Archaized brick prepared by using montmorillonite and illite and preparing method thereof

A technology of illite and antique bricks, which is applied in the field of antique bricks, can solve the problems of increased danger and difficulty in controlling drying shrinkage, and achieve the effects of reducing damage, natural antique effect, and improving early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

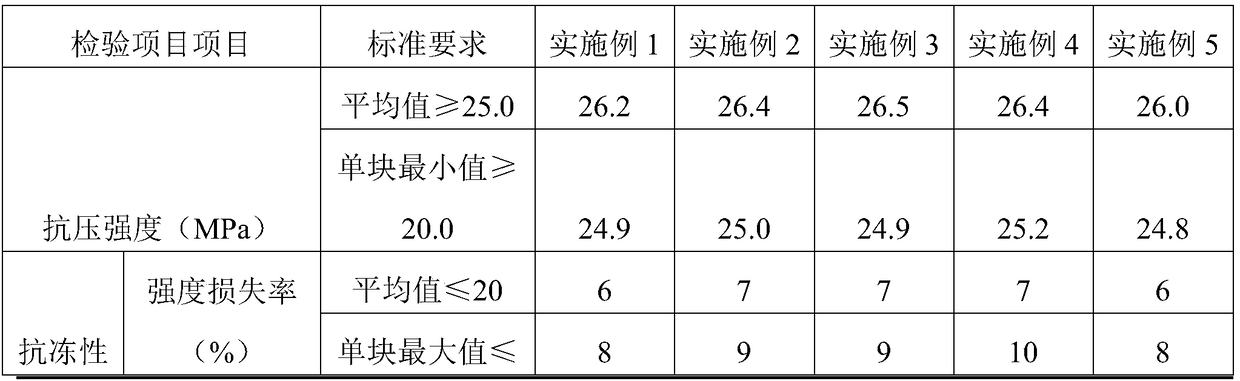

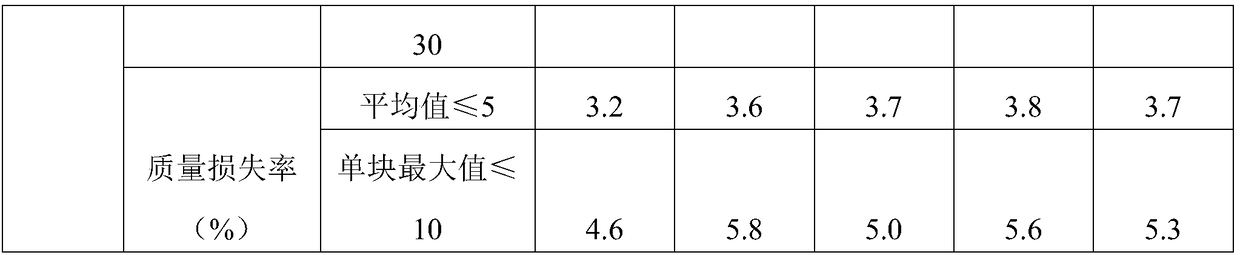

Examples

Embodiment 1

[0027] This embodiment provides an antique brick prepared by using montmorillonite and illite, which is prepared from the following raw materials in parts by weight: 20 parts of montmorillonite, 20 parts of illite, 8 parts of chlorite, and 20 parts of sludge , 8 parts of salt gypsum, 8 parts of white cement, 4 parts of modified plant fiber, 0.5 part of iron black, 0.8 part of disodium EDTA, 1.0 part of calcium hydroxide, and 1.0 part of sodium hexametaphosphate.

[0028] Wherein, the modified plant fiber is prepared by the following method: crush the plant fiber, and then perform air explosion loosening treatment; add the air-aeration treated plant fiber into the modifier and soak for 4 hours, filter, dry, That is, the modified agent is composed of the following components in parts by weight: 18 parts of acetic acid, 8 parts of sodium acetate, and 70 parts of ethanol; the plant fiber is corn stalk fiber.

[0029] The present embodiment utilizes montmorillonite and illite to pr...

Embodiment 2

[0036] This embodiment provides an antique brick prepared by using montmorillonite and illite, which is prepared from the following raw materials in parts by weight: 15 parts of montmorillonite, 25 parts of illite, 5 parts of chlorite, and 25 parts of sludge , 5 parts of salt gypsum, 10 parts of white cement, 3 parts of modified plant fiber, 1 part of iron black, 0.5 part of disodium EDTA, 1.5 parts of calcium hydroxide, and 0.5 part of sodium hexametaphosphate.

[0037] Wherein, the modified plant fiber is prepared by the following method: the plant fiber is pulverized, and then air-exploded and loosened; the plant fiber after the air-aeration treatment is added to the modifier and soaked for 3 hours, filtered, dried, That is, the modified agent is composed of the following components in parts by weight: 20 parts of acetic acid, 5 parts of sodium acetate, and 100 parts of ethanol; the plant fiber is wheat straw fiber.

[0038] The present embodiment utilizes montmorillonite a...

Embodiment 3

[0045] This embodiment provides an antique brick prepared by using montmorillonite and illite, which is prepared from the following raw materials in parts by weight: 25 parts of montmorillonite, 15 parts of illite, 10 parts of chlorite, and 15 parts of sludge , 10 parts of salt gypsum, 5 parts of white cement, 5 parts of modified plant fiber, 1.0 part of disodium EDTA, 0.5-1.5 parts of calcium hydroxide, and 0.5 part of sodium hexametaphosphate.

[0046] Wherein, the modified plant fiber is prepared by the following method: the plant fiber is pulverized, and then air-exploded and loosened; the plant fiber after the air-aeration treatment is added to the modifier and soaked for 5 hours, filtered, dried, That is, the modified agent is composed of the following components in parts by weight: 15 parts of acetic acid, 10 parts of sodium acetate, and 50 parts of ethanol; the plant fiber is wheat straw fiber.

[0047] The present embodiment utilizes montmorillonite and illite to prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com