Patents

Literature

68results about How to "Improve gelling activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation of single-component alkali-activated cement and application method thereof

ActiveCN102730996AExpand the range of raw materialsEasy to GrindClinker productionAlkali activatedMixed materials

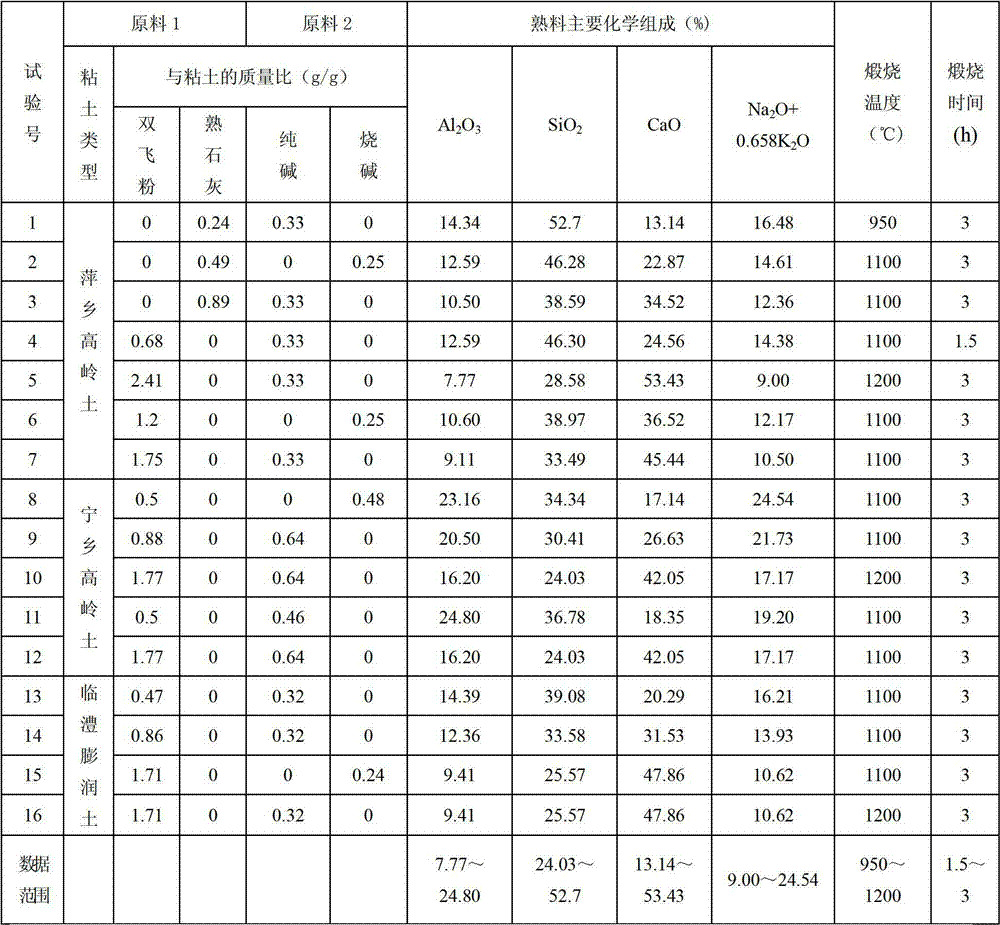

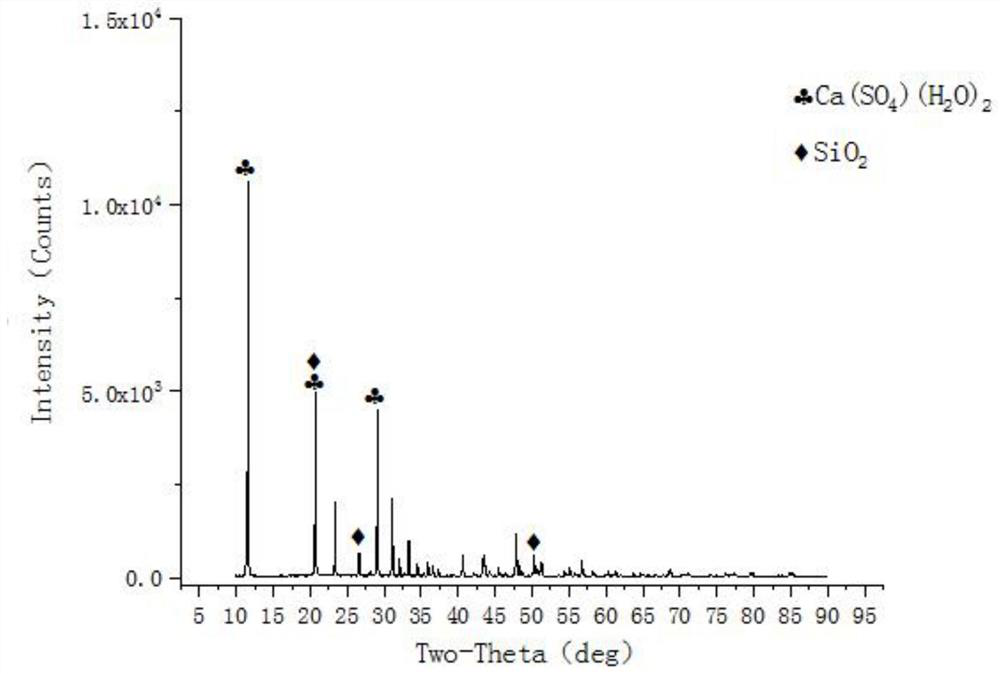

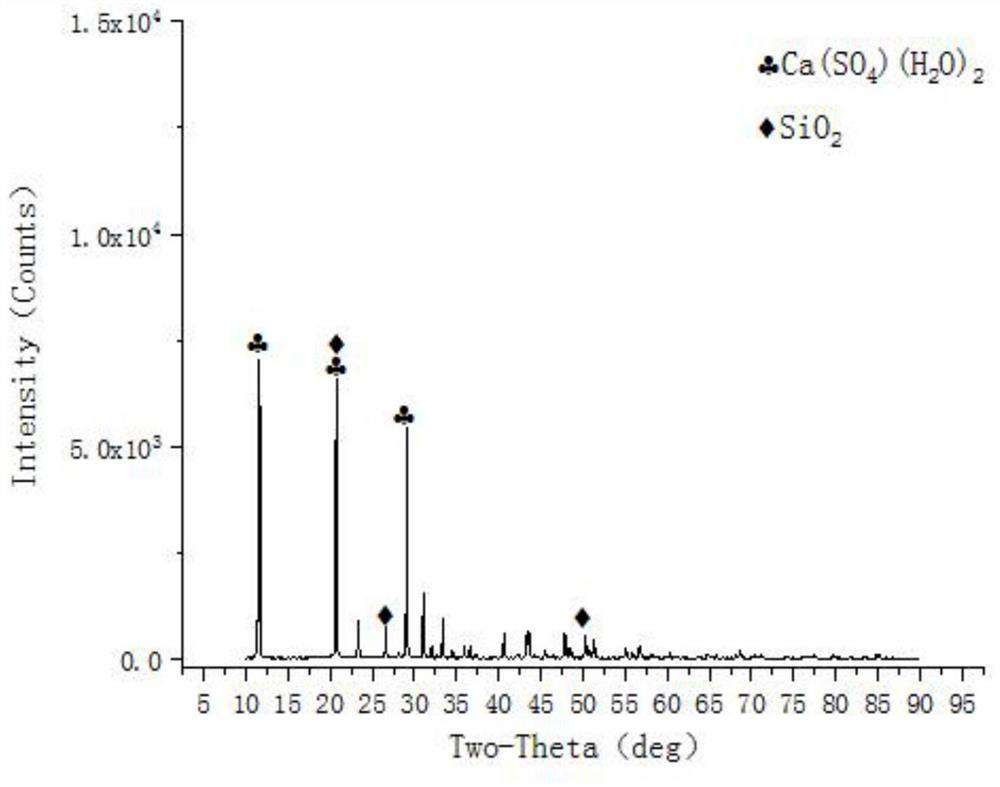

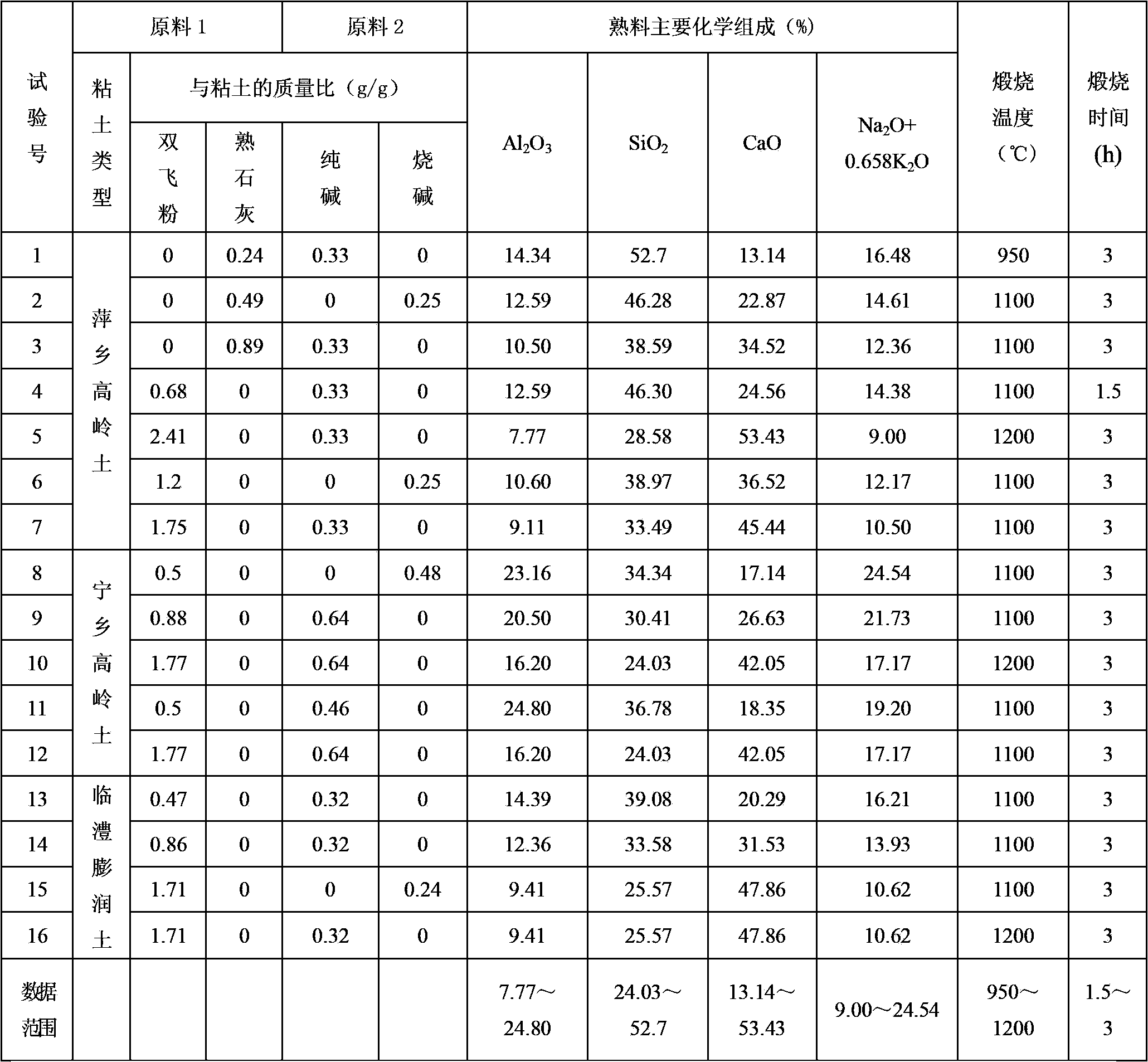

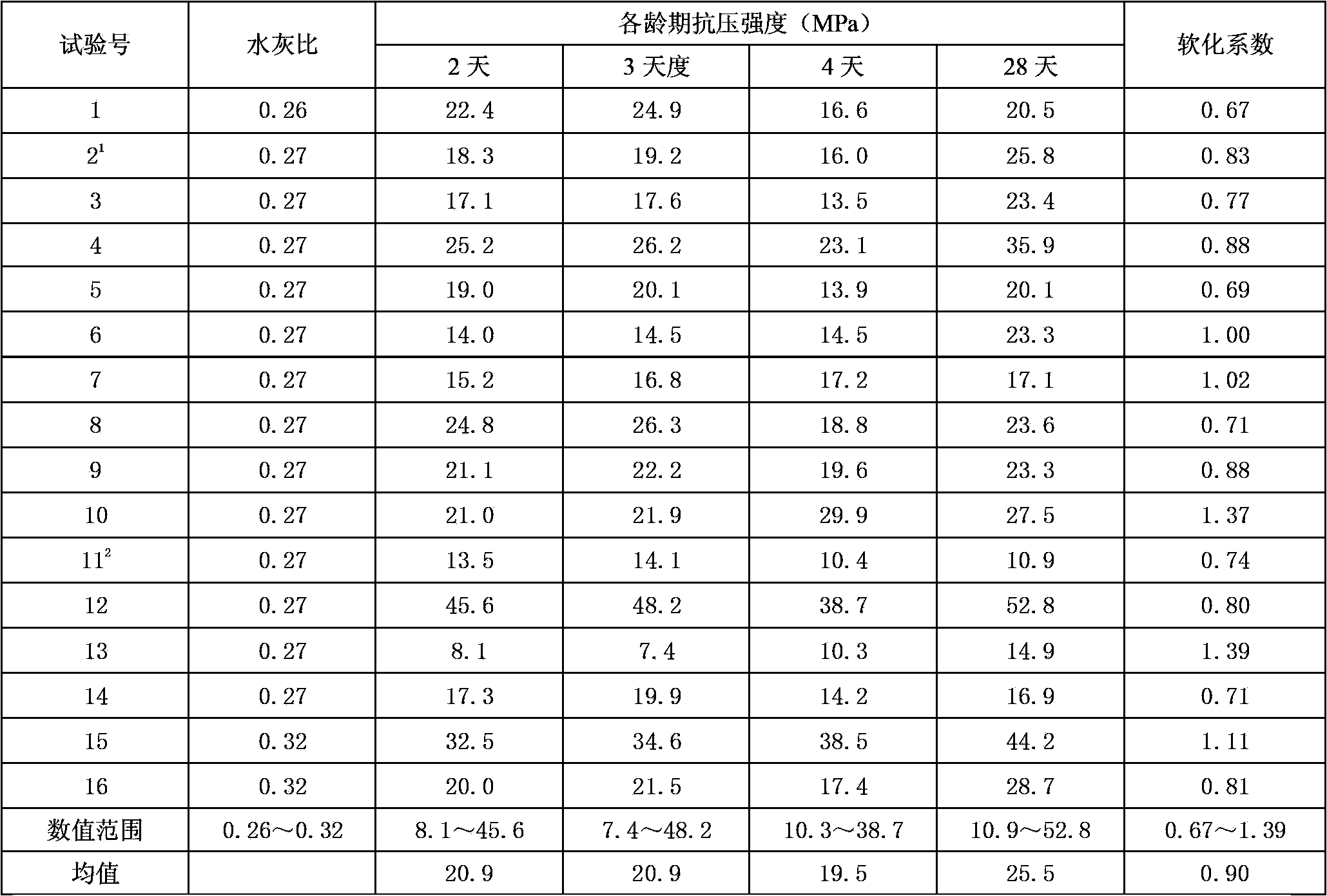

The invention belongs to the novel cement material field and specifically relates to the preparation of a single-component alkali-activated cement and an application method thereof, wherein a raw material 1 including SiO2, Al2O3, and CaO are mixed with the raw material 2 including Na2O in a certain ratio; the ratio should be decided so that the percentage of the weight of each component of the calcined product, which is obtained by calcining the mixed materials at a temperature greater than or equal to 1100 DEG C, in the total weight is as follows: Al2O3: 8-25%; SiO2: 24-55%; CaO: 10-55%; and Na2O +0.658K2O: 6-25%; after being calcined at a temperature ranging from 950-1200 DEG C for 1.5-3 h, the mixed materials are then ground to obtain cement powder; the cement powder is mixed with water into paste; next, the paste is cured at 50-80 DEG C for 2-3 days so that neat cement paste briquettes excellent in strength can be obtained; and the strength can be continuously increased if curing is continuously performed under normal temperature. The preparation of the single-component alkali-activated cement has the following advantages that: the raw material range of the alkali-activated cement is greatly expanded; the storage, transportation and utilization of the cement are more convenient; and the improvement of the cementitious activity of the cement and the reduction of the cost are expected to be realized.

Owner:HUNAN UNIV OF SCI & TECH

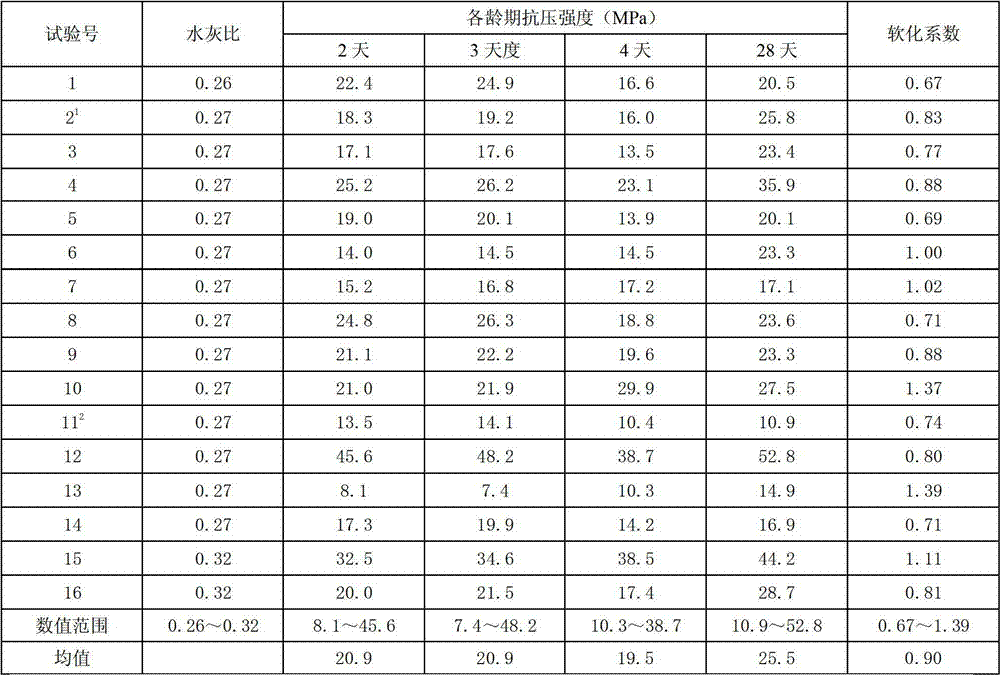

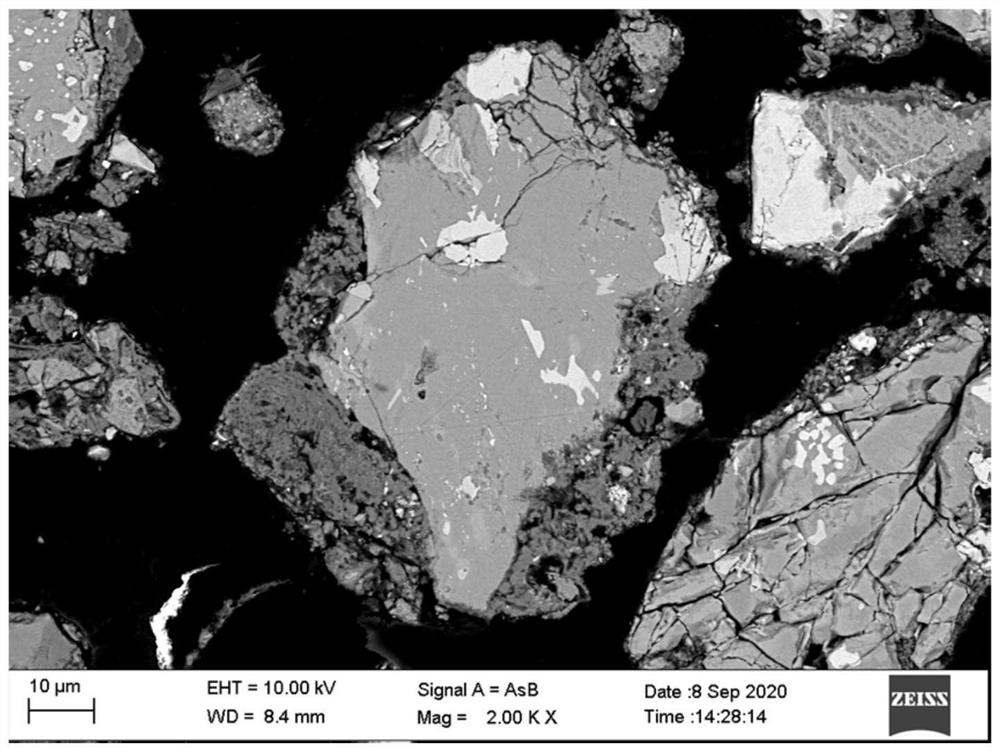

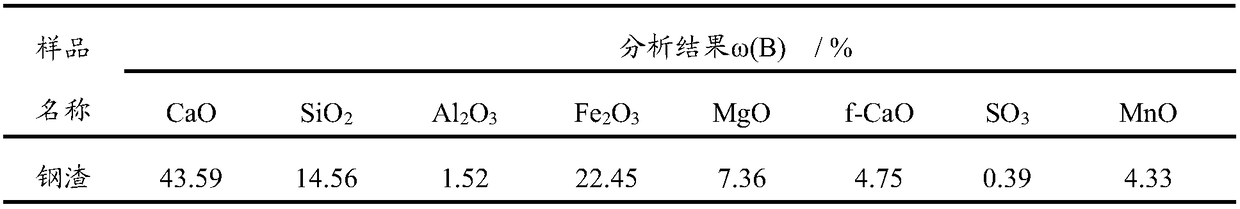

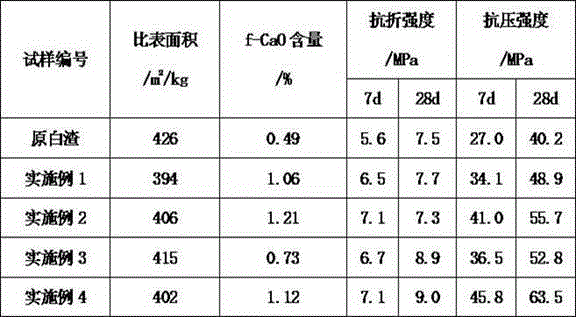

Steel slag auxiliary cementing material and preparation method and application thereof

ActiveCN113072311AWide application range of concentrationImprove stabilityCement productionSlagCement Material

The invention discloses a steel slag auxiliary cementing material and a preparation method and application thereof. The preparation method comprises the following steps: (1) crushing undisturbed steel slag, selecting iron, and grinding in a mill to obtain steel slag particles; (2) putting the steel slag particles into stirring pretreatment equipment, and mixing and uniformly stirring the steel slag and an additive solution; (3) grinding the pretreated steel slag particles in a grinding machine, and meanwhile, introducing carbon dioxide gas to grind the steel slag particles into steel slag micro powder with a certain particle size; and (4) putting the steel slag micro powder into stirring reaction equipment, and introducing carbon dioxide gas into the reaction equipment to obtain the stabilized and activated steel slag auxiliary cementing material. According to the method, free CaO and part of free MgO are rapidly eliminated, so that the problem of poor stability of the steel slag is solved, the gelling activity of the steel slag is improved to a great extent, it is ensured that the stability of the auxiliary gelling material of the steel slag is qualified when the auxiliary gelling material of the steel slag is doped into cement or concrete, and application of the steel slag in building materials such as cement and concrete is promoted.

Owner:NANJING UNIV OF TECH

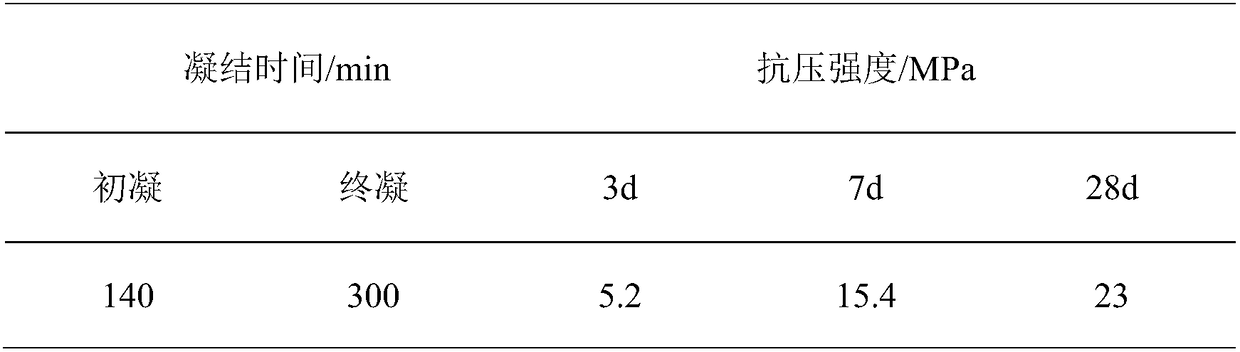

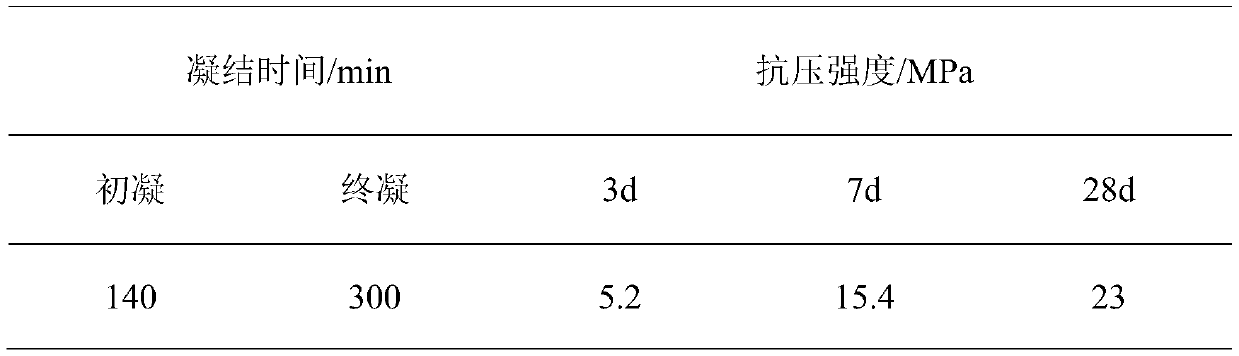

Method for preparing grouting material by using water-containing red mud synergistic blast furnace slag

The invention provides a novel red mud-based grouting material and preparation method thereof. The grouting material is prepared from the following components by weight percent: 70-80% of red mud liquid, 15-25% of blast furnace slag powder, 5-10% of compound alkali-activator, 2-10% of water reducing agent and 1-2% of early strength agent. The novel red mud-based grouting material prepared from redmud and the blast furnace slag powder is good in fluidity, high in early strength and short in time of coagulation, and does not shrink. The preparation method provided by the invention reasonably utilizes industrial waste, can reduce the influence of the waste on the environment, and is easy in preparation; the method is simple in steps, convenient to operate and high in practicability.

Owner:SHANDONG UNIV

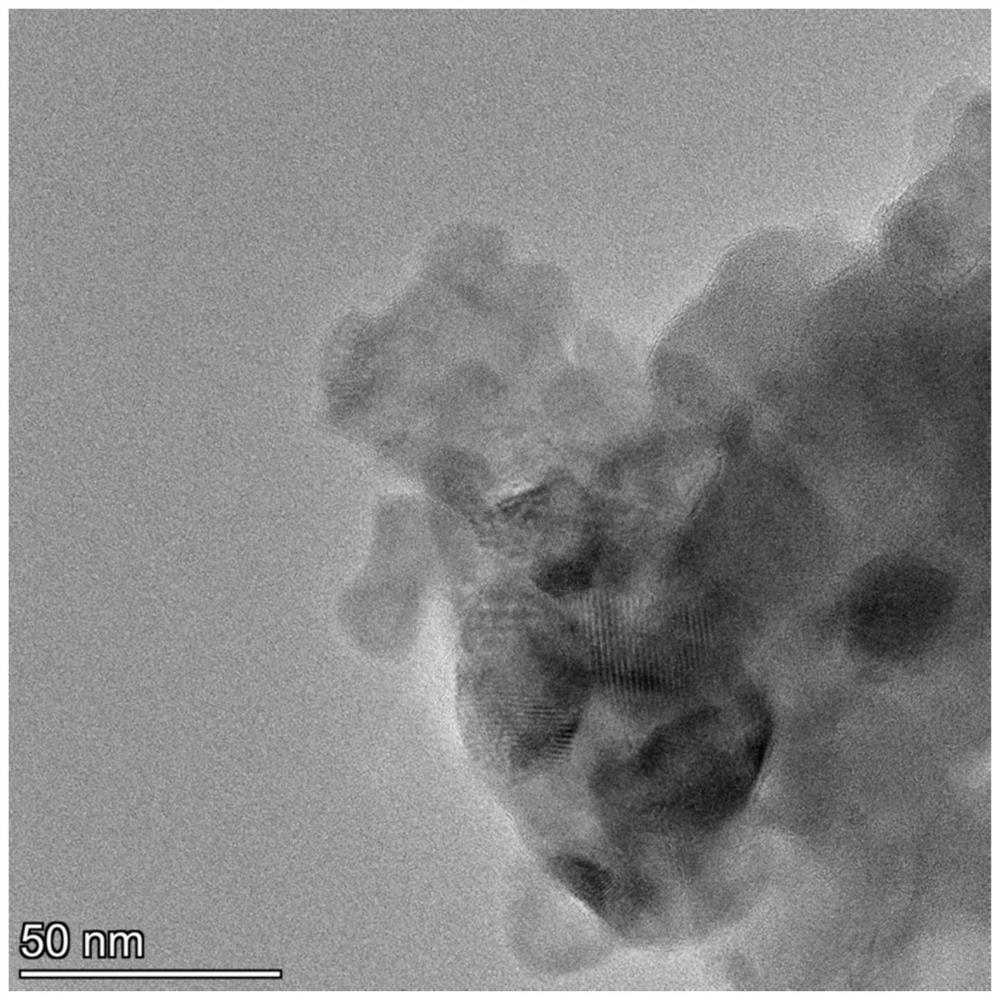

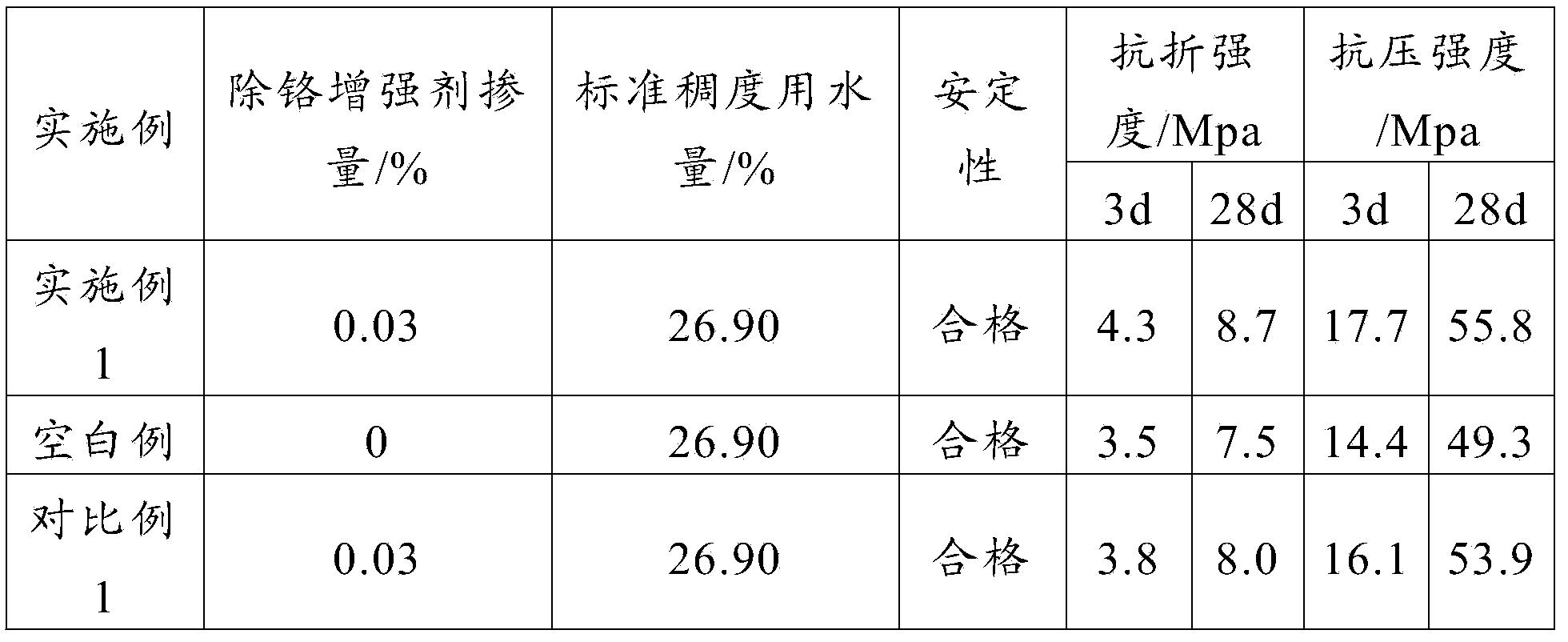

Chromium removal enhancer and preparation method thereof

The invention provides a method for preparing a chromium removal enhancer. The method comprises the following steps: (a) calcining kaolin, mixing the calcined kaolin and an acid solution, performing suction filtration, and washing and drying the obtained solid; (b) mixing the kaolin obtained in the step (a) and an mixed solution, and reacting to obtain the chromium removal enhancer, wherein the mixed solution is a mixed solution of a reducing agent, an antioxidant, an enhancer and water. According to the chromium removal enhancer prepared by the invention, the kaolin is taken as a raw material, the reducing agent, the antioxidant and the enhancer are mixed with the modified kaolin, and the chromium removal enhancer is obtained after the reaction. According to the chromium removal enhancer prepared by the invention, due to dual effects of adsorption and reduction, hexavalent chromium in cement is effectively removed, and physical properties of the cement are improved. The invention also provides the chromium removal enhancer prepared according to the method.

Owner:SHANDONG HONGYI TECH

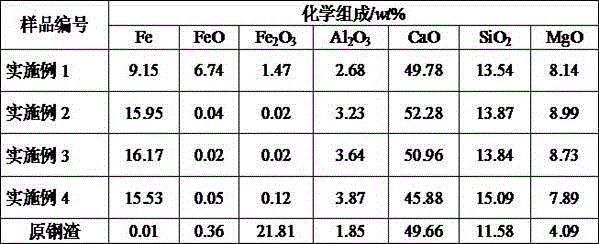

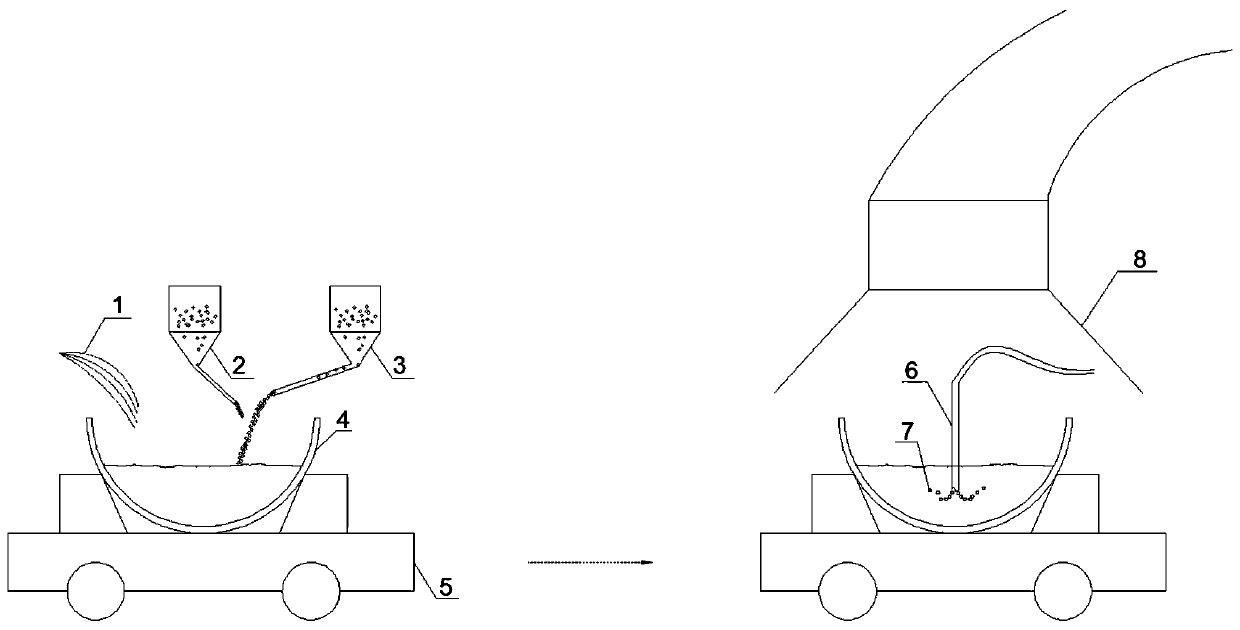

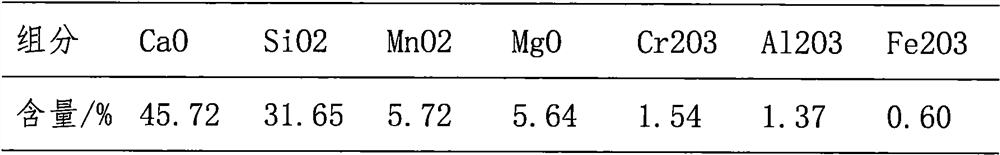

Method for reducing, quenching and tempering molten steel slags in reducing atmosphere

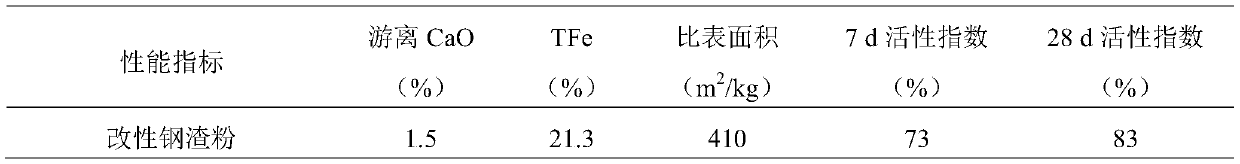

The invention relates to a method for reducing, quenching and tempering molten steel slags in a reducing atmosphere. The method comprises the following steps: firstly, crushing and grinding steel slags and a reducing component regulating material until the Blaine specific surface area is 200-400m<2> / kg, mixing a proper amount of water into the mixture, uniformly mixing, pressing the mixture into a pat, and baking; then, calcining the pat in a reducing atmosphere high-temperature furnace (the high-temperature electric resistance furnace is vacuumized firstly when a test is performed) at a temperature of 1300-1600 DEG C in a protective atmosphere, and insulating for more than 30 minutes to enable each component to carry out a chemical reaction at a high temperature; and finally, cooling, crushing and grinding the reduced material to prepare modified steel slag powder. According to the method, Fe2O3 and FeO in the steel slags can be reduced to zero-valent iron on the one hand, on the other hand, an iron-aluminum-calcium phase can be decomposed to release CaO, and the zero-valent iron and CaO are beneficial to formation of high cementitious activity silicate minerals, so that mineral composition of the steel slags can be essentially optimized, and the cementitious activity of steel slags is improved.

Owner:SHAOGUAN COLLEGE

Pidgeon process for making magnesium and boronic mineralizer for partially replacing fluorite

The invention relates to a Pidgeon process for making magnesium and a boronic mineralizer for partially replacing fluorite. The Pidgeon process is characterized by comprising the following steps: metering and burdening calcined dolomite as a raw material, ferrosilicon as a reducing agent and a mineralizer together, wherein the mineralizer consists of 0.5-3.0% of fluorite and 0.3-3.1% of boronic raw material according to proportions in the total weight of pellets, the ferrosilicon accounts for 12-18% of the total weight of the pellets, and the balance of calcined dolomite; then briquetting the materials after smashing, placing the materials into a reduction tank, heating to 1150-1250 DEG C, vacuum pumping inside the reduction tank, cooling after heat preservation, and collecting crude magnesium. Compared with the prior art, the Pidgeon process has the following advantages: although the price of a boronic compound industrial product in the mineralizer is higher than that of the fluorite, the boronic compound industrial product is less in dosage than the fluorite and reduces the pollution to the environment of fluorine. In addition, conventional equipment and process conditions do not need to be changed; and secondly, the modified magnesium slag obtained by the Pidgeon process has better cementitious activity.

Owner:西安弗尔绿创矿业科技有限责任公司

Novel high-temperature steel slag modifier and modification pretreatment process

ActiveCN110055370AAchieve high temperature modificationAchieve recyclingManufacturing convertersSlagNitrogen

The invention discloses a novel high-temperature steel slag modifier and a modification pretreatment process, and belongs to the technical field of steel slag modification. The novel high-temperaturesteel slag modifier comprises a substance containing elemental silicon and a substance containing elemental carbon, the content of the elemental silicon in the substance containing the elemental silicon is more than or equal to 60%, and the content of the elemental carbon in the substance containing the elemental carbon is more than or equal to 80%. The invention further discloses the novel high-temperature steel slag modification pretreatment process which comprises the following steps 1) adding the substance containing the elemental carbon and the substance containing the elemental silicon into a slag tank in advance; 2) when a converter is deslagging, adding the substance containing the elemental silicon into the slag tank at the same time; 3) blowing nitrogen into a material after deslagging, and collecting generated dust at the same time; and 4) carrying out hot stuffy treatment on steel slag subjected to nitrogen blowing treatment in the step 3). The novel high-temperature steelslag modifier and the modification pretreatment process can effectively improve the stability and grindability of the steel slag and improve the recovery rate of the slag and steel.

Owner:MAANSHAN IRON & STEEL CO LTD

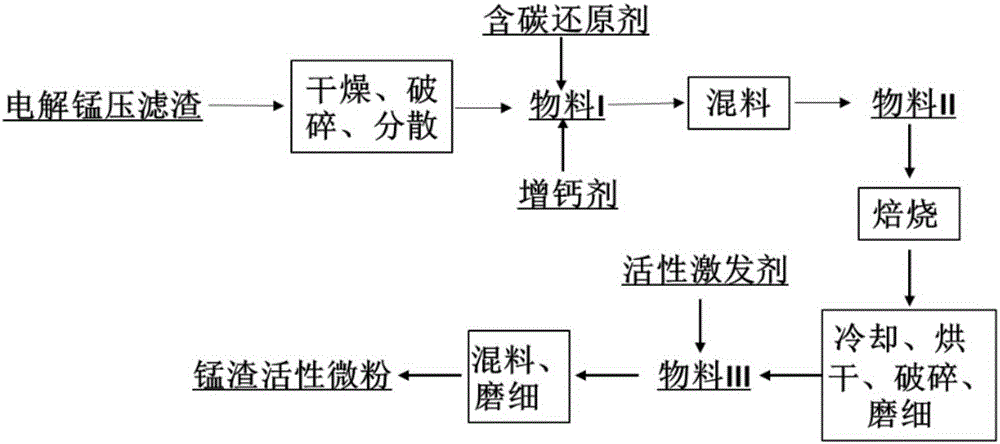

Preparation method of manganese slag activate micro powder for concrete admixture

InactiveCN105174764AImprove gelling activityGuaranteed mechanical propertiesSolid waste managementSlagCalcium

The invention discloses a preparation method of manganese slag activate micro powder for a concrete admixture. The method aims at recycling electrolytic manganese filter press slags, the electrolytic manganese filter press slags are prepared into the manganese slag activate micro powder through roasting, cooling and addition of reductant, calcium increasing agents and reactive activators, and the manganese slag activate micro powder serves as fine packing in concrete. According to the preparation method of the manganese slag activate micro powder for the concrete admixture, recycling of the electrolytic manganese filter press slags is achieved, the activate micro powder produced through the method can effectively improve cementitious activity of the concrete, recycling of industrial slags is achieved, and considerable economic and environmental protection significance is achieved.

Owner:石朝军 +1

Slag adhesion resistant material for slag tank and preparation method of slag adhesion resistant material

The invention provides a slag adhesion resistant material for a slag tank and a preparation method of the slag adhesion resistant material. The slag adhesion resistant material is prepared from the following raw materials in percentage by weight: 70-90wt% of superfine slag powder, 6-30wt% of additive and 1-3wt% of binder (total 100%). The preparation method comprises the following steps of mixingthe superfine slag powder, the additive and the binder with formula amounts, adding water, and performing uniform stirring and mixing to obtain the slag adhesion resistant material. Compared with theprior art, the slag adhesion resistant material provided by the invention is low in cost by adopting blast furnace slag as a main raw material, is ground with the granularity being 300-400 meshes, isuniformly mixed with the additive and the binder to control the viscosity of the slurry, is strong in adhesion with the slag tank, short in solidification time, high in refractoriness and good in slagadhesion resistance effect, can realize a target of overturning the tank for more than or equal to 3 times after spraying the slag tank for one time. Meanwhile, the use of the superfine slag powder is broadened and the resource additional value is improved.

Owner:MAANSHAN IRON & STEEL CO LTD

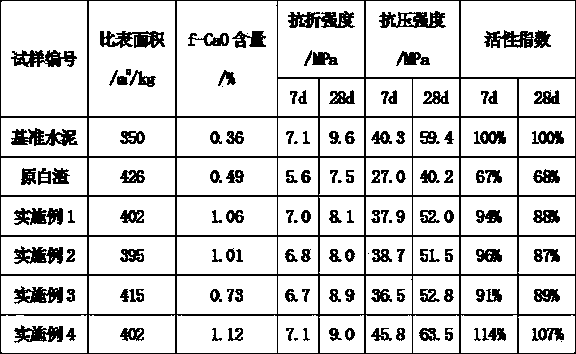

Adjusting material for carrying out high temperature activation treatment on electric furnace white slag, and application thereof

ActiveCN104016599AImprove mineral compositionImprove gelling activityCement productionCalcium in biologyChemical reaction

The invention relates to an adjusting material for carrying out high temperature activation treatment on electric furnace white slag. The adjusting material comprises the components by weight: 0-55% of converter slag, 40-100% of calcareous material (in terms of CaO) and 0-5% of auxiliary materials. When the adjusting material is in practical use, the converter slag, the calcareous material and the auxiliary materials are mixed according to the above weight proportions to be used as the adjusting material; the adjusting material is ground into fine powder; 15-35% by weight of the adjusting material and 65-85% by weight of the white slag are mixed uniformly; the mixture is calcined, so that chemical reactions occur among components; air cool or water cool are carried out after calcination; and a calcined product is broken and ground to prepare the activated white slag powder. 28 d activity indicator is higher than 85% when Blaine specific surface area is 400-500 m<2> / kg. Mineral composition of the white slag is optimized essentially; gelatinization activity of the white slag is increased; high value-added resource utilization rate of the white slag and steel slag solid wastes is increased; and environment protection is facilitated.

Owner:SHAOGUAN COLLEGE

Steel slag hardening and tempering agent and using method thereof

ActiveCN112374776AShorten the setting timeSolve the problem of poor activityTemperingChemical reaction

According to the invention, a hardening and tempering agent component is directly added before steel tapping and discharging, and the hardening and tempering agent and the liquid steel slag are subjected to a chemical reaction under a high-temperature condition so that the content of active mineral phases of the steel slag is increased, the content of free calcium oxide and magnesium oxide is reduced, and the problems of low activity and poor stability of the steel slag are solved from the source of steel slag formation, meanwhile, smooth deslagging can be realized.

Owner:FUJIAN FURUN BUILDING MATERIAL TECH

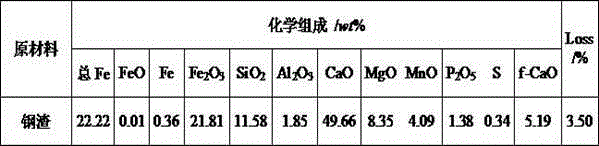

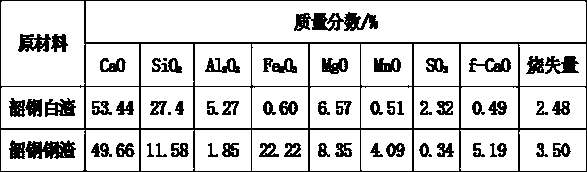

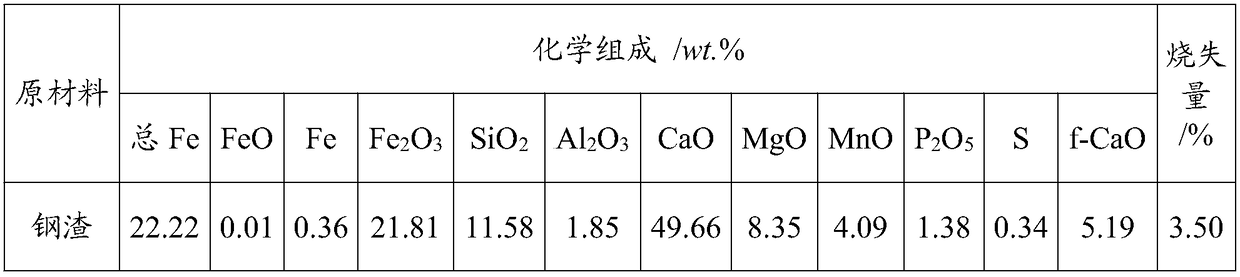

Stokehole modified steel slag and preparation method thereof

ActiveCN113087420AEasy to operateImprove gelling activitySolid waste managementCement productionSteelmakingMolten steel

The invention provides stokehole modified steel slag and a preparation method thereof. According to the invention, steel slag which is discharged from converter steelmaking and has a temperature of 1400 DEG C or above is discharged to a slag tank, and meanwhile, a modifier (limestone powder, sandstone and fly ash) is mixed with the molten steel slag, wherein the particle size of the modifier is smaller than 0.15 mm, the modifier comprises, in percentage by weight, 1%-15% of the limestone powder, 1%-10% of sandstone powder and 1%-10% of the fly ash, and the total addition amount of the modifier is 5-25%; and the total content of CaO and MgO in the chemical components of the steel slag is less than 55%. The modified steel slag can be used as a cement admixture or a concrete admixture and is applied to cement or concrete. The modified steel slag is high in gelation activity, and the preparation method is simple to operate.

Owner:张文

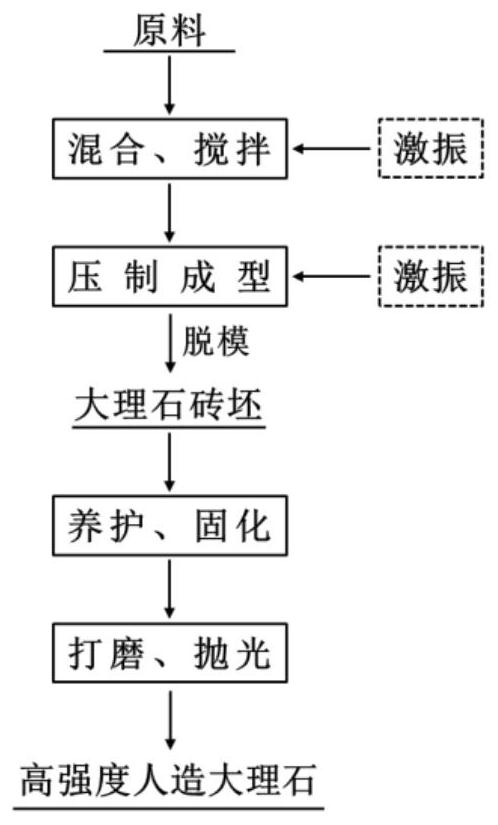

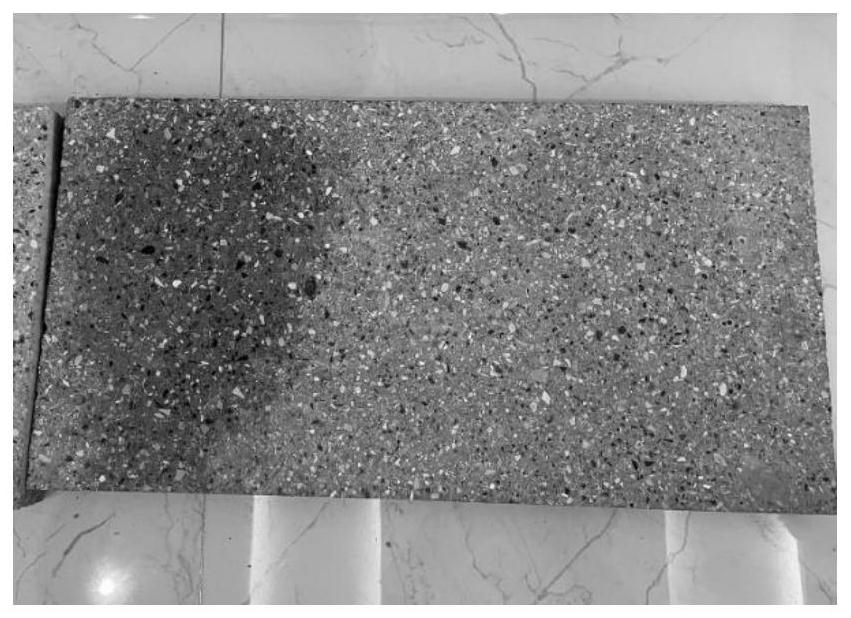

Method for preparing high-strength artificial marble by exciting and activating low-calorific-value coal ash slag

ActiveCN113954203AImprove gelling activityIncrease contentSolid waste managementCeramic shaping apparatusCompression moldingBrick

The invention relates to a method for preparing high-strength artificial marble by exciting and activating low-calorific-value coal ash slag. The raw materials mainly comprise fly ash slag, furnace slag and cement, the fly ash slag and the furnace slag are generated by combustion of low-calorific-value coal through a circulating fluidized bed, the cement and the fly ash slag serve as binding materials, and the furnace slag serves as aggregate. The raw materials in different proportions are intensively stirred by a vibration exciter and are subjected to vibration compression molding by the vibration exciter, and finally the high-strength artificial marble is prepared. The method has the advantages that high-frequency excitation is carried out in the mechanical stirring process, resonance is generated when the excitation frequency is close to the inherent frequency of materials, the materials obtain strong energy and are activated, the activity problem of the low-heating-value coal ash residues is solved, and the raw materials are evenly distributed on the microcosmic scale; in the forming process, the vibration exciter is used for vibration excitation, and an artificial marble green brick with a compact structure can be obtained under extremely small forming pressure; and a comprehensive utilization approach is provided for low-silicon, low-aluminum, high-calcium, high-sulfur and low-activity ash, and a technical support is provided for industrial production.

Owner:UNIV OF SCI & TECH BEIJING +1

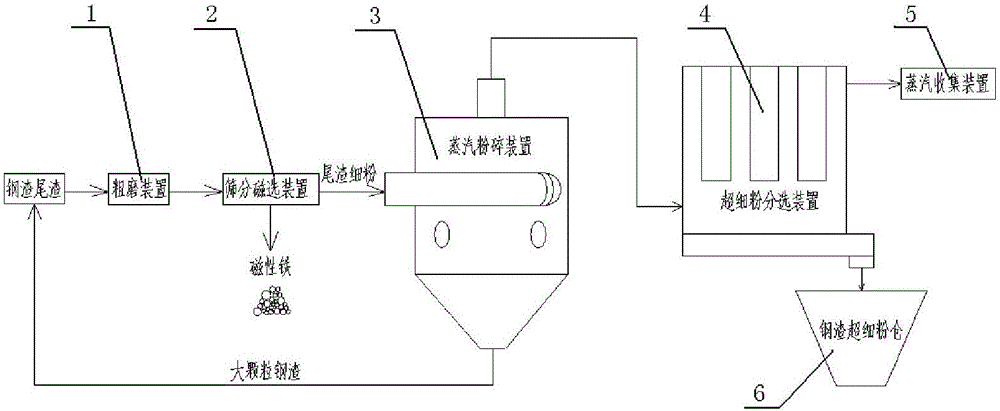

Steel slag superfine powder production process

InactiveCN105855014ASolve the problem of ultra-fineReduce manufacturing costGrain treatmentsHigh energySlag

The invention discloses a steel slag superfine powder production process and belongs to the technical field of resource comprehensive utilization and environment protection. The steel slag superfine powder production process comprises the steps that a coarse grinding device is used for conducting coarse crushing on steel slag tailings; the steel slag tailings subjected to coarse crushing are sorted by a screening magnetic separation device and then are divided into tailing fine powder and magnetic iron; the tailing fine powder enters a steam crushing device and is impacted and crushed by overheated high energy steam; the mixture of the steel slag superfine powder formed after impacting and crushing by the high energy steam and the overheated steam enters a superfine powder sorting device; the steel slag superfine powder is discharged out of the superfine powder sorting device and enters a steel slag superfine powder bin; and the overheated steam is discharged out of the top of the superfine powder sorting device and collected by a steam collection device. The steel slag superfine powder production process has the advantages that ferric oxide in the tailings is extracted to the greatest extent, the produced steel slag superfine powder not only can be used as concrete additives, but also can be used as rubber and plastic filling and coating filling, and the price of the powder is up to more than one thousand yuan per ton.

Owner:BEIJING SHOUGANG INT ENG TECH

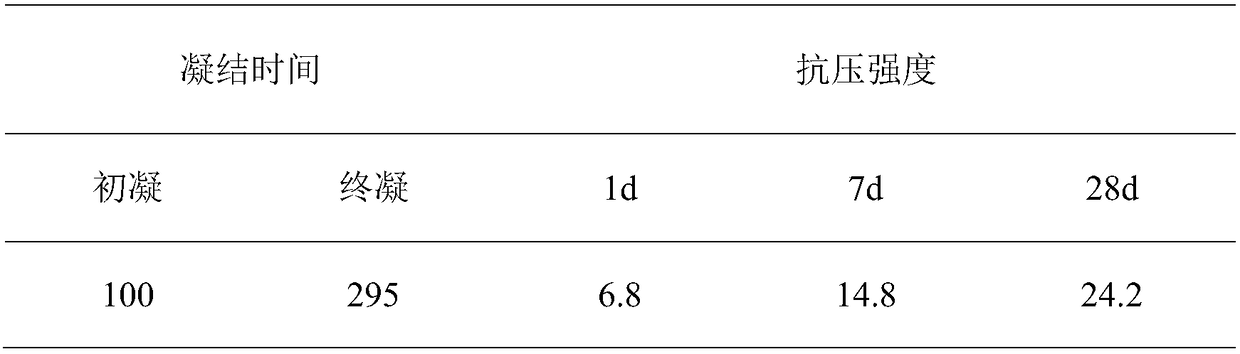

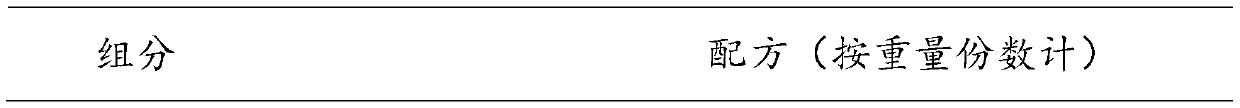

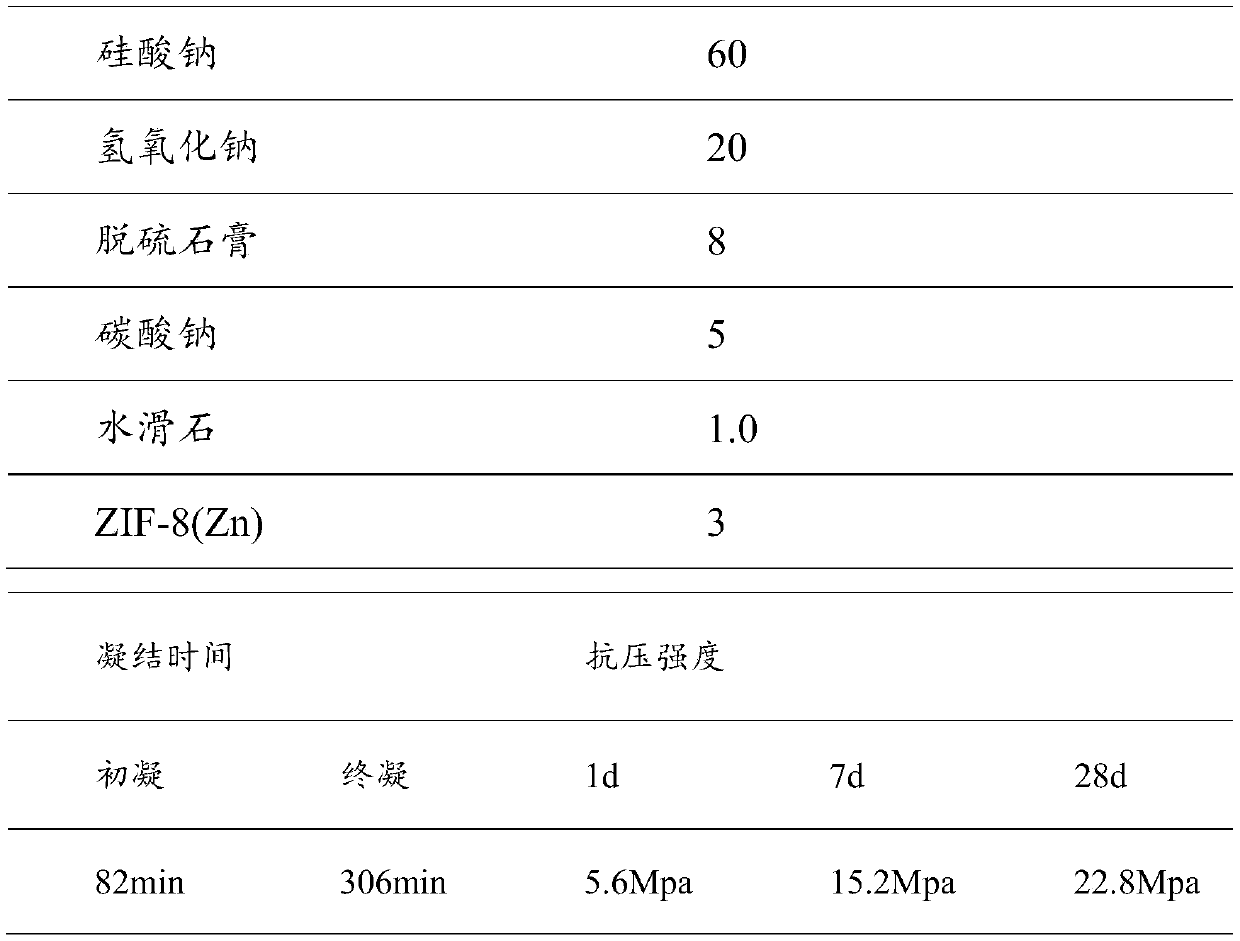

High-efficiency solid waste-based cementing activity excitant

The invention relates to an efficient solid waste-based cementing activity activator, and relates to the field of material science and solid waste resource utilization. The problem that solid waste such as red mud, coal gangue and tailings is difficult to utilize is mainly solved, and the high-performance red mud-based cementing material is prepared. The efficient red mud-based cementing activityactivator comprises 40 to 60 parts of alkali metal silicate, 10 to 20 parts of alkali metal hydroxide, 0 to 15 parts of a high-calcium solid waste material, 4 to 8 parts of carbonate, 0 to 5 parts ofhydrotalcite and 0 to 8 parts of an imidazole porous crystal material. The prepared red mud-based cementing material has the advantages of high mechanical strength, short setting time and the like.

Owner:SHANDONG UNIV

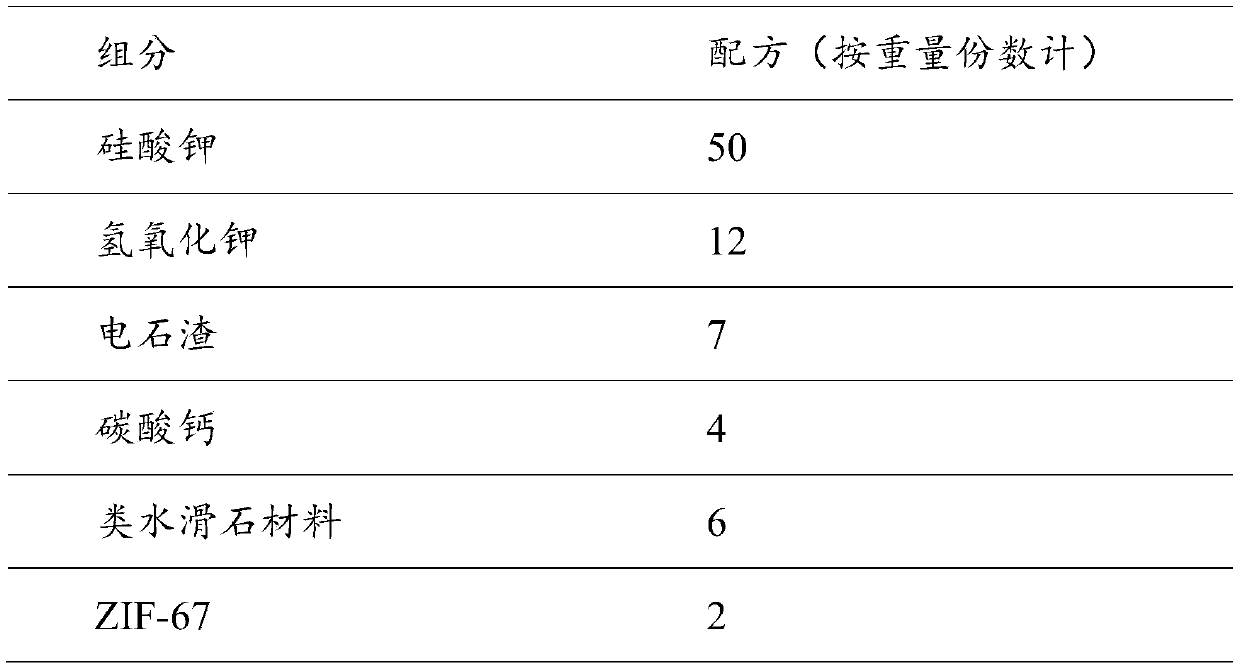

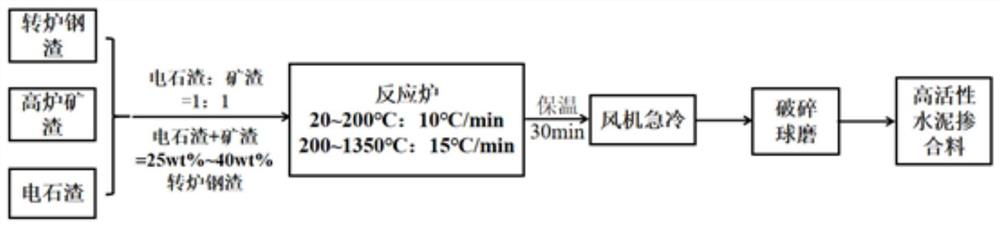

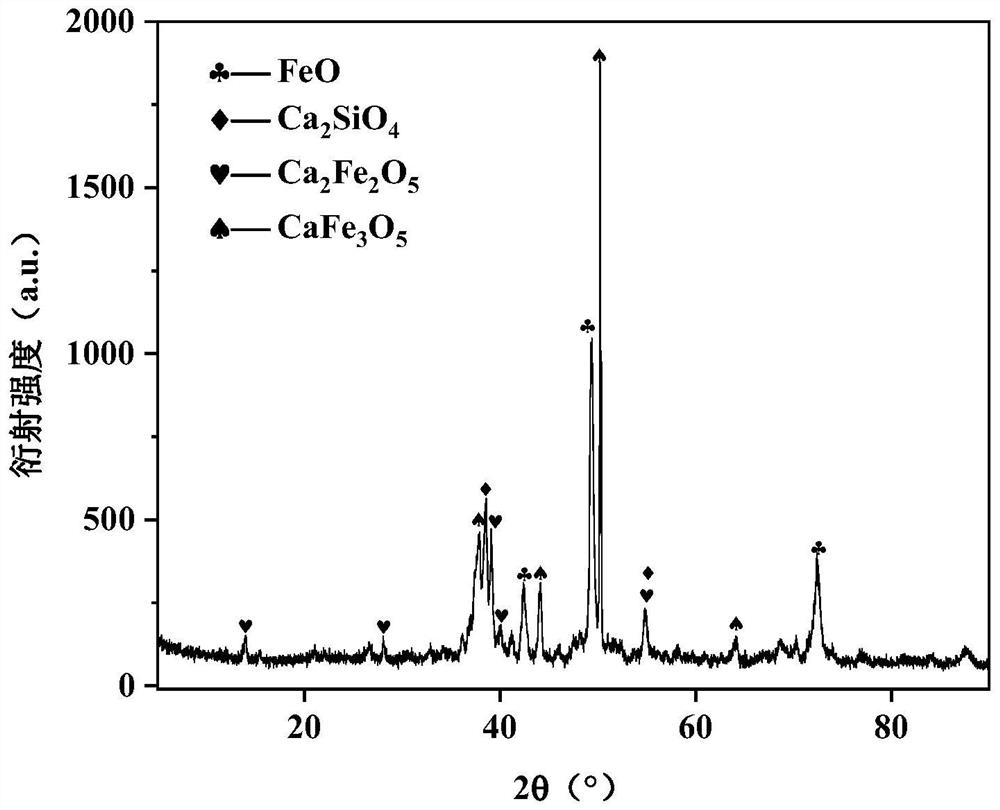

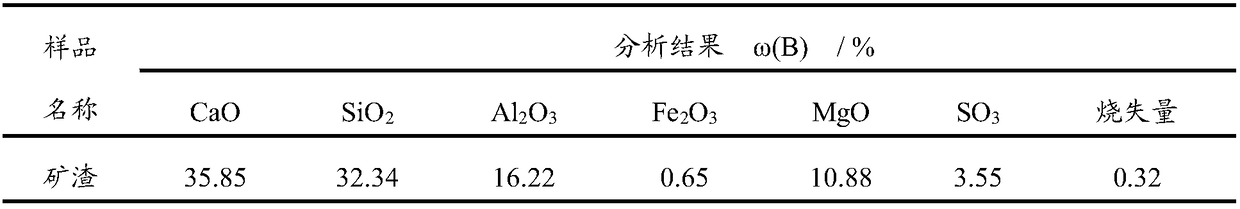

Preparation method of high-activity cement admixture

ActiveCN114014572APromote generationC/S reductionSolid waste managementCement productionTemperingSlag

The invention discloses a preparation method of a high-activity cement admixture, and belongs to the technical field of converter steel slag treatment application and industrial solid waste building material resource utilization. The method comprises the following steps: mixing converter steel slag as a main raw material and carbide slag and blast furnace slag as auxiliary materials, heating in a reaction furnace until the temperature of the molten converter steel slag is reached, carrying out heat preservation treatment, quenching to room temperature, and crushing and ball-milling into powder, thereby obtaining the high-activity cement admixture. According to the invention, the molten converter steel slag is taken as the main raw material, the industrial solid waste is taken as the hardening and tempering agent, and the high-activity cement admixture with the activity reaching S95 grade is prepared from all solid wastes, so that the aim of synergistically utilizing various industrial solid wastes is fulfilled, and the quality level of subsequent utilization of the converter steel slag is effectively improved; the utilization problem caused by activity and stability of the converter steel slag is solved, the iron content of the converter steel slag as a cement admixture is effectively reduced, and the substitution ratio of cement is increased to a certain extent.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES +1

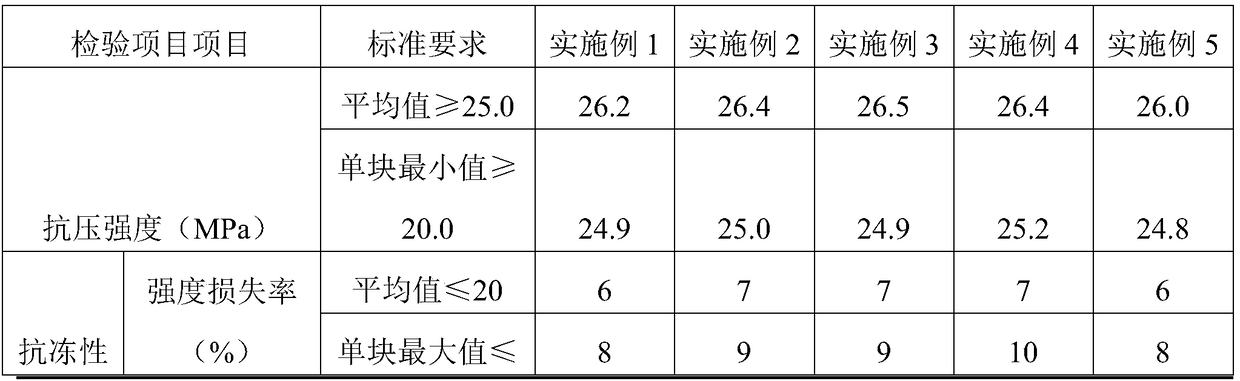

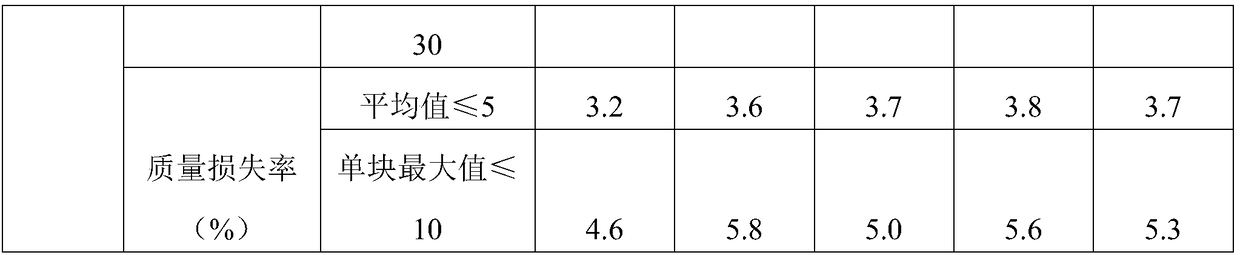

Archaized brick prepared by using montmorillonite and illite and preparing method thereof

PendingCN109336535AImprove gelling activityImprove early strengthCeramic shaping apparatusBrickSludge

The invention discloses an archaized brick prepared by using montmorillonite and illite and a preparing method thereof and belongs to the technical field of ancient building restoration. The archaizedbrick prepared by using the montmorillonite and the illite is prepared by the following raw materials in parts by weight: 15-25 parts of montmorillonite, 15-25 parts of illite, 5-10 parts of chlorite, 15-25 sludge, 5-10 parts of salt gypsum, 5-10 parts of white cement, 3-5 parts of modified vegetable fibre, 0-1 part of iron black, 0.5-1.0 parts of EDTA disodium, 0.5-1.5 parts of calcium hydroxideand 0.5-1.5 parts of sodium hexametaphosphate. The archaized brick prepared by using the montmorillonite and the illite, disclosed by the invention, has the advantage that a problem that cracks are easy to generate on a montmorillonite sintered brick is avoided by using the montmorillonite and the illite as main raw materials and using a pressing method to prepare the archaized brick. The archaized brick prepared by using the method disclosed by the invention has the advantages that the compressive strength is good, the freezing resistance is good, GB / T82392014 standard requirements are satisfied, the color of a brick body is a caesious color, the color is more vivid, and the archaized effect is natural.

Owner:HENAN BESTBUILDER NETWORK TECH CO LTD

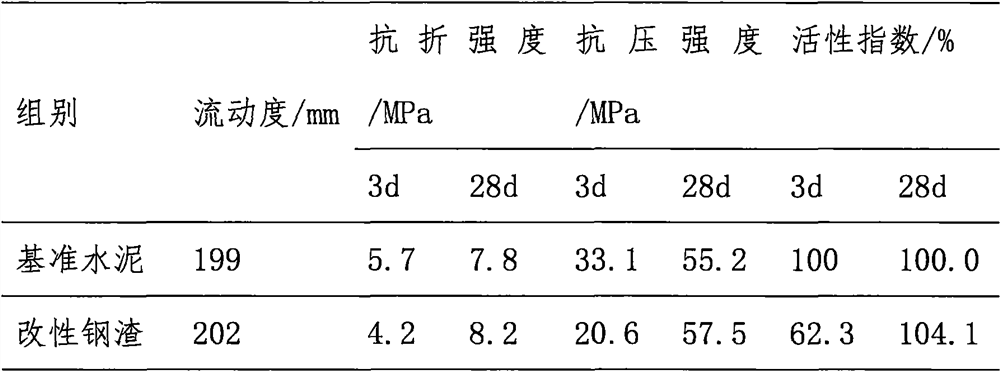

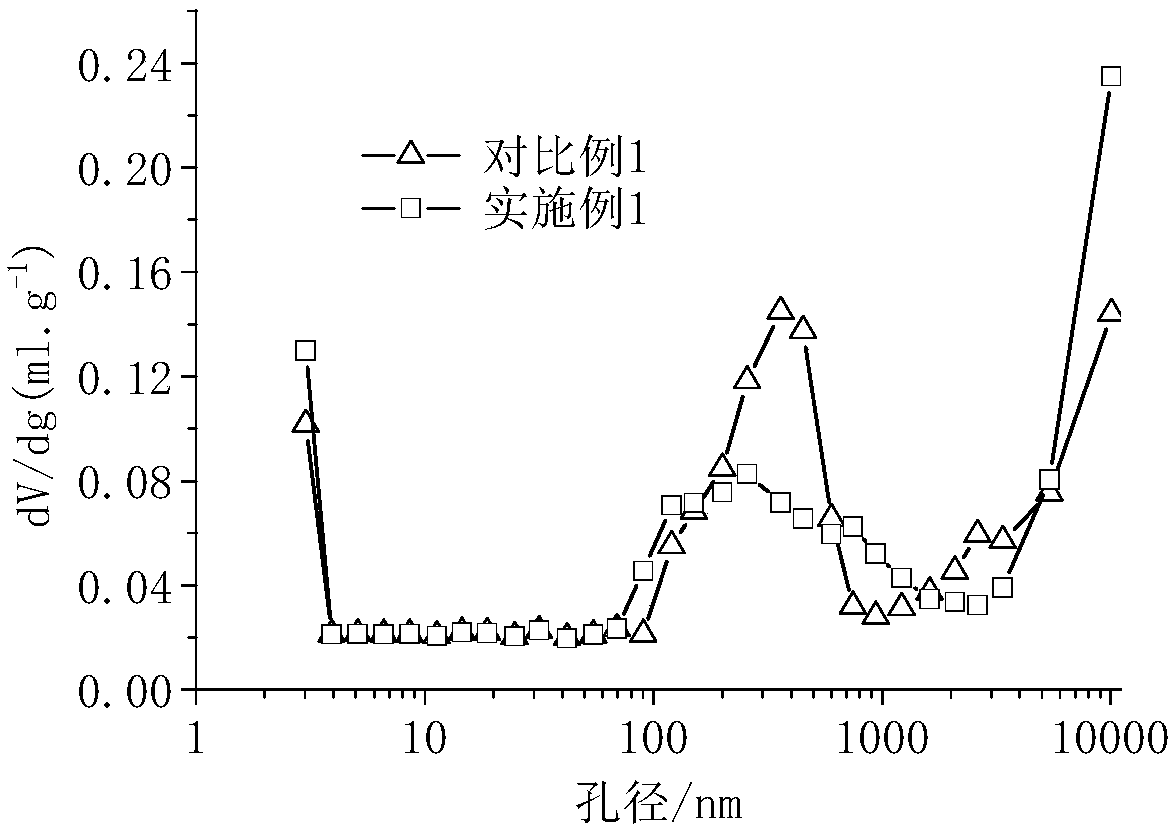

G85-grade ground iron steel slag and preparation method thereof

ActiveCN109250929AImprove the level of resource utilization of added valueSimple structureCement productionSlagResource utilization

The invention provides G85-grade ground iron steel slag and a preparation method thereof, and belongs to the technical field of building materials. According to the G85-grade ground iron steel slag and the preparation method thereof, converter steel slag is used as a raw material, and after the converter steel slag is subjected to thermal curing treatment, magnetic separation, drying, crushing, grinding and vortex air flow classification treatment, the treated converter steel slag and ground slag are mixed to prepare the G85-grade ground iron steel slag. The prepared G85-grade ground iron steel slag is up to specifications in ground iron steel slag (GB / T28293-2012) standards, the cementitious activity is high, after the G85-grade ground iron steel slag and slag are compounded, a cement slurry pore structure can be optimized, and a steel slag high added value resource utilization level is raised.

Owner:SHAOGUAN COLLEGE

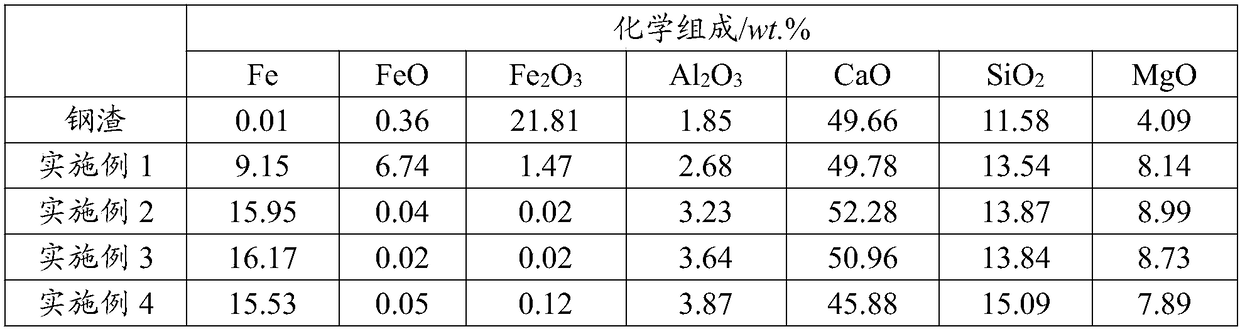

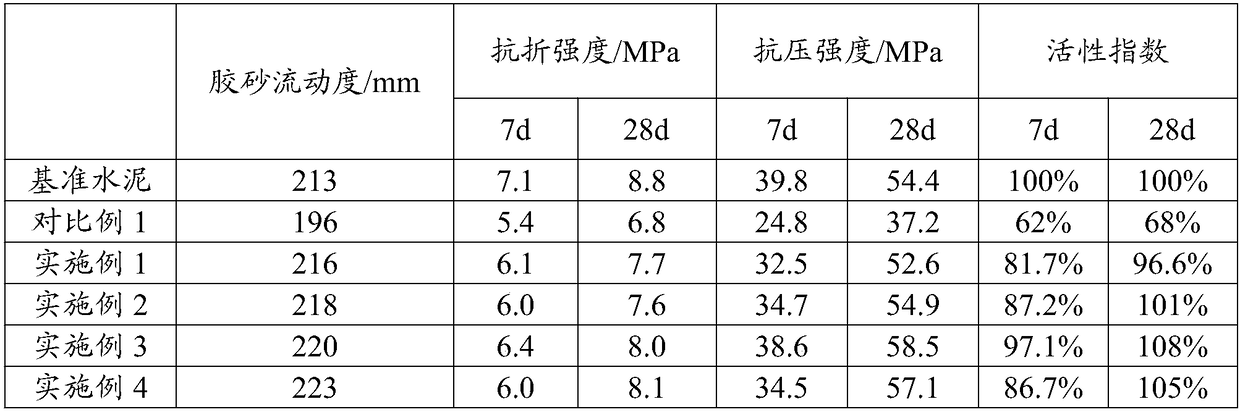

Steel slag based mineral admixture, preparation method and application thereof

The invention provides a preparation method of a steel slag based mineral admixture. The method includes the steps of: calcining a mixture of steel slag and a conditioning modifier in an inert gas atmosphere to obtain the steel slag based mineral admixture. The conditioning modifier is one or a mixture of two or more of graphite, activated carbon, bituminous coal, anthracite, lignite, coke and coal gangue. The steel slag based mineral admixture obtained by the preparation method provided by the invention is compounded with cement in a mass ratio of 3:7 into a cementing material, GB / T 17671-1999 is employed to test the cementing performance of the cementing material, after 7d of curing, the cementing activity index can reach 97.1%, and after 28d of curing, the cementing activity index can reach 108%, therefore the mineral admixture obtained by the preparation method provided by the invention has excellent cementing activity.

Owner:SHAOGUAN COLLEGE

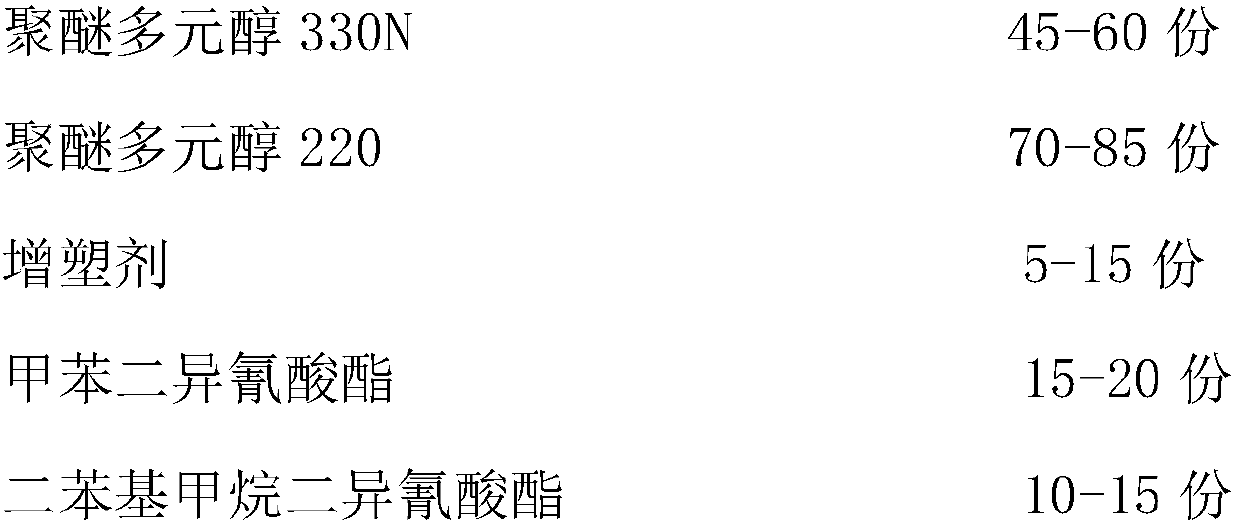

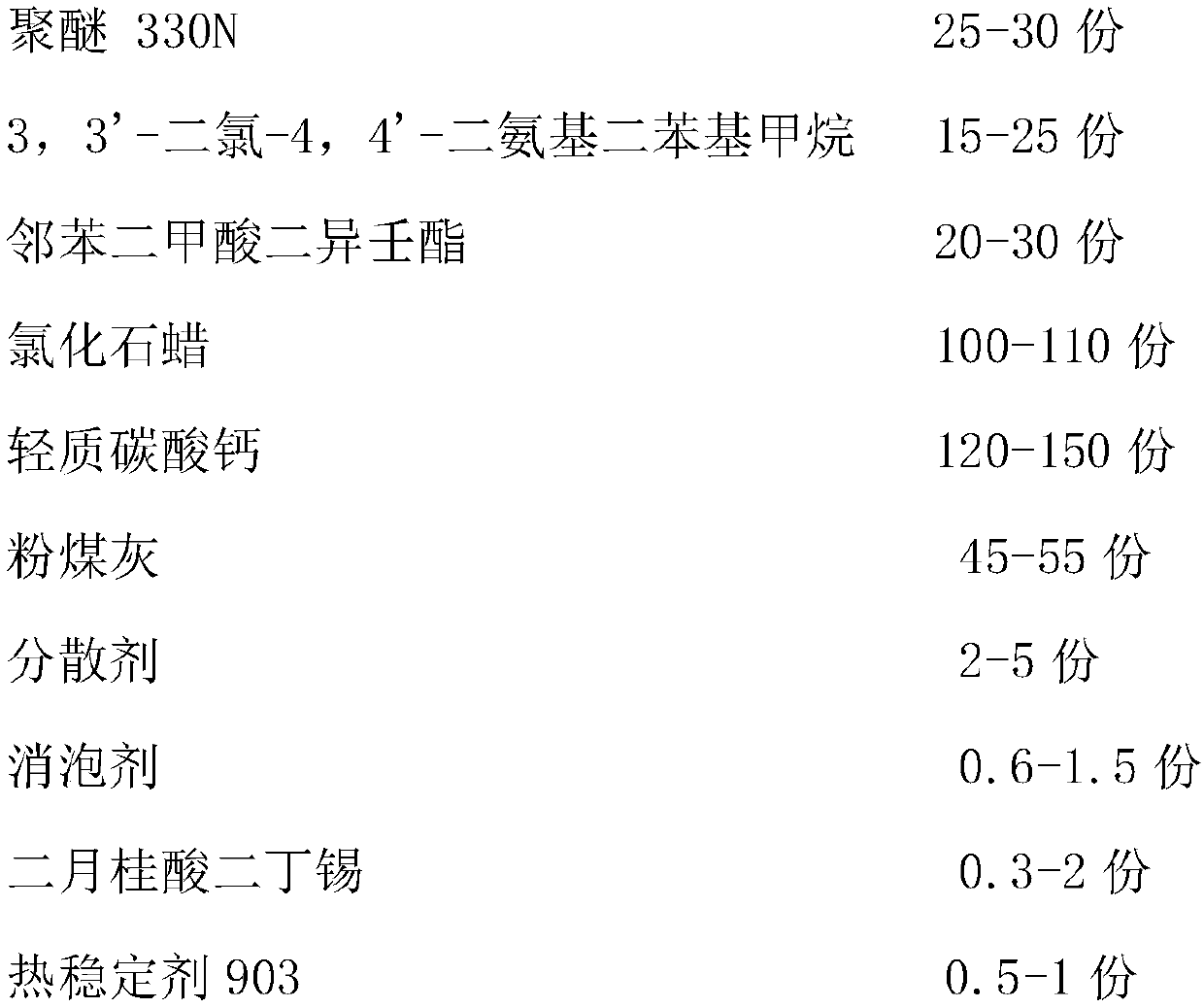

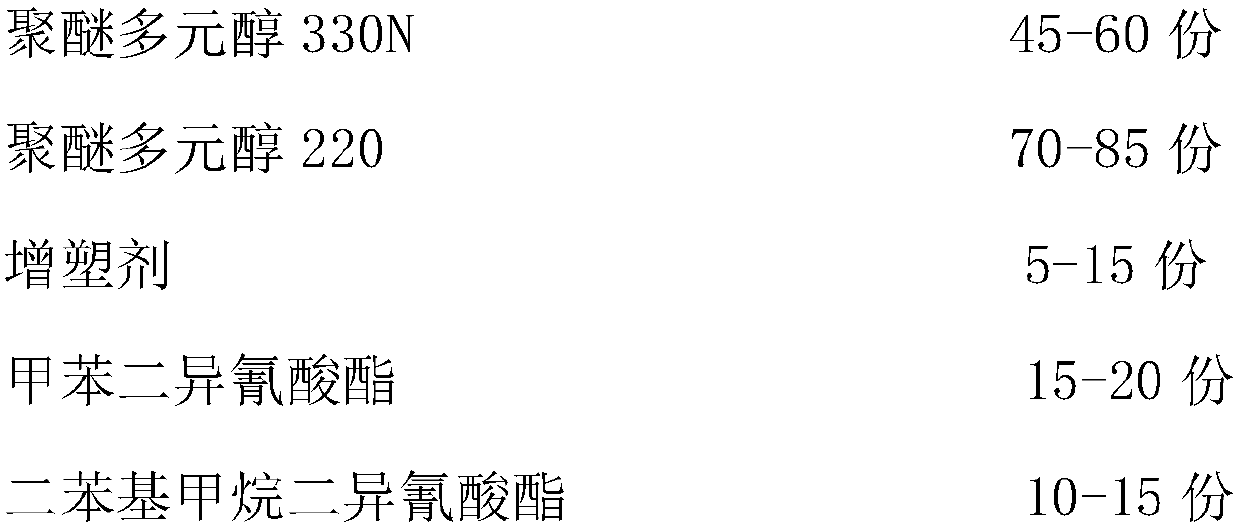

Two-component polyurethane waterproof coating and preparation method thereof

InactiveCN108047919ALow costLow pricePolyurea/polyurethane coatingsToluene diisocyanateChlorinated paraffins

The invention provides a two-component polyurethane waterproof coating. The two-component polyurethane waterproof coating comprises a component A and a component B, wherein the component A comprises 45 to 60 parts of polyether polyol 330N, 70 to 85 parts of polyether polyol 220, 5 to 15 parts of a plasticizer, 15 to 20 parts of toluene diisocyanate and 10 to 15 parts of diphenylmethane diisocyanate; and the component B comprises 25 to 30 parts of polyether 330N, 15 to 25 parts of 3,3'-dichloro-4,4'-diamino diphenyl methane, 20 to 30 parts of diisononyl ortho-phthalate, 100 to 110 parts of chlorinated paraffin, 120 to 150 parts of light calcium carbonate, 45 to 55 parts of fly ash, 2 to 5 parts of a dispersant, 0.6 to 1.5 parts of an antifoaming agent, 0.3 to 2 parts of dibutyltin dilaurateand 0.5 to 1 part of a heat stabilizer 903. The invention provides the two-component polyurethane waterproof coating and the preparation method thereof. According to the invention, through physical activities like particle effect and micro-aggregate effect of the fly ash, cementitious activities of a product can be promoted, and performances of the product are improved; meanwhile, by utilizationof a composite cross-linking agent, the proportion of rigid chain segments in a molecular chain is increased, so tensile strength and hardness are enlarged.

Owner:安徽中能众诚新能源科技有限公司

Electric furnace white slag performance optimization treatment method

ActiveCN104058610AImprove mineral compositionImprove gelling activityCement productionChemical reactionSlag

The invention relates to an electric furnace white slag performance optimization treatment method which comprises the following processing steps: taking a certain amount of electric furnace white slag; adding the following materials in percentage by weight into the electric furnace white slag, 20-35% of calcium-based material (measured by CaO), 0-2% of aluminum-based material (measured by Al2O3), 0-5% of iron-based material (measured by Fe2O3) and 0-2% of fluxing agent (measured by CaF2); mixing, and then grinding into fine powder; calcining the fine powder at high temperature to ensure that the components are subjected to chemical reaction; after calcining is finished, quickly cooling through air cooling; and then, crushing and milling the mixture to finally obtain white slag having high gelation activity. Thus, the mineral composition of the white slag is optimized; the gelation activity of the white slag is improved; and meanwhile, the recycling utilization ratio of the white slag solid waste is increased, thereby being beneficial to environment protection.

Owner:SHAOGUAN COLLEGE

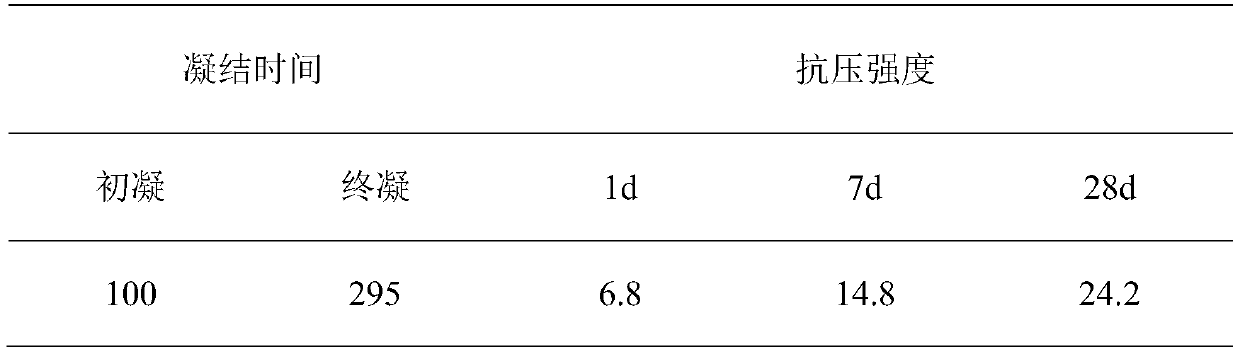

Method for preparing grouting material by using water-containing red mud and blast furnace slag

Owner:SHANDONG UNIV

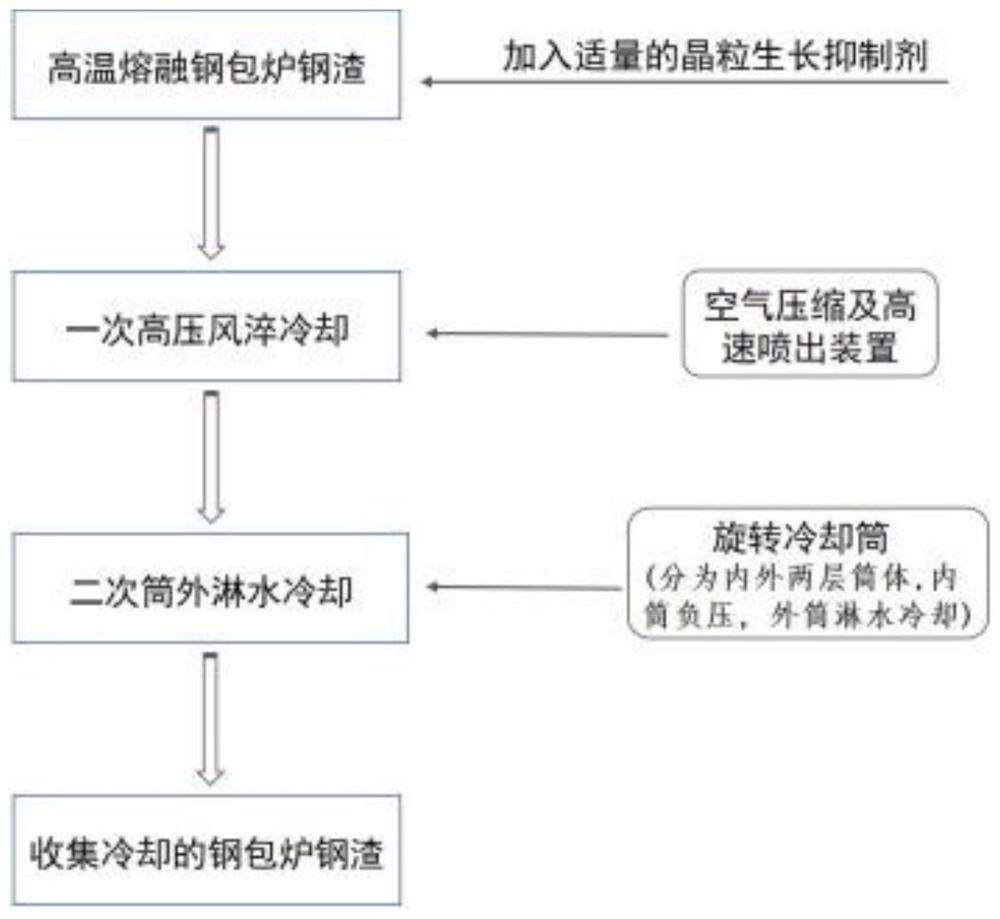

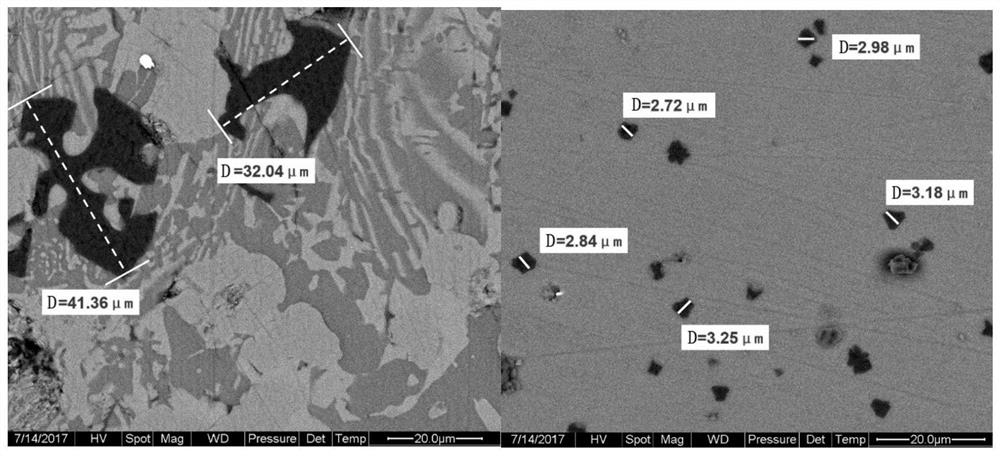

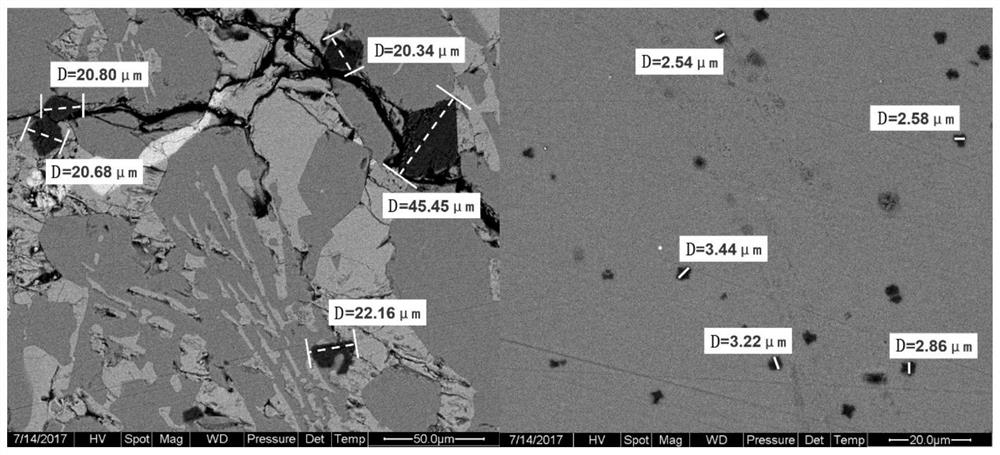

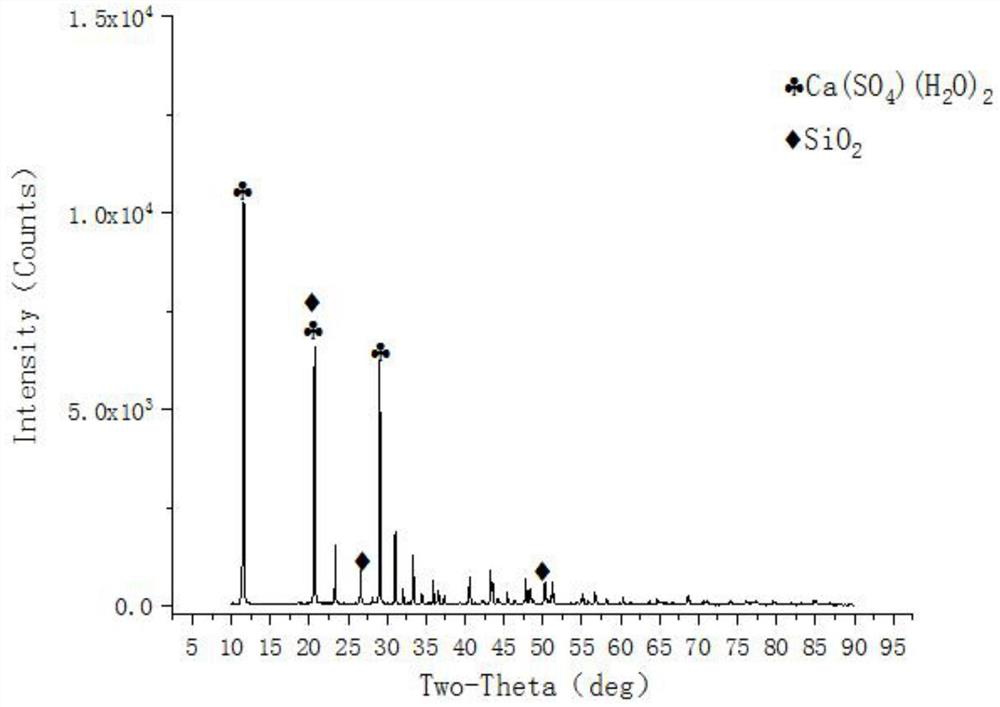

Method for refining size of free magnesium oxide in ladle furnace slag

ActiveCN111809006AImprove volume stabilityEfficient use ofRecycling and recovery technologiesLadle furnace slagMolten state

The invention discloses a method for refining the size of free magnesium oxide in ladle furnace slag. The method comprises the steps of adding an appropriate amount of grain growth inhibitors into theladle furnace slag, and raising temperature to enable the ladle furnace slag to be in a molten state; in the process of slag liquid flowing out through a chute, conducting air quenching and rapid cooling treatment for the ladle furnace slag with high-pressure high-speed air; collecting ladle furnace slag particles treated by air quenching by a rotary cooling drum, and conducting secondary outer-drum water circulating cooling; and finally, collecting the treated ladle furnace slag. The method conducts primary air quenching cooling and secondary outer-drum water circulating cooling for the molten ladle furnace slag and is supplemented by the effect of the grain growth inhibitors, so that the average size of free magnesium oxide in the treated ladle furnace slag is reduced by one order of magnitude, and small size and high activity are maintained. The method is very helpful to improve the volume stability of the ladle furnace slag used as a gelling material for building materials, and promote the efficient resource utilization of the building materials.

Owner:SUN YAT SEN UNIV +1

Method for improving gelling activity of ardealite

PendingCN111792862AGuaranteed infiltrationSmall granularityPhysical chemistryEnvironmental engineering

The invention discloses a method for improving the gelling activity of ardealite. The method comprises the following steps: (1) ageing phosphogypsum with water to obtain aged phosphogypsum; (2) carrying out wet grinding on the aged phosphogypsum to obtain wet-ground phosphogypsum; (3) roasting the wet-ground phosphogypsum, and cooling to obtain roasted phosphogypsum; and (4) respectively carryingout two-stage dump leaching on the roasted ardealite by using a medicament 1 and a medicament 2 to obtain the ardealite with improved gelling activity. The method has the advantages that the process is simple, the cost is low, the gelling activity of the phosphogypsum can be greatly improved, a building material prepared from the treated phosphogypsum is high in strength and strong in water leaching resistance, the doping amount can be larger than 70%, and a way is provided for large-scale use and comprehensive utilization of the phosphogypsum.

Owner:GUIZHOU UNIV

Preparation of single-component alkali-activated cement and application method thereof

ActiveCN102730996BExpand the range of raw materialsEasy to GrindClinker productionAlkali activatedMixed materials

The invention belongs to the novel cement material field and specifically relates to the preparation of a single-component alkali-activated cement and an application method thereof, wherein a raw material 1 including SiO2, Al2O3, and CaO are mixed with the raw material 2 including Na2O in a certain ratio; the ratio should be decided so that the percentage of the weight of each component of the calcined product, which is obtained by calcining the mixed materials at a temperature greater than or equal to 1100 DEG C, in the total weight is as follows: Al2O3: 8-25%; SiO2: 24-55%; CaO: 10-55%; and Na2O +0.658K2O: 6-25%; after being calcined at a temperature ranging from 950-1200 DEG C for 1.5-3 h, the mixed materials are then ground to obtain cement powder; the cement powder is mixed with water into paste; next, the paste is cured at 50-80 DEG C for 2-3 days so that neat cement paste briquettes excellent in strength can be obtained; and the strength can be continuously increased if curing is continuously performed under normal temperature. The preparation of the single-component alkali-activated cement has the following advantages that: the raw material range of the alkali-activated cement is greatly expanded; the storage, transportation and utilization of the cement are more convenient; and the improvement of the cementitious activity of the cement and the reduction of the cost are expected to be realized.

Owner:HUNAN UNIV OF SCI & TECH

High-density concrete doped with metal aggregate and preparation method of high-density concrete

InactiveCN110183167AImprove aging resistanceGood weather resistanceCeramicwareSodium metasilicateSlag

The invention discloses high-density concrete doped with metal aggregate. The high-density concrete comprises the following raw materials, in parts by weight: 300-450 parts by weight of steel slag, 100-140 parts by weight of broken coal gangue, 120-140 parts by weight of fly ash, 200-300 parts by weight of cement (625 or 625R Portland cement), 50-85 parts by weight of fine aggregate, 24-29 parts by weight of coarse aggregate, 20-25 parts by weight of boron glass sand, 10-20 parts by weight of S105 mineral slag powder, 0.5-1 part by weight of an admixture, 200-250 parts by weight of water, 280-350 parts by weight of yellow sand, 5-12 parts by weight of nickel slag, 2-10 parts by weight of a foaming agent, 55-60 parts by weight of sodium metasilicate, 38-43 parts by weight of slaked lime, 15-25 parts by weight of manganese sulfate, and 30-45 parts by weight of broken recycled diatomaceous earth. The invention also discloses a preparation method of the high-density concrete. The high-density concrete doped with the metal aggregate provided by the invention has greatly-improved durability and workability, and the method achieves the effects of saving energy, reducing emission and reducing costs.

Owner:南通昆腾新材料科技有限公司

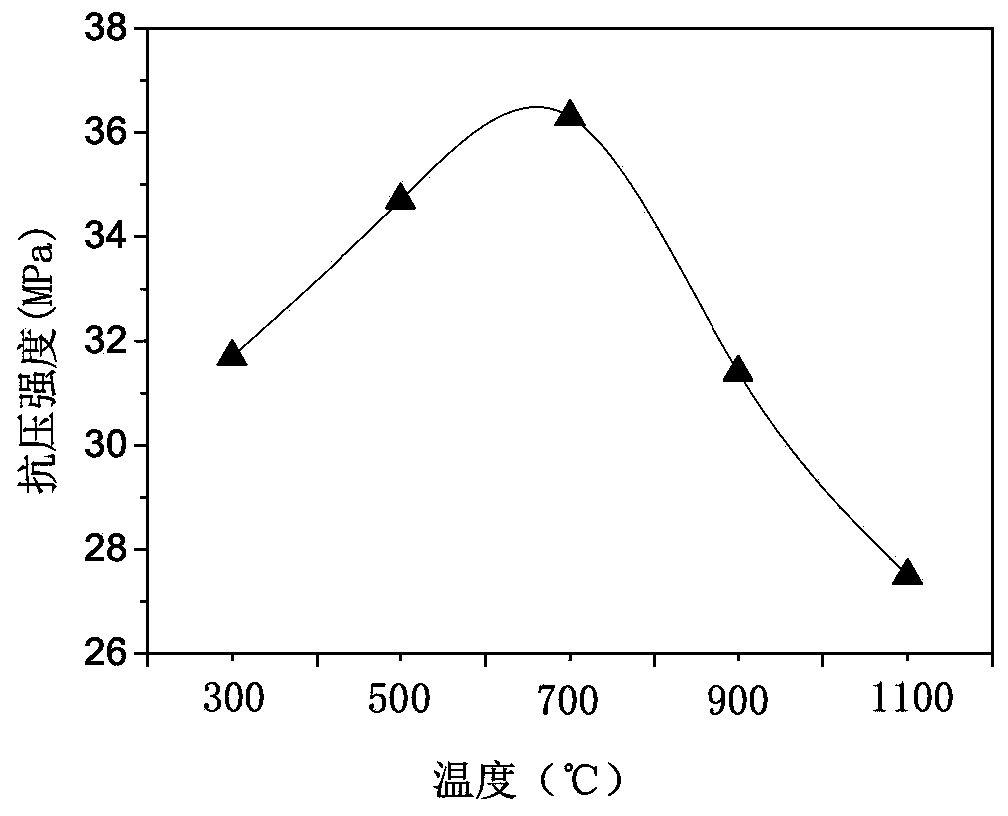

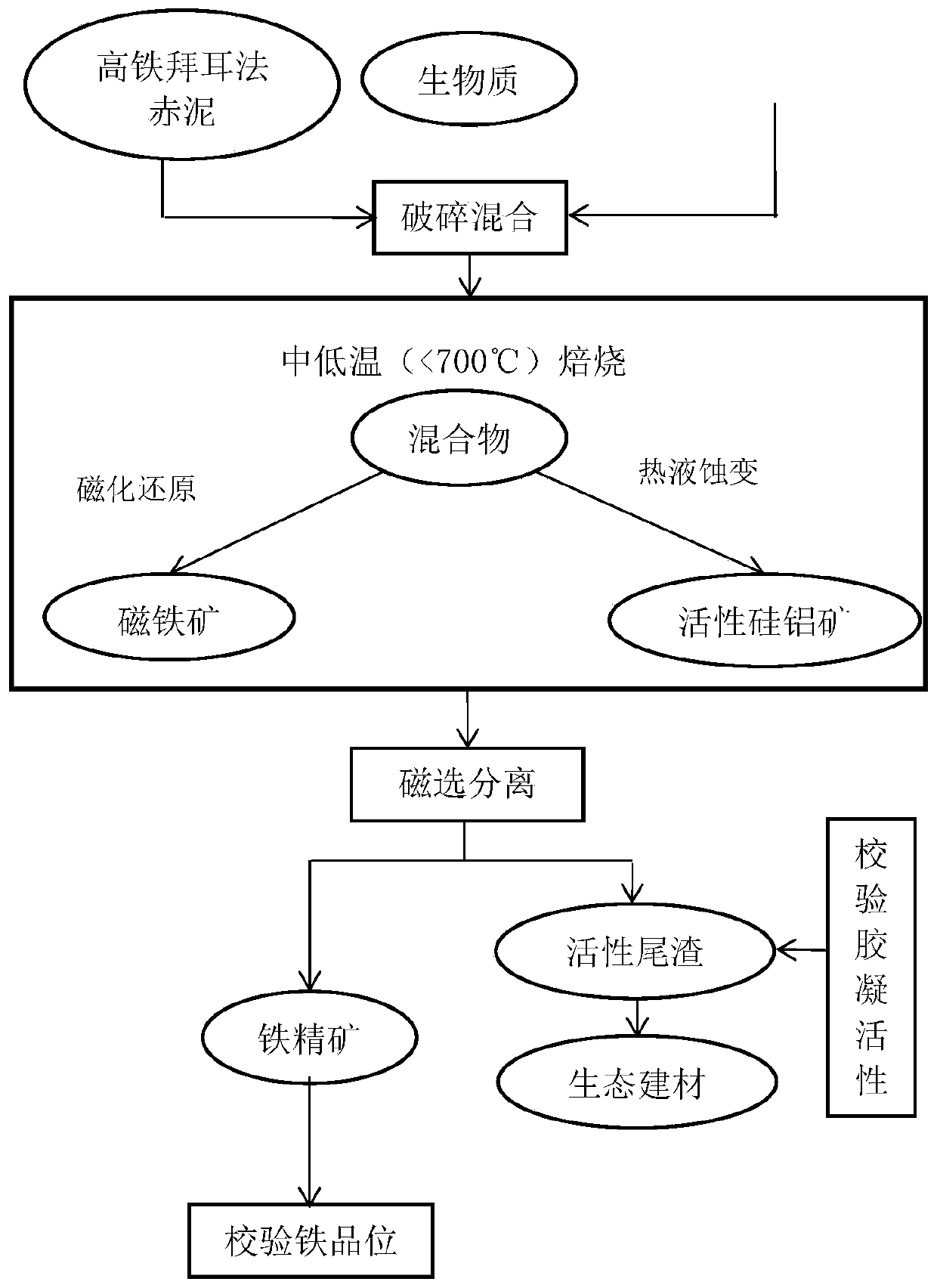

Method for Simultaneously Improving the Activity of Inorganic Components by Iron Oxide in Red Mud Reduction by Biomass

The invention discloses a method for biomass reduction of iron oxide in red mud and synchronous improvement of inorganic component activity, and belongs to the technical field of iron ore concentrate production by high-iron Bayer process red mud. The usage of biomass accounts for 5%-50% that of the high-iron Bayer process red mud, raw materials are weighed and uniformly mixed, and obtained mixture is sintered at the temperature ranging from 400 DEG C to 750 DEG C. Iron ore concentrate meeting blast furnace iron making requirements and inorganic materials with high cementitious activity are obtained after magnetic separation. Biomass raw materials replace pulverized coal to reduce hematite in the high-iron Bayer process red mud, reduction temperature can be reduced by about 200 DEG C, and optimal inorganic component cementitious activity can be synchronously obtained. The steps of hematite reduction and inorganic cementitious activity improvement are combined, the high-iron red mud serving as solid waste discharged in the aluminum oxide production process is used by 'stepped all components', energy consumption is reduced as compared with carbon-based reduction, carbon emission is decreased, investment and production cost is reduced, and environmental benefits, social benefits and economic benefits are remarkable.

Owner:UNIV OF SCI & TECH BEIJING

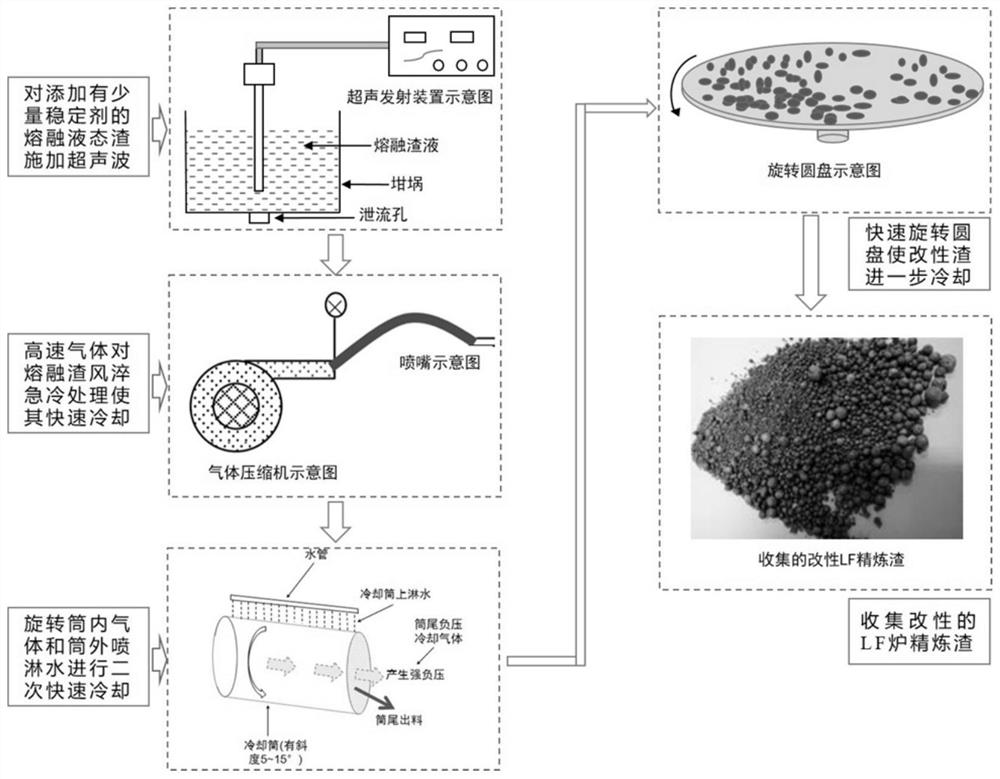

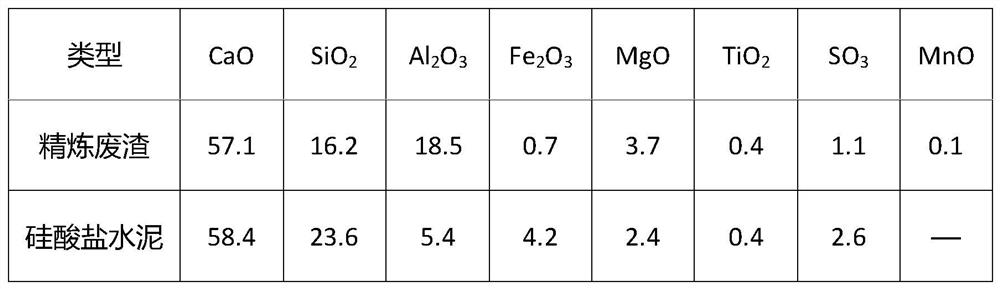

Modified LF furnace refining waste residue with high gelling activity as well as preparation method and application thereof

ActiveCN111646712AIncreased hydration activity and gelling propertiesImprove economic efficiencyCement productionSlagBuilding material

The invention discloses a modified LF furnace refining waste residue with high gelling activity, a preparation method and application, wherein the modified LF furnace refining waste residue is mainlycomposed of amorphous C12A7 mineral and beta-C2S mineral and the content reaches 60% or above, and the modified LF furnace refining waste residue also contains a small amount of C3A, C3S, CaO, MgO, CaF2 and other minerals. The invention also provides a preparation method of the modified LF furnace refining waste residue with high gelling activity and application of the modified LF furnace refiningwaste residue as a cement-based material and a quick-hardening gelling material. The invention discloses modified LF furnace refining waste slag with high gelling activity, which is an effective wayfor optimizing and modifying waste slag generated in steel refining slag and recycling building materials of the waste slag. The early-strength quick-hardening cement has the characteristics of high hydration activity, early strength and quick hardening, is wide in source and low in cost, has huge potential of being used as a cementing material or an auxiliary cementing material to be applied to cement-based building materials and special engineering materials, and is wide in application prospect.

Owner:SUN YAT SEN UNIV

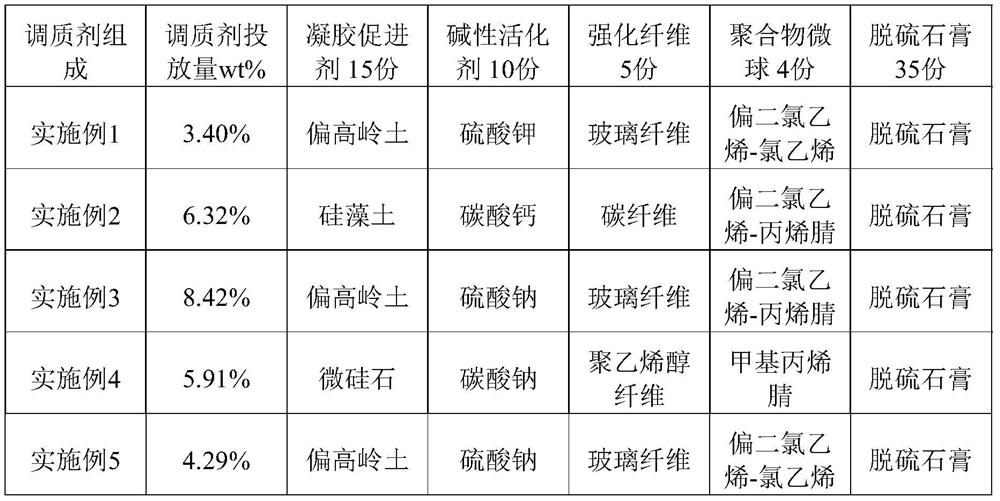

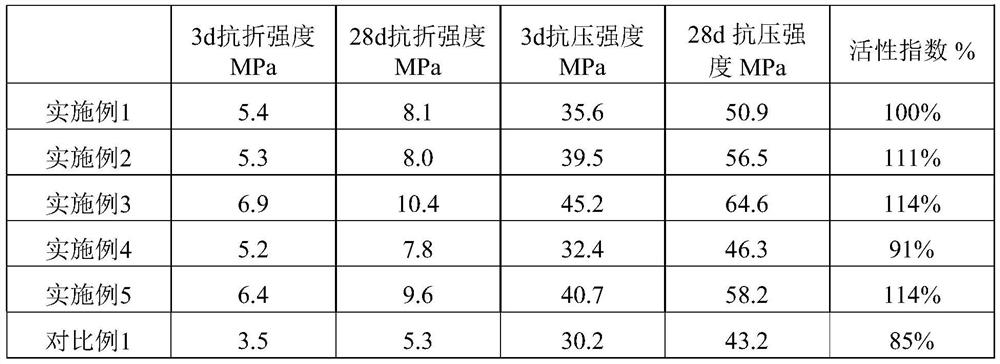

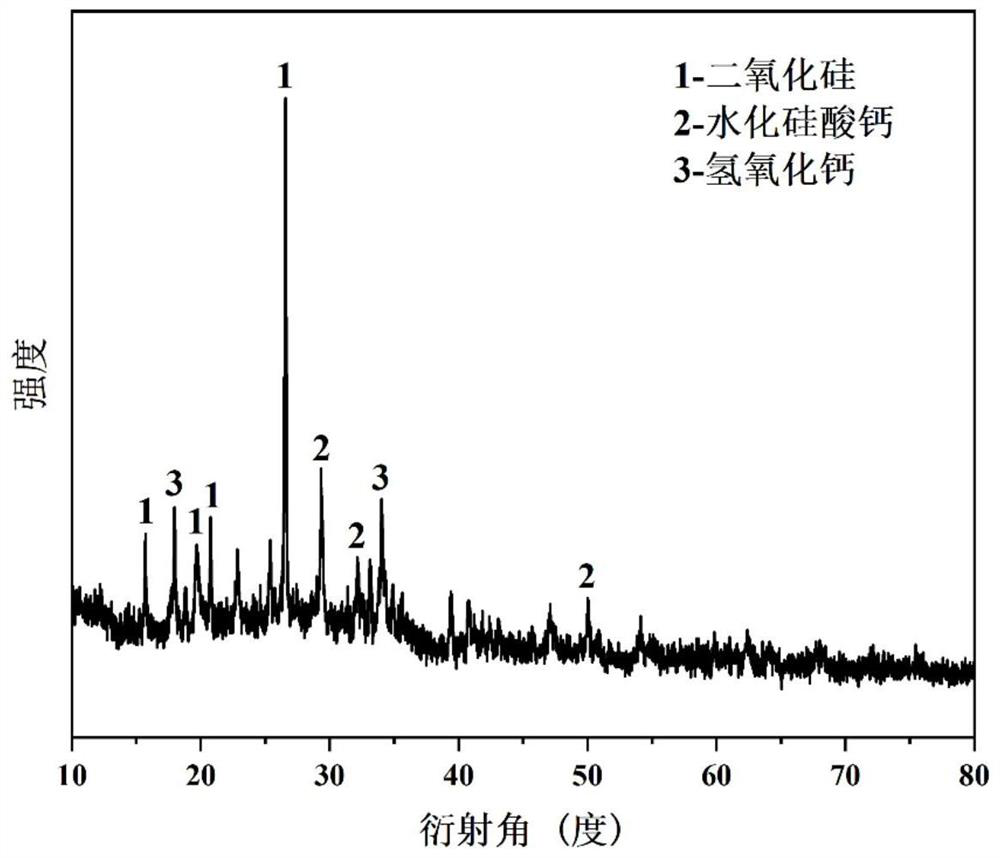

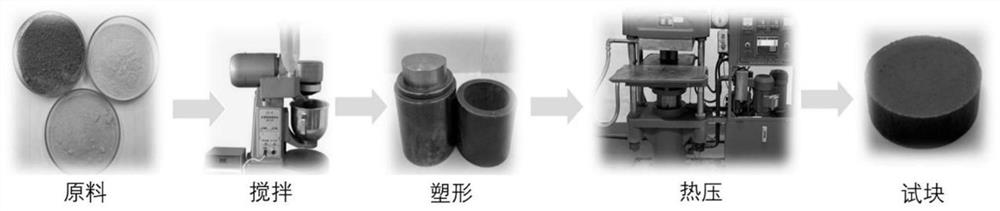

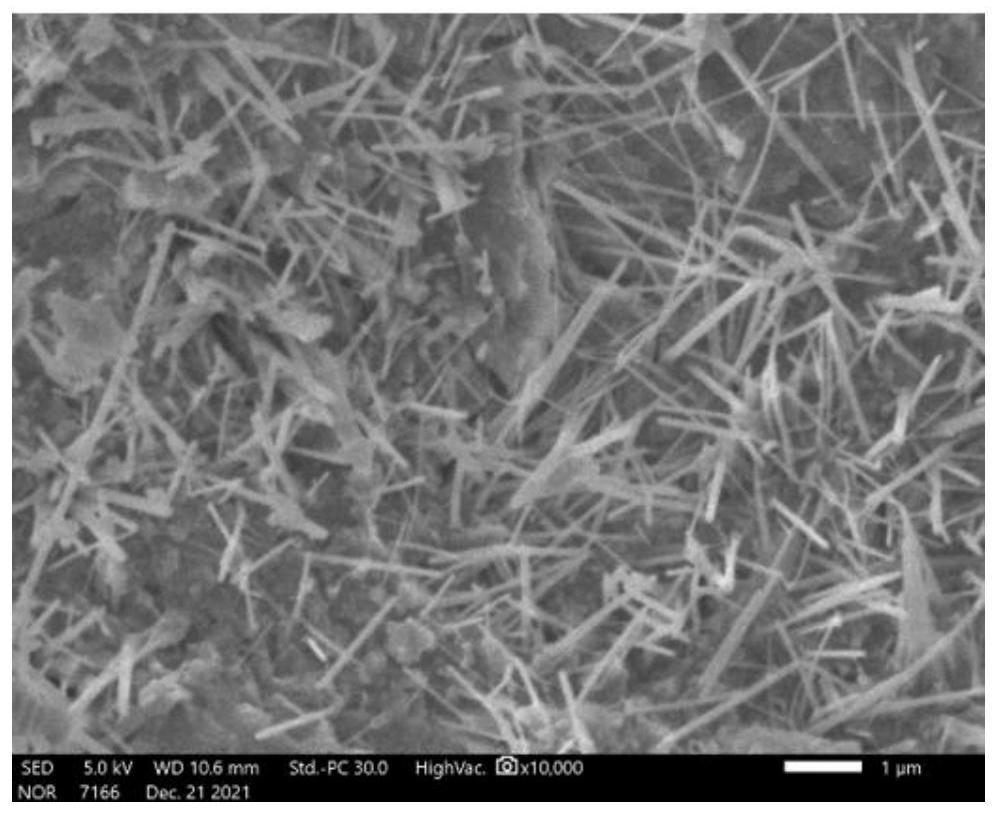

Hot-press molded maintenance-free solid waste-based artificial stone and preparation method thereof

The invention relates to the technical field of building materials, and provides a hot-press molded maintenance-free solid waste-based artificial stone and a preparation method thereof. According to the characteristics that main components of the circulating fluidized bed fly ash contain quartz SiO2 and Al2O3 and main components of the carbide slag contain Ca (OH) 2, the circulating fluidized bed fly ash and the carbide slag are subjected to a pozzolanic reaction in the hot pressing process, and hydrated calcium silicate and hydrated calcium aluminate products are obtained; the fly ash of the circulating fluidized bed is subjected to certain sulfate excitation by utilizing the characteristics that main components in the desulfurized gypsum contain CaSO4. 2H2O and the desulfurized gypsum contains SO4 < 2->, so that the gelling activity of the fly ash of the circulating fluidized bed is improved; and finally, along with the proceeding of the hot pressing process, hydration reaction can be carried out between the three solid wastes of the circulating fluidized bed fly ash, the carbide slag and the desulfurized gypsum and water to generate gelatinous substances such as hydrated aluminosilicate and the like, so that the strength of the artificial stone is improved.

Owner:SHANXI UNIV

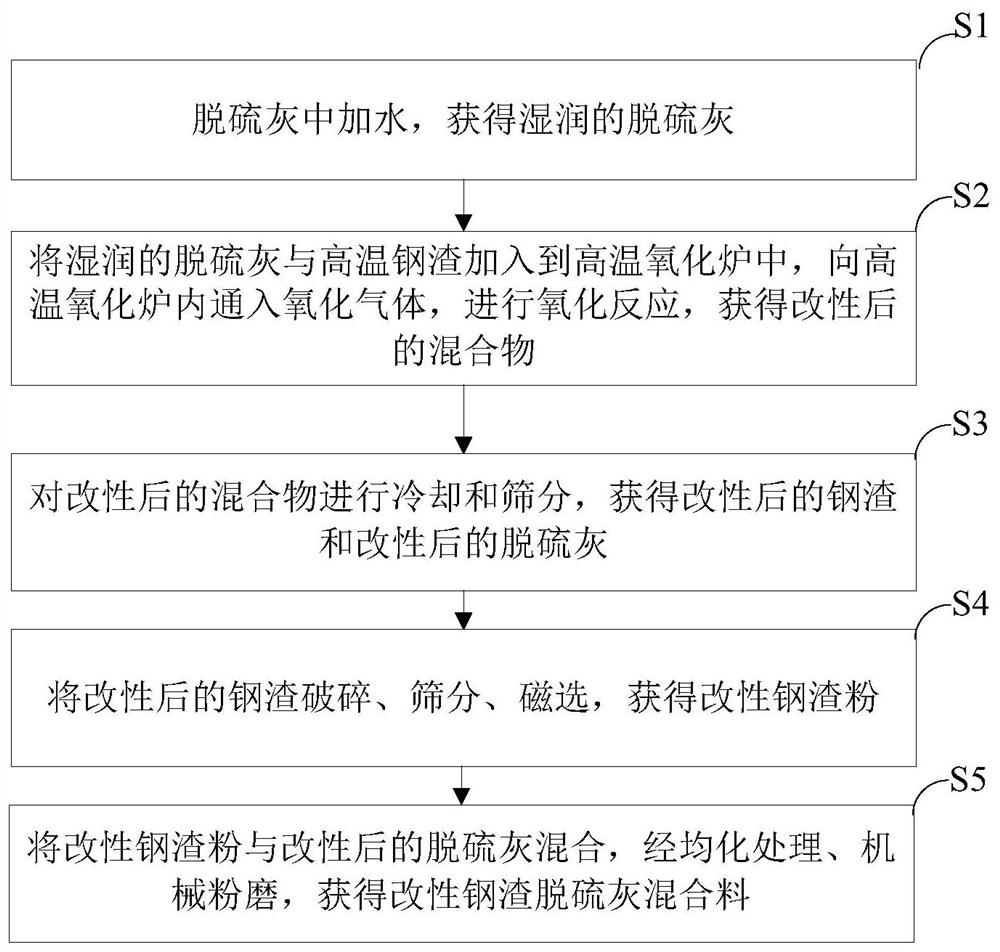

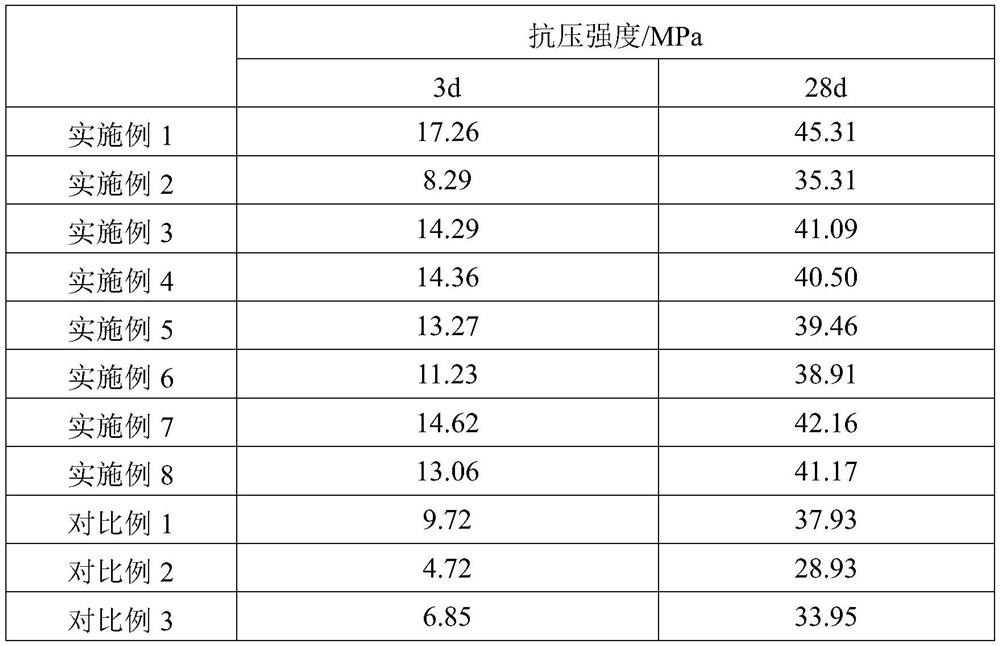

Modified steel slag desulfurization ash mixture, preparation method thereof and cementing material

The invention provides a preparation method of a modified steel slag and desulfurized ash mixture, which comprises the following steps: firstly, adding water into desulfurized ash to obtain wet desulfurized ash; secondly, adding the wet desulfurized fly ash and high-temperature steel slag into a high-temperature oxidation furnace, introducing oxidizing gas into the high-temperature oxidation furnace, and carrying out oxidation reaction to obtain a modified mixture; thirdly, cooling and screenign the modified mixture, and obtaining modified steel slag and modified desulfurized fly ash; carrying out crushing, screening and magnetic separation on the modified steel slag to obtain modified steel slag powder; and finally, mixing the modified steel slag powder with the modified desulfurized fly ash, and carrying out homogenization treatment and mechanical grinding to obtain the modified steel slag desulfurized fly ash mixture. The prepared modified steel slag and desulfurized ash mixture is used as a main component of a cementing material, so that the utilization amount of steel slag is increased, the production and preparation cost of the cementing material is reduced, and the early performance of the cementing material is remarkably improved.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com