Modified LF furnace refining waste residue with high gelling activity as well as preparation method and application thereof

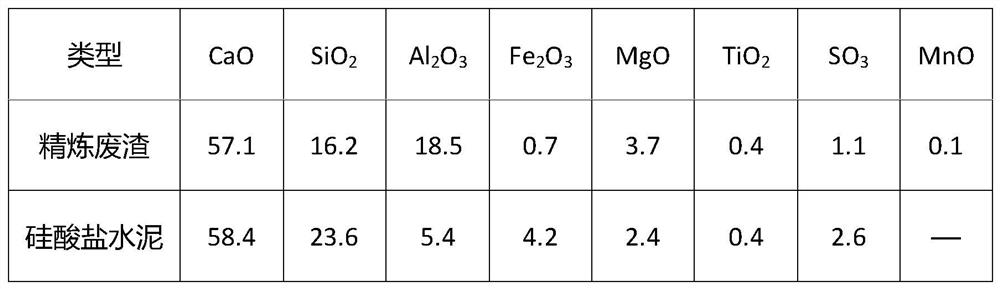

A technology for refining waste residue and modification, applied in cement production and other directions, can solve the problems of low activity and inferior crystal form, and achieve the effects of high economic benefit, improved hydration activity and gelation, and is conducive to popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

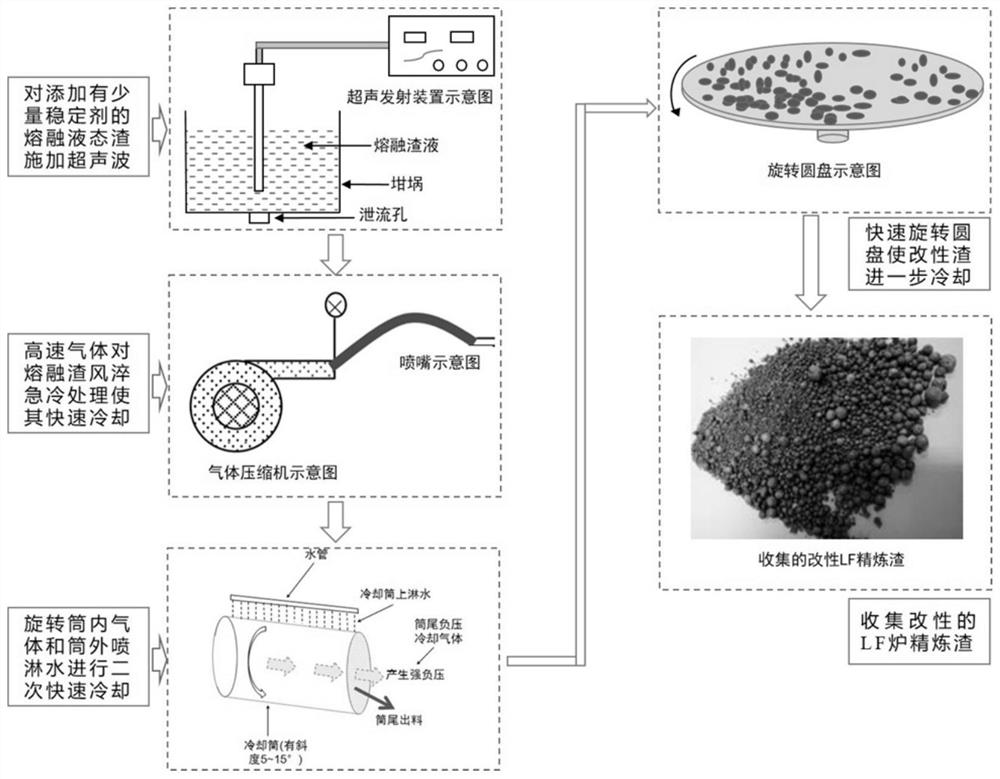

[0043] First, add 0.5% B to the high-temperature molten liquid LF furnace refining slag 2 o 3 stabilizer, and apply 100KHZ ultrasonic waves; then, the liquid refining slag flows out through the discharge hole at the bottom of the crucible, and high-speed gas is used to crush the liquid slag during the outflow of the slag liquid, so that it forms liquid slag droplets and rapidly cools in flight. And fall into the rotating cooling cylinder (the cylinder body has an inclination angle of 10° with the horizontal plane), and carry out secondary rapid cooling through negative pressure gas in the cylinder and spray cooling water outside the cylinder; then, the refined slag of the LF furnace after secondary cooling The discharge from the end of the cylinder falls into the 300r / min fast rotating disc to make it further cooled; finally, the cooled modified LF furnace refining slag is collected.

Embodiment 2

[0045] First, add 0.5% B to the high-temperature molten liquid LF furnace refining slag 2 o 3 stabilizer, and apply 150KHZ ultrasonic waves; then, the liquid refining slag flows out through the discharge hole at the bottom of the crucible, and high-speed gas is used to crush the liquid slag during the outflow of the slag liquid, so that it forms liquid slag droplets and rapidly cools in flight. And fall into the rotating cooling cylinder (the cylinder body has an inclination angle of 10° with the horizontal plane), and carry out secondary rapid cooling through negative pressure gas in the cylinder and spray cooling water outside the cylinder; then, the refined slag of the LF furnace after secondary cooling The discharge from the end of the cylinder falls into the 700r / min fast rotating disc to make it further cooled; finally, the cooled modified LF furnace refining slag is collected.

[0046] The performance test of the modified LF furnace refining waste slag prepared by the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com