Preparation method of high-performance magnesium slag

A high-performance, magnesium slag technology, applied in the field of high-performance magnesium slag, can solve the problems of difficult utilization of metal magnesium slag, unstable mineral composition, poor stability, etc., and achieve the effects of easy to master, low price and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing high-performance magnesium slag is prepared by using dilute acid solution and high-temperature metal magnesium slag just out of the tank produced in the process of producing metal magnesium by the Pidgeon method as raw materials, specifically: taking the high-temperature metal just out of the tank Magnesium slag is sprayed with dilute acid solution for rapid cooling, and after the spray treatment is completed, it is dried naturally, and finally the high-performance magnesium slag is obtained; wherein, the dilute acid solution is prepared by diluting industrial waste dilute sulfuric acid The resulting acidic aqueous solution, the acid concentration is determined by the H in the solution + Calculated as 0.02mol / L; when spraying, spray 0.35m per ton of high-temperature magnesium slag 3 dilute acid solution.

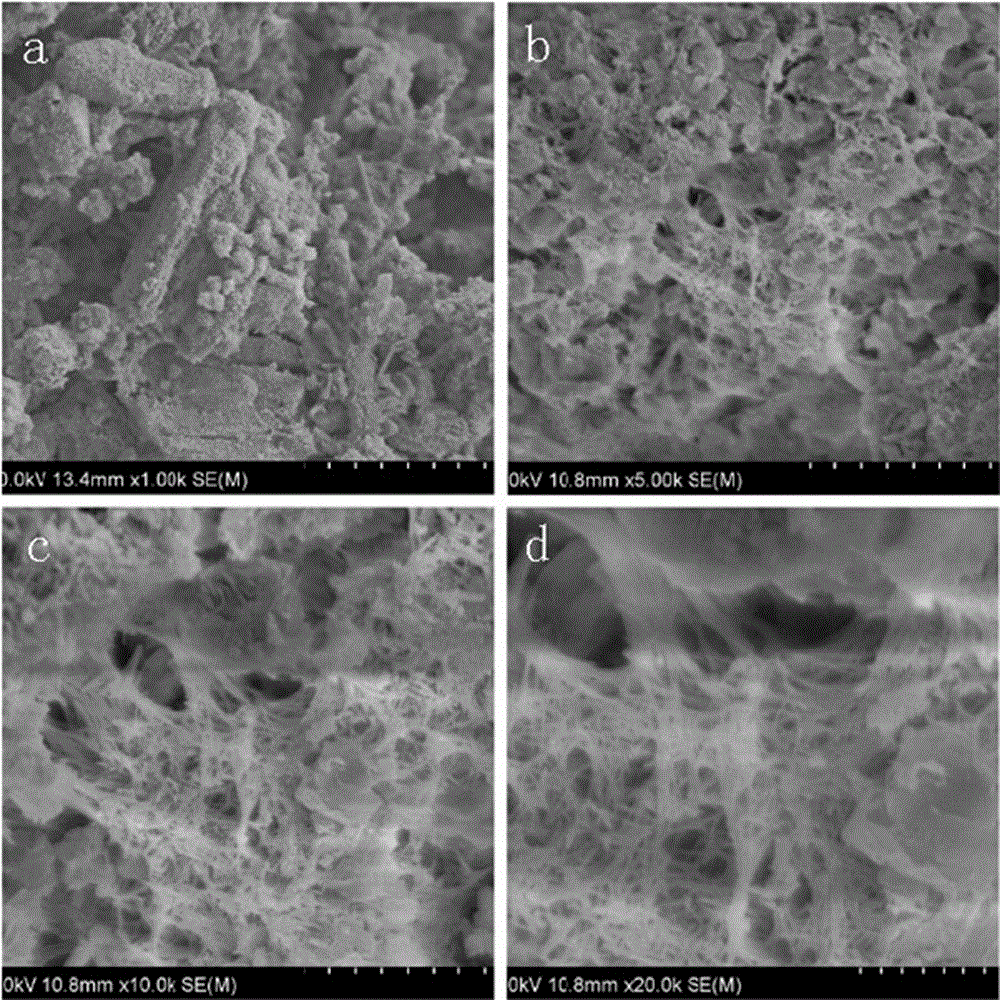

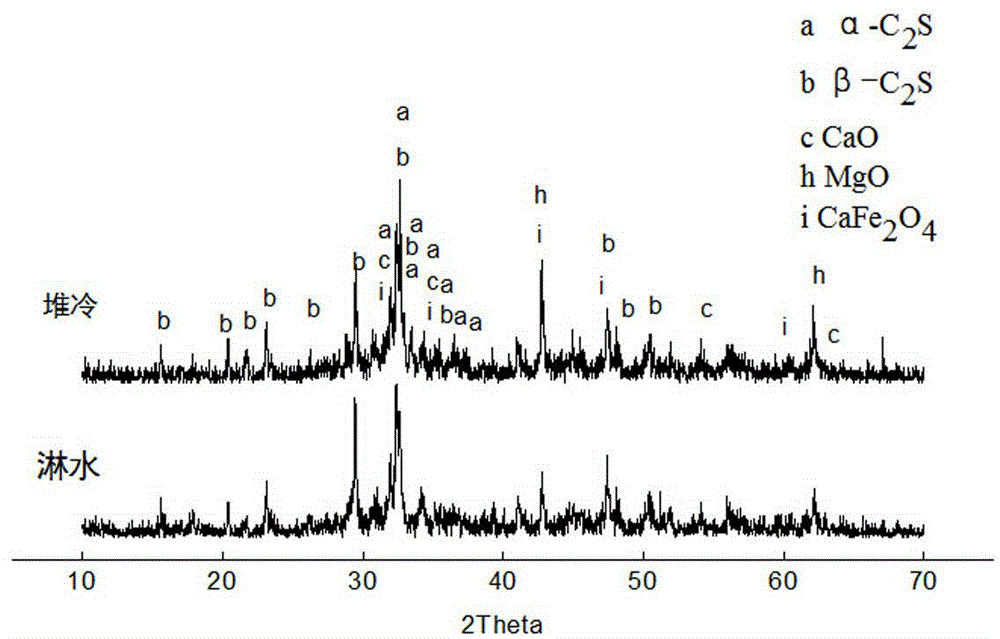

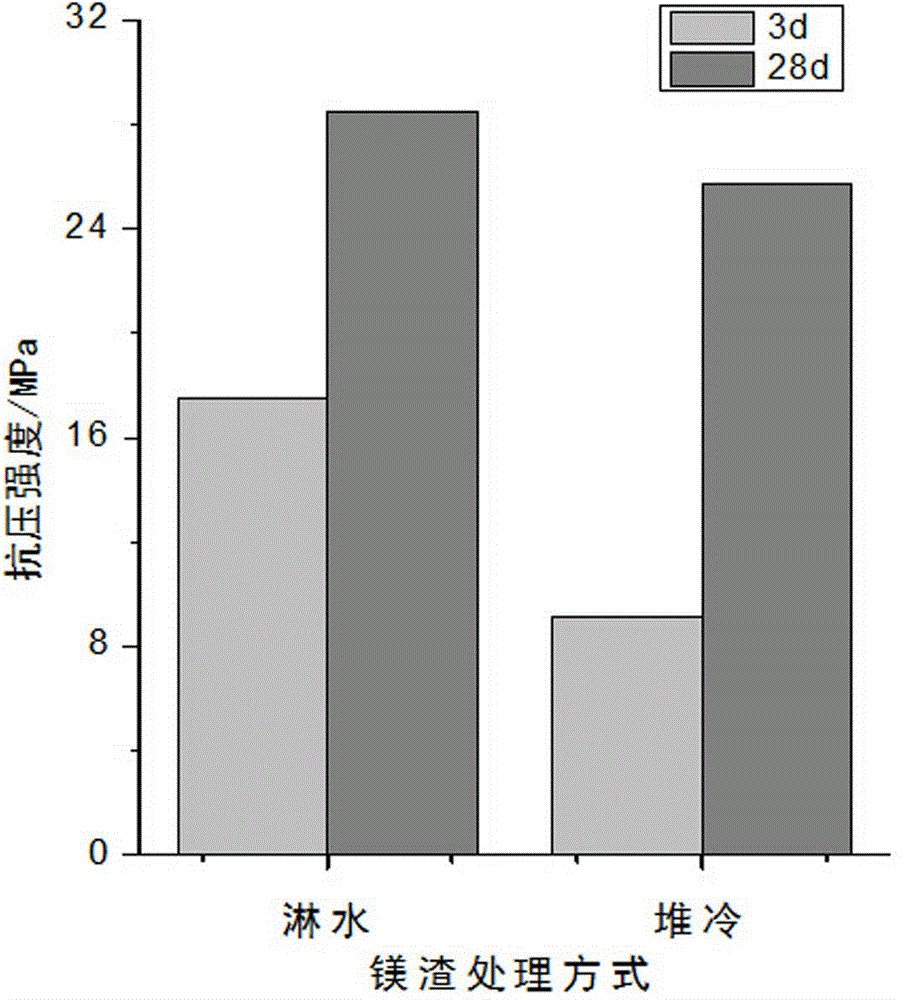

[0025] The mineral composition and morphology of the obtained high-performance magnesium slag were characterized by XRD and SEM.

[0026] fi...

Embodiment 2

[0032] A method for preparing high-performance magnesium slag is prepared by using dilute acid solution and high-temperature metal magnesium slag just out of the tank produced in the process of producing metal magnesium by the Pidgeon method as raw materials, specifically: taking the high-temperature metal just out of the tank Magnesium slag is sprayed with dilute acid solution for rapid cooling, and then dried after the spray treatment is completed, and finally the high-performance magnesium slag is obtained; wherein, the dilute acid solution is prepared by diluting industrial waste dilute sulfuric acid The resulting acidic aqueous solution, the acid concentration is determined by the H in the solution + Calculated as 0.05mol / L; when spraying, spray 0.1m per ton of high-temperature magnesium slag 3 dilute acid solution.

Embodiment 3

[0034]A method for preparing high-performance magnesium slag is prepared by using dilute acid solution and high-temperature metal magnesium slag just out of the tank produced in the process of producing metal magnesium by the Pidgeon method as raw materials, specifically: taking the high-temperature metal just out of the tank Magnesium slag is sprayed with dilute acid solution for rapid cooling, and after the spray treatment is completed, it is dried naturally, and finally the high-performance magnesium slag is obtained; wherein, the dilute acid solution is prepared by diluting industrial waste dilute sulfuric acid The resulting acidic aqueous solution, the acid concentration is determined by the H in the solution + Calculated as 0.01mol / L; when spraying, spray 0.5m per ton of high-temperature metal magnesium slag 3 dilute acid solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com