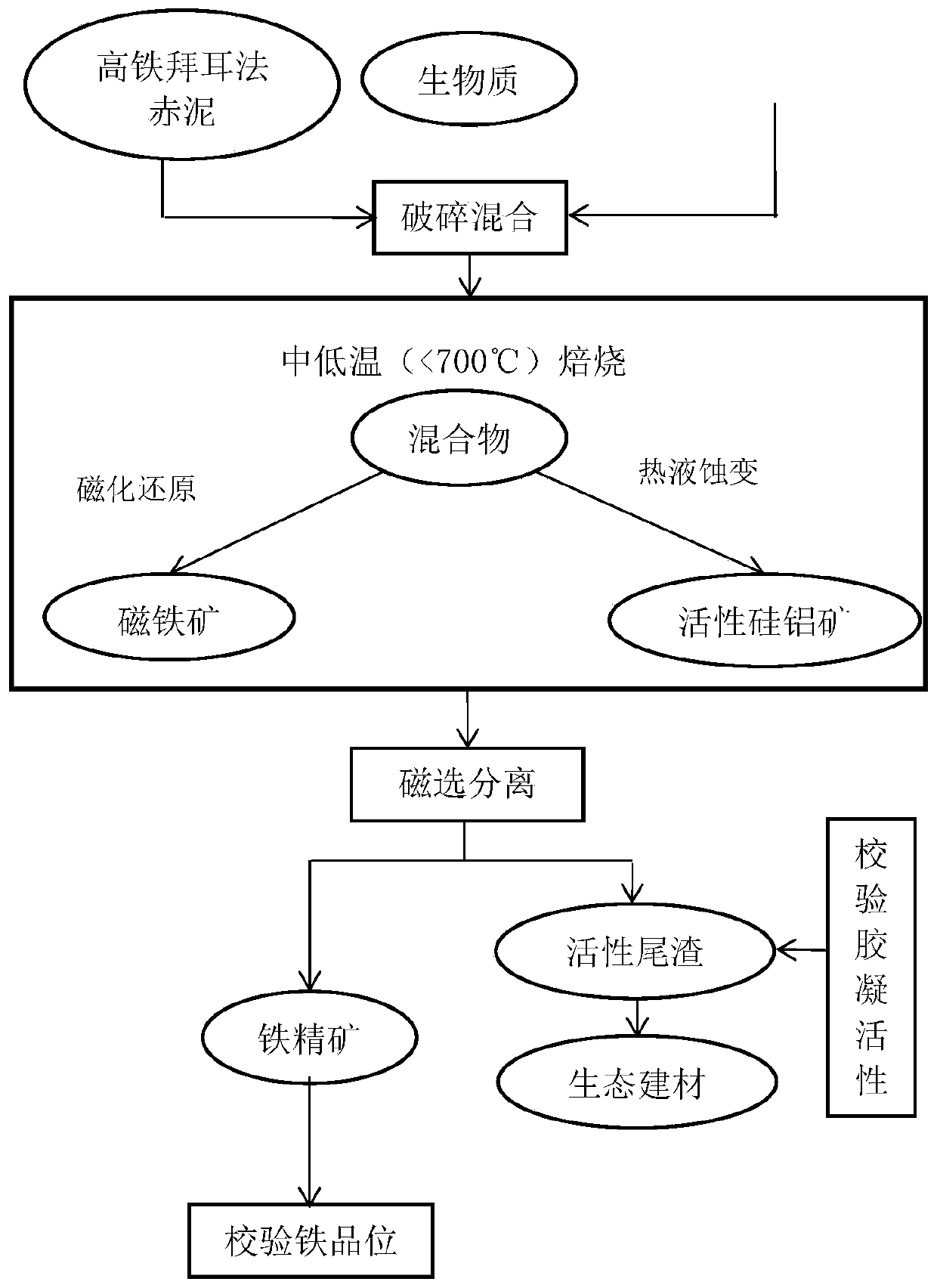

Method for Simultaneously Improving the Activity of Inorganic Components by Iron Oxide in Red Mud Reduction by Biomass

A technology of inorganic components and biomass raw materials, applied in the direction of cement production, etc., can solve the problems of expanding the consumption of iron tailings, low gelling activity of iron tailings, and the inability to apply large amounts, so as to improve the gelling activity, Effects of environmental protection and waste reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

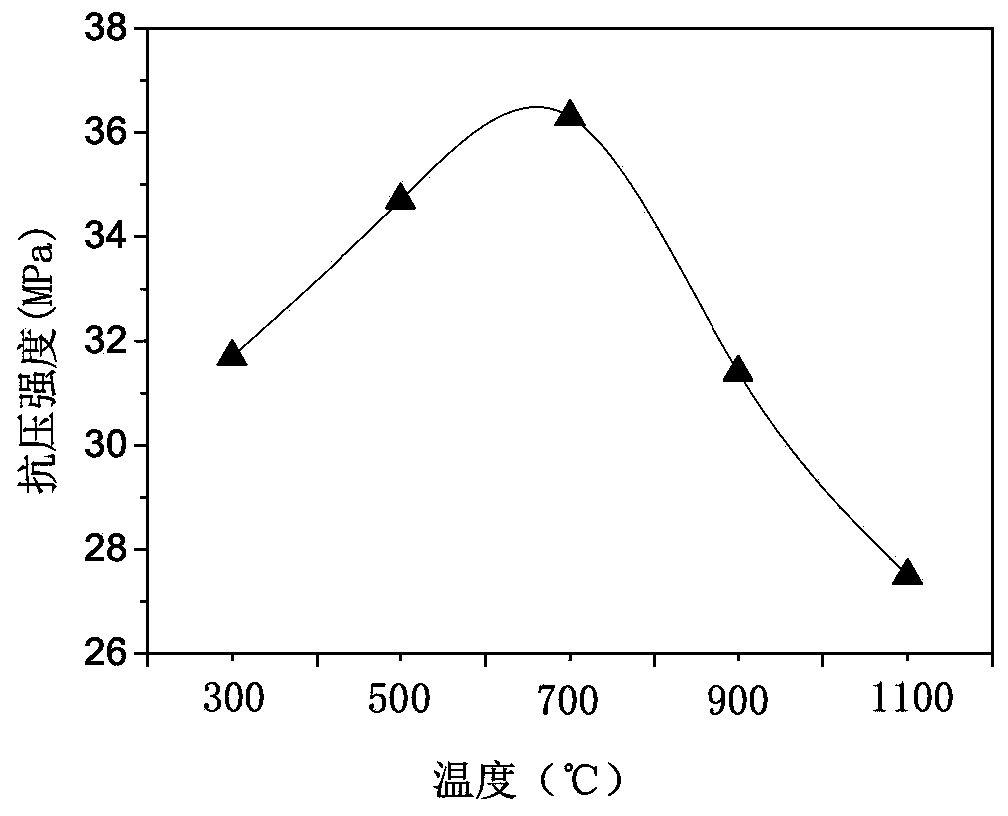

Embodiment 1

[0022] The selected biomass is pine sawdust. The raw materials are processed and sieved to a particle size below 0.3mm, and the high-iron Bayer process red mud is ground to a fine particle size of 0.08mm (92%). The amount of biomass used is 15% of the amount of red mud used in the high-speed iron Bayer process, the reaction temperature is set at 550°C, and iron concentrate with a grade of 65% is obtained by roasting in a tube furnace for 32 minutes, and the recovery rate reaches 85%. It has high gelling activity and can be directly used in building materials.

Embodiment 2

[0024] The biomass is selected as corn stalks. The raw materials are processed and screened to a particle size below 0.3mm, and the high-iron Bayer process red mud is ground to a fine particle size of 0.08mm (92%). The amount of biomass used is 24% of the amount of red mud used in the high-speed iron Bayer process, the reaction temperature is set at 630°C, and iron concentrate with a grade of 70% is obtained by roasting in a tube furnace for 40 minutes, and the recovery rate reaches 96%. It has high gelling activity and can be directly used in building materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com