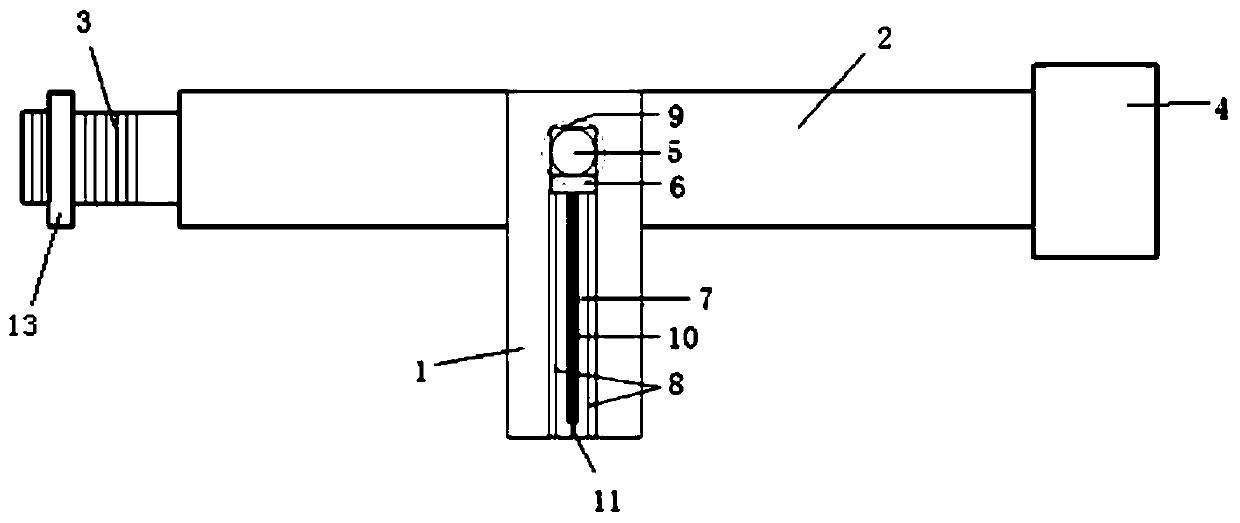

Anti-blocking device for mixing pile drill rod and working method

A technology for mixing piles and preventing blocking, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of affecting the quality of the project, blockage of the shotcrete holes, and inability to spray the shotcrete holes, so as to avoid waste piles, increase Large friction force, ensuring the effect of cement penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

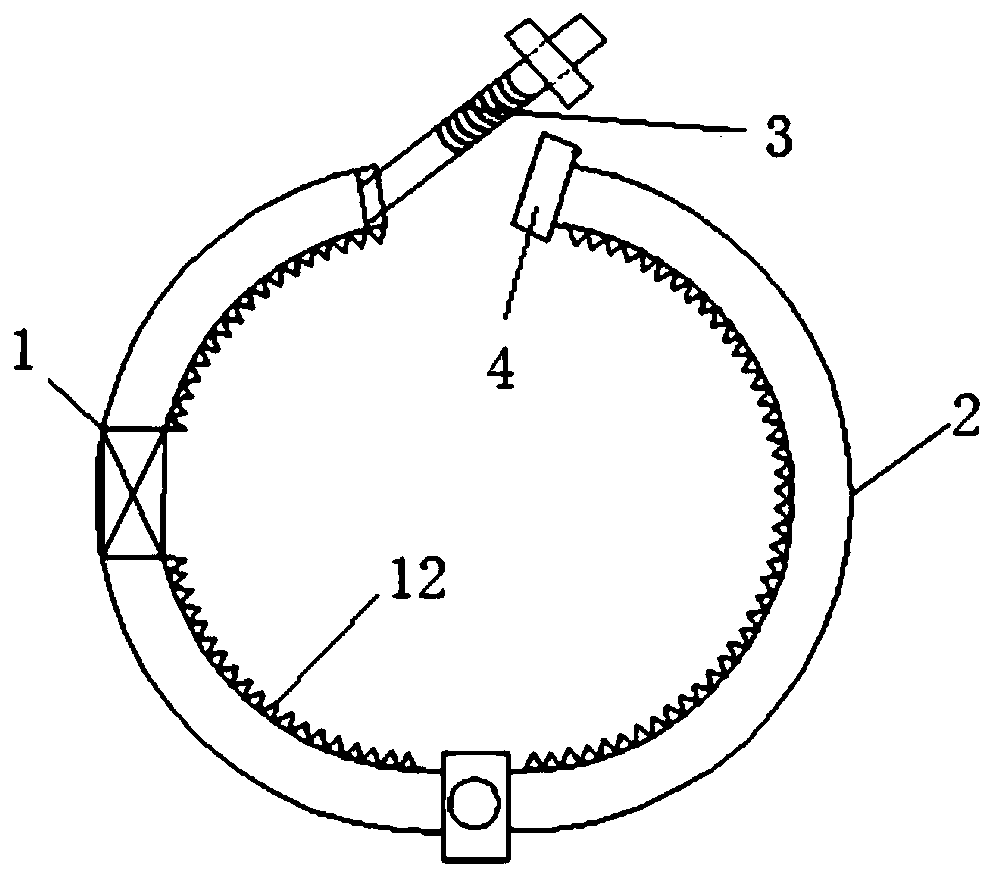

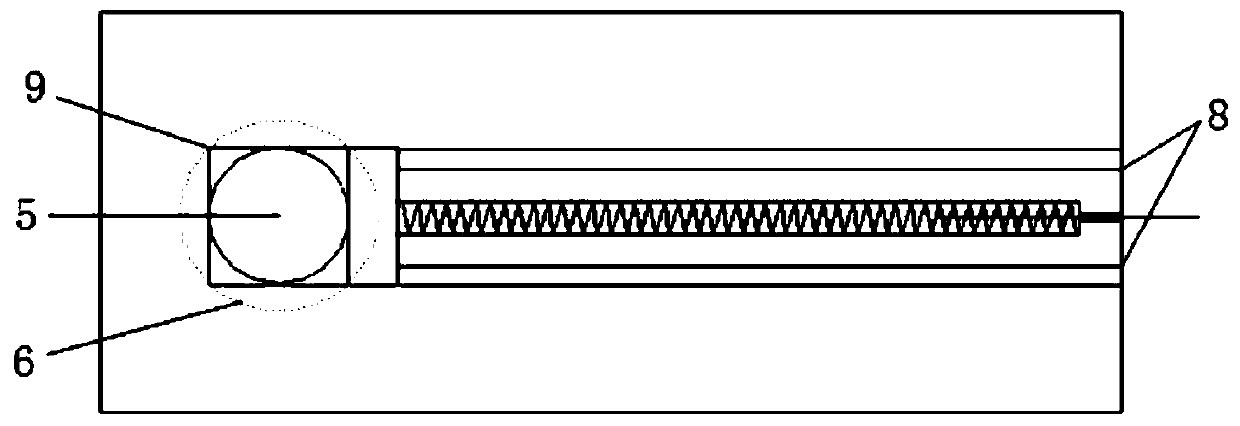

Method used

Image

Examples

Embodiment 2

[0038]This embodiment discloses a working method of an anti-blocking device for a stirring pile drill pipe: align the slurry outlet channel of the anti-blocking seat with the grouting hole of the drill pipe, and insert the fixing nut into the clamping groove of the clamping block, so that The binding strap is bound and fixed on the drill pipe, so that the anti-blocking seat is fixedly connected with the drill pipe. Before binding the binding tape, a sealing ring is placed between the spray hole and the slurry outlet channel, and the anti-blocking seat presses the sealing ring on the drill pipe. On the top, use the sealing ring to seal the spray hole and the slurry channel.

[0039] The drill pipe starts to drill into the soil layer. During the drilling process, the anti-blocking slider blocks the slurry outlet channel under the action of the spring, so that the soil in the soil layer cannot enter the slurry outlet channel or the grouting port, avoiding the When the drill pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com