Novel process for continuously smelting magnesium metal with electric furnace

An electric furnace smelting and metal magnesium technology, which is applied in the field of electric furnace microwave heating and smelting metal magnesium, can solve the problems of pollution, low thermal efficiency, and high labor intensity, and achieve the effects of removing dust pollution, saving heat energy, and improving the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

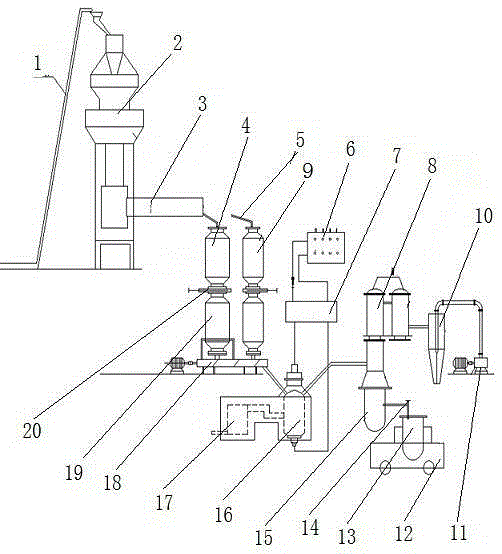

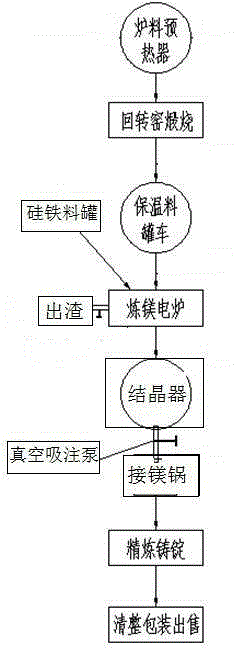

[0025] figure 1 As shown, the process equipment for smelting metal magnesium by continuous method includes furnace charge preheater 2, rotary kiln 3, movable heat preservation tank 4, fixed heat preservation tank 19, screw conveyor 18, microwave electric furnace 16, crystallizer, magnesium pot 13 , vacuum injection pump 14, magnesium pot 15; the movable insulation tank 4 and the fixed insulation tank 19 are connected by a heat-resistant gate valve 20; the fixed insulation tank 19 is provided with a screw conveyor 18 and a screw conveyor 18 Connect the microwave electric furnace 16, the microwave electric furnace 16 is connected with the crystallizer through the aisle on the top of the furnace, the potassium-sodium separator 8 is connected above the crystallizer, and the potassium-sodium separator 8 is connected with the dust collector 10; The pot 13 below is provided with the magnesium pot 15, and the magnesium pot 15 is arranged on the leveling car 12.

[0026] The preheater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com