Preparation method of high-activity cement admixture

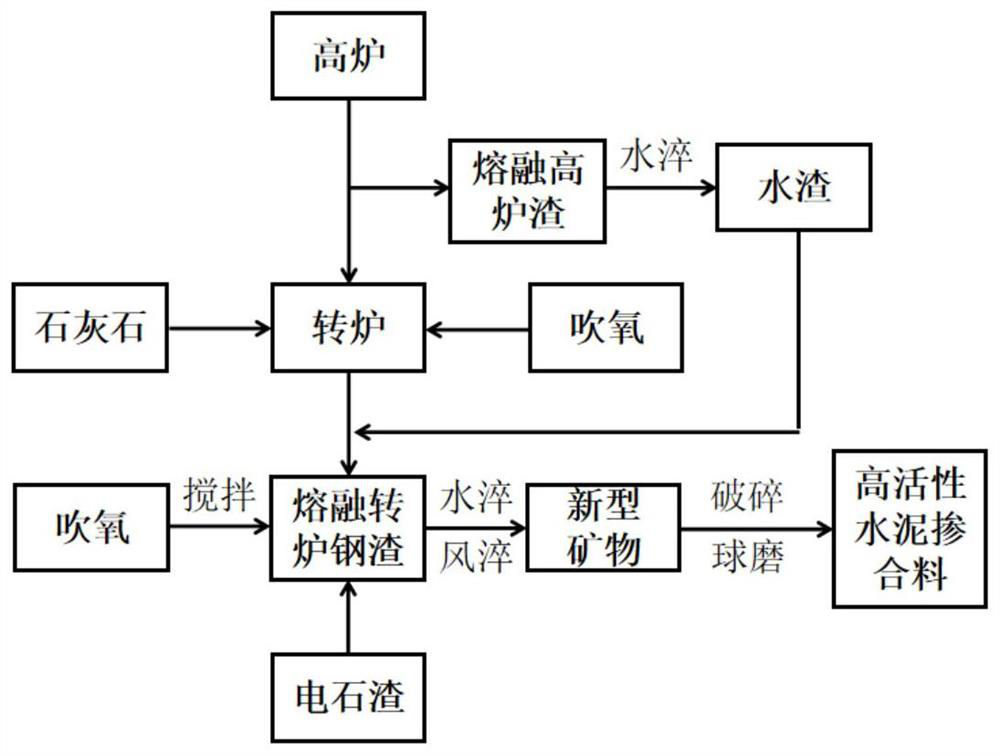

A cement admixture, high activity technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of high iron content, complicated process, poor stability, etc., to increase mineral content, The effect of simplifying the process method and solving the utilization problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

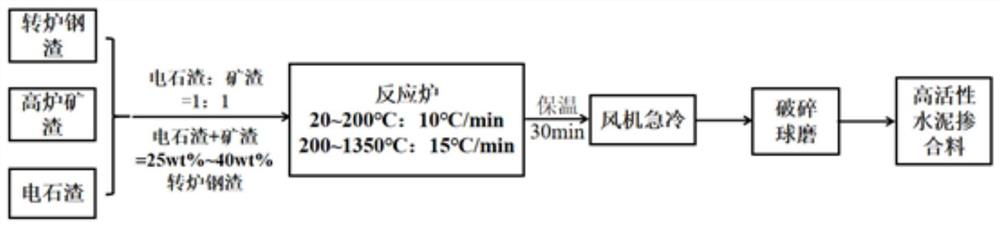

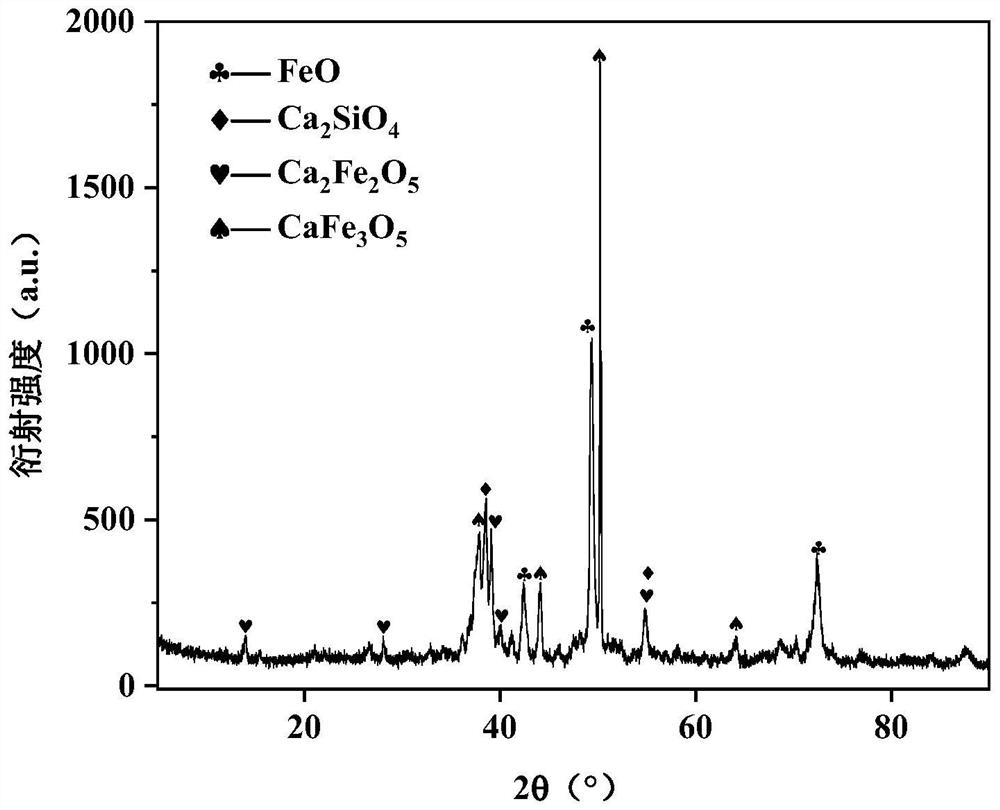

[0043] Take 320g of converter steel slag, the proportion is 80%; 40g of carbide slag, the proportion is 10%; 40g of blast furnace slag, the proportion is 10%. Mix the three evenly and put them into a crucible, then put the crucible into a box-type muffle furnace and raise the temperature to 1350°C. The specific heating process is: 10°C / min for 20-200°C, and 15°C / min for 200-1350°C. After 30 minutes of heat preservation, the sample was taken out together with the crucible for rapid cooling by fan. The cooled sample was crushed, pulverized by a vibratory mill, and subjected to XRD and chemical composition tests respectively. The test results are shown in Table 2 and Figure 4 shown.

[0044] As shown in Table 2, the calcium and aluminum content of the highly active cement admixture prepared by using carbide slag and blast furnace slag as the molten converter steel slag conditioner under high temperature conditions increased significantly. The iron content is reduced, and the ...

Embodiment 2

[0048] Take 280g of converter steel slag, the proportion is 70%; 60g of carbide slag, the proportion is 15%; 60g of blast furnace slag, the proportion is 15%. Mix the three evenly and put them into a crucible, then put the crucible into a box-type muffle furnace and raise the temperature to 1350°C. The specific heating process is: 10°C / min for 20-200°C, and 15°C / min for 200-1350°C. After 30 minutes of heat preservation, the sample was taken out together with the crucible for water quenching and rapid cooling. The cooled samples were crushed, pulverized by vibratory milling, and subjected to XRD and chemical composition tests respectively. The test results are shown in Table 3 and Figure 5 shown.

[0049] As shown in Table 3, the calcium and aluminum content of the highly active cement admixture prepared by using carbide slag and blast furnace slag as the molten converter steel slag conditioner under high temperature conditions increased significantly. The iron content is r...

Embodiment 3

[0053] Such as figure 2 As shown, take 300g of converter steel slag, the proportion of which is 75%; 50g of carbide slag, the proportion of which is 12.5%; 50g of blast furnace slag, the proportion of which is 12.5%. Mix the three evenly and put them into a crucible, then put the crucible into a box-type muffle furnace and raise the temperature to 1350°C. The specific heating process is: 10°C / min for 20-200°C, and 15°C / min for 200-1350°C. After 30 minutes of heat preservation, the sample was taken out together with the crucible for rapid cooling by fan. The cooled samples were crushed and pulverized by vibratory milling, and XRD and chemical composition tests were carried out respectively. The test results are shown in Table 4.

[0054] As shown in Table 4, the calcium and aluminum content of the highly active cement admixture prepared by using carbide slag and blast furnace slag as the molten converter steel slag conditioner under high temperature conditions increased sign...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com