Method for improving gelling activity of ardealite

A phosphogypsum, active technology, applied in the field of improving the gelation activity of phosphogypsum, can solve the problems of many equipment, large investment, long process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

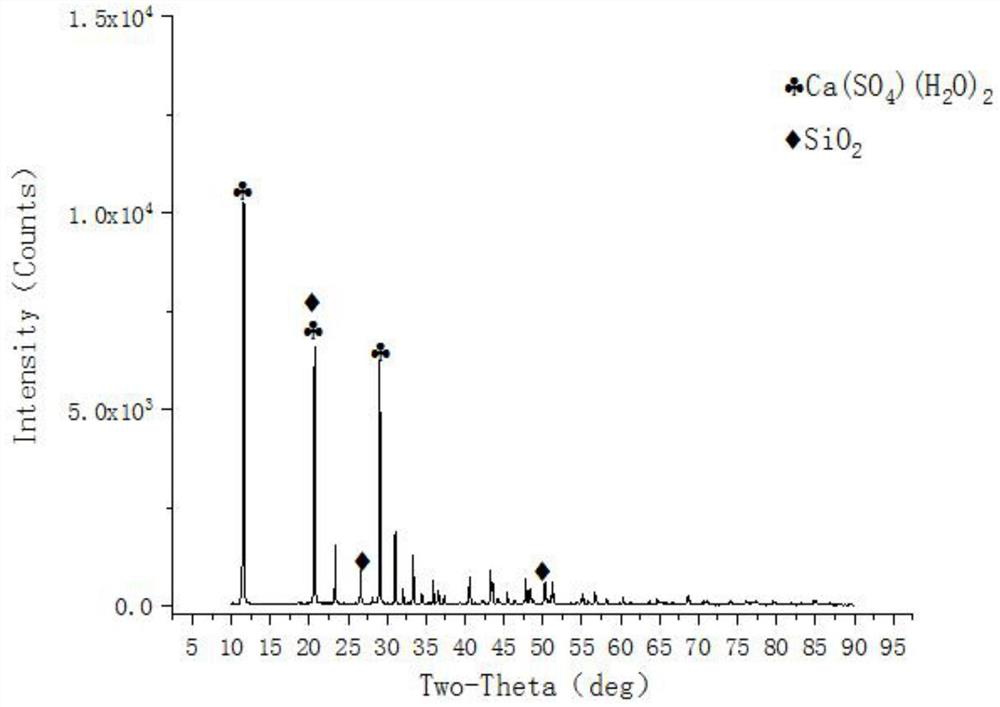

[0039] Example 1. A method for improving the gelling activity of phosphogypsum, the method steps are as follows:

[0040] (1) first age the phosphogypsum retrieved from the storage yard with tap water for 24 hours, and control the water content to 35% during aging to obtain the aged phosphogypsum;

[0041] (2) wet-mill the aged phosphogypsum with a ball mill for 30 minutes to obtain wet-milled phosphogypsum;

[0042] (3) Roast the wet-milled phosphogypsum to 400°C, keep it warm for 3 hours, and then cool it down naturally to obtain the roasted phosphogypsum;

[0043] (4) First apply agent 1 to the phosphogypsum after roasting for heap leaching for 5 hours, then apply agent 2 for heap leaching for 10 hours, and the heap leaching temperature is 25-30°C to obtain phosphogypsum with improved gelling activity; wherein agent 1 is an aqueous solution, After 100g of roasting, phosphogypsum is used in an amount of 240ml. The mass fraction of potassium oxide in the aqueous solution is...

Embodiment 2

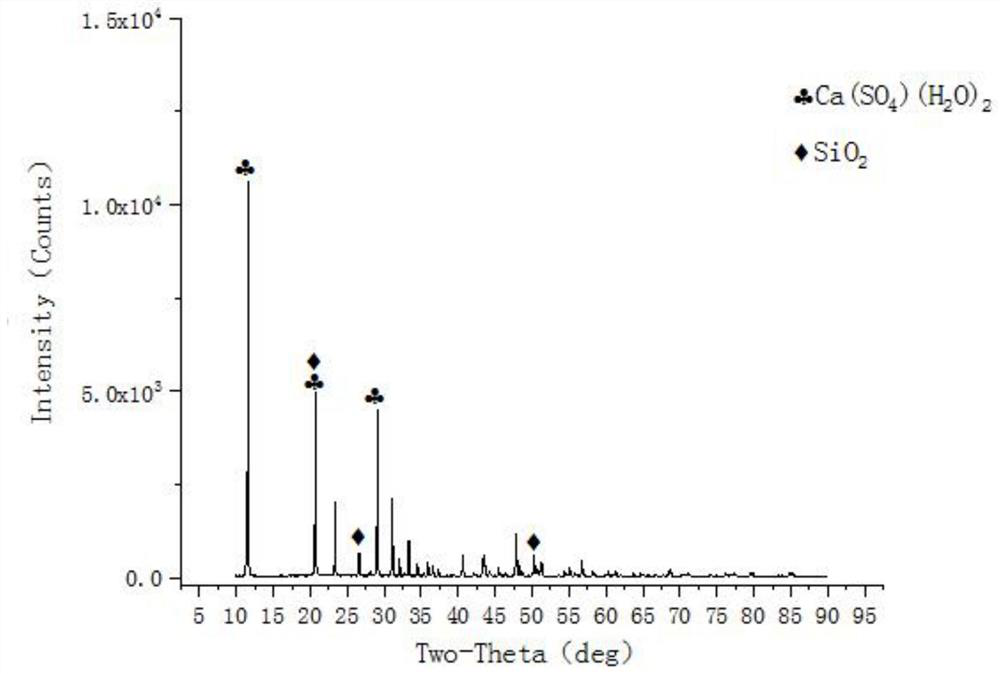

[0044] Example 2. A method for improving the gelling activity of phosphogypsum, the method steps are as follows:

[0045] (1) first age the phosphogypsum retrieved from the storage yard with tap water for 30 hours, and control the water content to 35% during aging to obtain aged phosphogypsum;

[0046] (2) wet-mill the aged phosphogypsum with a ball mill for 40 minutes to obtain wet-milled phosphogypsum;

[0047] (3) Roast the wet-milled phosphogypsum to 600°C, keep it warm for 5 hours and then cool it down naturally to obtain the roasted phosphogypsum;

[0048] (4) First apply agent 1 to the phosphogypsum after roasting for heap leaching for 8 hours, then apply agent 2 for heap leaching for 12 hours, and the heap leaching temperature is 25-30°C to obtain phosphogypsum with improved gelling activity; wherein agent 1 is an aqueous solution, After 100g of roasting, phosphogypsum is used in an amount of 280ml. The mass fraction of potassium oxide in the aqueous solution is 0.02%,...

Embodiment 3

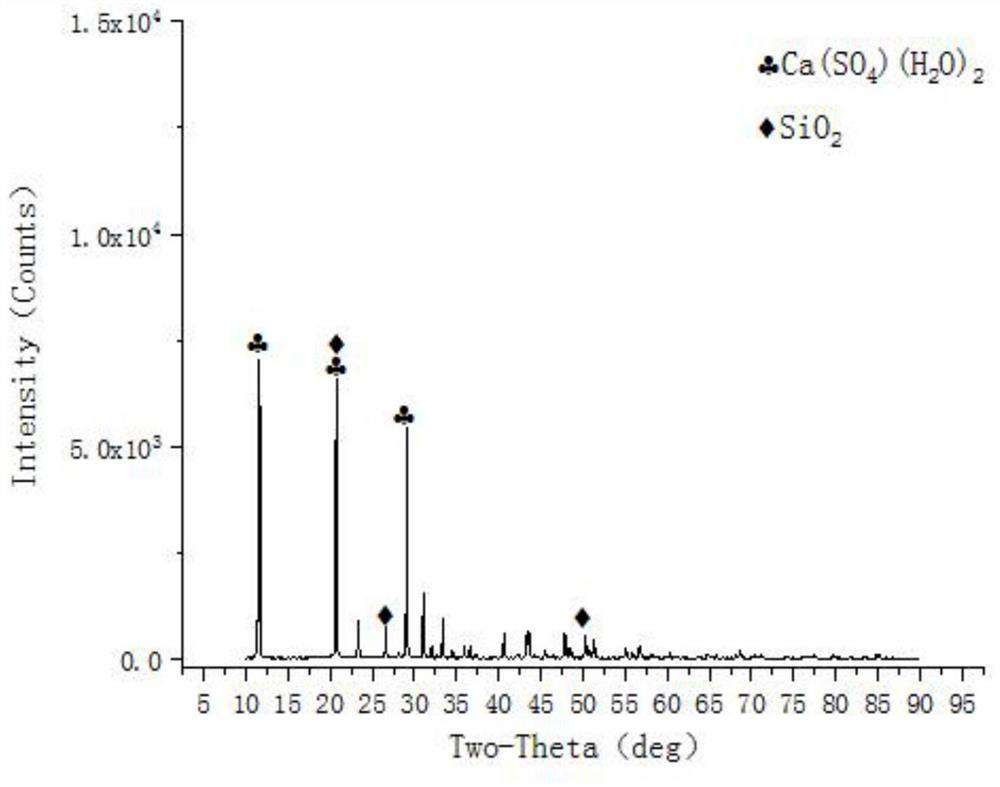

[0049] Example 3. A method for improving the gelling activity of phosphogypsum, the method steps are as follows:

[0050] (1) first age the phosphogypsum retrieved from the stockyard with tap water for 24 hours, and control the water content to 50% during aging to obtain aged phosphogypsum;

[0051] (2) wet-mill the aged phosphogypsum with a ball mill for 40 minutes to obtain wet-milled phosphogypsum;

[0052] (3) Roast the wet-milled phosphogypsum to 500°C, keep it warm for 4 hours, and then cool it naturally to obtain the roasted phosphogypsum;

[0053] (4) First apply agent 1 to the phosphogypsum after roasting for heap leaching for 7 hours, then apply agent 2 for heap leaching for 14 hours, and the heap leaching temperature is 25-30°C to obtain phosphogypsum with improved gelling activity; wherein agent 1 is an aqueous solution, After 100g of roasting, phosphogypsum is used in an amount of 450ml. The mass fraction of potassium oxide in the aqueous solution is 0.5%, the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com