Inverted packaging technology for wafer-level LED

A light-emitting diode, flip-chip packaging technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of inconsistent thickness of phosphor glue, inconsistent chip light color, long time, etc., to achieve the consistency of color and color temperature Good, uniform coating thickness, high process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

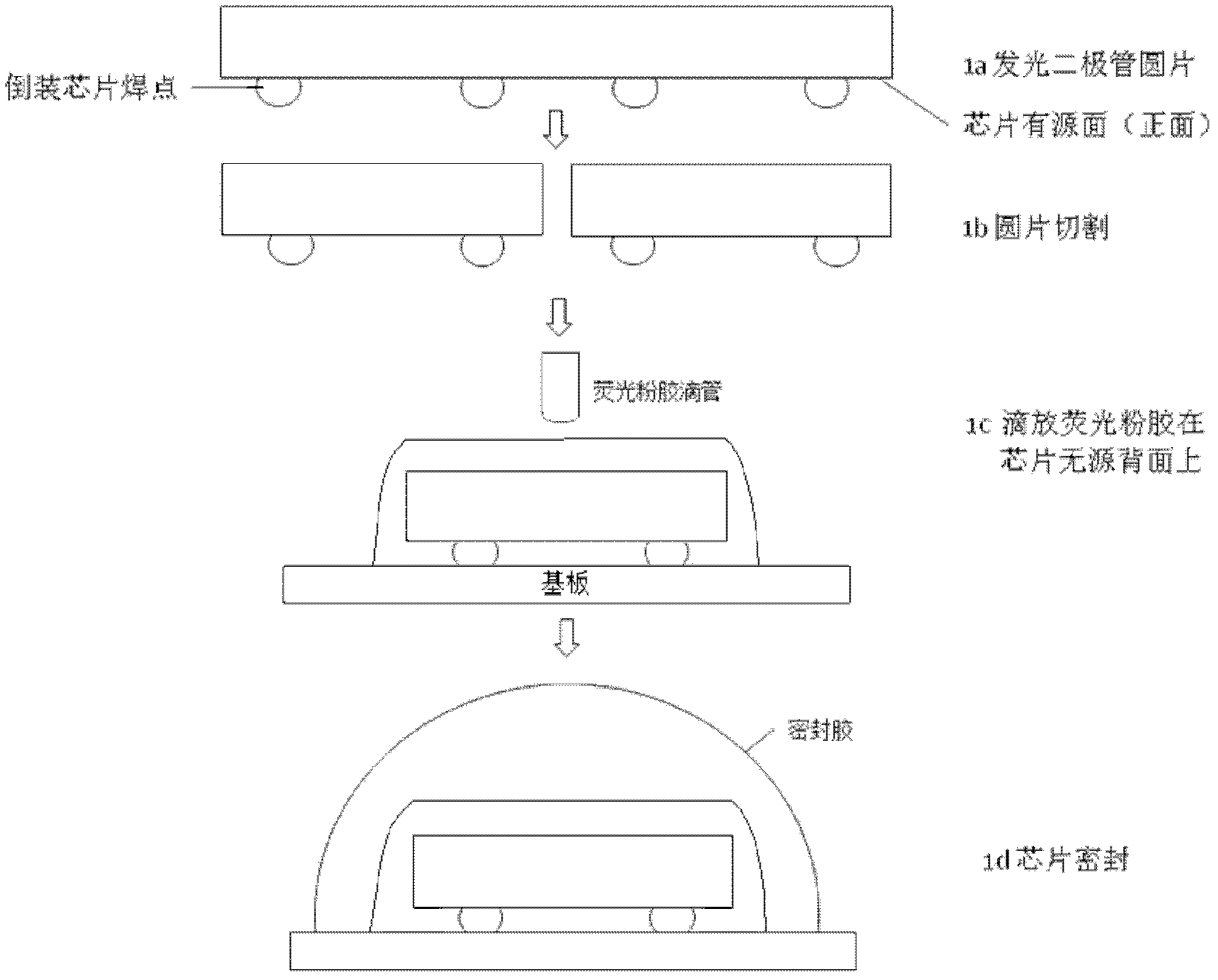

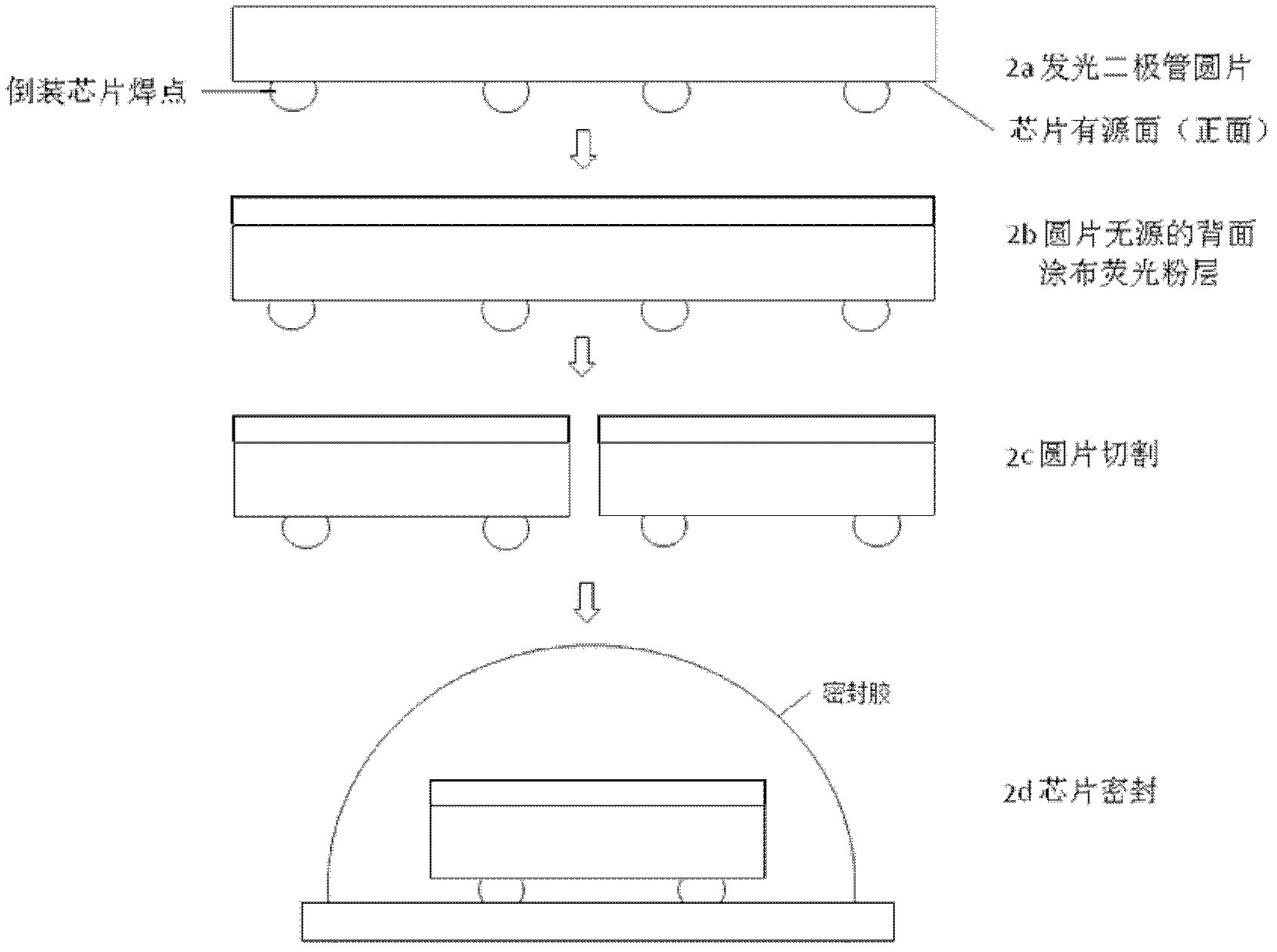

[0024] Such as figure 2 As shown, the wafer-level light-emitting diode flip-chip packaging process in the embodiment of the present invention includes the following steps:

[0025] 4a——Make chip soldering points on the front side of the LED wafer.

[0026] 4b——Coating phosphor glue on the back of the light-emitting diode wafer and curing it, so that a layer of thick and uniform phosphor coating is formed on the back of the light-emitting diode wafer.

[0027] The coating methods of phosphor glue include spin coating, spray coating, lamination and other methods. Typically during the spin coating process, the wafer is vacuumed onto a rotary table. There are many electrode bumps (chip soldering points) on the flip-chip wafer, which cannot be vacuum-adsorbed onto the rotary table. Therefore, the wafer can be placed face down on a flat plate with a thin layer of high adhesive, and the flat plate is vacuum adsorbed on the rotary table. Another method is to use an uncured thick ...

Embodiment 2

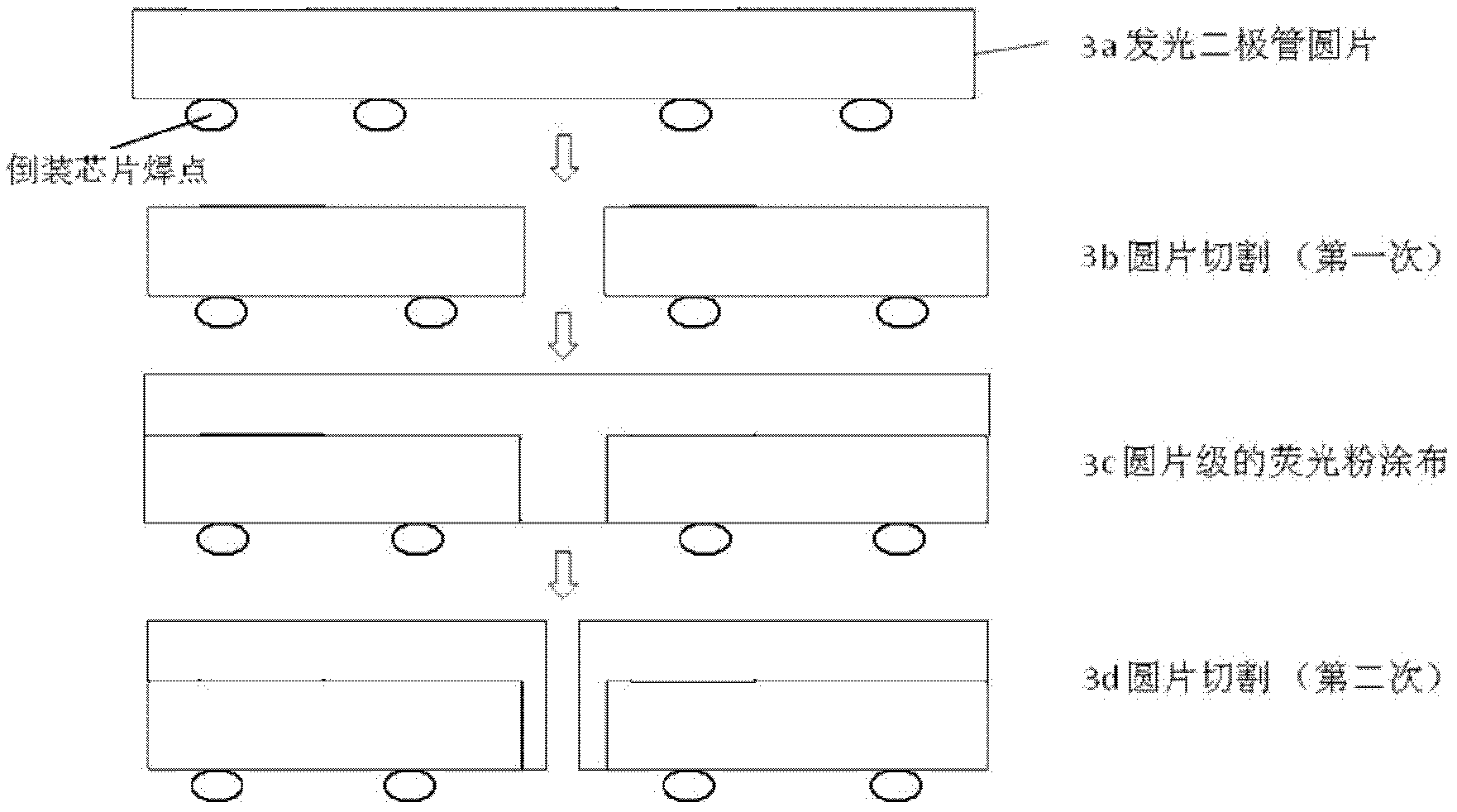

[0033] In order to make the side of the chip emit light, in this embodiment, a phosphor coating is also coated on the side of the light-emitting diode wafer. The proportion of light emitted from the side of the chip depends on the type and size of the chip. For a vertical chip of about 1 mm, there is about 15% side light. For a horizontal chip of the same size, the side light is about 30%. For chips a few millimeters in size, the side light may be reduced to less than 10% of the total luminous flux.

[0034] The realization method of this structure is the improvement on the basis of embodiment 1 technique. Such as image 3 shown, including the following steps:

[0035] 5a——Make chip soldering points on the front side of the light-emitting diode wafer;

[0036] 5b——cutting the light-emitting diode wafer (using a wider grinding wheel or laser beam cutting);

[0037] 5c——While coating phosphor glue on the back of the light-emitting diode wafer, the gap between the light-emi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com