Method for preparing silicon-potash fertilizer based on magnesium slag

A technology of silicon-potassium fertilizer and magnesium slag, which is applied in the direction of fertilization equipment, fertilizer mixture, application, etc., can solve the problems such as the large influence of the composition of magnesium slag, and achieve the effects of low raw material cost, simple processing technology, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The main components of potassium feldspar are: K 2 O 9.45%, SiO 2 62.06%, Al 2 o 3 21.45%, Fe 2 o 3 1.08%;

[0023] The main components of magnesium slag are: SiO 2 25.36%, CaO 59.54%, MgO 2.96%, Al 2 o 3 3.30%, Fe 2 o 3 3.93% etc.

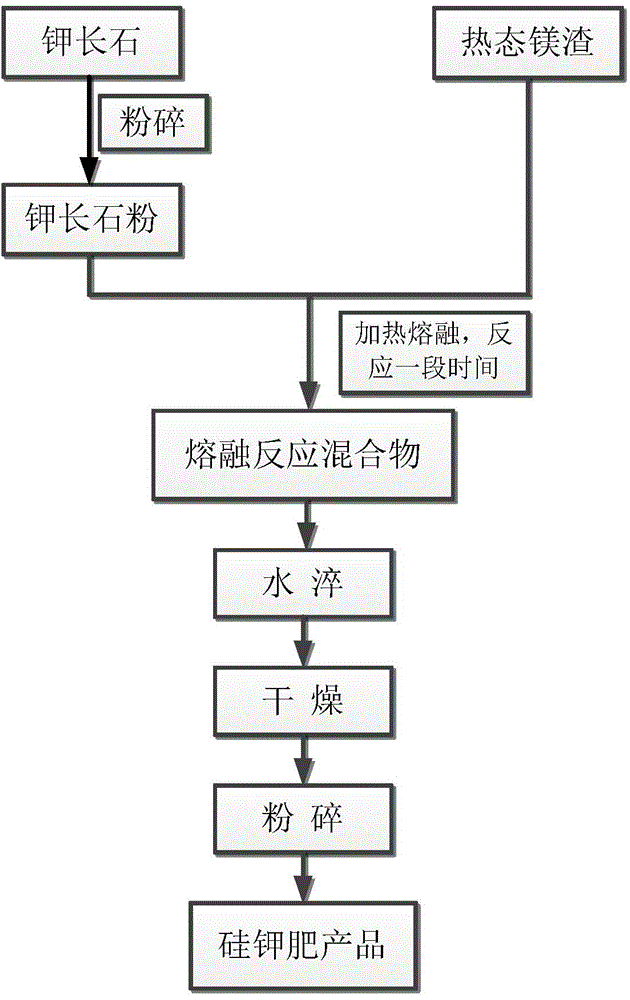

[0024] Preparation method: mix 55% magnesium slag and 45% potassium feldspar powder, melt at 1350°C at high temperature, and keep for 60 minutes after the melting reaction; then take out the melt, water quench, dry, and pulverize to obtain silicon potassium fertilizer.

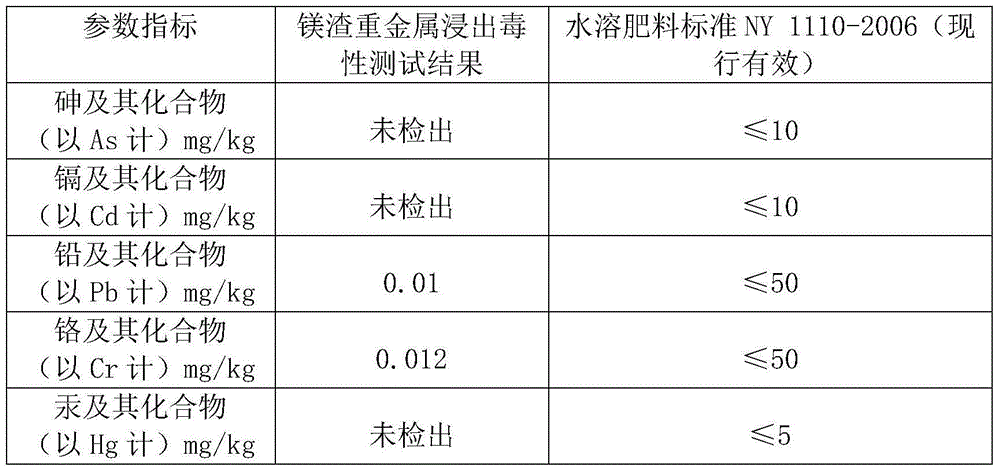

[0025] The silicon-potassium fertilizer produced by the method has an effective potassium content of 5 percent and an effective silicon content of 30 percent to 40 percent, which is higher than that of silicon-potassium fertilizers on the market. At the same time, it has the characteristics of non-toxic, odorless, non-corrosive, long-lasting fertilizer effect, and not easy to lose. The silicon-potassium fertilizer prepared by the method also contains nutrie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com