Loading device for smelting magnesium by Pidgeon process

A charging device and magnesium smelting technology, which is applied to lighting and heating equipment, furnace components, furnaces, etc., can solve the problems of high labor intensity for workers, large fluctuations in furnace temperature, and harsh working environment, and achieve considerable economic benefits. Effect of reducing fuel consumption and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

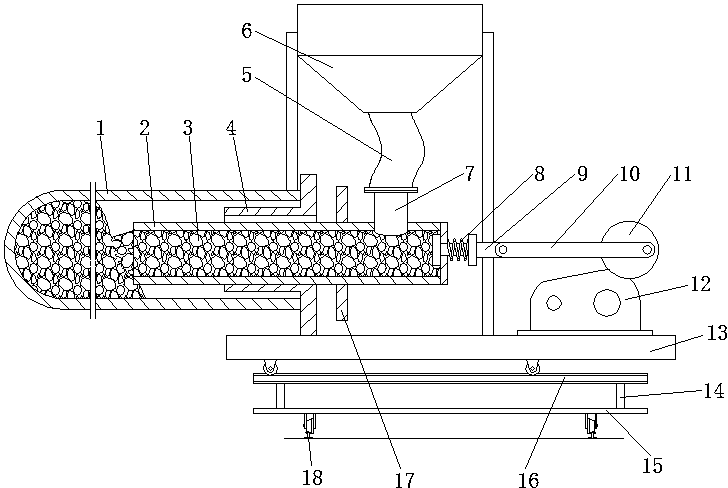

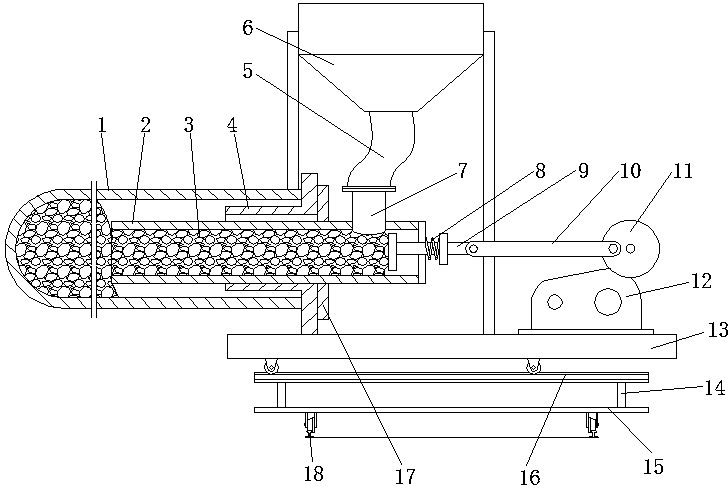

[0025] Such as figure 1 , 2 The front is shown on the left, and the rear is shown on the right. A silo 6 is installed on the longitudinally moving trolley 13, and the material outlet on the hopper and the inlet 7 on the feeding pipe 2 are connected through a soft connection 5, so that the raw materials in the silo can pass through the outlet, the soft connection , The feeding port on the feeding pipe enters into the feeding pipe. Since the feeding pipe moves back and forth in a straight line from left to right, while the feed bin is fixed, the problem of dynamic and static connection can be solved by using soft connection.

[0026] A power device 12 is installed on the longitudinally moving trolley 13, and the crank slider mechanism is driven by the power device to change the rotary motion into a linear movement of the slider, and the material 3 in the feeding pipe is pushed into the metal magnesium reaction tank 1 to realize loading. Mechanization of material work.

[002...

Embodiment 2

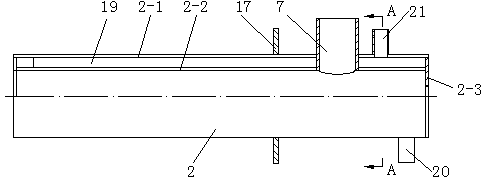

[0037] Such as Figure 6 , 7 , 8, on the basis of Embodiment 1, the structure of the feed pipe 2 cooling devices has been changed, specifically six partitions 19 fixed along its axis are evenly distributed in the closed jacket inner cavity, and the feed pipe The inner cavity of the jacket is divided into 6 chambers, of which the left and right ends of the three spaced partitions are closed with the two ends of the feeding pipe, and the right end of the other three spaced partitions is closed with the right end of the feeding pipe, and the left end is closed with the feeding pipe. There is a gap on the left end of the material pipe, and 3 cooling medium inlet pipes 21-2 and 3 cooling medium outlet pipes 20-2, 3 cooling medium inlet pipes and 3 The cooling medium outlet pipe is respectively connected through the semi-arc-shaped inlet arc-shaped pipe 21-1 and the semi-arc-shaped discharge arc-shaped pipe 20-1. The cooling medium inlet 21 and the cooling medium outlet 20, the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com