Novel reduction method in pidgeon magnesium refining process

A magnesium smelting and process technology, applied in the field of new reduction, can solve the problems of increased energy consumption in the process, affecting the reduction efficiency, and the material cannot be effectively reduced, and achieves the effect of reducing the reduction temperature, shortening the reduction time, and fully reducing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] 1. Calcining of dolomite;

[0013] 2. Ingredients for making balls: Calcined white, ferrosilicon powder (75% Si) and fluorite powder (94% CaF 2 ) according to the weight ratio of 79.8:17.1:3.1 to measure ingredients, grind, and then press into balls.

[0014] Reduction: Heat 190kg pellets in a Φ377×3100 reduction tank to 1200°C, keep it at 0.5 rpm for 5 to 7 hours under a vacuum condition of less than 13.3Pa, and magnesium oxide will be reduced to magnesium vapor, which will crystallize into coarse magnesium.

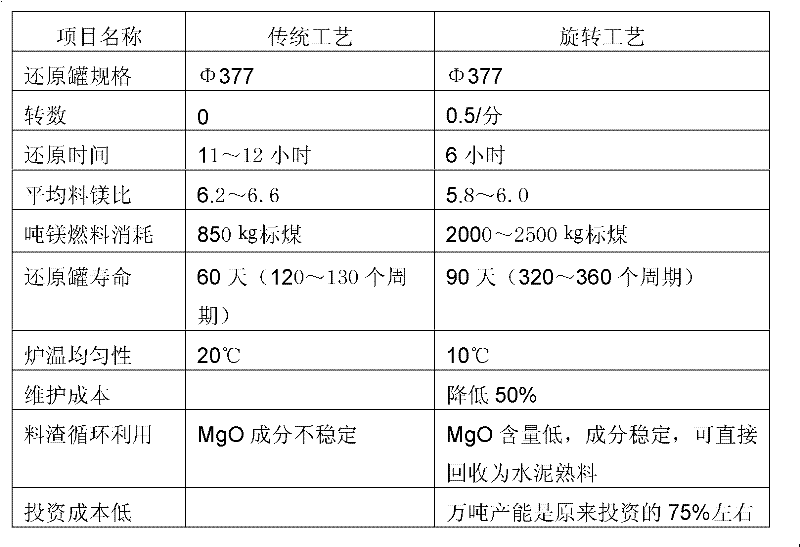

[0015] The difference between the method of the present invention and the existing reduction method is that the original static reduction tank is rotated to achieve high-efficiency reduction. By comparing the experimental results, the following index comparison table of the old and new processes is obtained:

[0016]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com