Method of producing high sinkingproof organobentonite

A technology of bentonite and high anti-sedimentation, applied in chemical instruments and methods, inorganic chemistry, aluminum silicate, etc., can solve the problems of insufficient activation, low production efficiency, long time consumption, etc., achieve anti-settling performance and transparency, and product The effect of high quality and improved transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

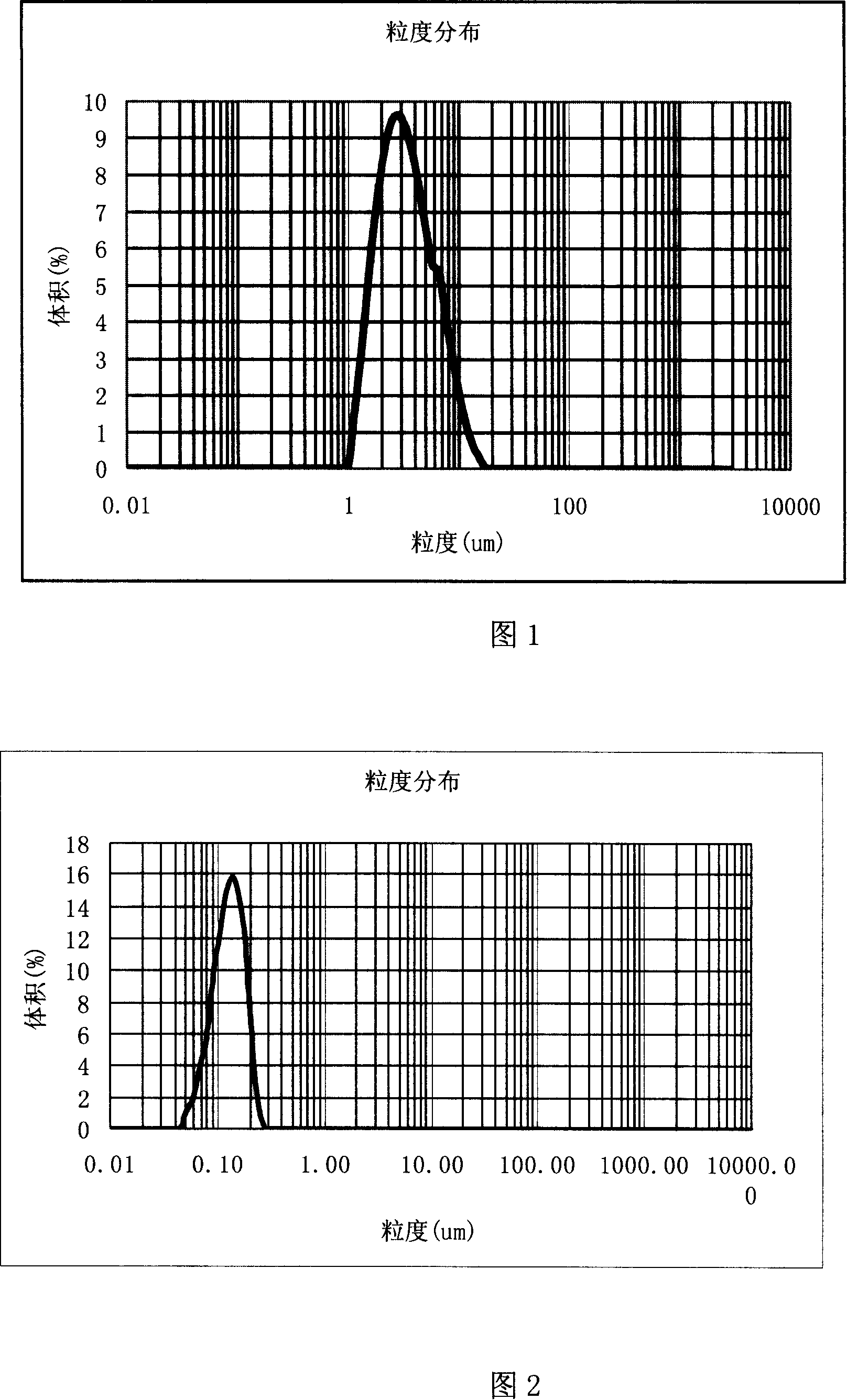

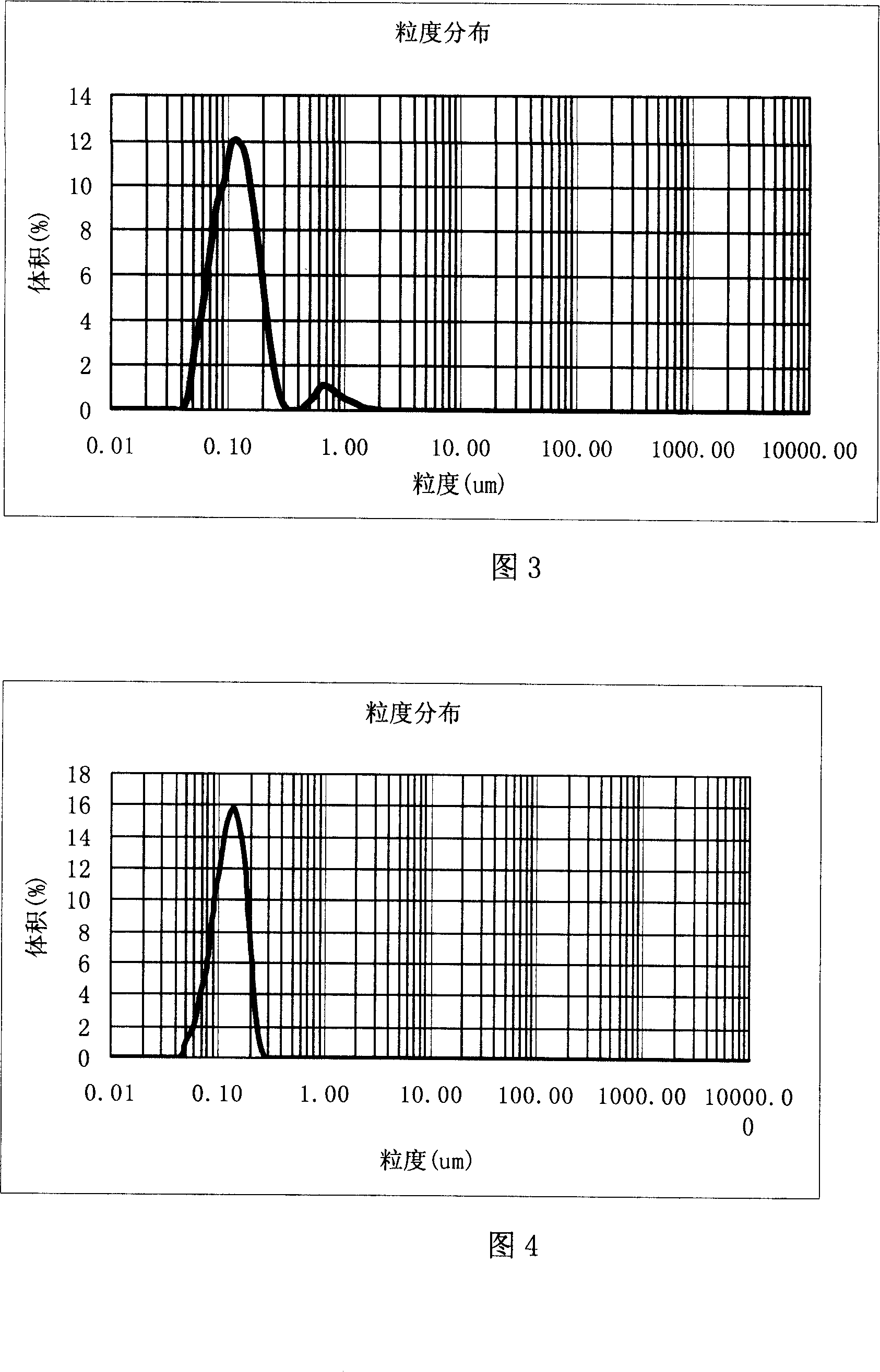

[0044] In a 1000ml beaker, add 20 g of bentonite with a montmorillonite content of 95%, add 500 ml of water, wherein the weight ratio of bentonite to water is 1: 25, stir for 20 minutes, then add 0.7 gram of sodium carbonate and disperse and stir for 30 minutes to make the bentonite Sufficient wetting and dispersion form sodium-based bentonite suspension, (the particle size distribution of high-pressure homogeneous sodium-based bentonite suspension is not as shown in Figure 1), this sodium-based bentonite suspension is used NiroNS1001L type high-pressure homogenizer at 100 standard atmospheres Lower homogenization, (the particle size distribution of sodium bentonite suspension after homogenization is shown in Figure 2). Then add the homogenized bentonite suspension to octadecyltrimethylammonium chloride solution to carry out organic activation reaction for 30 minutes, and then filter and dry to obtain high anti-sedimentation organic bentonite.

Embodiment 2

[0046] In the beaker of 1000ml, add centrifuged back montmorillonite content and be 95% bentonite suspension 500g, wherein the weight ratio of bentonite and water is 1: 25, stir for 20 minutes, then add 0.7 gram of sodium carbonate and disperse and stir for 30 minutes to make The bentonite is fully wetted and dispersed to form a sodium-based bentonite suspension, and the sodium-based bentonite suspension is homogenized at 200 standard atmospheres using a Niro NS1001L high-pressure homogenizer. (the particle size distribution of the sodium-based bentonite suspension after homogenization is shown in Figure 3) then the bentonite suspension that was homogenized was added to octadecyltrimethylammonium chloride solution to carry out organic activation reaction for 30 minutes, then filtered and dried to obtain the final product High anti-settling organic bentonite.

Embodiment 3

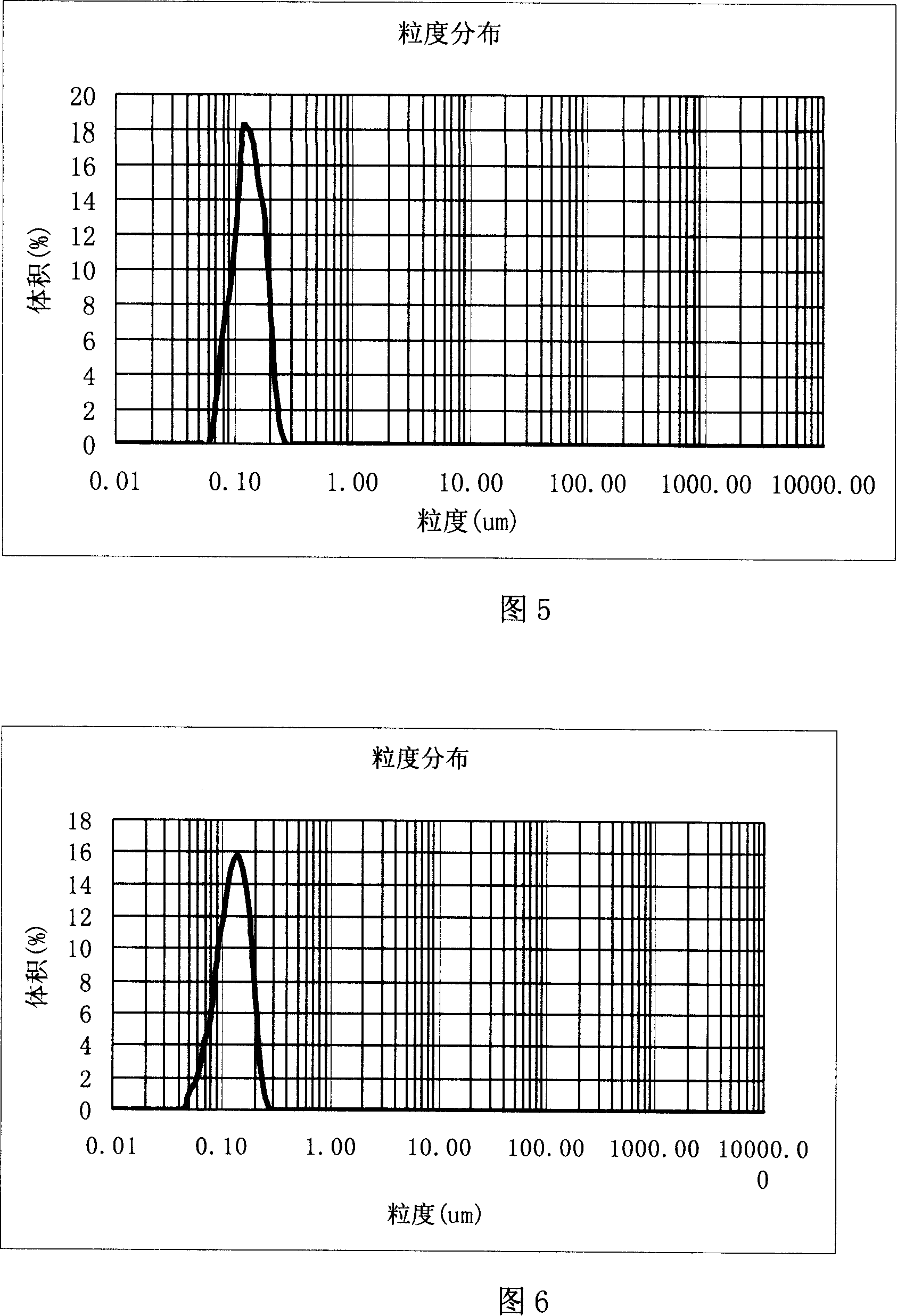

[0048] In the beaker of 1000ml, add centrifuged back montmorillonite content and be 95% bentonite suspension 500g, wherein the weight ratio of bentonite and water is 1: 25, stir for 20 minutes, then add 0.7 gram of sodium sulfate and disperse and stir for 30 minutes to make The bentonite is fully wetted and dispersed to form a sodium-based bentonite suspension, and the sodium-based bentonite suspension is homogenized at 1200 standard atmospheres using a Niro NS1001L high-pressure homogenizer. (the particle size distribution of the sodium bentonite suspension after homogenization is shown in Figure 4). Then, the homogenized bentonite suspension is added into octadecyl dimethyl benzyl ammonium chloride solution to carry out organic activation reaction for 30 minutes, and then filtered and dried to obtain high anti-sedimentation organic bentonite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com