Surface plasmon excimer electrically-induced excitation source with medium-metal near field coupling structure and manufacturing method thereof

A surface plasmon and near-field coupling technology, which is applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of small adjustable range of emission wavelength, small propagation distance of surface plasmons, and cumbersome preparation process. Achieve the effect of wide emission wavelength range, easy device integration, and simplified preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Taking the GaAs-based semiconductor quantum well epitaxial material with a wavelength range of 0.5-1 μm as an example, a surface plasmon electric excitation source with a dielectric-metal near-field coupling structure and its Production Method.

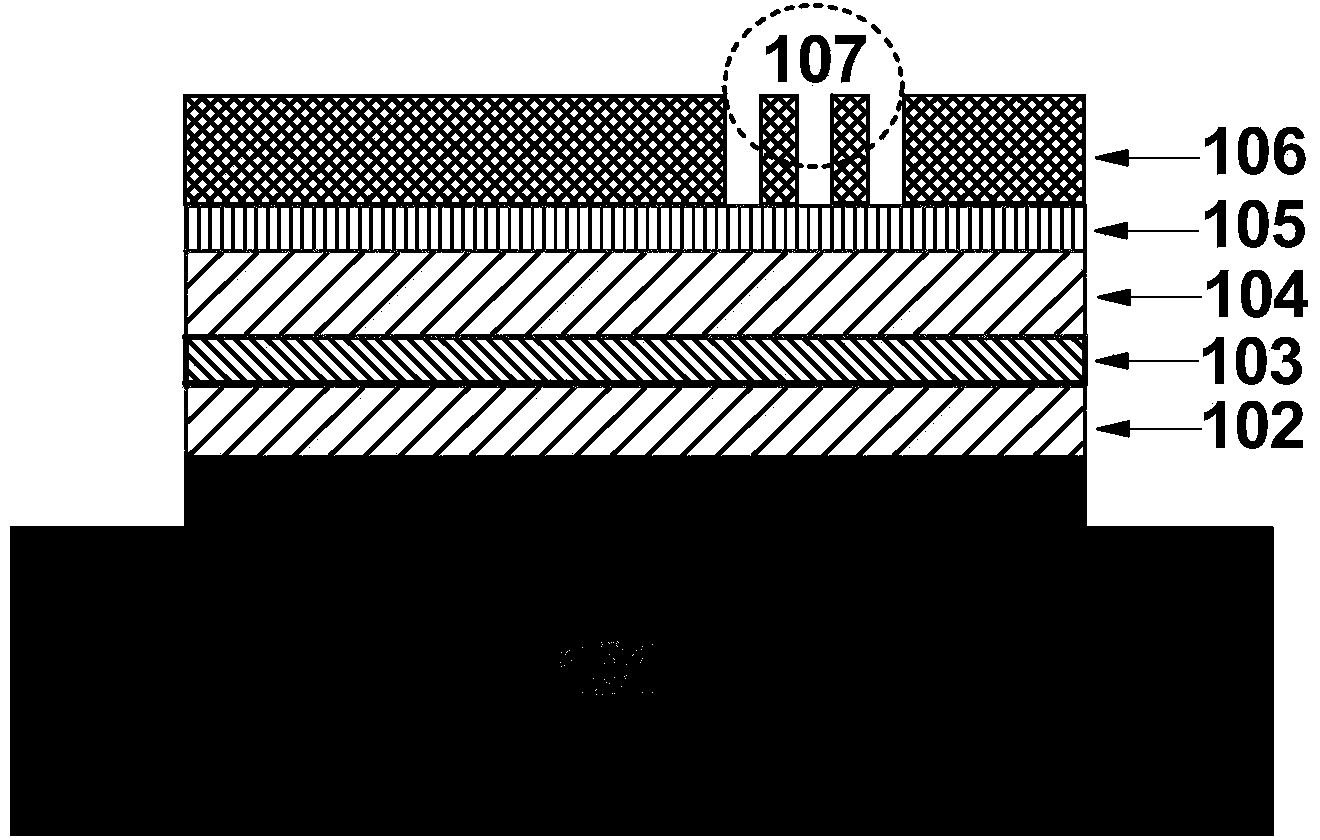

[0042] figure 1 It is a schematic diagram of the structure of the surface plasmon electric excitation source. A surface plasmon electric excitation source with a dielectric-metal near-field coupling structure, including a substrate 101, a semiconductor quantum well epitaxial layer, a metal layer 106, and a coupling output structure 107; the semiconductor quantum well epitaxial layer is loaded on The surface of the substrate 101 ; the metal layer 106 is carried on the surface of the semiconductor quantum well epitaxial layer, and the outcoupling structure 107 is located in the metal layer 106 .

[0043] The semiconductor quantum well epitaxial layer includes a quantum well structure layer and a p-type ohmic contact layer 105; ...

Embodiment 2

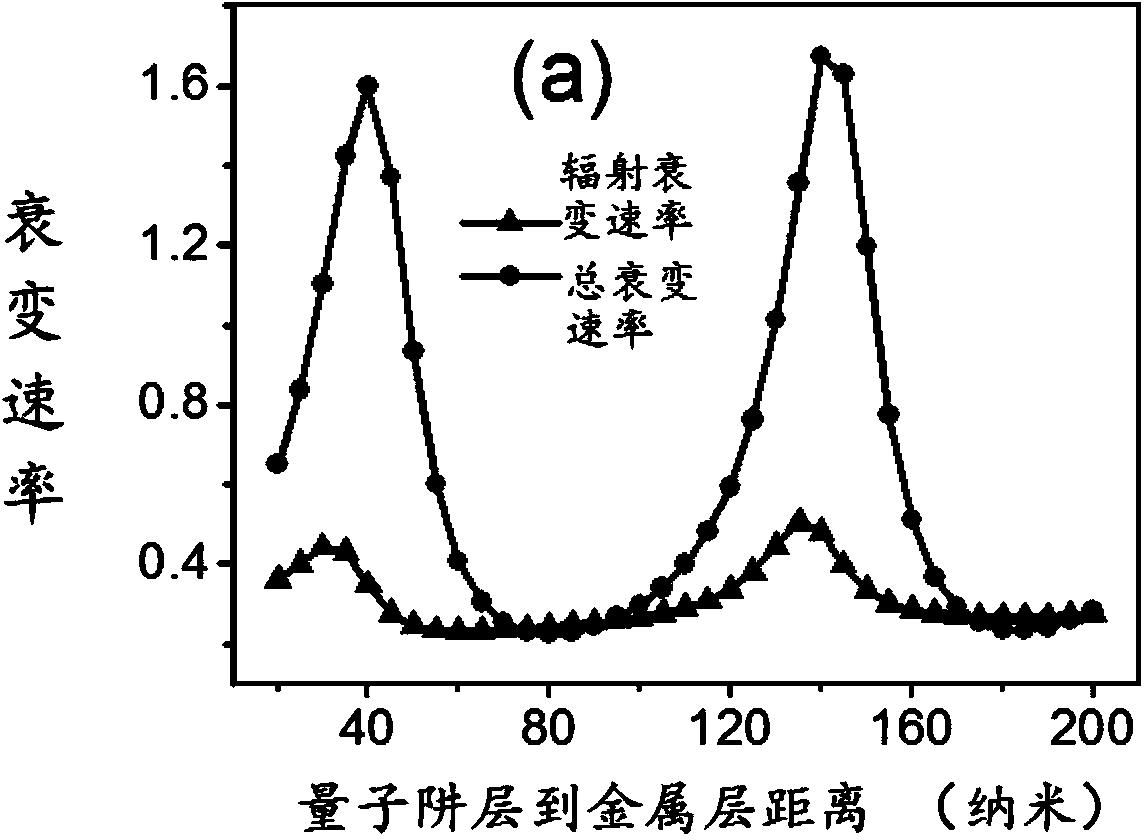

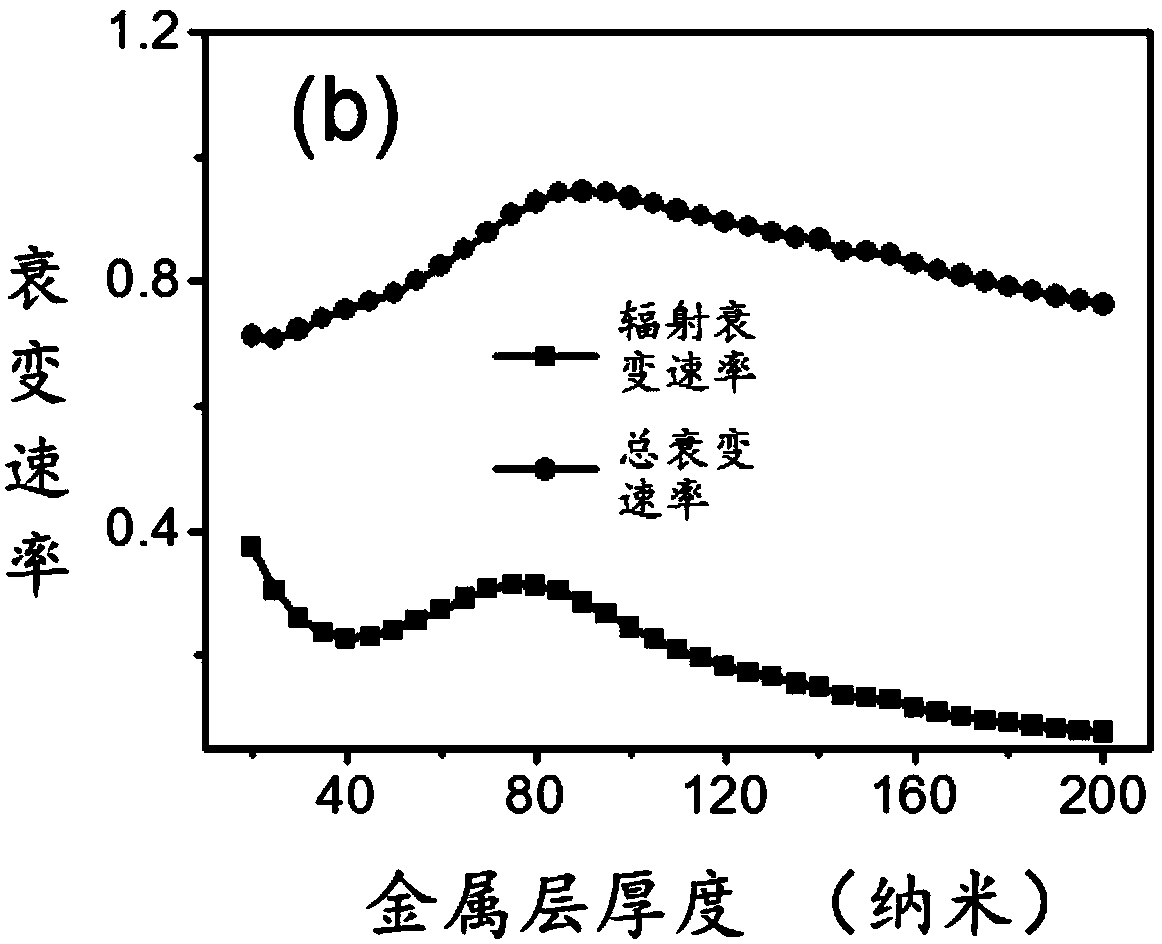

[0052] A surface plasmon electric excitation source with a dielectric-metal near-field coupling structure and its manufacturing method, repeating Example 1, the difference is that the semiconductor quantum well epitaxial layer has a wavelength range of 0.9-1.6 μm InP-based material; due to the increased working wavelength, the optimal distance between the quantum well layer 103 and the metal layer 106 is about 40-60nm, and the thickness of the metal layer 106 is about 90-120nm. The coupling output structure is a hole array.

Embodiment 3

[0054] A surface plasmon electric excitation source with a dielectric-metal near-field coupling structure and its manufacturing method, repeating Example 1, the difference is that the semiconductor quantum well epitaxial layer has a wavelength range of 0.4-0.6 μm GaN-based material; due to the short working wavelength, the optimum distance between the quantum well layer 103 and the metal layer 106 is about 25-35nm, and the thickness of the metal layer 106 is about 60-90nm. The coupling output structure is a grating structure.

[0055] In the preparation method of a surface plasmon electric excitation source with a dielectric-metal near-field coupling structure described in the present invention, firstly, electron beam exposure or photolithography is used to obtain the pattern of the coupling output structure on the quantum well epitaxial layer , and then deposit metal, and then use the method of stripping with glue, and the device can also be realized. However, the quantum we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com