Vacuum infusion epoxy resin for carbon fiber

An epoxy resin and vacuum infusion technology, which is applied in the fields of wind turbine blades, ships, yachts and automobile bodies, can solve the problems of obvious mechanical properties of materials and unsatisfactory curing agent performance, so as to improve the performance of FRP and improve Wetting properties and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of described carbon fiber vacuum impregnation epoxy resin, it comprises each component of described ratio and the following steps:

[0042] Step 1, prepare the resin component

[0043] a. Preheat bisphenol A epoxy resin 127 and epoxy diluent BDGE to 60°C-65°C;

[0044] b, adding bisphenol A type epoxy resin 127 and part of epoxy diluent BDGE preheated in step 1 to the reactor;

[0045] c, adding bisphenol F type epoxy resin 170 to the reactor;

[0046]d, start the stirrer, and stop after stirring at a speed of 24-28rpm for 30-40min;

[0047] e, add the remaining epoxy diluent BDGE,

[0048] f. In a vacuum environment, start the stirring program, control the high speed 28 rpm, low speed 24 rpm, keep stirring for 60-90 minutes, and turn off the stirring program;

[0049] g, stop vacuuming, and return to normal pressure in the reactor to obtain the first component;

[0050] Step 2, preparing the curing agent component;

[0051] h, with polyethe...

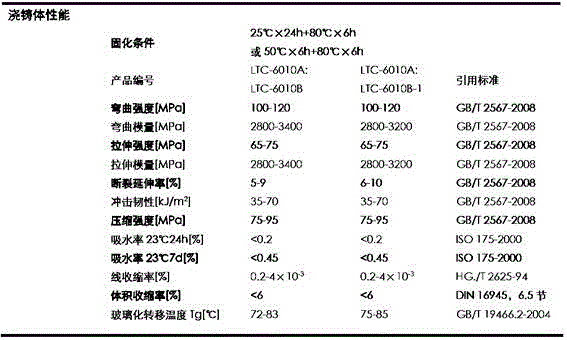

Embodiment 1

[0055] Example 1 uses curing agent 6010B.

[0056] Resin component (LTC-6010A): bisphenol A type epoxy resin 127 65%

[0057] Bisphenol F epoxy resin 170 25%

[0058] Epoxy Thinner BDGE 10%; and

[0059] Curing agent component (LTC-6010B): polyetheramine curing agent D230 68%

[0060] Cyclohexanediamine DCH99 22%

[0061] 2-Methylpentamethylenediamine Dytek A 10%

[0062] (The same below, unless otherwise specified)

Embodiment 2

[0063] Embodiment 2 adopts curing agent 6010B-1, namely

[0064] Resin component (LTC-6010A): bisphenol A type epoxy resin 127 65%

[0065] Bisphenol F epoxy resin 170 25%

[0066] Epoxy Thinner BDGE 10%; and

[0067] Curing agent component (LTC-6010B-1): Polyetheramine curing agent D230 60%

[0068] Cyclohexanediamine DCH99 22%

[0069] 2-Methylpentamethylenediamine Dytek A 18%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com