G85-grade ground iron steel slag and preparation method thereof

A technology of steel slag powder and steel slag micropowder, which is applied in cement production and other fields, and can solve problems such as cracking, low gelling activity, and low compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

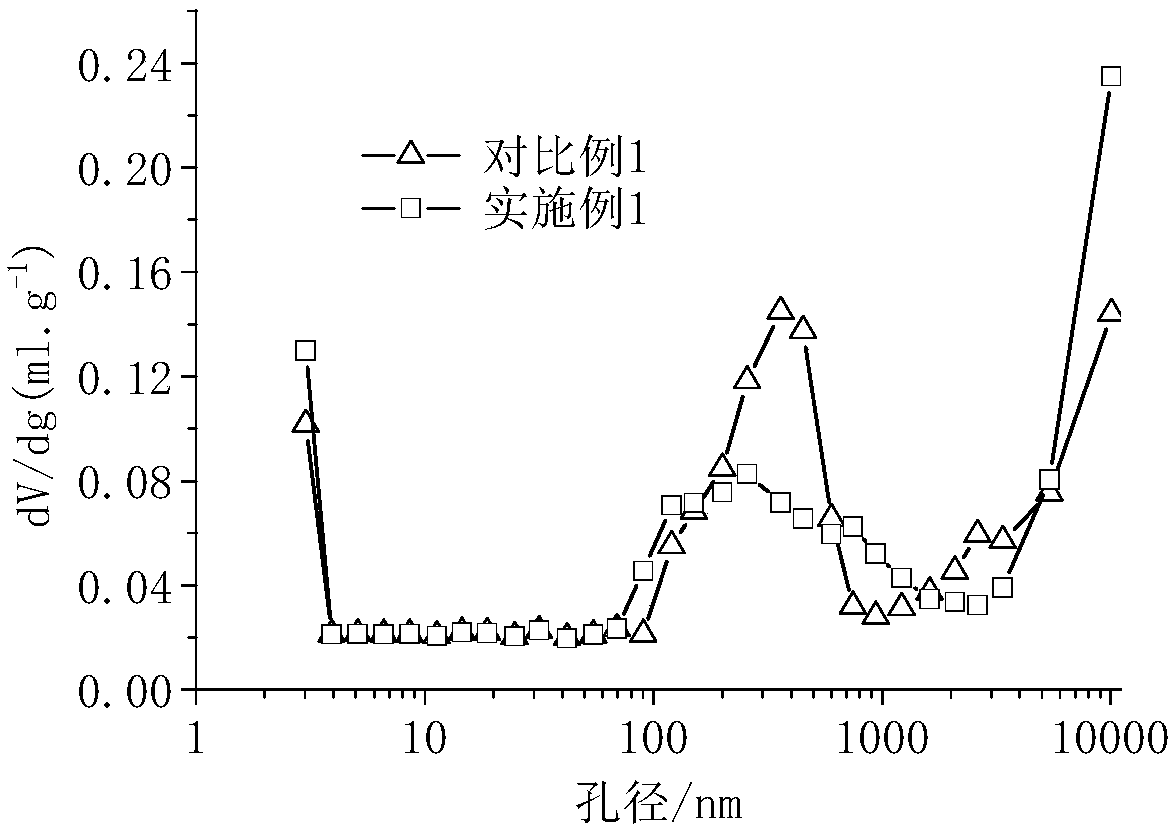

Image

Examples

preparation example Construction

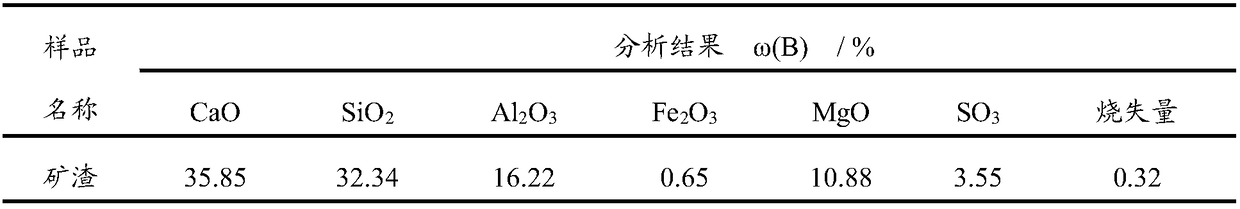

[0026] The invention provides a preparation method of G85 grade iron and steel slag powder, comprising the following steps:

[0027] The converter steel slag is subjected to heat-stuffing treatment, and the iron is recovered by magnetic separation to obtain the converter heat-stuffing steel slag;

[0028] The hot stuffy steel slag of the converter is sequentially dried, crushed and ground to obtain steel slag powder;

[0029] After classifying the steel slag powder, the steel slag fine powder is obtained, and the classification is carried out in a cyclone air classifier;

[0030] The steel slag fine powder is mixed with slag powder to obtain G85 grade steel slag powder.

[0031] In the invention, the hot stuffy steel slag of the converter is recovered by magnetic separation after the hot stuffy treatment of the converter steel slag. In the present invention, the temperature of the hot stuffing treatment is preferably 600°C to 1000°C, more preferably 800°C to 900°C, most pref...

Embodiment 1

[0041]1) Using magnetically separated converter hot stuffy steel slag produced by a certain iron and steel plant as raw material, the main technical indicators are as follows: converter steel slag enters hot stuffy furnace at 800°C, magnetic field strength is 1200GS during magnetic separation, metal in converter hot stuffy steel slag The iron content is 2.8%, the f-CaO content is 4.75%, and the density is 3.29g / cm 3 , the chemical composition of converter hot stuffy steel slag is shown in Table 1, which contains other unpredictable unknown components;

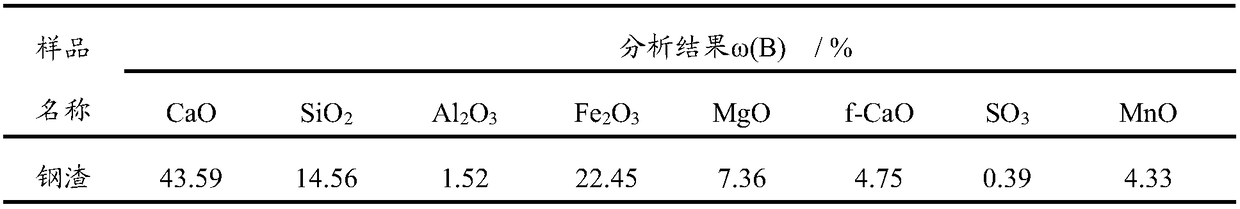

[0042] Table 1 Main chemical composition of converter hot stuffy steel slag

[0043]

[0044] 2) Dry the hot stuffy steel slag of the converter until the moisture is less than 1%, crush it with a jaw crusher until the particle size is less than 4.75mm, and grind it with a ball mill (5kg / mill) to prepare steel slag powder. During the grinding process, add three Ethanolamine grinding aid, the dosage is 0.04%, and the prepared...

Embodiment 2

[0056] 1) Using magnetically separated converter hot stuffy steel slag produced by a steel plant as raw material, the main technical indicators are as follows: the temperature of converter steel slag entering the hot stuffy digestion furnace is about 800°C, and the magnetic field strength during magnetic separation is about 1200GS; the remaining hot stuffy steel slag The metallic iron content is 2.8%, the f-CaO content is 4.75%, and the density is 3.29g / cm 3 ; The chemical composition is shown in Table 1;

[0057] 2) Dry the hot stuffy steel slag of the converter until the water content is less than 1%, crush it with a jaw crusher until the particle size is less than 4.75mm, and grind it with a ball mill (5kg / mill) to prepare steel slag powder. During the grinding process, add Triethanolamine grinding aid, the dosage is 0.04%; the prepared Blaine specific surface area is 322m 2 / kg of steel slag powder;

[0058] 3) The steel slag powder is sent to the cyclone airflow classif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com