High-efficiency solid waste-based cementing activity excitant

A technology of active activator and base glue, which is applied in the field of high-efficiency solid waste-based gelation active activator, can solve the problems of low activity of solid waste, non-renewable raw materials, restricted use, etc. Sexual, stimulating effect with high efficiency

Active Publication Date: 2020-04-24

SHANDONG UNIV

View PDF8 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Traditional cement materials have disadvantages such as high energy consumption, high pollution, high cost, and non-renewable raw materials. Therefore, the research and development of solid waste-based cementitious materials has become a research hotspot in the field of cement cementitious materials.

However, solid waste has the disadvantage of low activity, which limits its use in construction projects.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

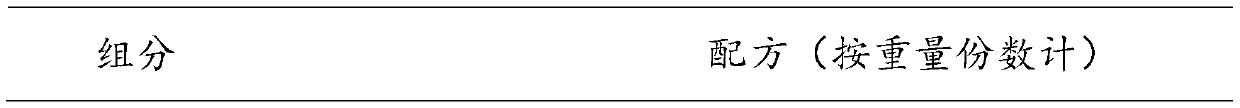

[0031] Formulation example 1 of the present invention:

[0032]

[0033]

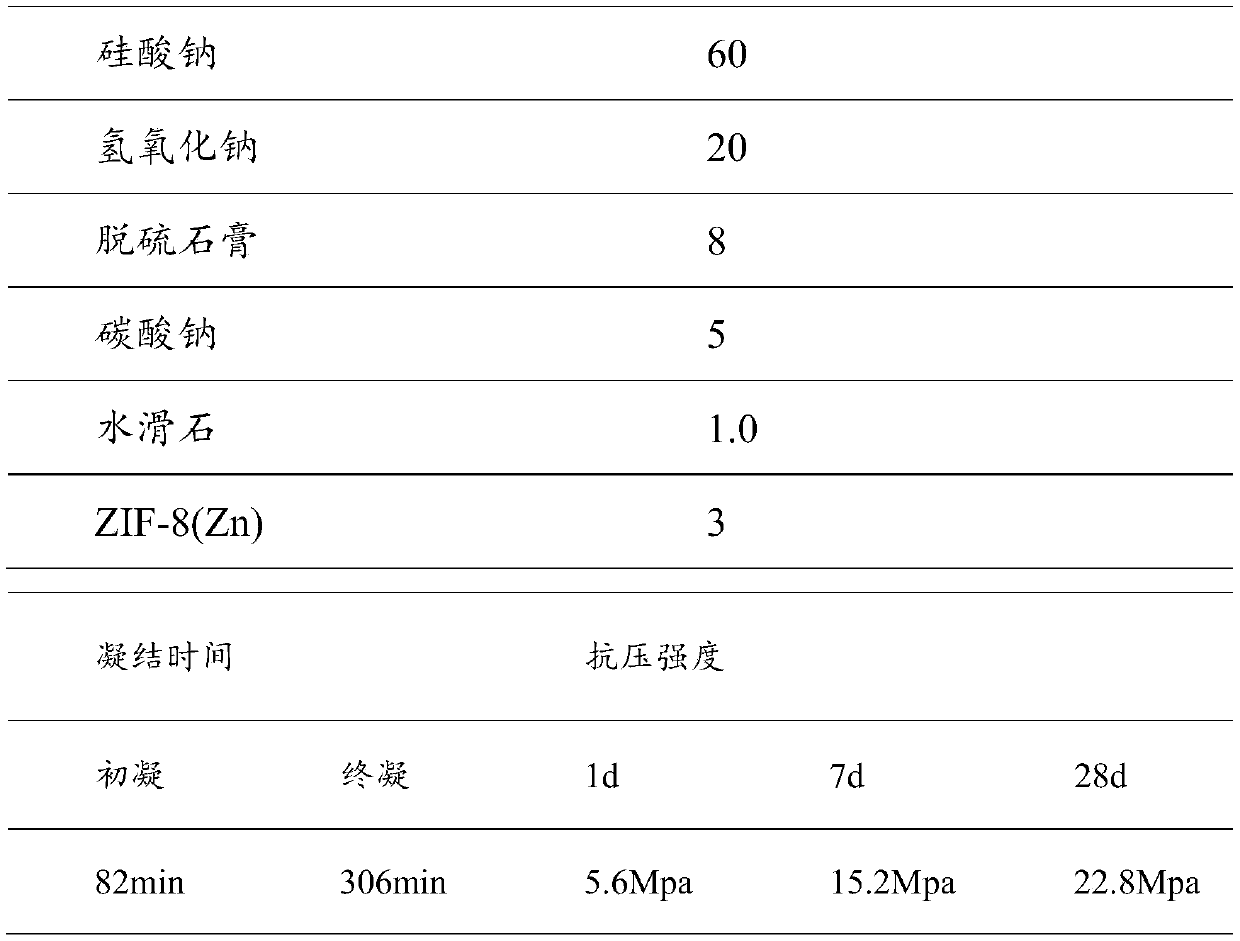

Embodiment 2

[0035] Among them, fly ash-coal gangue is selected as the solid waste, the weight ratio of the two is 1:1, the dosage of the activator is 8% of the total mass of the fly ash-coal gangue, the water-cement ratio is 0.6, the demoulding in 24 hours, 80% ℃ maintenance, formula example 2 of the present invention:

[0036]

[0037]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to an efficient solid waste-based cementing activity activator, and relates to the field of material science and solid waste resource utilization. The problem that solid waste such as red mud, coal gangue and tailings is difficult to utilize is mainly solved, and the high-performance red mud-based cementing material is prepared. The efficient red mud-based cementing activityactivator comprises 40 to 60 parts of alkali metal silicate, 10 to 20 parts of alkali metal hydroxide, 0 to 15 parts of a high-calcium solid waste material, 4 to 8 parts of carbonate, 0 to 5 parts ofhydrotalcite and 0 to 8 parts of an imidazole porous crystal material. The prepared red mud-based cementing material has the advantages of high mechanical strength, short setting time and the like.

Description

technical field [0001] The invention belongs to the fields of material science and solid waste resource utilization, and particularly relates to a high-efficiency solid waste-based gelling activity stimulator. Background technique [0002] The information disclosed in this Background section is only for enhancement of understanding of the general background of the invention and should not necessarily be taken as an acknowledgement or any form of suggestion that this information forms the prior art already known to a person of ordinary skill in the art. [0003] At present, with the rapid development of my country's economy, a large amount of cement-based cementitious materials are required for a large number of projects. Traditional cement materials have the disadvantages of high energy consumption, high pollution, high cost, and non-renewable raw materials. Therefore, the research and development of solid waste-based cementitious materials has become a research hotspot in t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B24/40

CPCC04B40/0039C04B12/04C04B22/062C04B22/145C04B22/10C04B22/06C04B24/40C04B22/064

Inventor 李术才李召峰张健林春金

Owner SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com