Method and device for intermittently and continuously smelting crystallized magnesium by Pidgeon process reduction tank

A reduction tank, intermittent technology, applied in the field of Pidgeon method reduction tank intermittent continuous smelting of crystalline magnesium, can solve the problems of shortened reaction time, short life of the reduction tank, fragile material balls, etc., to reduce costs and avoid materials Performance damage and destruction, effect of prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

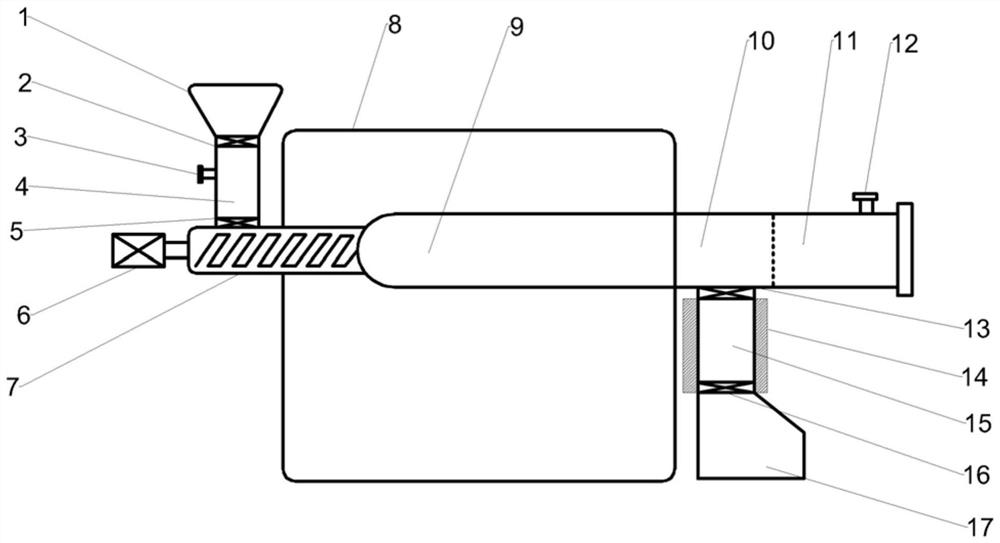

[0039] like figure 1 As shown, the embodiment of the present invention provides a batch-type continuous device for reduction tanks for Pidgeon process magnesium metallurgy. In the device of the present invention, the device of the present invention is divided into three parts, and the left part is the continuous feeding functional area. Including: feed bin 1, first and second electronic valves 2, 5, first vacuum valve 3, feed replacement bin 4, motor 6 and screw feeder 7; the middle part is the reaction function area, including: furnace body 8 , reduction tank body (comprising reaction area 9, transition area 10 and crystallization area 11) and second vacuum valve 12; The lower right part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com