Magnesium slag modifier and magnesium slag modification method

A technology of modifier and magnesium slag, applied in the field of pollution control, to achieve the effect of increasing the amount of addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: Magnesium slag is crossed 60 mesh sieves, add boric acid, mix evenly by boric acid: magnesium slag=1: 200-340 (weight ratio), then make with press sample machine, the sample of 40 * 40 * 9mm, adopt horse Furnace roasting, controlled temperature 1150°C, roasting at the above temperature for 3 hours, air cooling, and discharging. The γ-orthosilicate in the existing magnesium slag can be converted into β-orthosilicate.

Embodiment 2

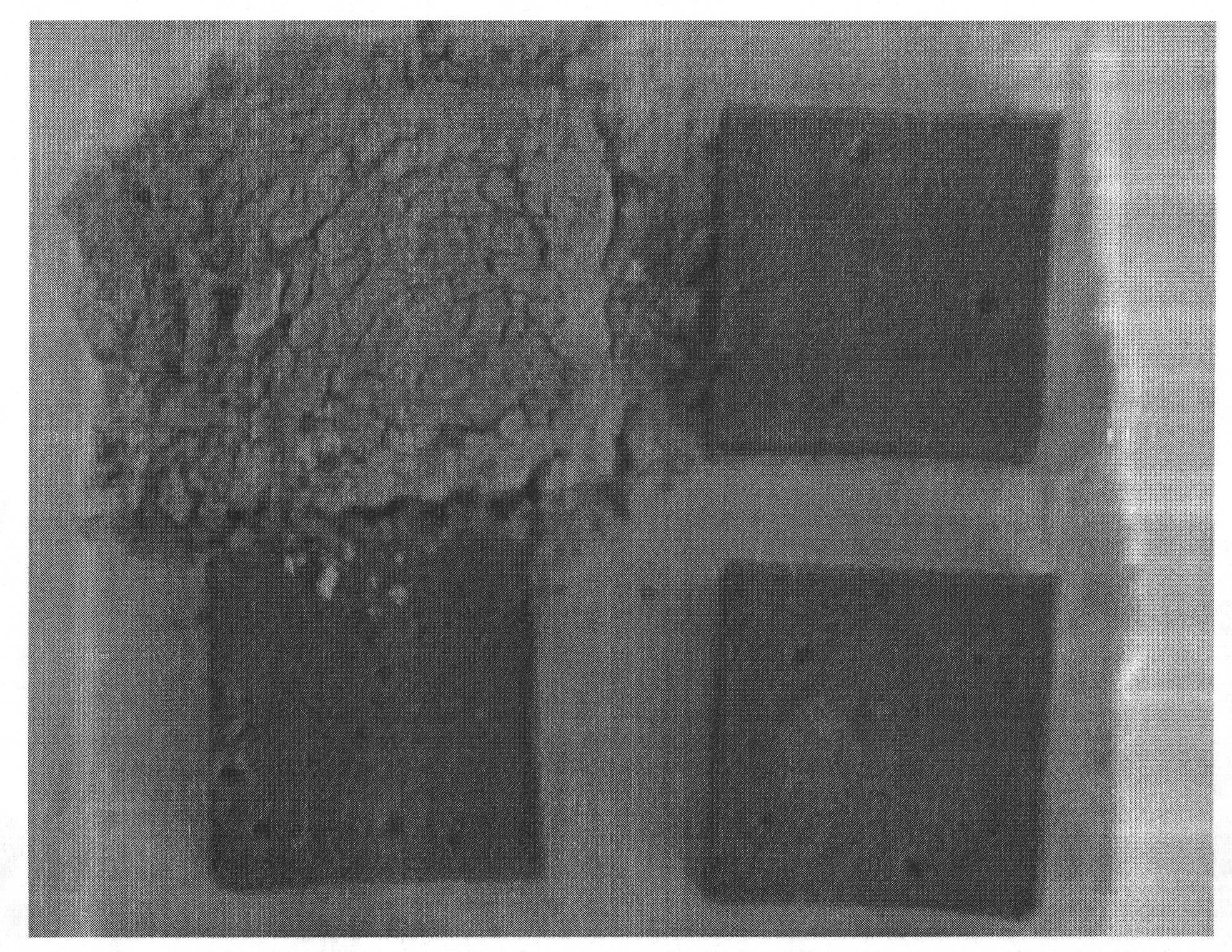

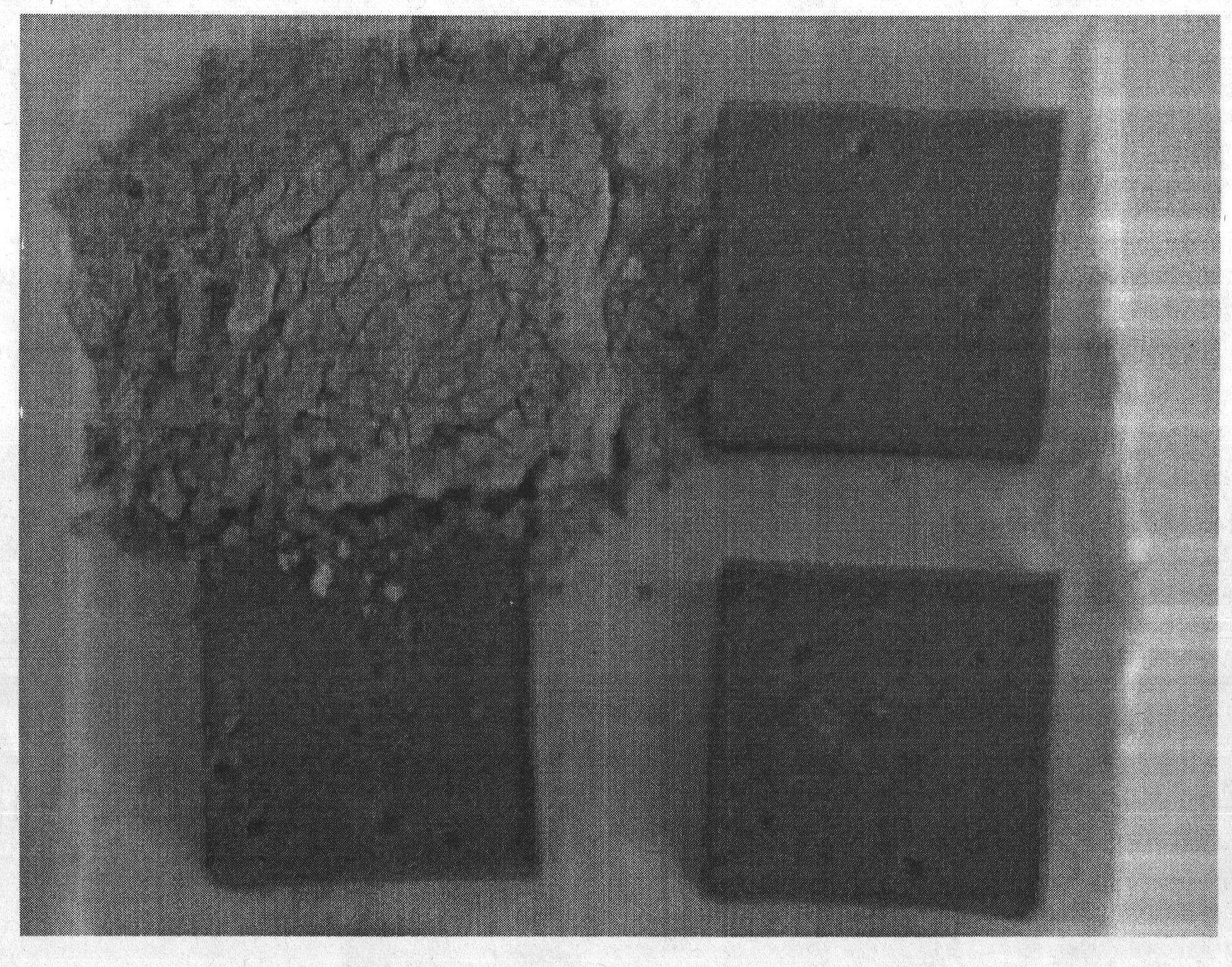

[0015] Embodiment 2: as figure 1 Among them, the upper left is magnesium slag without adding boric acid, and the remaining three samples are made by adding boric acid according to boric acid:magnesium slag=1:333 (weight ratio), and then using a press machine to make a sample of 40×40×9mm. The temperature of the muffle furnace was controlled at 1200°C, and the sample was roasted for 6 hours. It can be seen from the figure that the dicalcium orthosilicate in the magnesium slag sample without boric acid is mainly γ-dicalcium orthosilicate (from the cooled sample Whether it is pulverized to judge). However, the sample added with boric acid did not pulverize after cooling.

[0016] Embodiment 2: Magnesium slag is crossed 60 mesh sieves, add boric acid, mix evenly by boric acid: magnesium slag=1: 200-340 (weight ratio), then make with press machine, the sample of 40 * 40 * 9mm, adopt horse Furnace roasting, control temperature 1300°C, roast at the above temperature for 6 hours, ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com