Process for producing metal magnesium by phosphorus furnace tail gas

A technology of phosphorus furnace tail gas and metal magnesium, which is applied in the field of utilization of tail gas in the production of yellow phosphorus by electric furnace method, to achieve the effects of enhancing resistance, reducing pollution and reducing environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

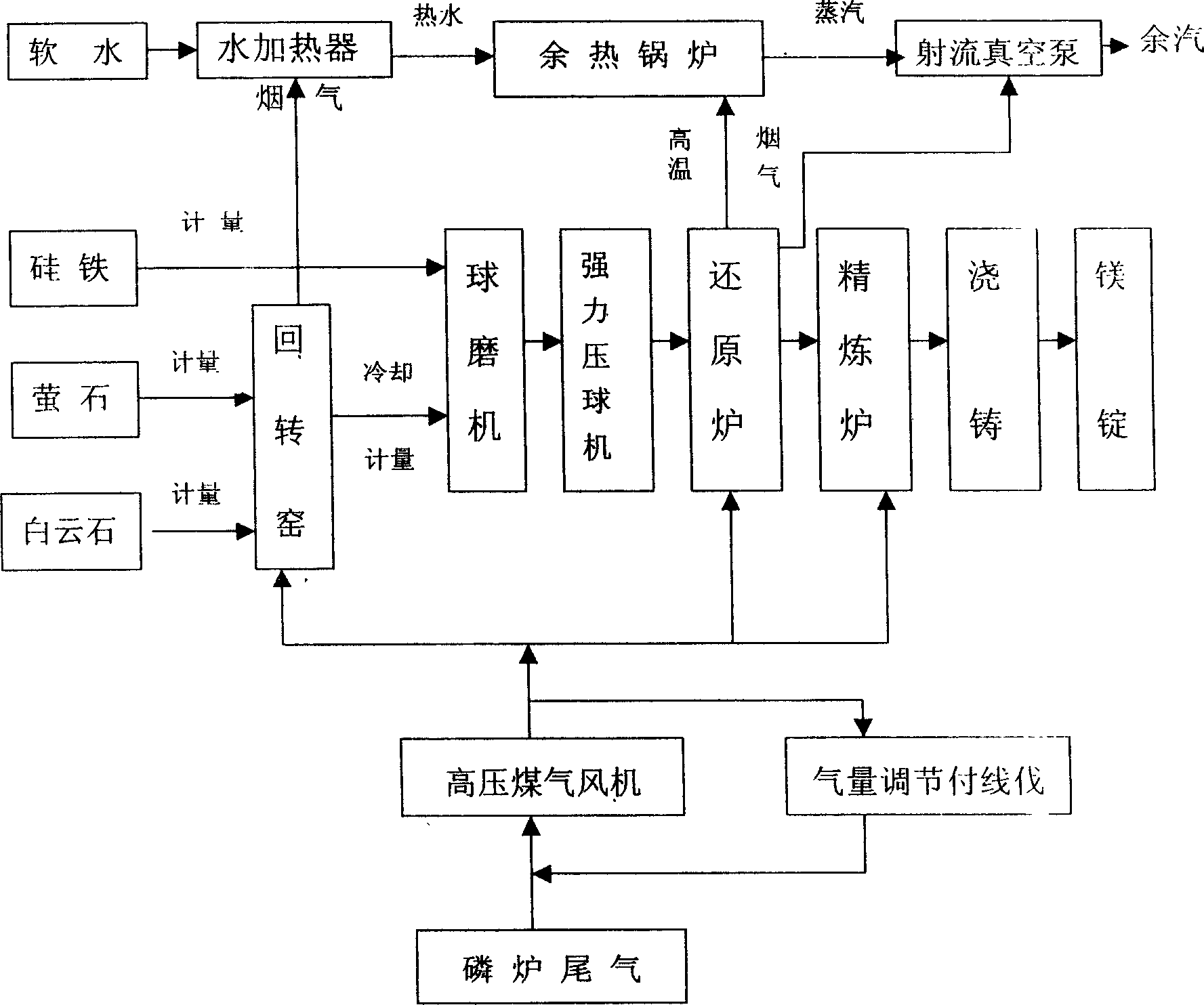

[0013] Embodiment 1: fully use phosphorus furnace tail gas as fuel to produce metallic magnesium

[0014] The specific process flow is shown in Figure 1. A sealed tail gas delivery system consisting of a gas pipeline, a high-pressure gas fan and a secondary line is installed between the adjacent electric furnace yellow phosphorus production unit and the Pidgeon method metal magnesium production unit. The system extracts and pressurizes the exhaust gas from the phosphorus furnace to the calcined white rotary kiln, reduction furnace and refining furnace of the Pidgeon process magnesium production plant, and uses an appropriate amount of air for combustion, and burns through the gas burners installed in the above equipment , calcining dolomite into magnesium lime, reducing metal magnesium, and melting magnesium when metal magnesium is refined. Among them, the temperature of the rotary kiln and reduction furnace is controlled at about 1200°C, and the temperature of the refining fu...

Embodiment 2

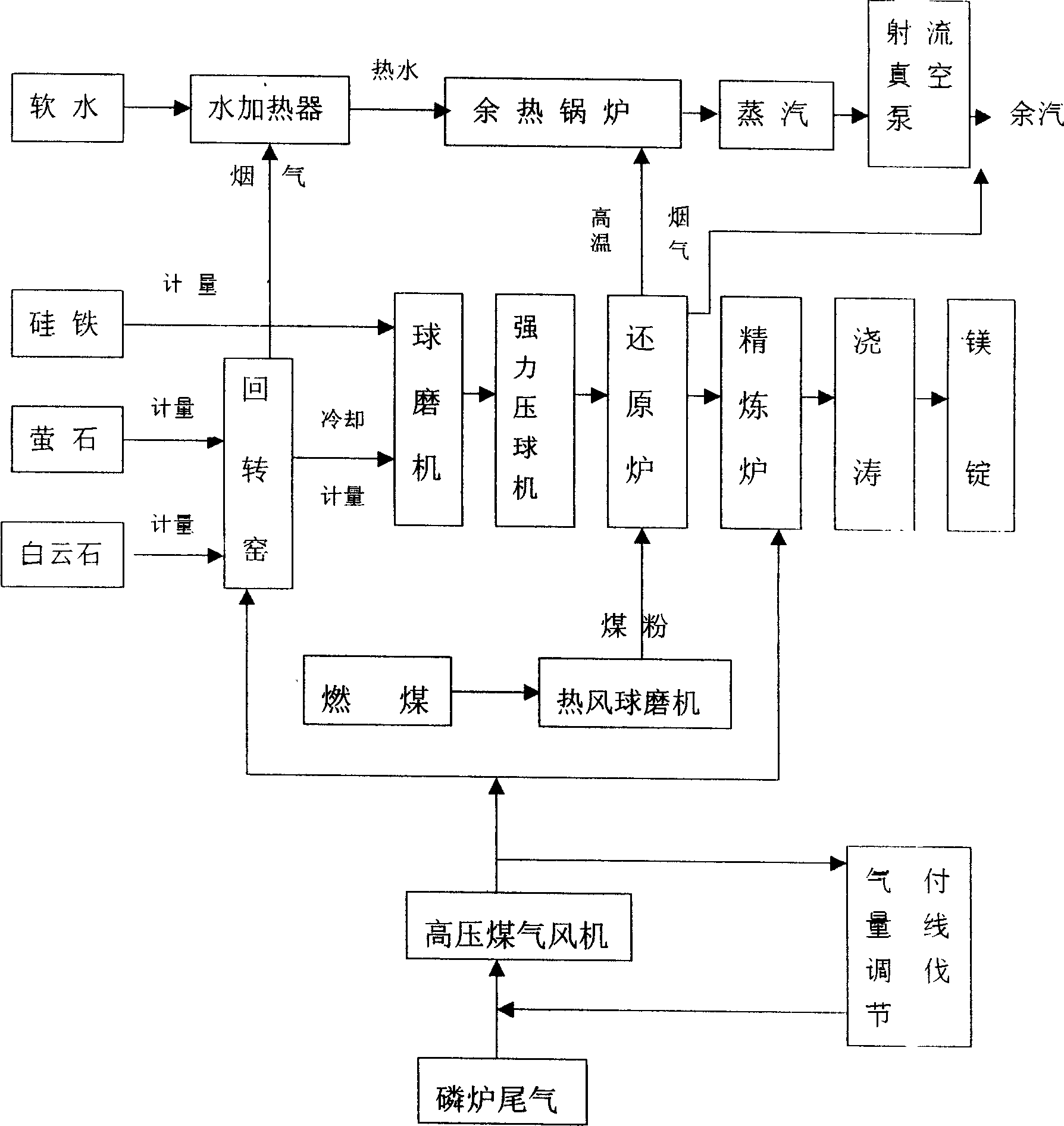

[0015] Embodiment 2: use coal combustion to cooperate with phosphorus furnace tail gas as fuel

[0016] The specific process flow is shown in Figure 2. Between the adjacent electric furnace yellow phosphorus production unit and the Pidgeon method metal magnesium production unit, a sealed tail gas delivery system consisting of a gas pipeline, a high-pressure gas fan and a secondary line is installed. The system extracts and pressurizes the tail gas of the phosphorus furnace to the calcined white rotary kiln and refining furnace of the Pidgeon method magnesium production device, and uses an appropriate amount of air for combustion. The gas burner installed in the equipment burns the dolomite Calcined into magnesium lime at 1200°C, melting magnesium at 700-750°C during metal magnesium refining; and building the reduction furnace into a coal-fired reverberatory furnace, using coal with a calorific value higher than 20930kJ / kg as fuel, reaching 1200°C Requirements, and stable for 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Calorific value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com