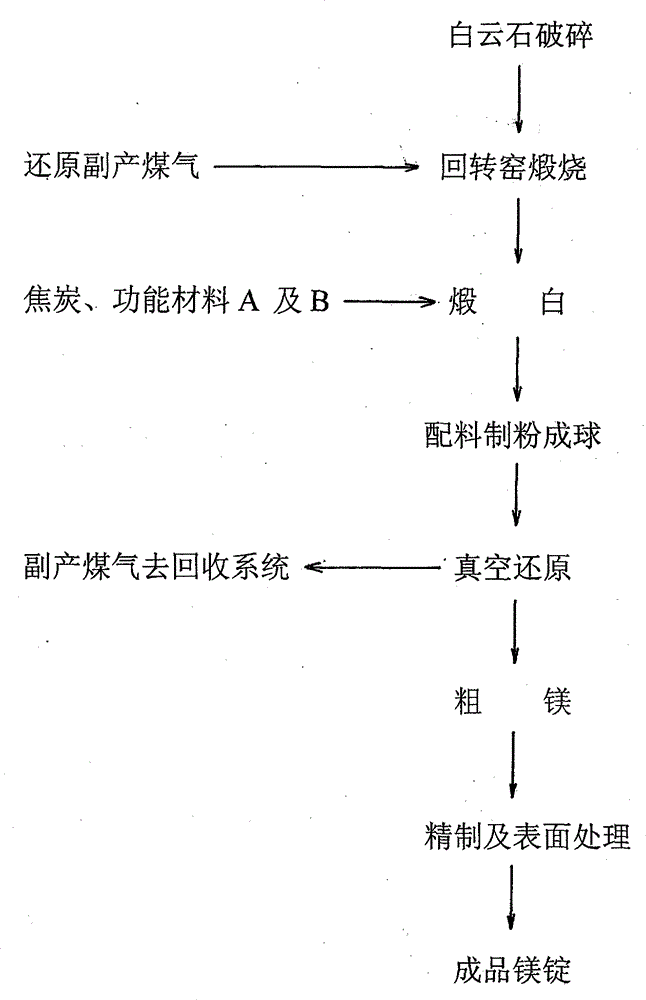

Method for preparing magnesium metal by calcined dolomite through carbon-thermal reduction

A metal magnesium, calcined white technology, applied in lighting and heating equipment, waste heat treatment, furnace components, etc., can solve the problems of complex cooling equipment, easy explosion of magnesium powder and high temperature CO, and high cost of reducing agents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The calcined white, coke and functional materials A and B containing MgO≥36wt% are crushed to 100---120 mesh, and the ingredients are prepared according to the ratio of C:MgO.CaO:A:B=5.30:81.50:12.34:0.96. Mixing powder making and pelletizing; the fixed carbon content of coke is 85wt%, in functional material A, SiC:MgF 2 :=90:10, the particle size of B is 100 mesh, put the ball into the reduction tank, and carry out the vacuum reduction for 6 to 7 hours under the condition of vacuum degree of 20Pa and reduction temperature of 1230---1250℃, and the gaseous state The magnesium is cooled under the condition of 580-680°C in the condenser to obtain crude magnesium with a purity of more than 83.2%, and the output rate of crude magnesium is 79.6%.

Embodiment 2

[0016] The calcined white, coke and functional materials A and B containing MgO≥38wt% are crushed to 100---120 mesh, and the ingredients are prepared according to the ratio of C:MgO.CaO:A:B=5.30:81.50:12.34:0.96. Mixing powder making and pelletizing; the fixed carbon content of coke is 85wt%, in functional material A, SiC:MgF 2 =95:5, the particle size of B is 100 mesh, put the ball into the reduction tank, and carry out the vacuum reduction for 6 to 7 hours under the conditions of vacuum degree of 10Pa and reduction temperature of 1250---1270°C, while the gaseous magnesium The crude magnesium with a purity of more than 86.1% is obtained by cooling in the condenser at 580-680° C., and the yield of crude magnesium is 83.4%.

Embodiment 3

[0018] The calcined white, coke and functional materials A and B containing MgO≥40wt% are crushed to 100---120 mesh, and the ingredients are prepared according to the ratio of C:MgO.CaO:A:B=5.30:81.50:12.34:0.96. Mixing powder making and pelletizing; the fixed carbon content of coke is 85wt%, in functional material A, SiC:MgF 2 =96:4, the particle size of B is 100 mesh, put the ball into the reduction tank, and carry out the vacuum reduction for 6 to 7 hours under the condition of vacuum degree of 5Pa and reduction temperature of 1270---1300°C, while the gaseous magnesium The crude magnesium with a purity of over 88.3.0% is obtained by cooling in a condenser at 580-680° C., and the yield of crude magnesium is 86.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com