Magnesium slag baking-free brick and preparation method thereof

A technology of burn-free bricks and magnesium slag, applied in the field of burn-free bricks, can solve the problems of large differences in structure and performance of hydration products, long curing time of burn-free bricks, and harsh curing conditions, and achieve low prices and mild curing conditions , The effect of low product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of magnesia slag unburned bricks:

[0037] (1) Weigh water-reduced magnesium slag 168, fly ash 80, river sand 104, gypsum 16, clinker 32, and mix the above raw materials evenly;

[0038] (2) Add 32 grams of drinking water, use a mortar mixer to stir for 4 minutes, transfer the material to the aging pond and cover it with a plastic film to prevent the water from evaporating, and stew the material for 1 hour;

[0039] (3) The aged material is put into the non-burning brick forming mold (set mold, diameter 5cm, upper mandrel and lower mandrel, demoulding sleeve), and pressurized (pressurization conditions: press with 0.3KN / s to pressurize to 36.0KN), hold the pressure for two minutes and remove the mold;

[0040] (4) After removing the formwork, cover the test block with a plastic film, put it in the curing room for natural curing for 3 days, and obtain the magnesium slag unburned brick.

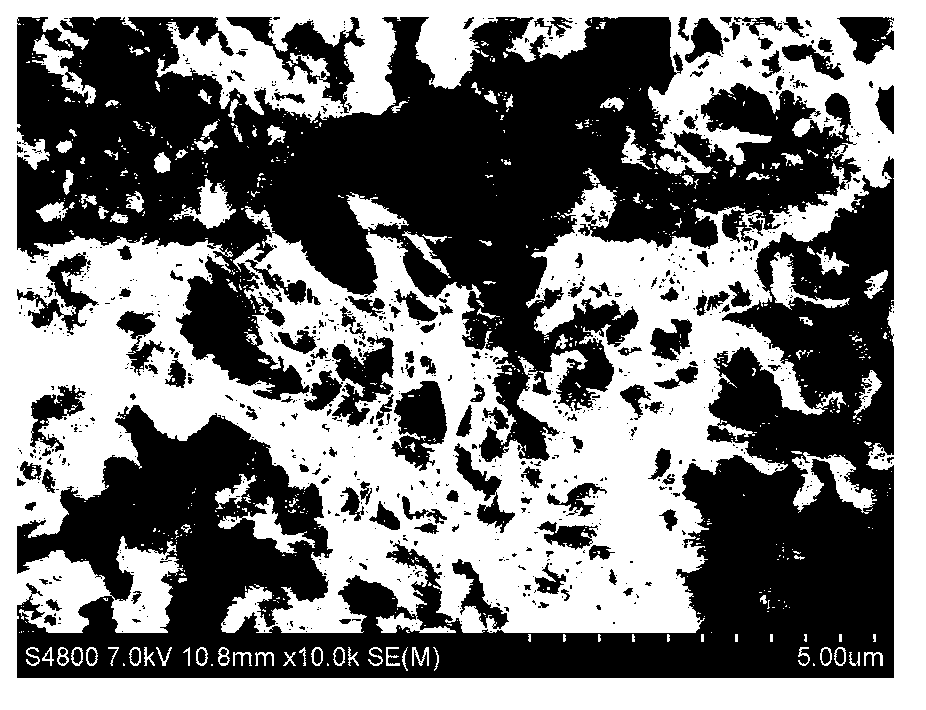

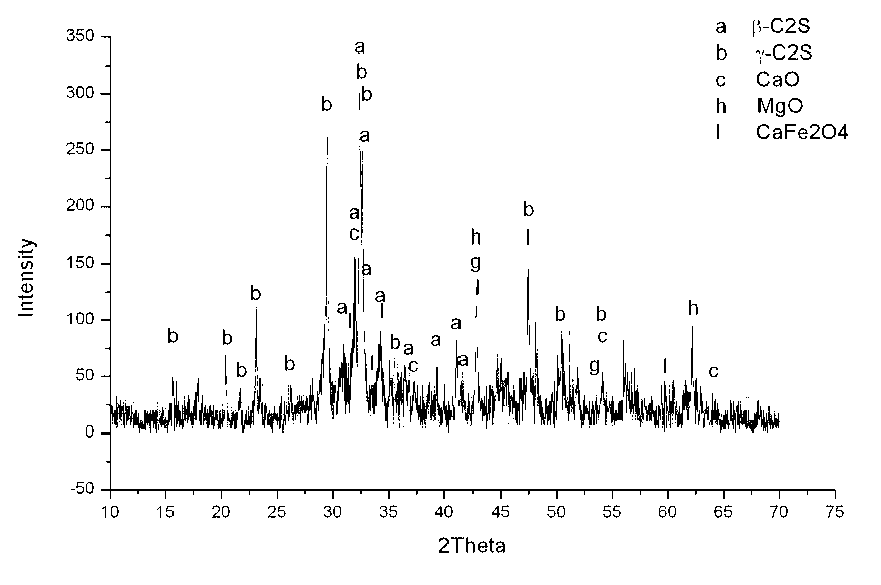

[0041] The raw materials and the obtained products were studied and c...

Embodiment 2-7

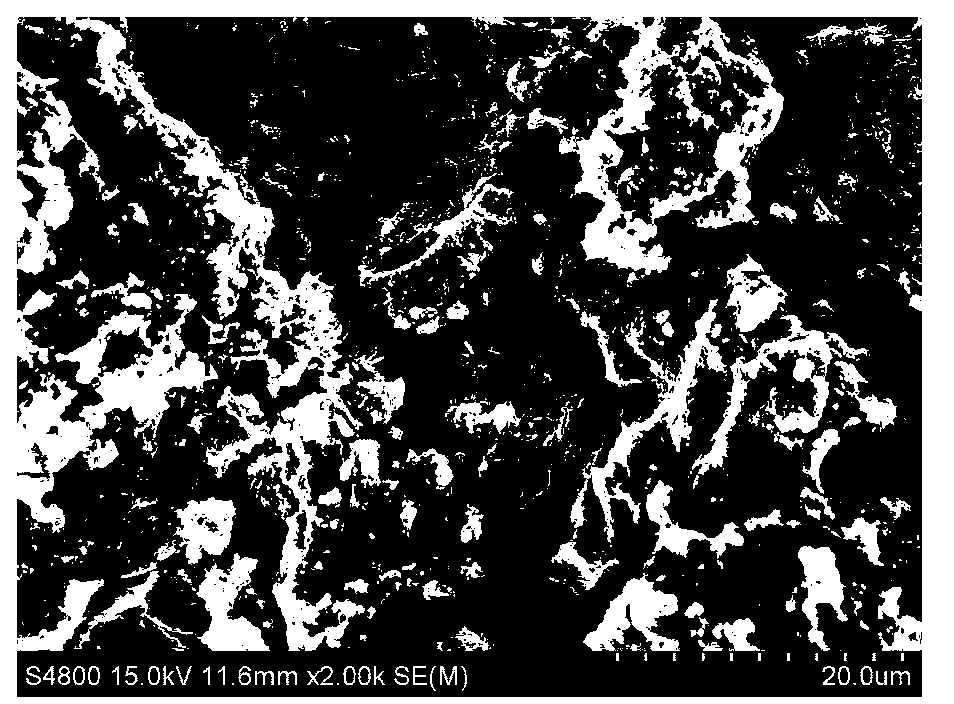

[0048] Take by weighing water drenching reduction magnesium slag, fly ash, river sand, gypsum, clinker according to the table, above raw materials are mixed uniformly; All the other conditions are with embodiment 1, to embodiment 2, 4, 6 gained products are respectively used SEM etc. The morphology and structure characterization analysis was carried out, and the results are as follows Image 6 , 7 , 8; Research on the compressive properties of the products obtained in Examples 1-7. The result is as Figure 9 , 10

[0049] Table 1 embodiment raw material ratio table

[0050] Example

Sprinkling water to reduce magnesium slag

fly ash

river sand

plaster

Clinker

analysis results

Sprinkling water to reduce magnesium slag

figure 1 、 2

1

168

80

104

16

32

image 3 、 4 、5

Figure 9

2

200

48

104

16

32

Image 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com