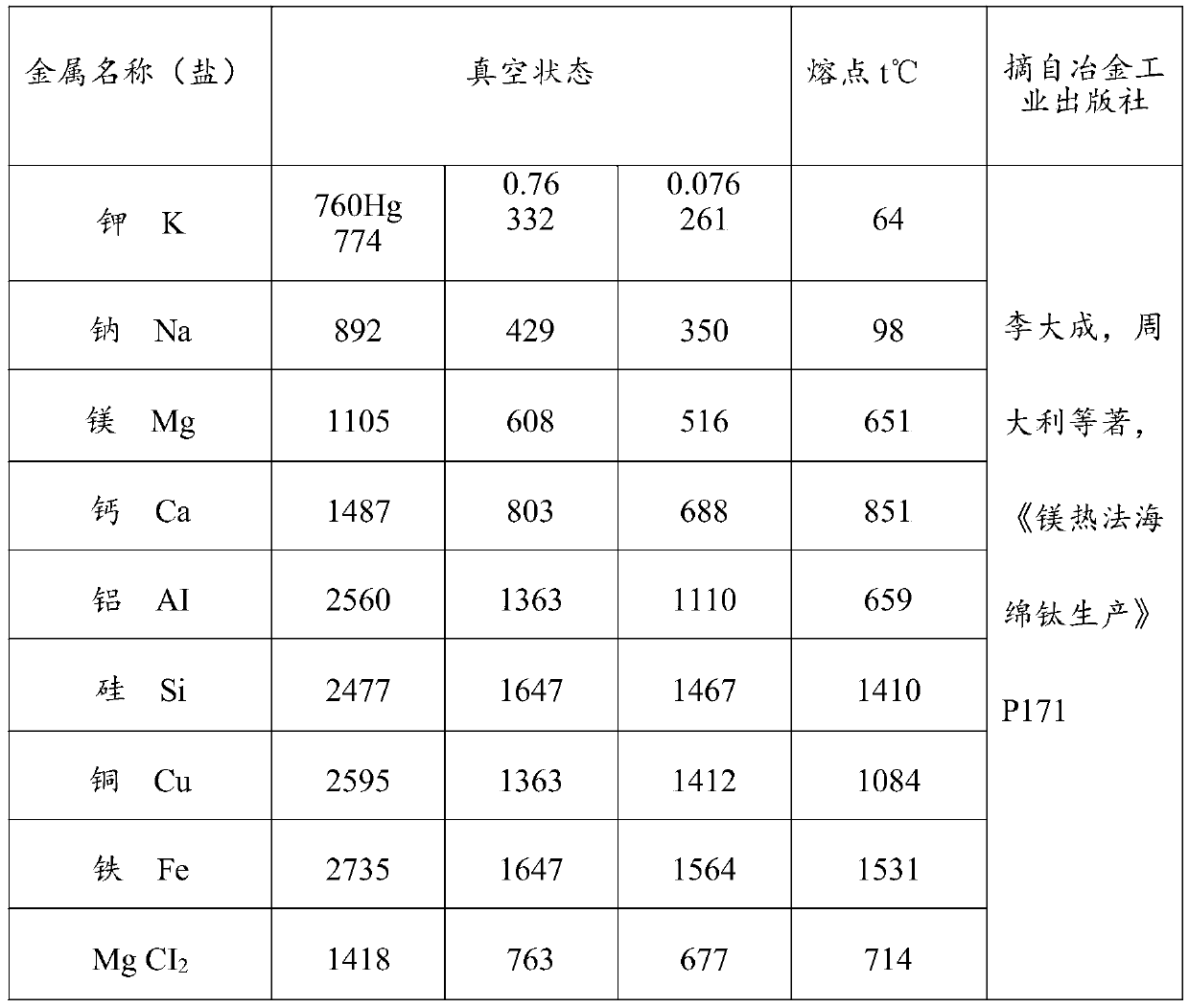

Method for recycling magnesium refining flux waste residues by means of boiling point differences

InactiveCN110453083ALess investmentInvestment saving and energy saving and environmental protectionSilicaCalcium/strontium/barium fluoridesRecovery methodDensity difference

The invention discloses a method for recycling magnesium refining flux waste residues by means of boiling point differences, and belongs to the technical field of resource recycling of metallurgical solid waste resources. The method comprises the step that magnesium and chloride in the magnesium refining flux waste residues are respectively recycled by means of the boiling point differences through raw material treatment, gasification and condensation separation. According to the method, the boiling point differences of residual magnesium, chloride and oxides in the magnesium refining flux waste residues under vacuum and high-temperature conditions are utilized, the residual magnesium and chloride in the flux waste residues are extracted, and magnesium and chloride are respectively obtained by means of a density difference; and meanwhile, gradual recycling is conducted on the waste residues subjected to magnesium and chloride extraction according to different chemical and physical properties of various components in the waste residues, magnesium oxide, sulfate used for chemical fertilizers, mineralizer used for the cement production and calcining process of a Pidgeon-process magnesium smelting plant and fluorite powder as a production raw material of enamel industry. Therefore, the waste residue extracting and recycling method is more thorough and economical and suitable for popularization and application.

Owner:山西宝盛远华新材料股份有限公司 +1

Yield and efficiency increasing method for smelting rough metal magnesium by Pidgeon process

InactiveCN102534251AThe effect of increasing production and efficiency is obviousStable outputAnalysis methodPidgeon process

The invention discloses a yield and efficiency increasing method for smelting rough metal magnesium by a Pidgeon process, and aims to provide a more effective new yield and efficiency increasing method for smelting rough magnesium. According to the technical scheme, high-quality magnesium clinker is adopted, a quality analysis method is changed, and a new production formula of the high-quality magnesium clinker is designed. The ratio of raw materials to the magnesium is reduced, and the yield of the rough magnesium in a single tank and profit are improved. The method is a unique method for improving a process technology for smelting the magnesium by the Pidgeon process in future.

Owner:关树翔

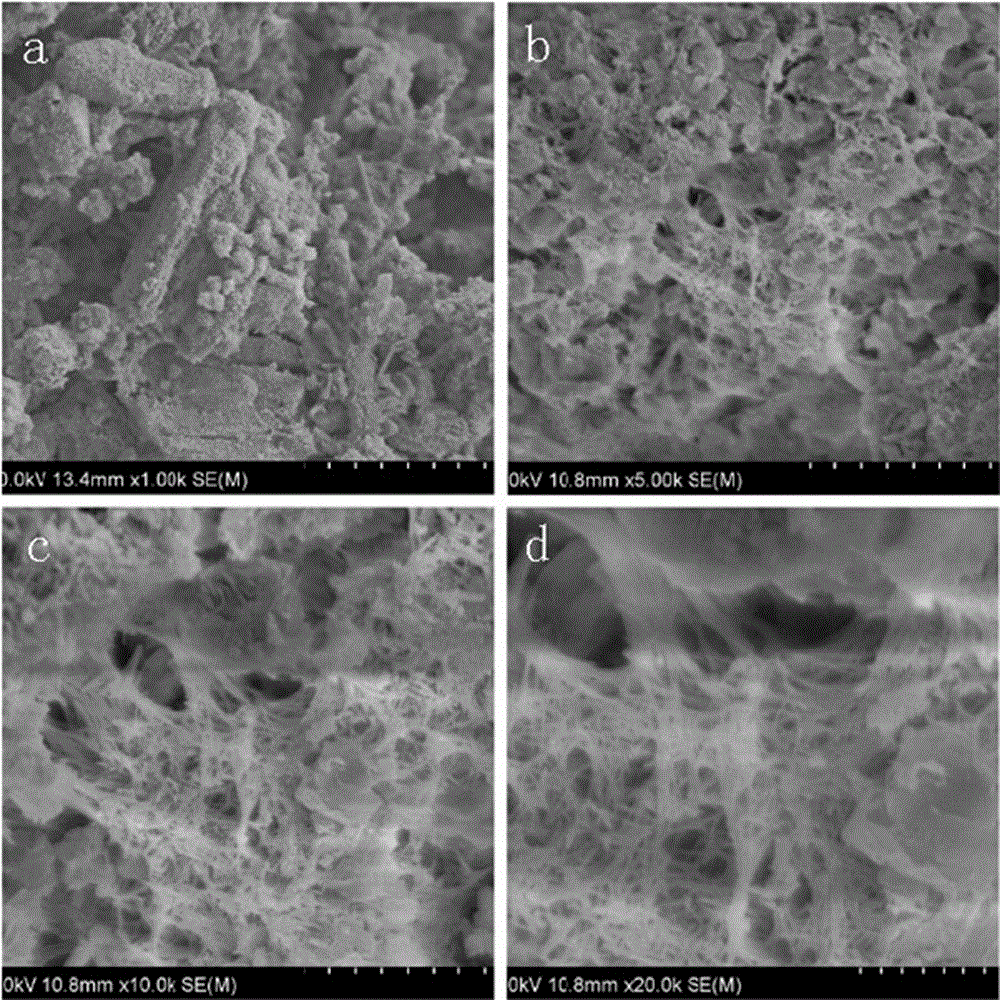

Preparation method of high-performance magnesium slag

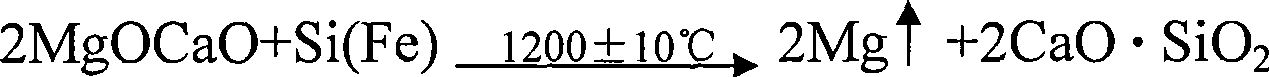

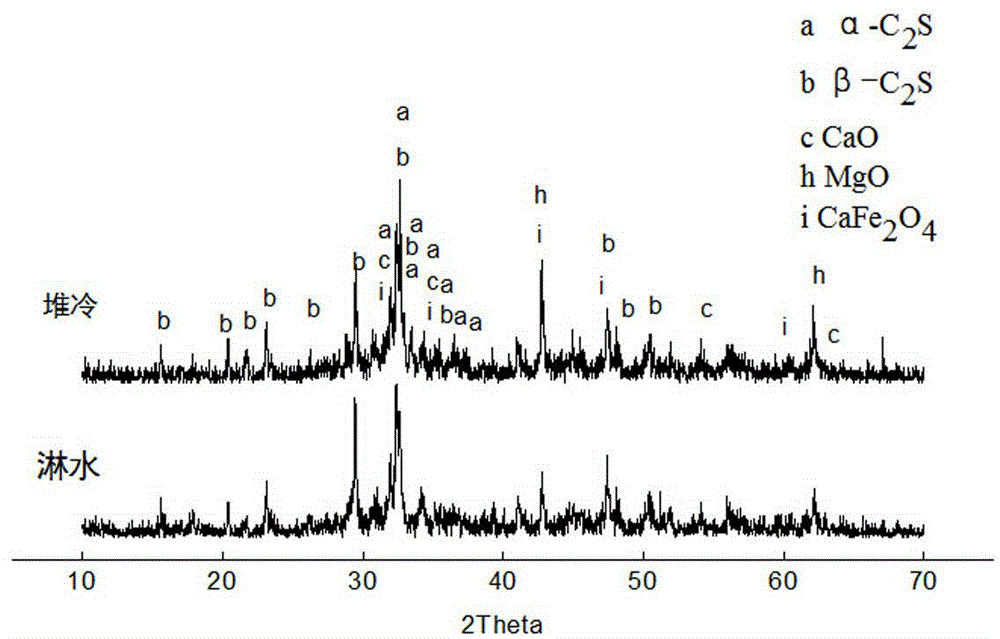

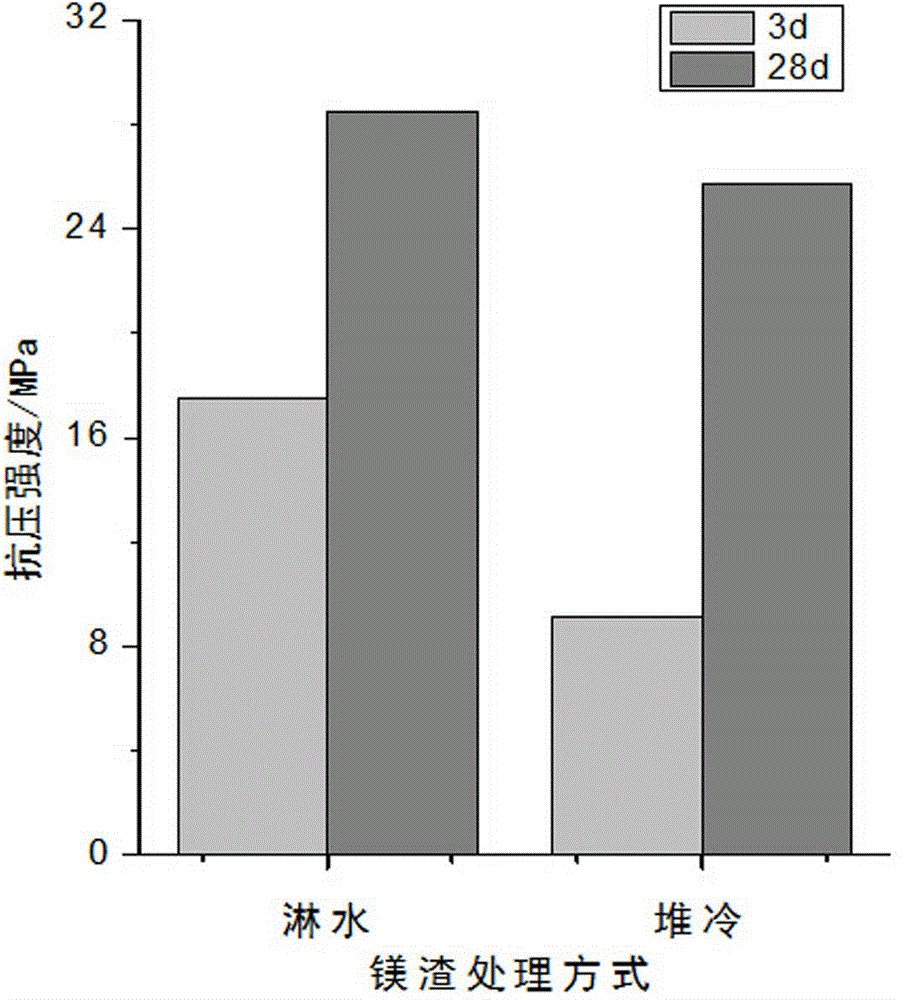

The invention relates to a preparation method of high-activity high-stability high-performance magnesium slag, which solves the problems of difficulty in effective utilization of metal magnesium slag and the like due to high tendency to powdering, instable mineral composition, coarse particles, poor stability and low activity in the existing accumulated and discharged magnesium slag. High-temperature magnesium slag, which is just discharged out of the tank in a Pidgeon magnesium smelting process, is used as the main raw material to prepare the high-activity high-stability metal magnesium slag by a dilute acid solution spraying process, thereby enhancing the utilization ratio of the magnesium slag and lowering the environmental pollution. The method is simple, and has the advantages of wide raw material sources and low price. The treated magnesium slag has the advantages of fine particles, loose structure, lower powdering ratio, high active component content in minerals and low expansion ratio, and is easy for milling. The treatment method is easy to master, and has the characteristics of high cooling speed, short production cycle and the like; the technical indexes of the magnesium slag product can satisfy the standard requirements for architectural waste slag; and the method fuses the concept of environmental protection, and thus, has higher economic and social benefits.

Owner:ZHONGBEI UNIV

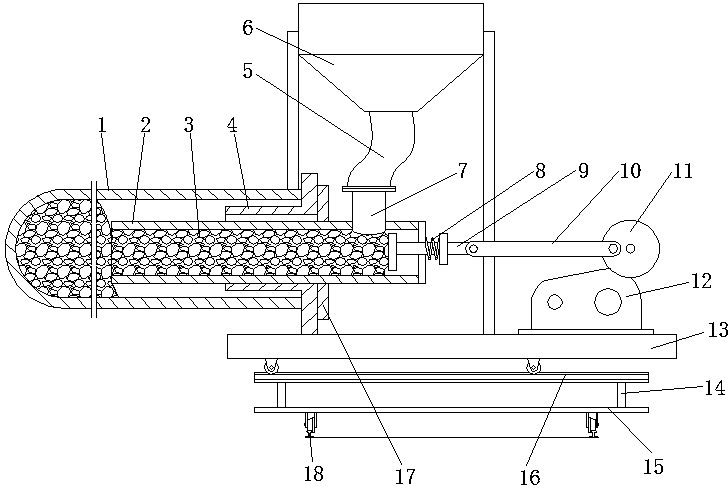

Method and device for intermittently and continuously smelting crystallized magnesium by Pidgeon process reduction tank

The invention discloses a method and a device for intermittently and continuously smelting crystallized magnesium by a Pidgeon process reduction tank. The method comprises the following steps that raw materials in a stock bin are intermittently reacted in batches by using an electronic valve, and a feeding replacement bin and the reduction tank are vacuumized; the raw material pellets in the stock bin enter a spiral feeder and are pushed to a reaction area of the reduction tank; raw material pellet magnesium oxide is replaced by silicon to form magnesium steam, and the magnesium steam enters a crystallization area to form crystallized magnesium which is collected; and reaction waste in the reaction area is pushed by continuously entering raw material pellets to move to the transition area and enter the replacement bin, and the waste is cooled, falls into a slag bin and is moved out. By adding an automatic feeding device and an automatic discharging device and arranging the vacuum tank transition area, intermittent continuity of the transverse tank magnesium smelting process is achieved, the magnesium metallurgy efficiency is improved, then energy consumption is reduced, cost is reduced, pollution is eliminated, the environment is improved, and the service life of the reduction tank is prolonged.

Owner:XI AN JIAOTONG UNIV

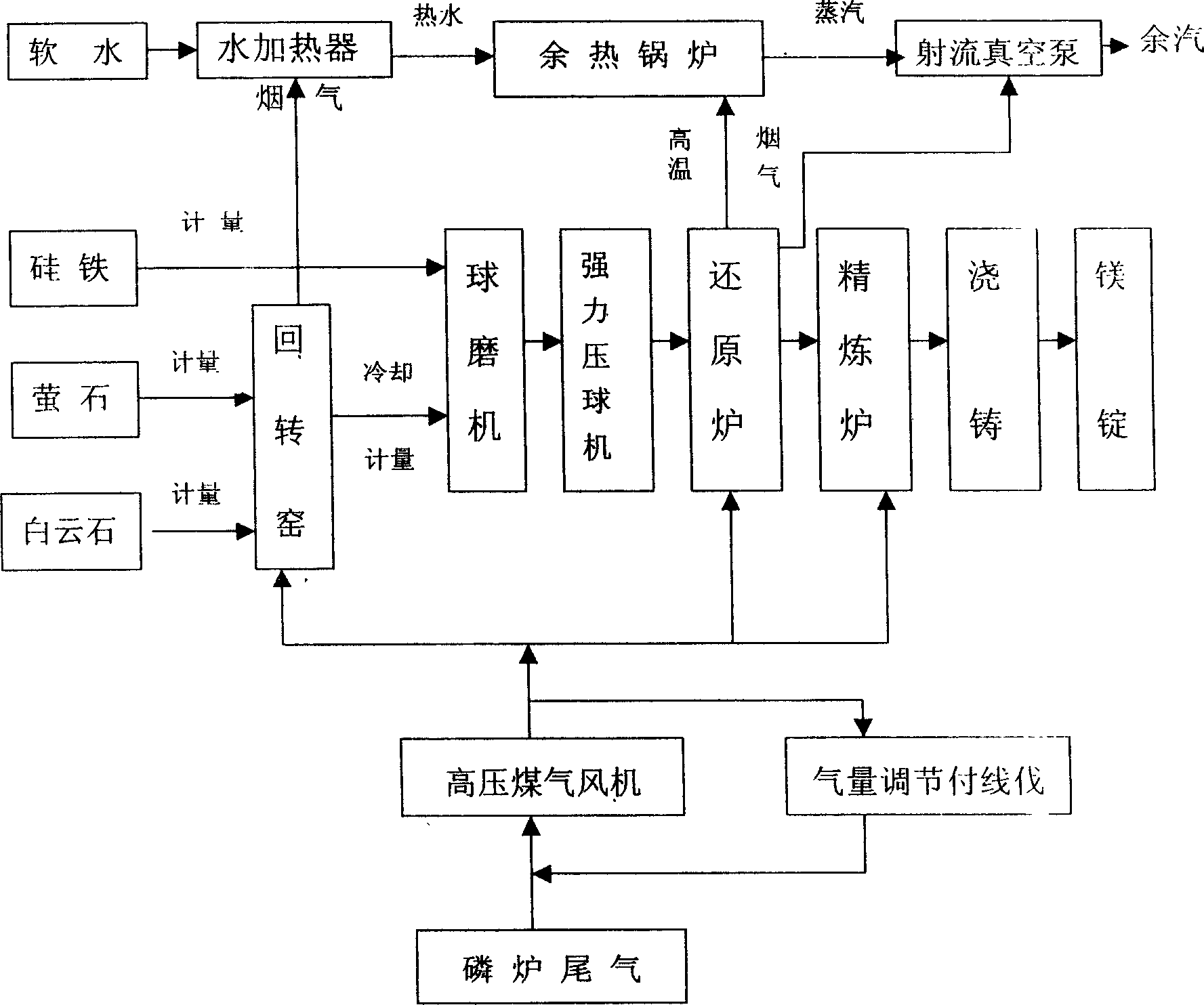

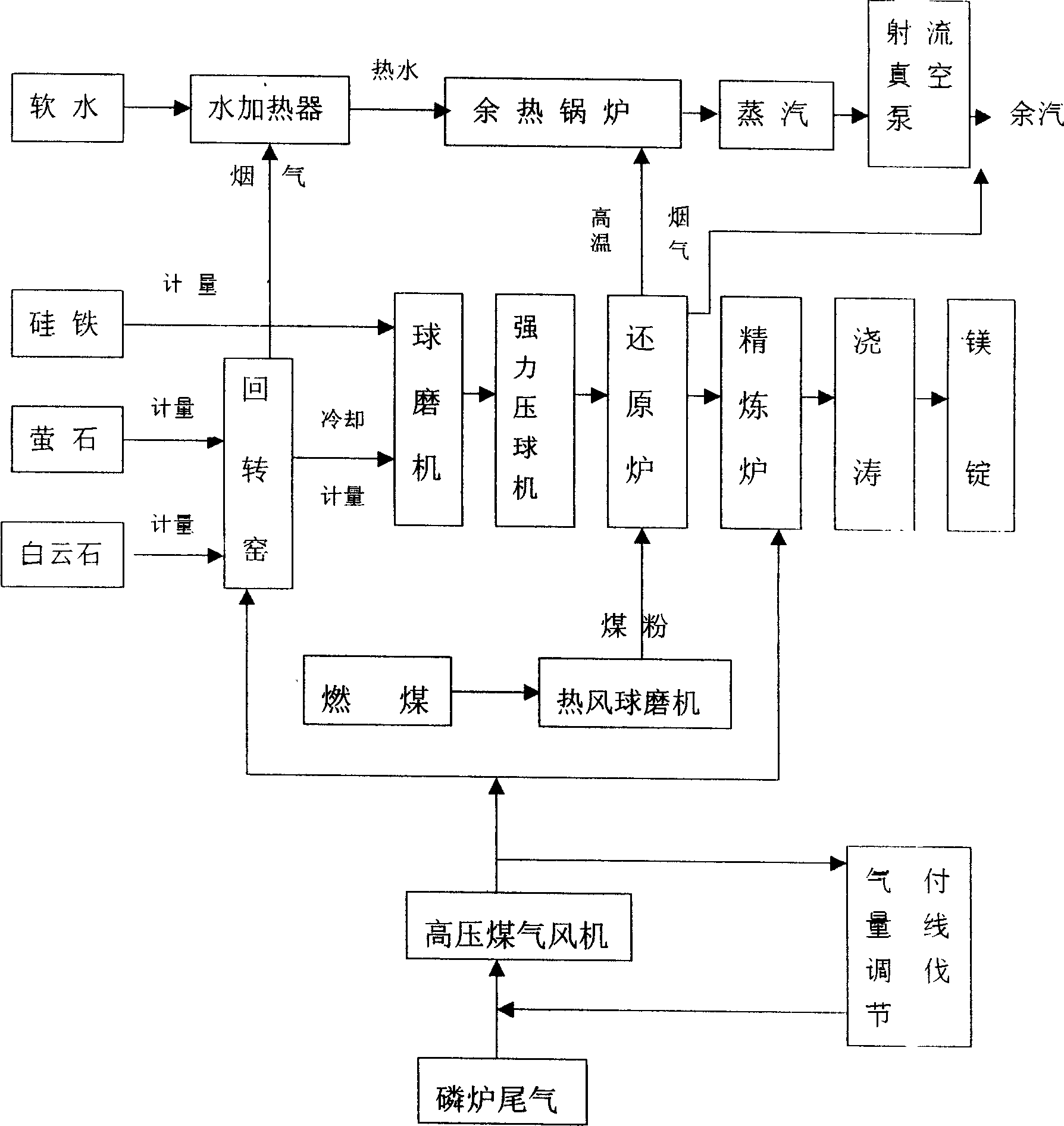

Process for producing metal magnesium by phosphorus furnace tail gas

This invention discloses a method of producing magnesium with phosphorus furnace tail gas, which relates to the production of alkali metal magnesium and utilization of phosphorus furnace tail gas, the purpose of this invention is to supply a technology of producing magnesium with yellow phosphorus electric furnace tail gas. This invention fixes hermetical transporting system composed of gas transmitting channel, high pressure gas fan and subsidiary line between close electric furnace yellow phosphorus producing devices and Pijiang method magnesium producing devices. Through this system phosphorus furnace tail gas is drawed out raised pressure to calcining white rotary kiln, deoxidizing furnace and refining furnace of Pijiang method producing magnesium devices, and burned by gas-fired burner set in the devices, which can be used to calcining white and deoxidize magnesium in Pijiang method producing magnesium or as heat source of melting magnesium when refining magnesium. There is valve on the gas transmitting channel and subsidiary line, which is used to adjust tail gas quantity and pressure.

Owner:李乾宽

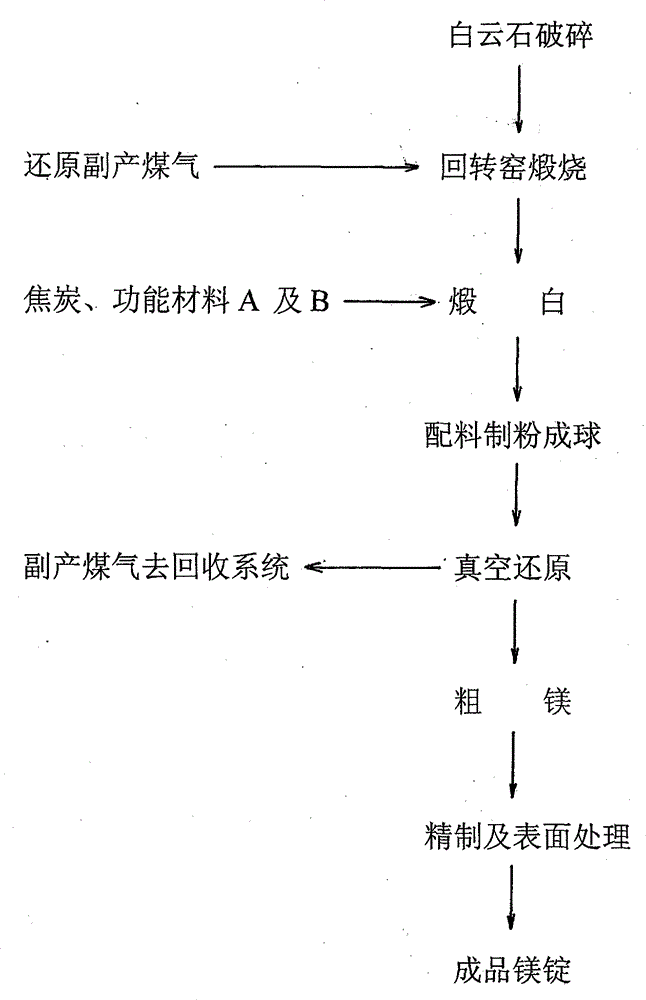

Method for preparing magnesium metal by calcined dolomite through carbon-thermal reduction

InactiveCN104611563AReduce manufacturing costIncrease profitWaste heat treatmentPidgeon processDolomite

The invention relates to a method for preparing magnesium metal by calcined dolomite through carbon-thermal reduction, which has the characteristics of energy saving, low carbon and environmental protection. The calcined dolomite is employed as a raw material, coke, coal or petroleum coke are taken as a main reducing agent, a functional material A is selected as an auxiliary reducing agent and a catalysis flux, and a functional material B is a displacement-type catalysis flux. The method comprises the following steps: fragmenting and pulverizing calcined dolomite, coke and the functional material A and the functional material B, mixing materials for molding and filling in a reduction jar, performing vacuum reduction under vacuum degree of 1-20Pa and reduction temperature of 1200-1300 DEG C to obtain the crude magnesium with purity of more than 91%. According to the invention, coke is taken as the main reducing agent for substituting ferrosilicon with high energy consumption, the by-product gas is taken as heat source of a production system, the production cost for magnesium metal by the technology in the invention is lower than that of the magnesium metal by a pidgeon process by more than 30%, production cycle is shortened to 8 hours from 12 hours, equipment utilization rate is increased, and characteristics of low carbon, energy saving and environmental protection are the most important highlights.

Owner:SHANGHAI JUBO ENERGY TECH CO LTD

Optimized magnesium slag-based cementing material and preparation method thereof

The invention discloses an optimized magnesium slag-based cementing material and a preparation method thereof. The optimized magnesium slag-based cementing material comprises optimized magnesium slag, and the optimized magnesium slag is magnesium slag obtained after modified magnesium slag is subjected to natural aging or hot casting treatment; the modified magnesium slag is magnesium slag obtained after activity maintaining and stability maintaining treatment is conducted on magnesium slag generated by Pidgeon magnesium smelting; the preparation method of the optimized magnesium slag-based cementing material comprises the following steps: obtaining modified magnesium slag in a magnesium smelting plant, and placing the modified magnesium slag in a slag field for natural aging or hot casting treatment to obtain an optimized magnesium slag raw material; and carrying out coarse crushing and fine crushing pretreatment on the optimized magnesium slag raw material to obtain an optimized magnesium slag material. The optimized magnesium slag-based cementing material provided by the invention can completely replace high-cost cement, greatly reduces the cost of the cementing material, provides a new utilization approach for solid waste treatment in two large pillar industries of coal chemical industry and magnesium smelting, and solves the problems of long setting time and low consolidation strength in the middle and early periods of the magnesium slag cementing material.

Owner:西安弗尔绿创矿业科技有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com