Steel slag auxiliary cementing material and preparation method and application thereof

A cementitious material and an auxiliary technology are applied in the field of steel slag auxiliary cementitious material and its preparation, and can solve the problems of poor abrasiveness, low hydration activity, and poor stability of steel slag.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

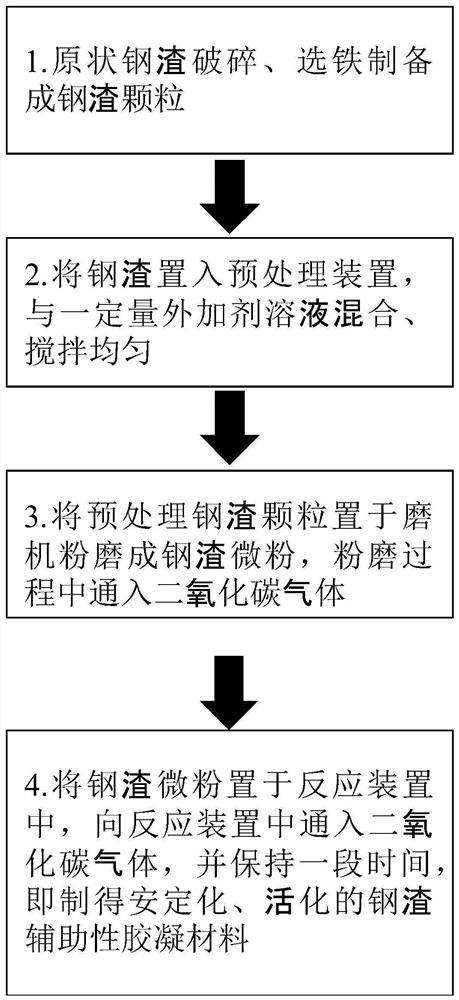

[0023] A steel slag auxiliary cementitious material rapidly stabilized and activated by carbon dioxide and a preparation method thereof, comprising the following steps:

[0024] (1) Take 1200g of steel slag particles (0.02-0.6mm in particle size) after crushing and iron selection and put them into the stirring pretreatment equipment;

[0025] (2) Spray 96g of water evenly on the steel slag surface (that is, the concentration of the admixture solution is 0%), and stir evenly;

[0026] (3) placing the pretreated steel slag particles in a mill for grinding, and simultaneously introducing 99% carbon dioxide gas to grind the steel slag particles to a size smaller than 0.10 mm;

[0027] (4) Put the steel slag micropowder in the stirring reaction equipment, feed 99% carbon dioxide gas into the reaction equipment, keep it under normal pressure for 30 minutes, and obtain the stabilized and activated steel slag auxiliary cementitious material.

Embodiment 2

[0029] The steel slag and test method adopted in this embodiment are all the same as those in Embodiment 1.

[0030] The steps for preparing the finished steel slag auxiliary cementitious material in this example are different from those in Example 1 in that 240 g of water is evenly sprayed in step (2), and kept at normal pressure for 45 minutes in step (4).

Embodiment 3

[0032] The steel slag and test method adopted in this embodiment are all the same as those in Embodiment 1.

[0033] The steps of preparing the finished steel slag auxiliary cementitious material in this example are different from those in Example 1 in that the gas in steps (3) and (4) is industrial tail gas with a carbon dioxide concentration of about 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com