A non-curing rubber asphalt waterproof coating that can be applied at room temperature to prevent flames and suppress smoke

A technology of asphalt waterproof coating and non-curing rubber, applied in asphalt coatings, other rubber coatings, fireproof coatings, etc., can solve the problems of asphalt smoke environmental pollution, gradual emergence of invisible drawbacks, degradation and aging, etc., and reduce construction energy consumption. and environmental pollution, reducing shear rate and energy consumption, and reducing the effect of mixing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

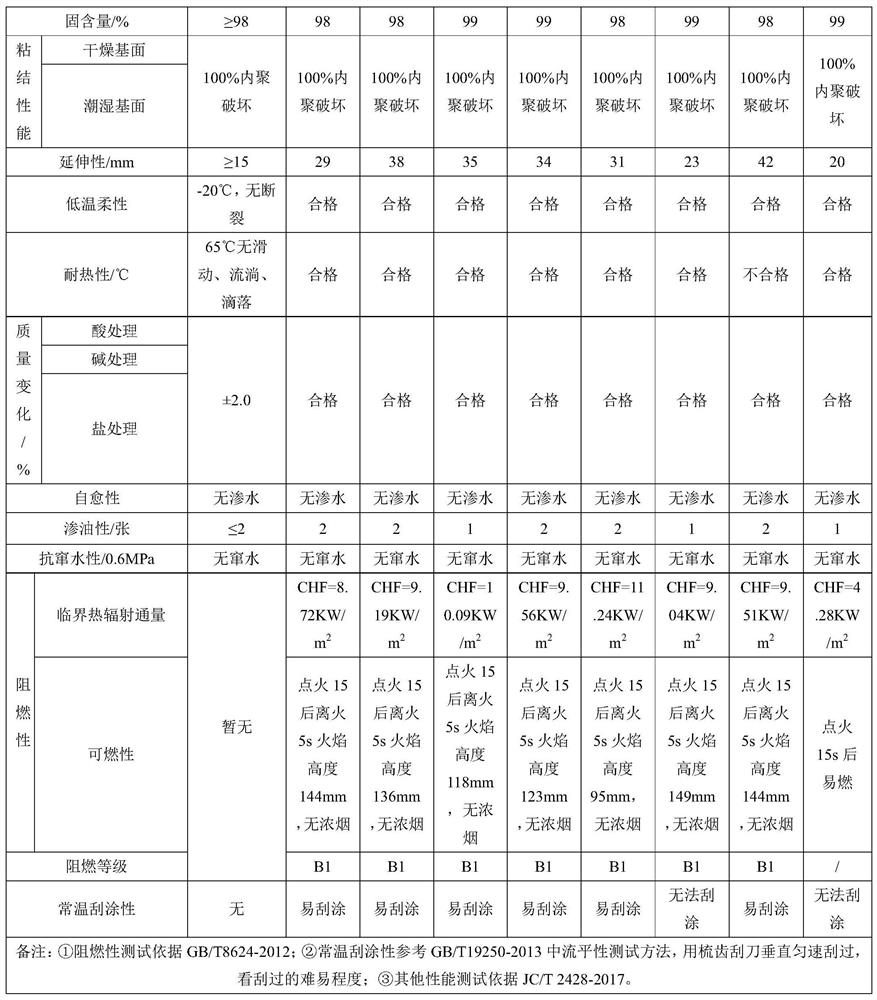

Examples

Embodiment 1

[0023] Pour 30 parts of 70# asphalt, 10 parts of 200# asphalt and 15 parts of rubber filling oil into the development tank, heat up to 140-160°C while stirring, add 0.1 part of 560 activator, control the speed at 300 rpm, and stir 40min for development. Then add 12 parts of 40 mesh waste rubber powder and continue to stir for 60 minutes. After the waste rubber powder is completely developed, add 8 parts of oil-extended styrene-butadiene rubber modifier and stir for 50 minutes. After it is completely dissolved, continue to add 0.2 parts of BL asphalt modification After dispersing and stirring for 30 minutes, add 16 parts of tricresyl phosphate and 3 parts of zinc borate, disperse and stir for 40 minutes, then cool down and discharge the material, and then the flame-retardant and smoke-suppressing non-curing rubber asphalt waterproof coating can be constructed at room temperature.

Embodiment 2

[0025] Pour 30 parts of 90# asphalt, 10 parts of 200# asphalt and 15 parts of aromatic oil into the development tank, heat up to 140-160°C while stirring, add 0.15 parts of 420 rubber desulfurizer, control the speed at 300 rpm, and stir Develop for 50min. Then add 13 parts of 40 mesh waste rubber powder and continue to stir for 50 minutes. After the waste rubber powder is completely developed, add 10 parts of butadiene rubber modifier and stir for 40 minutes. After it is completely dissolved, continue to add 0.2 parts of 8903 asphalt modifier and disperse After stirring for 20 minutes, add 16 parts of resorcinol bis(diphenyl phosphate) and 3 parts of zinc aluminate, disperse and stir for 40 minutes, then cool down and discharge the material, and then the non-cured rubber asphalt waterproof can be constructed at room temperature. coating.

Embodiment 3

[0027] Pour 40 parts of 70# bitumen and 20 parts of naphthenic oil into the development tank, heat up to 140-160°C while stirring, add 0.2 parts of 560 activator, control the speed at 300 rpm, and stir for 50 minutes. Then add 14 parts of 40 mesh waste rubber powder and continue to stir for 50 minutes. After the waste rubber powder is fully developed, add 12 parts of oil-extended styrene-butadiene rubber modifier and stir for 40 minutes. After it is completely dissolved, continue to add 0.2 parts of Sasobit asphalt modification After dispersing and stirring for 30 minutes, add 14 parts of tricresyl phosphate and 5 parts of molybdenum oxide, disperse and stir for 40 minutes, then cool down and discharge the material, and then the non-curing rubber asphalt waterproof coating that can be applied at room temperature is flame-retardant and smoke-suppressing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com