Stokehole modified steel slag and preparation method thereof

A steel slag and modification technology, applied in the field of modified steel slag powder and its preparation, can solve the problems of low activity and poor stability of steel slag.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a method for preparing modified steel slag, comprising the following steps:

[0025] The molten steel slag in the steelmaking furnace is discharged into the slag tank, fully stirred with the modifier prepared in advance, and then quenched to obtain the modified steel slag.

[0026] The components and contents of the modifying agent are respectively 1%-15% of limestone powder, 1%-10% of sandstone powder and 1%-10% of fly ash, and the particle diameters are all less than 0.15mm.

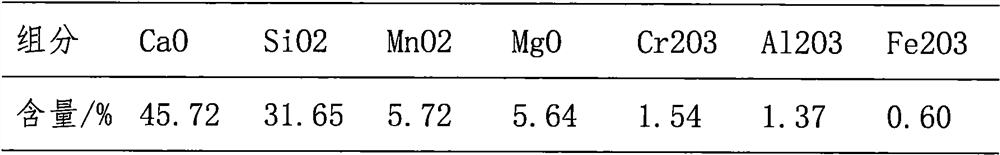

[0027] The steel slag is suitable for the steel slag whose chemical composition has a total content of CaO and MgO less than or equal to 55%. In the example of the present invention preferably include the chemical composition of following mass content: CaO 44-46%, SiO2 30-32%, MgO 3-6%, Al2O31-2%, Fe2O3 O-1%, more preferably: CaO 45.72% , SiO2 31.65%, MgO 5.64%, Al2O3 1.37%, Fe2O3 0.60%.

[0028] In the present invention, in the modified steel slag, the content of the st...

Embodiment 1

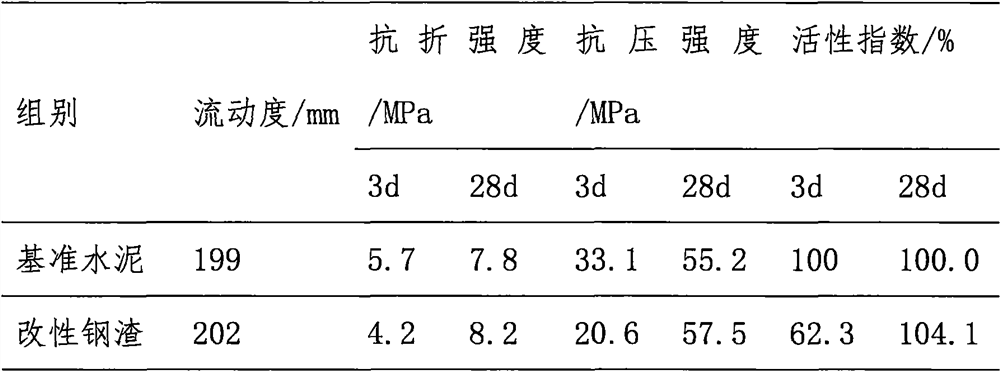

[0038] Press limestone powder: sandstone powder: the mass ratio of fly ash=13: 1: 1 prepares modifying agent in advance, the molten state steel slag that just discharges and modifying agent are mixed by the mass ratio of 85: 15 in steel-making workshop, After stirring evenly, let it stand for 20 minutes, then rapidly cool to close to room temperature, grind the obtained modified steel slag into steel slag powder with a specific surface area of 400-450m2 / kg, and mix evenly according to the mass ratio of modified steel slag powder: reference cement = 3:7 As the sample to be tested, according to GB / T 51003-2014 "Technical Specifications for the Application of Mineral Admixtures", the performance of the mortar was tested and the activity index of the modified steel slag powder was calculated. The results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com