Hot-press molded maintenance-free solid waste-based artificial stone and preparation method thereof

A technology of hot pressing and artificial stone, applied in the field of building materials, can solve the problem of high cost of raw materials, and achieve the effects of recycling, improving gelling activity and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

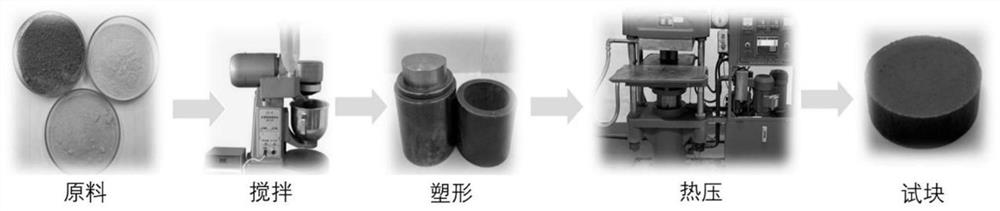

[0022] The invention provides a preparation method of a hot-pressed curing-free solid waste-based artificial stone, comprising:

[0023] The circulating fluidized bed fly ash, calcium carbide slag, desulfurized gypsum and water are mixed, and then hot-pressed to obtain a solid-waste-based artificial stone without curing by hot-pressing.

[0024] In the invention, the circulating fluidized bed fly ash, calcium carbide slag, desulfurized gypsum and water are mixed, and then hot-pressed to obtain a solid-waste-based artificial stone without curing by hot-pressing.

[0025] In the present invention, the circulating fluidized bed fly ash, calcium carbide slag and desulfurized gypsum are preferably pretreated by heating respectively before use. In the present invention, the heating temperature for the heating pretreatment of the circulating fluidized bed fly ash, calcium carbide slag and desulfurized gypsum is preferably 100-110°C, more preferably 105°C. The present invention has n...

Embodiment 1

[0048] A kind of preparation method of hot-pressed curing-free solid waste-based artificial stone

[0049] Raw material pretreatment: The circulating fluidized bed fly ash, calcium carbide slag and desulfurized gypsum were heated to constant weight at 105°C.

[0050] The raw materials required for the preparation of hot-pressed curing-free solid waste-based artificial stone: 80kg of circulating fluidized bed fly ash, 20kg of calcium carbide slag, 15kg of desulfurized gypsum and 35kg of water, of which circulating fluidized bed fly ash, calcium carbide slag and desulfurized gypsum After pretreatment; the weight ratio of CFB fly ash, carbide slag, desulfurized gypsum and water is 80:20:15:35.

[0051] Preparation:

[0052] (1) adding the prepared raw material in the stirring mixer and stirring for 30 minutes, and the stirring speed is controlled to be 200 rev / min to obtain the mixed material;

[0053] (2) Pour the mixture obtained in step (1) into a mold, and perform hot press...

Embodiment 2

[0057] A kind of preparation method of hot-pressed curing-free solid waste-based artificial stone

[0058] Raw material pretreatment: The circulating fluidized bed fly ash, calcium carbide slag and desulfurized gypsum were heated to constant weight at 105°C.

[0059] The raw materials required for the preparation of hot-pressed curing-free solid waste-based artificial stone: 80kg of circulating fluidized bed fly ash, 20kg of calcium carbide slag, 15kg of desulfurized gypsum and 35kg of water, of which circulating fluidized bed fly ash, calcium carbide slag and desulfurized gypsum After pretreatment; the weight ratio of CFB fly ash, carbide slag, desulfurized gypsum and water is 80:20:15:35.

[0060] Preparation:

[0061] (1) adding the prepared raw material in the stirring mixer and stirring for 30 minutes, and the stirring speed is controlled to be 200 rev / min to obtain the mixed material;

[0062] (2) Pour the mixture obtained in step (1) into a mold, and perform hot press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com