Technology for preparing magnesium metal by magnesium oxide aluminothermic reduction method

A magnesia-alumina and reduction technology, which is applied in the field of magnesium-aluminothermic reduction of magnesium metal, can solve the problems of high energy consumption, poor environmental compatibility, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

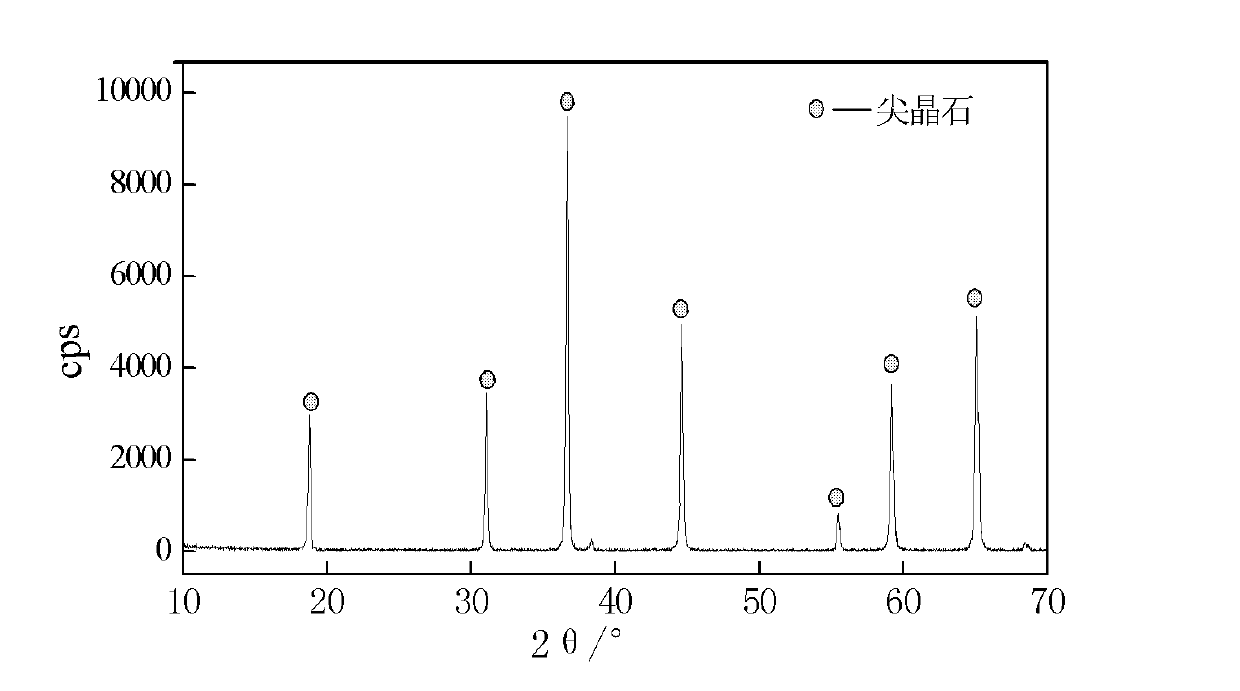

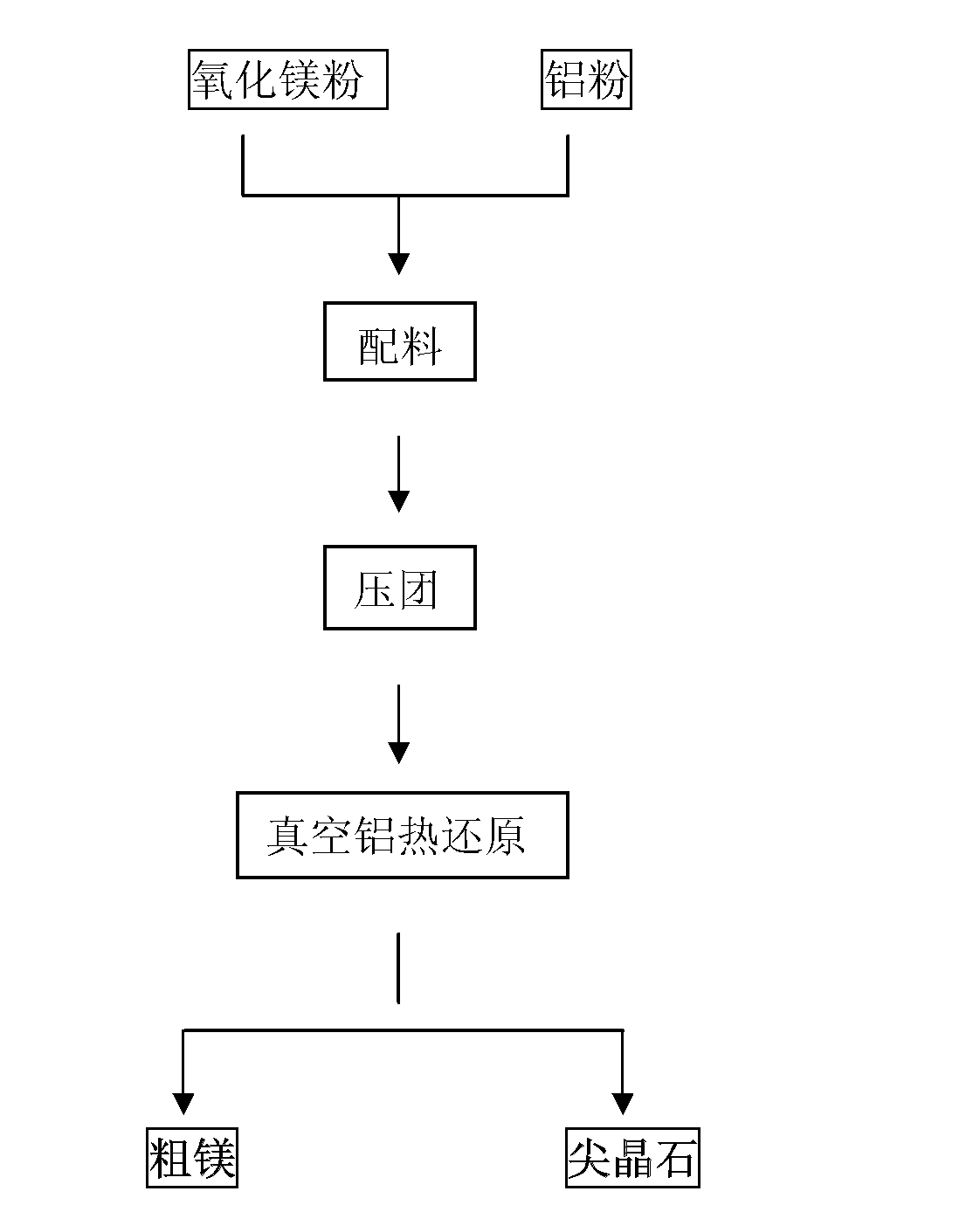

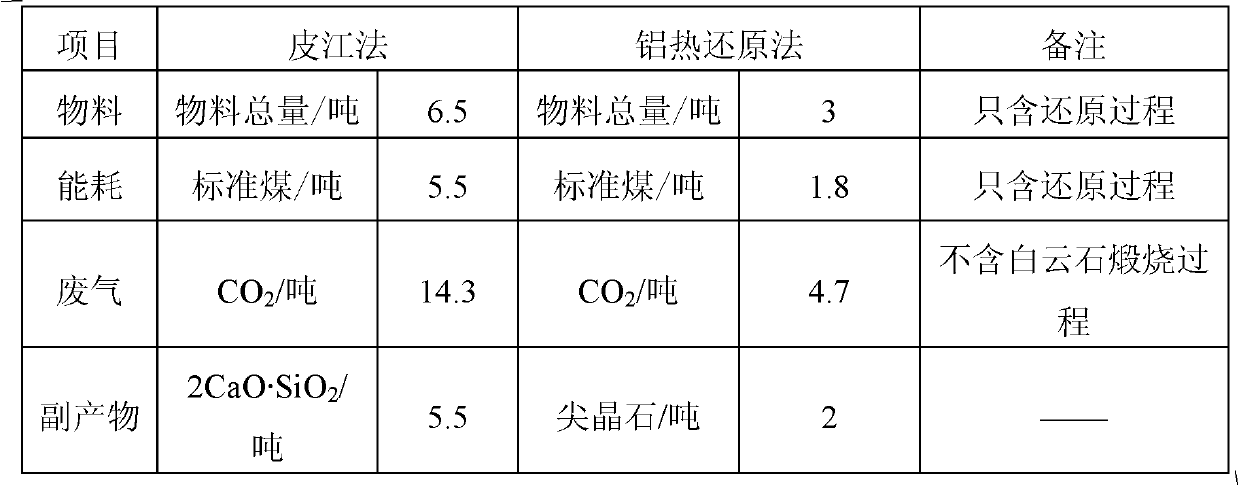

[0033] Process flow of the present invention such as figure 2 shown. A process for preparing metallic magnesium by the aluminothermic reduction method of magnesia in the present invention adopts magnesia powder as raw material, aluminum powder as reducing agent, and then carries out batching. Aluminothermic reduction is a vacuum smelting process to generate coarse magnesium and spinel (MgAl 2 o 4 ).

[0034] Specifically, the technical process of the present invention is to mix the magnesium oxide powder with a particle size of 100 to 200 mesh and the aluminum powder with a particle size of 70 to 100 mesh in a molar ratio of 2: (1.0 to 1.2); Pressed into briquettes under the condition of 40 MPa. Put the pressed agglomerate into a reduction furnace, vacuumize to 1-13.3Pa, and react for 3-6 hours at 1050-1150°C. The reaction produces crude magnesium, and the by-product spinel powder can be used as products, and there is no waste residue discharge in the whole process. Its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com