Modified steel slag desulfurization ash mixture, preparation method thereof and cementing material

A technology of cementitious material and desulfurization ash, which is applied in cement production and other directions, can solve the problems of slow hydration reaction and poor stability of desulfurization ash, and achieve the effects of improving the cementing activity, the later strength and the utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

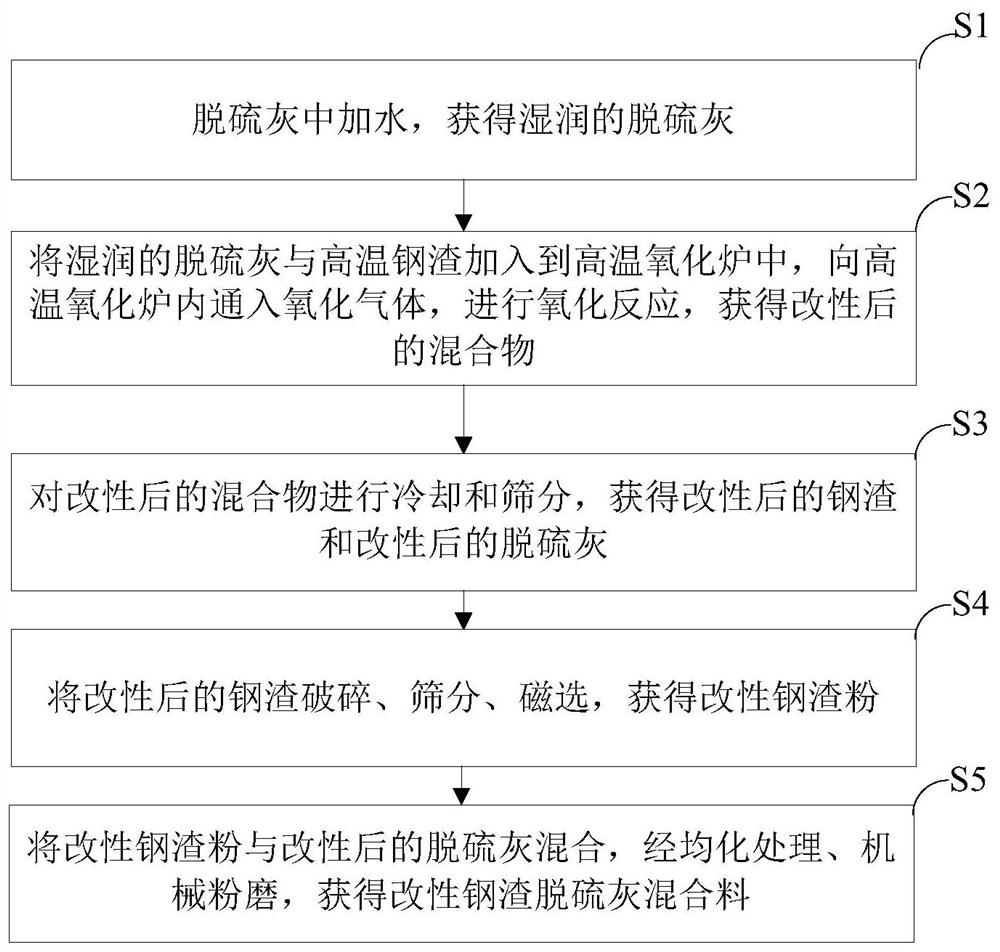

[0030] The invention provides a method for preparing a modified steel slag desulfurization ash mixture, comprising the following steps:

[0031] S1, add water to the desulfurization ash to obtain wet desulfurization ash;

[0032] S2. Adding moist desulfurization ash and high-temperature steel slag into a high-temperature oxidation furnace, introducing an oxidizing gas into the high-temperature oxidation furnace to carry out an oxidation reaction to obtain a modified mixture; the high-temperature steel slag is molten slag produced by steelmaking, The temperature of the high-temperature steel slag is 400-900°C;

[0033] S3, cooling and screening the modified mixture to obtain modified steel slag and modified desulfurization ash;

[0034] S4, crushing, sieving, and magnetically separating the modified steel slag to obtain modified steel slag powder;

[0035] S5. Mix the modified steel slag powder with the modified desulfurization ash, homogenize and mechanically grind to obtain...

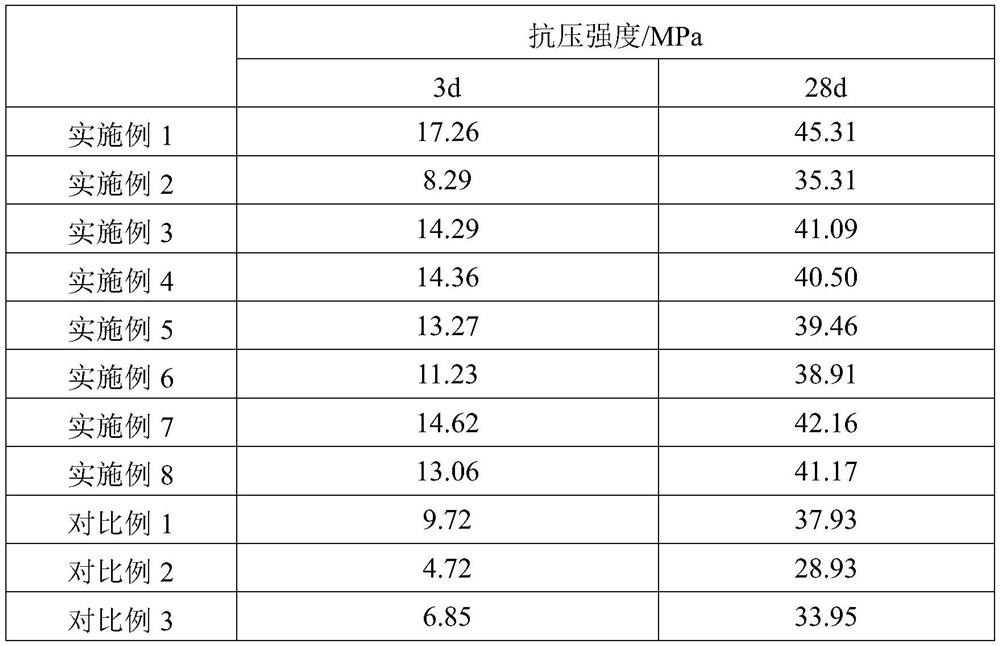

Embodiment 1

[0052] Add 25wt% water to the desulfurization ash to obtain wet desulfurization ash. Set a part of the wet desulfurization ash at the bottom of the high temperature oxidation furnace, then pour 900°C high temperature steel slag into the high temperature oxidation furnace, close the high temperature oxidation furnace, and evenly spray another part of the wet desulfurization ash to the high temperature through the feed port above the furnace. On the surface of steel slag, pass 5Nm into the high temperature oxidation furnace 3 Oxygen-air mixed gas for oxidation reaction to obtain a modified mixture. In the high-temperature oxidation furnace, the mass ratio of high-temperature steel slag to desulfurization ash is 2:1, and the oxidation reaction time is 5 hours.

[0053] The modified mixture is cooled to below 100°C, and the modified steel slag and modified desulfurization ash are screened through a sieving machine. The modified steel slag is crushed, screened, and magnetically s...

Embodiment 2

[0056] Add 35wt% water to the desulfurization ash to obtain wet desulfurization ash. Set a part of the wet desulfurization ash at the bottom of the high temperature oxidation furnace, then pour 600°C high temperature steel slag into the high temperature oxidation furnace, close the high temperature oxidation furnace, and evenly spray another part of the wet desulfurization ash to the high temperature through the feed port above the furnace. On the surface of steel slag, pass 10Nm into the high temperature oxidation furnace 3 Oxygen-air mixed gas for oxidation reaction to obtain a modified mixture. In the high-temperature oxidation furnace, the mass ratio of high-temperature steel slag to desulfurization ash is 1:1, and the oxidation reaction time is 8 hours.

[0057] The modified mixture is cooled to below 100°C, and the modified steel slag and modified desulfurization ash are screened through a sieving machine. The modified steel slag is crushed, screened, and magnetically ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com