A kind of G85 grade iron and steel slag powder and preparation method thereof

A technology of steel slag powder and steel slag micropowder, which is applied in cement production and other directions, can solve the problems of large shrinkage, low cementing activity and cracking of concrete.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The present invention provides a method of preparing a G85 steel slag powder comprising the steps of:

[0027] The converter steel slag is tested after the magnetic separation is recovered, and the converter is hot and ridiculous;

[0028] Switching the converter is sequentially dried, crushed and polished to obtain steel slag powder;

[0029] After the steel slag powder is graded, steel slag fine powder is obtained, and the hierarchical is carried out in a cyclone gas flow classifier;

[0030] The steel slag fine powder is mixed with the slag powder to give G85 steel slag powder.

[0031] The present invention performs a heat-boring replacement of the converter and then recovered iron to obtain a hot-boring steel slag. In the present invention, the temperature of the warm-up treatment is preferably from 600 ° C to 1000 ° C, more preferably from 800 ° C to 900 ° C, most preferably 850 ° C, and the warm-up treatment is preferably 8 h to 24 h, more preferably Ten ~ 16h, most ...

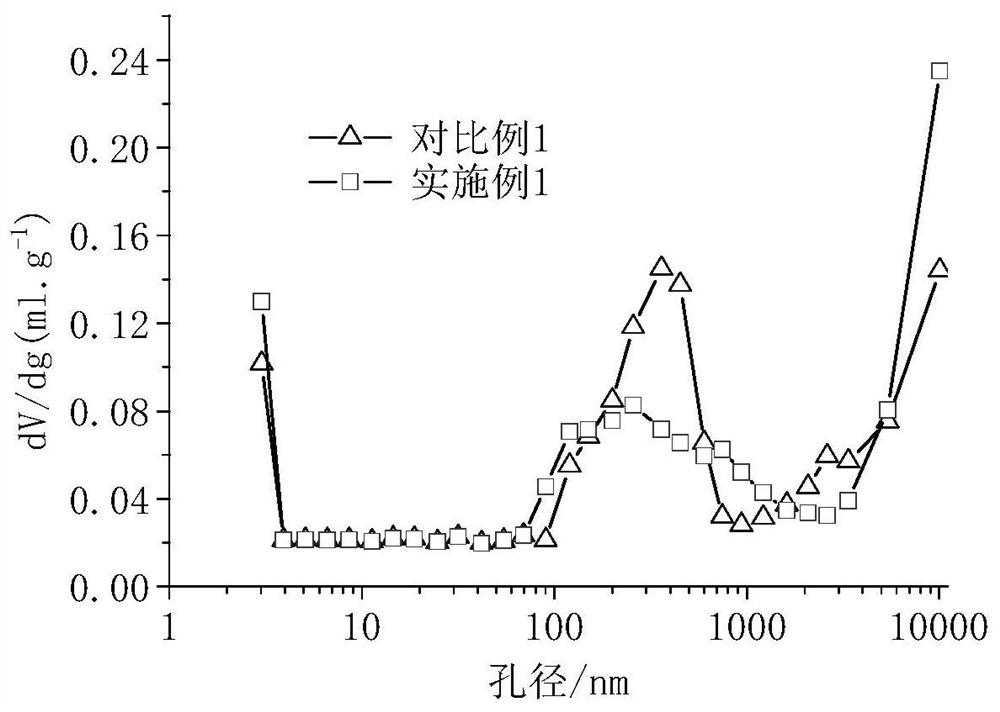

Embodiment 1

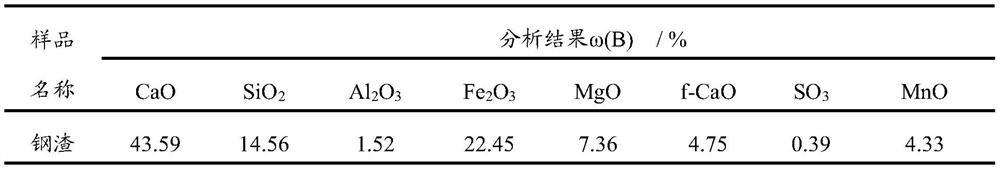

[0041]1) Taking the magnetic replacement of the converter after a certain steel plant, the main technical indicators are as follows: The converter steel slag is in a hot bumper in 800 ° C, and the magnetic field strength is 1200GS, the converter is hot. Steel slag. The iron content is 2.8%, the F-CaO content is 4.75%, the density is 3.29g / cm 3 The chemical composition of the mild steel slag chemical composition is shown in Table 1, including other unknown ingredients;

[0042] Table 1 The main chemical composition of the converter

[0043]

[0044] 2) Make the dried steel slag to dry the water to less than 1%, and the particle crusher is broken to a particle diameter of less than 4.75 mm, and the steel slag powder is prepared by the ball mill, and the grain mill is added. Ethanolamine protective mill, dosage is 0.04%, and the Bobs specific surface area is 322m. 2 / kg steel slag powder;

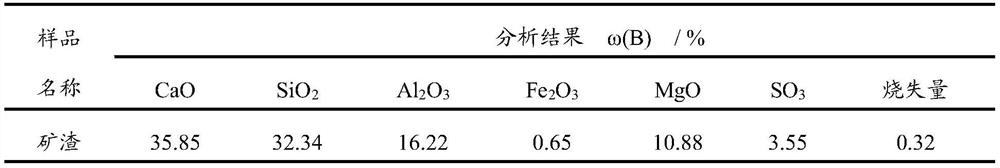

[0045] 3) Sending the steel slag powder into the spiral air flow classifier by the spiral...

Embodiment 2

[0056] 1) Taking the magnetic replacement of the converter after a certain steel plant, the main technical indicators are as follows: converter steel slag into the temperature of about 800 ° C, magnetic in the magnetic field strength of 1200GS; residual hot ridiculous steel slag The metal iron content was 2.8%, the F-CaO content was 4.29 g / cm. 3 The chemical composition is shown in Table 1;

[0057] 2) Dry the converter to dry the steel slag to less than 1%, by the jaw crusher to break into a particle diameter of less than 4.75 mm or less, and the polishing powder is prepared by the ball mill, and the powder grinding process is added. Trietan ethanolamine protective mill, dosage is 0.04%; the Betty surface area is 322m 2 / kg steel slag powder;

[0058] 3) Sending the steel slag powder into the spiral air flow classifier by the spiral feeder, the grading machine rotor rotational speed is controlled at 2500r / min, and the steel slag micropowder is prepared; wherein the position ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com