Steel slag superfine powder production process

A production process and ultrafine powder technology, applied in the fields of comprehensive resource utilization and environmental protection, can solve the problems of uneven particle size, increased production cost, poor filling effect, etc., to improve gelling activity, save production cost, and increase additional value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

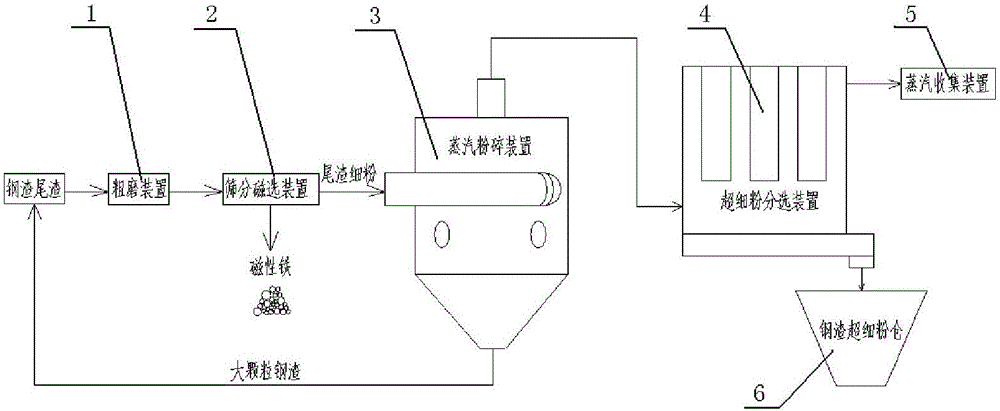

[0014] 1) The rough grinding device 1 is used to crush the steel slag tailings with a particle size of <10 mm to below 0.1 mm. The rough grinding device 1 can use either a ball mill or a vertical mill.

[0015] 2) After the steel slag tailings are crushed by the coarse grinding device 1, they enter the screening magnetic separation device 2 for screening and magnetic separation. After the screening and magnetic separation, they are divided into tailings fine powder and magnetic iron. The screening magnetic separation device 2 can Select machine.

[0016] 3) The tailings fine powder enters the steam crushing device 3, and superheated high-energy steam is used to impact and crush the tailings fine powder. The steam pressure is 0.1-0.4 MPa, and the steam temperature is 230-260°C. The mixture is discharged from the top of the steam crushing device 3 into the superfine powder sorting device 4, and the large particle steel slag is discharged from the bottom of the steam crushing dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com