Preparation method of manganese slag activate micro powder for concrete admixture

A technology of active micropowder and concrete, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of complex process, low added value, low utilization rate, etc., and achieve the realization of resources, high gelation Active and eliminate the effect of destroying the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

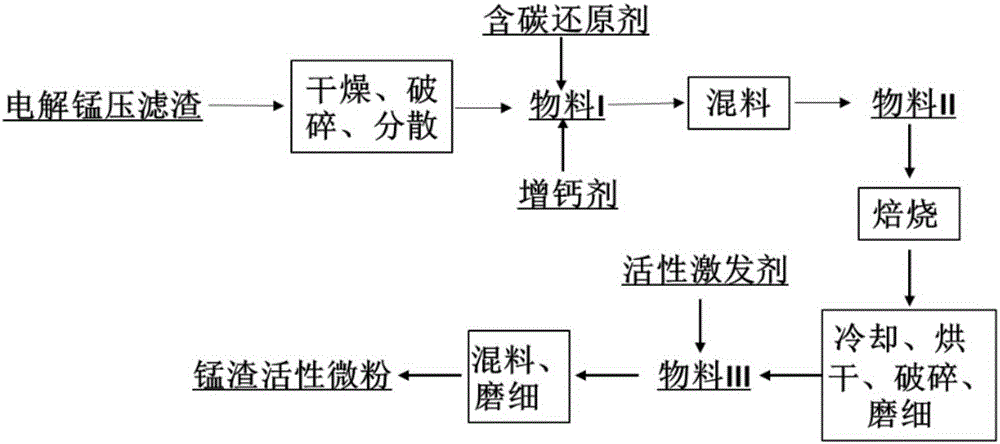

[0023] A method for preparing manganese slag active micropowder for concrete admixture, which specifically comprises the following steps:

[0024] Step 1: crushing, drying and dispersing the electrolytic manganese press filter residue to obtain material I;

[0025] Step 2: fully mixing the material I treated in step 1 with an appropriate amount of carbon-containing reducing agent and calcium increasing agent to obtain material II;

[0026] Step 3: put the material II processed in step 2 into a roasting device for roasting, the roasting temperature is 700-1600°C, and the roasting time is 0.5-6h;

[0027] Step 4: put the remaining material processed in step 3 into a cooling device for cooling, and then obtain material III after drying, crushing and grinding;

[0028] Step 5: mixing and grinding the material III obtained through step 4 with an appropriate amount of active activator to obtain manganese slag active micropowder;

[0029] Wherein, the average particle diameter of t...

Embodiment 1

[0031] (1) crushing, drying and dispersing the electrolytic manganese press filter residue to obtain material I, weigh 1000Kg, the average particle diameter of the material I is 1cm, and the water content is 10%;

[0032] (2) Take by weighing 100Kg bituminous coal and 50Kg calcium oxide according to the specified proportion, fully mix material I with bituminous coal and calcium oxide, obtain 1150Kg material II, the average particle diameter of described material II is 1cm, and water content is 10% ;

[0033] (3) The material II is roasted in a rotary kiln at a roasting temperature of 1200° C. and a roasting time of 1 h;

[0034] (4) After roasting, the remaining material is cooled, dried, crushed and ground by a single cylinder cooler to obtain 805Kg material III;

[0035] (5) Material III is mixed with 8.05Kg water glass and ground to obtain 813Kg manganese slag active micropowder, which can be used as concrete admixture, and the specific surface area of manganese slag act...

Embodiment 2

[0037] (1) crushing, drying and dispersing the electrolytic manganese press filter residue to obtain material I, weigh 500Kg, the average particle diameter of the material I is 0.5cm, and the water content is 8%;

[0038] (2) take by weighing 25Kg gac and 5Kg calcium carbonate by the proportioning of regulation, material I is fully mixed with gac and calcium carbonate, obtains 530Kg material II, and the average particle diameter of described material II is 0.5cm, and water content is 8 %;

[0039] (3) The material II is roasted in an electric furnace, the roasting temperature is 1350°C, and the roasting time is 0.5h;

[0040] (4) After roasting, the remaining material is cooled by multi-tube water quenching, dried, crushed and ground to obtain 366Kg material III;

[0041] (5) Material III is mixed with 1.10Kg sodium carbonate and 1.83Kg water glass and ground to obtain 369Kg manganese slag active micropowder, which can be used as concrete admixture, and the specific surface a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com