Patents

Literature

45results about How to "Stability qualified" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steel slag auxiliary cementing material and preparation method and application thereof

ActiveCN113072311AWide application range of concentrationImprove stabilityCement productionSlagCement Material

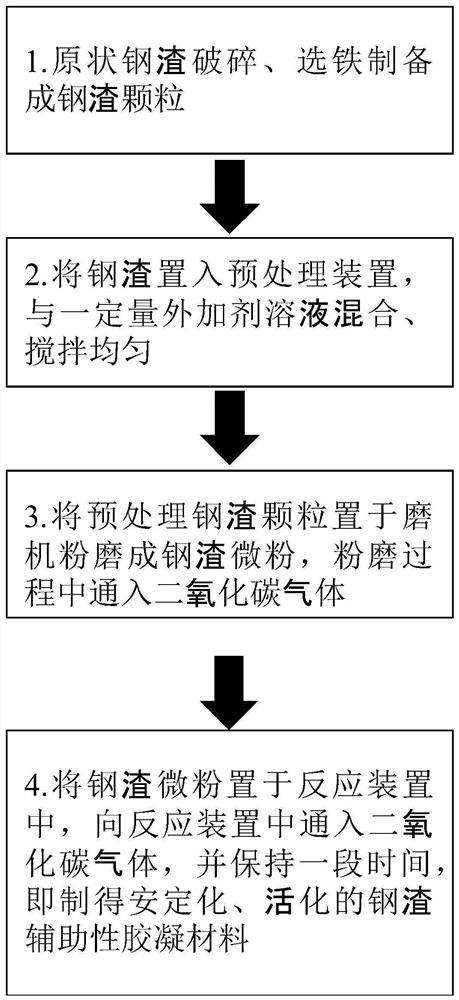

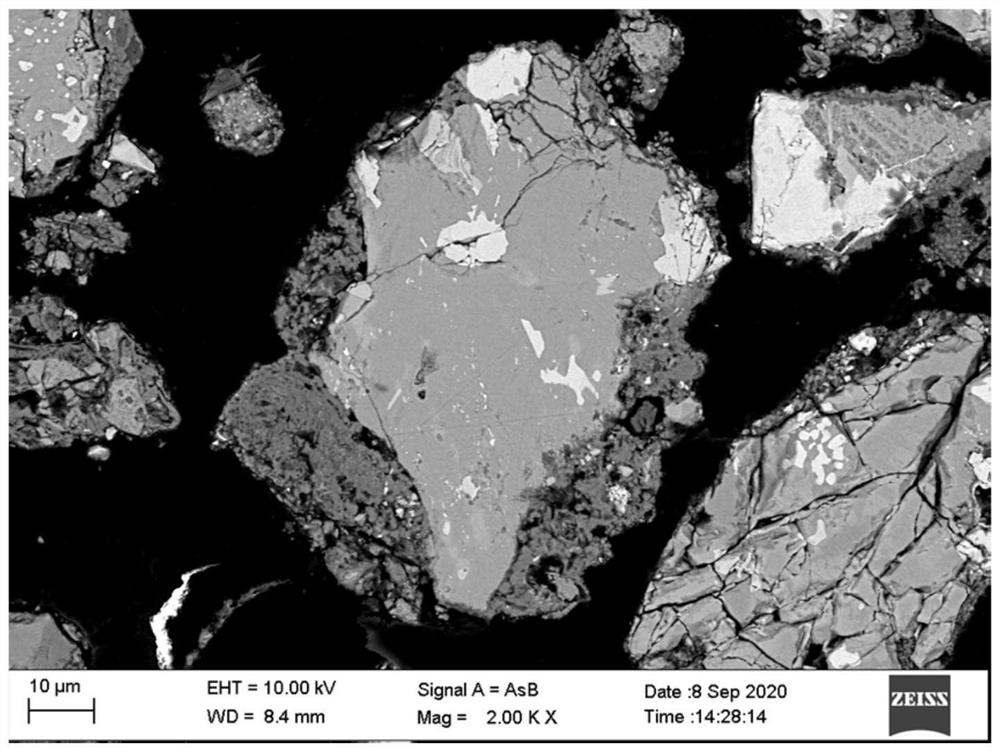

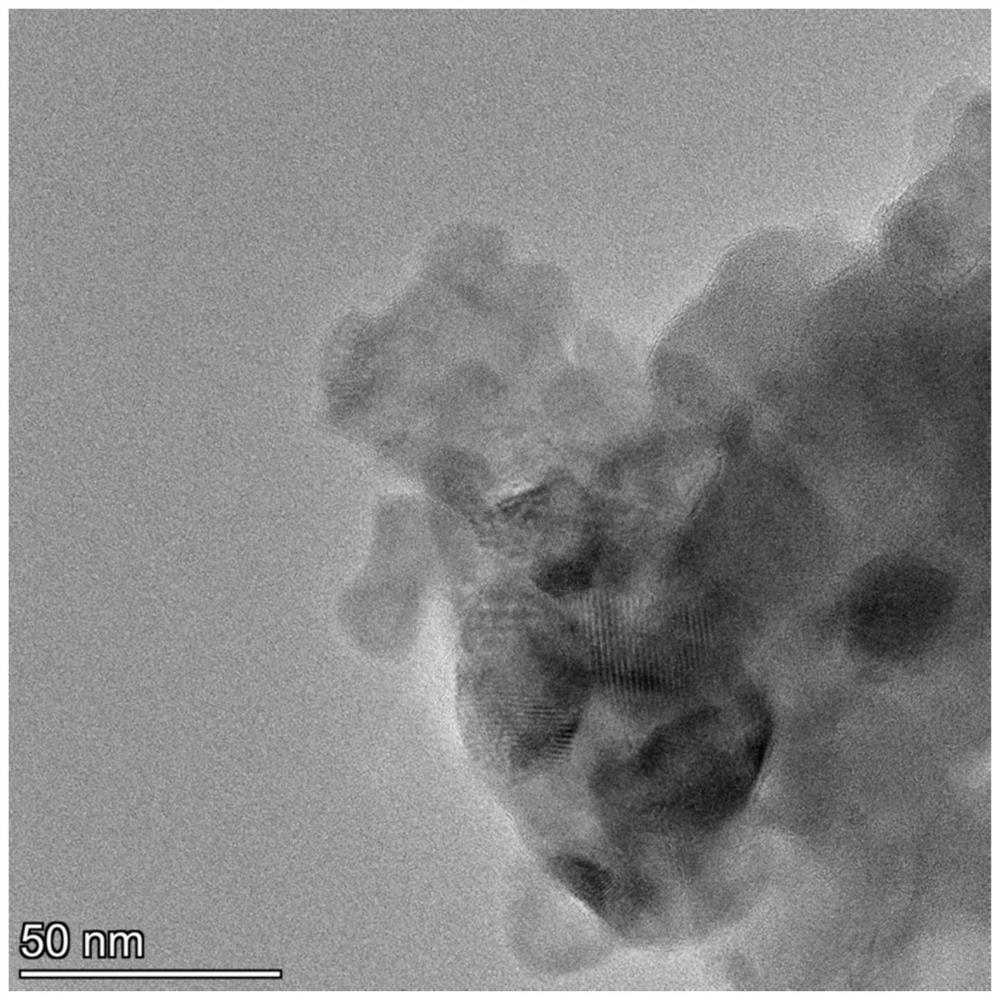

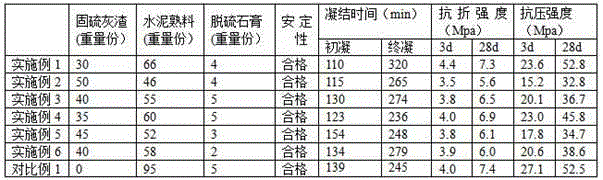

The invention discloses a steel slag auxiliary cementing material and a preparation method and application thereof. The preparation method comprises the following steps: (1) crushing undisturbed steel slag, selecting iron, and grinding in a mill to obtain steel slag particles; (2) putting the steel slag particles into stirring pretreatment equipment, and mixing and uniformly stirring the steel slag and an additive solution; (3) grinding the pretreated steel slag particles in a grinding machine, and meanwhile, introducing carbon dioxide gas to grind the steel slag particles into steel slag micro powder with a certain particle size; and (4) putting the steel slag micro powder into stirring reaction equipment, and introducing carbon dioxide gas into the reaction equipment to obtain the stabilized and activated steel slag auxiliary cementing material. According to the method, free CaO and part of free MgO are rapidly eliminated, so that the problem of poor stability of the steel slag is solved, the gelling activity of the steel slag is improved to a great extent, it is ensured that the stability of the auxiliary gelling material of the steel slag is qualified when the auxiliary gelling material of the steel slag is doped into cement or concrete, and application of the steel slag in building materials such as cement and concrete is promoted.

Owner:NANJING UNIV OF TECH

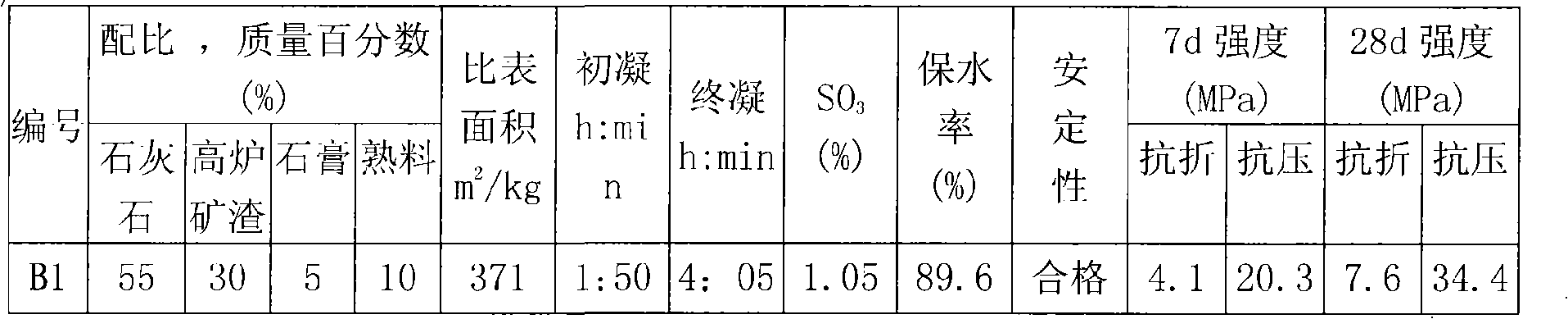

Hydraulicity cementitious materials and preparation method thereof

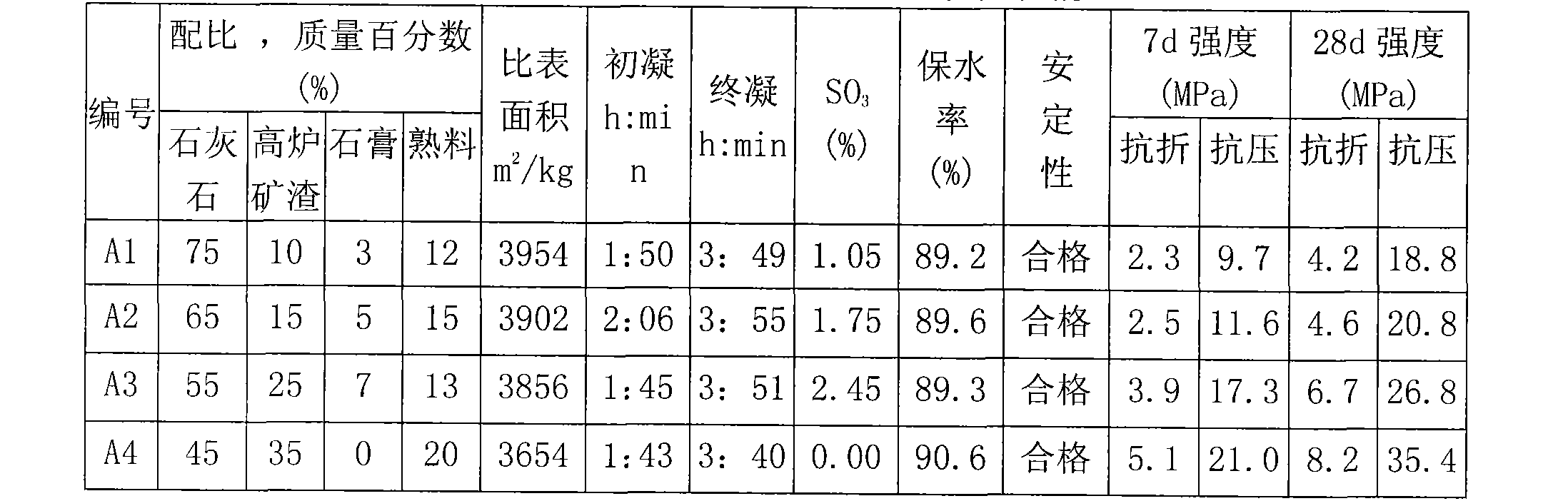

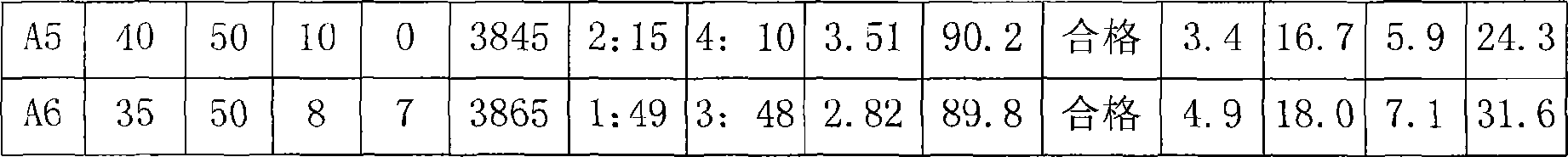

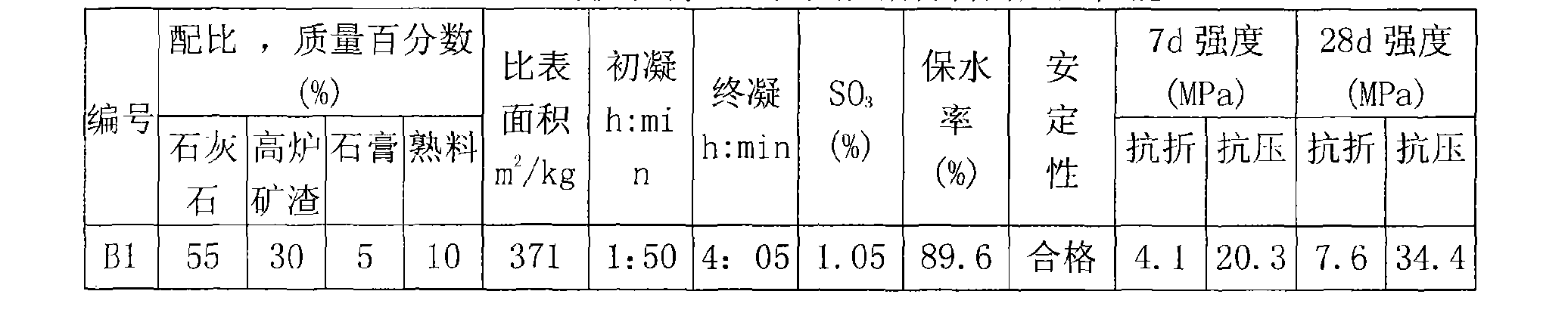

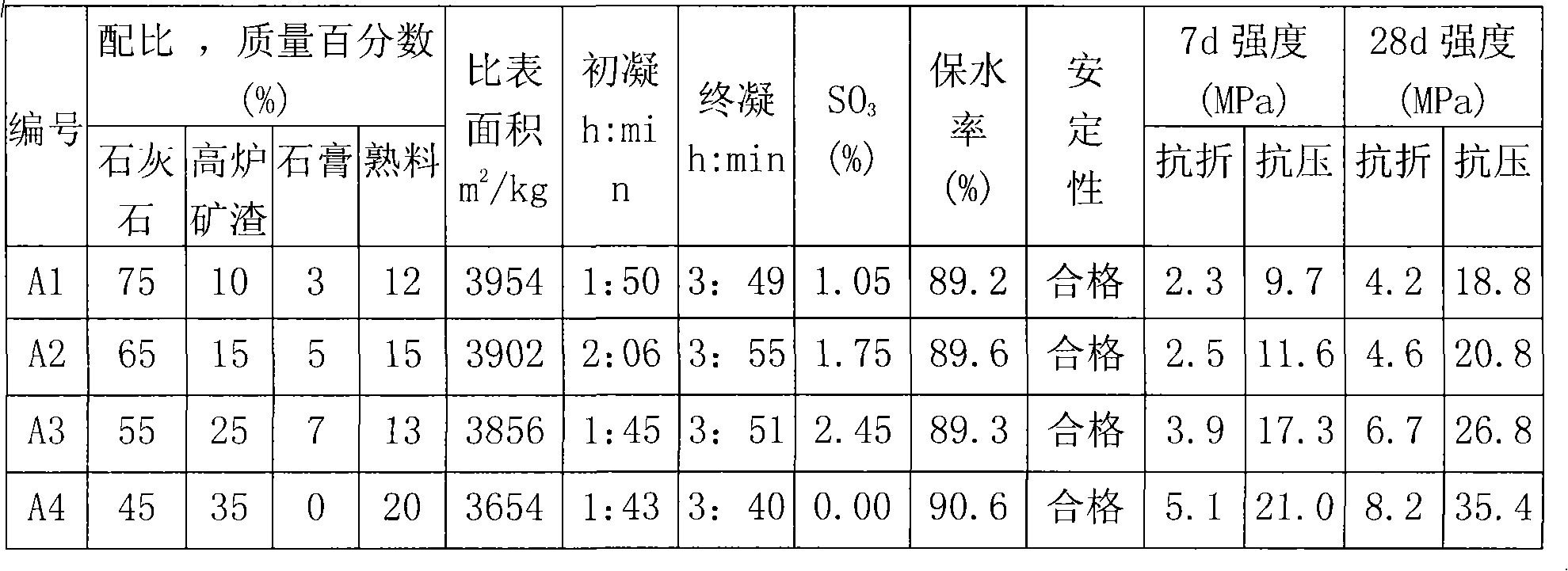

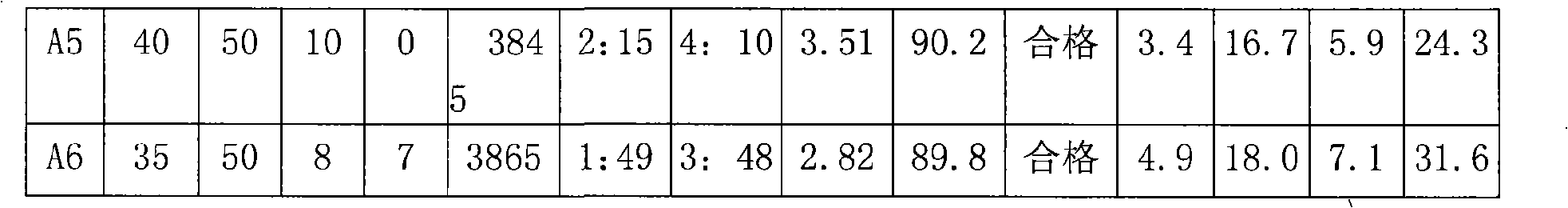

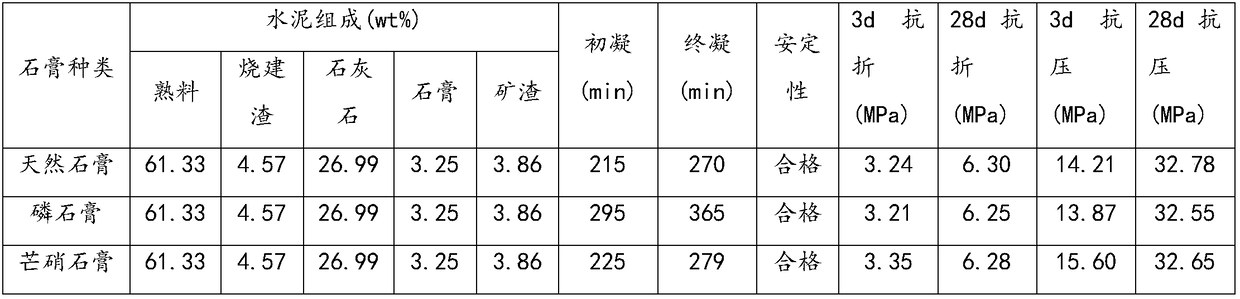

The invention belongs to the field of building materials, and in particular relates to a hydraulic cementing material and a method for preparing the same. The hydraulic cementing material is characterized in that the cementing material is prepared from raw materials of limestone, industrial residue, gypsum and admixture through mixing, and the mass percents of the raw materials are as follows: 35 to 75 percent of the limestone, 5 to 50 percent of the industrial residue, 0 to 10 percent of the gypsum, and 0 to 20 percent of the admixture, wherein the mass percents of the gypsum and the admixture cannot be 0 simultaneously, and the summation of the mass percent of each raw material is 100 percent. The invention can make full use of a large number of the limestone, and the method has the advantages of simple process, low cost, less energy consumption and environmental protection.

Owner:WUHAN UNIV OF TECH +1

Hydraulic gelate material and method for preparing same

The invention belongs to the field of a constructional material, in particular relates to a hydraulic binding material and a preparation method thereof. The hydraulic binding material is characterized in that the hydraulic binding material is prepared with 35 percent to 75 percent of limestone by mass, 5 percent to 50 percent of industrial residue by mass, 0 percent to 10 percent of plaster by mass and 0 percent to 20 percent of additives by mass through mixing. The mass percents of the plaster and the additives are not 0 at the same time, and the total of the mass percents of the raw materials is 100%. The hydraulic binding material and the preparation method can make use of much limestone; the preparation method is simple in process; the cost is low; little energy is consumed; and the hydraulic binding material is environment-friendly.

Owner:WUHAN UNIV OF TECH +1

Concrete grinding aid and preparation method thereof

InactiveCN101269928APromote hydrationHigh strengthSolid waste managementCement productionPolyacrylamideSODIUM SULFATE ANHYDROUS

The present invention relates to a cement grinding aid and a method for producing the cement grinding aid, which belongs to the production technical field of the cement. The grinding aid comprises the ingredients in weight percent as follows: 12 to 14 percent of polyacrylamide, 9 to 11 percent of polyacrylic acid, 5 to 7 percent of trolamine, 9 to 11 percent of triisopropanolamine, 6 to 8 percent of red mud, 12 to 14 percent of sodium sulfate anhydrous, 6 to 8 percent of quicklime, and 34 to 36 percent of water. The cement grinding aid not only has good grinding-assistant effect, but also can enhance the strength of the cement; the preparation method that is scientific, reasonable, simple, convenient and feasible divides the raw materials into two groups, wherein, group A is polyacrylamide, polyacrylic acid, trolamine and triisopropanolamine, and group B is the red mud, the sodium sulfate anhydrous, the quicklime and the water; the raw materials in group A and group B are respectively mixed uniformly and independently, and then the raw materials of the two groups are mixed uniformly together to obtain the cement grinding aid of the present invention.

Owner:YIYUAN CHENTONG BUILDING MATERIALS

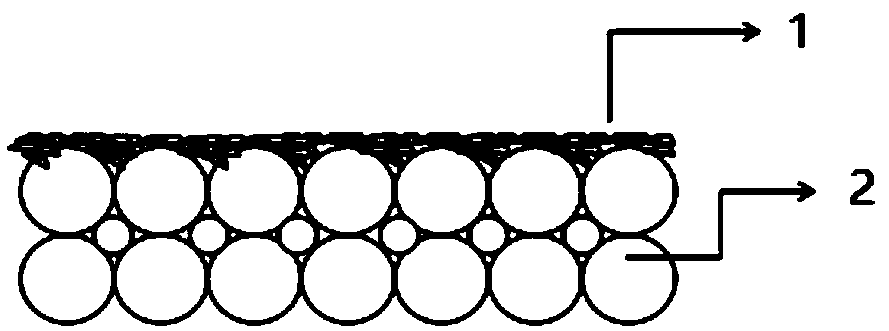

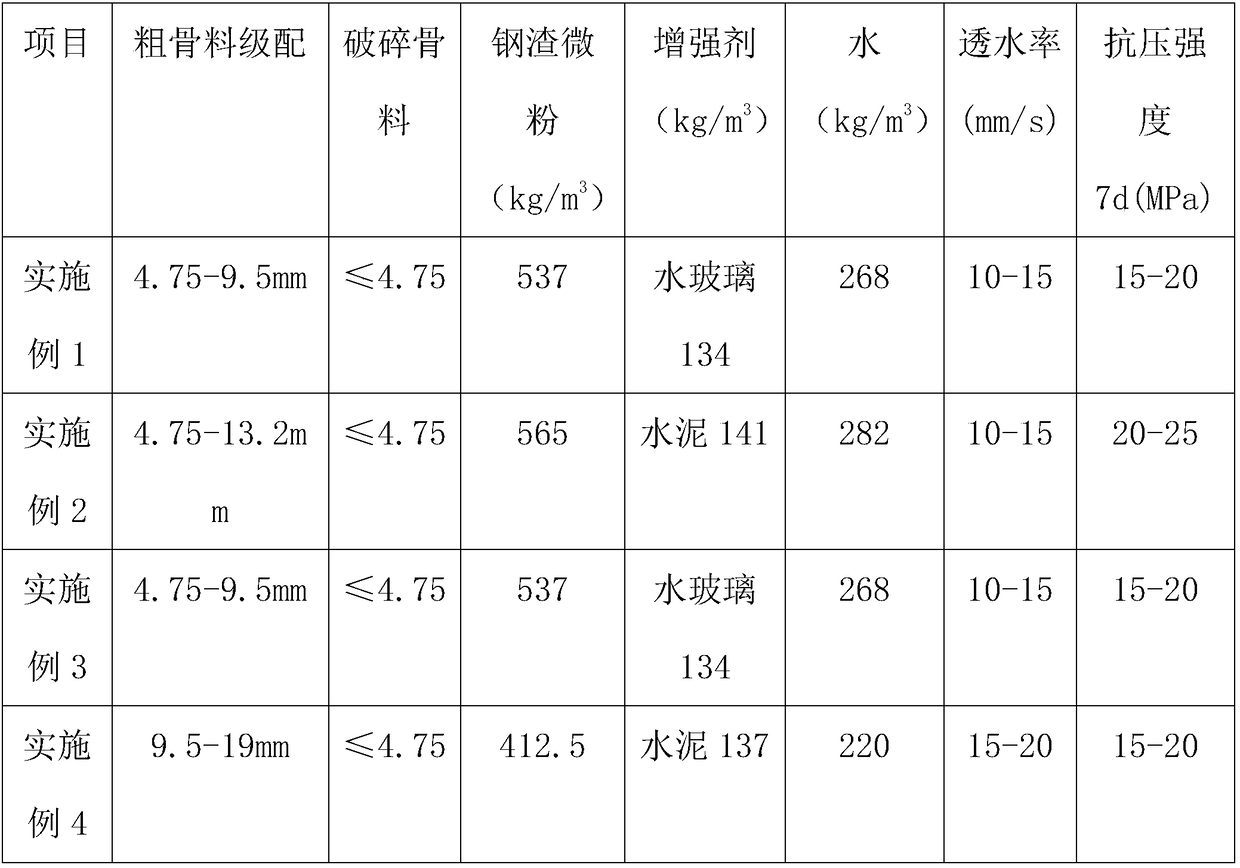

Water-permeable brick with artificial carbonized steel slag pellets as aggregates and preparation method thereof

ActiveCN108774041AUniform compositionShape controllableSolid waste managementPaving gutters/kerbsBrickSlag

The invention provides a water-permeable brick with artificial carbonized steel slag pellets as aggregates and a preparation method thereof, belonging to the technical field of green building materials. The water-permeable brick comprises a base layer and a surface layer, wherein the surface layer is located on the base layer; the base layer is made of continuously graded artificial carbonized steel slag pellet aggregates; and the surface layer is made of fine aggregates obtained by crushing and sieving carbonized steel slag bricks and formed after filling and leveling of the fine aggregates.The water-permeable brick comprises the following components by weight: 60 to 70% of artificial carbonized steel slag pellet aggregates, 5 to 10% of the fine aggregates obtained by crushing and sieving carbonized and cured steel slag bricks and having a particle size of no more than 4.75 mm, 15 to 20% of steel slag micropowder, 4 to 5% of a reinforcing agent and 4 to 5% of tap water. According tothe invention, through large addition amount of steel slag, industrial waste residues are greatly consumed; meanwhile, industrial waste gas CO2 is used as a raw material in the process of carbonization and curing, and the reaction of the CO2 with steel slag products in a carbonization kettle is an exothermic reaction, so no external heat source is need; and the advantages of waste utilization, carbon sequestration, energy conservation, emission reduction, simple preparation process, low equipment requirements, short production cycle and low cost are obtained.

Owner:DALIAN UNIV OF TECH

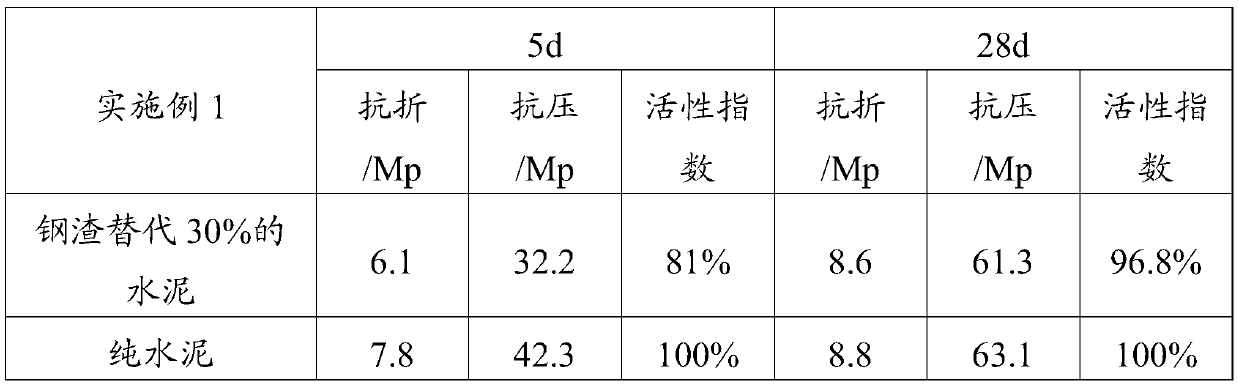

Method for modifying steel slag

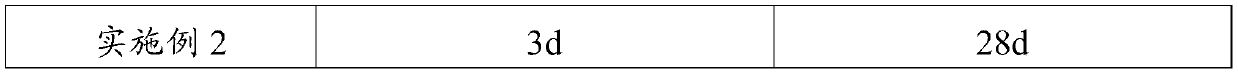

A method for modifying steel slag includes the following steps: adding a modifier into steel slag of a high-temperature converter, cooling to 600-800 DEG C, and then placing the mixture in a sealed environment for water spraying hot braising treatment to obtain pulverized steel slag; mixing that pulverized steel slag with clay and quicklime according to a mass ratio of 45: (12-18): (37-43), and uniformly stirring to obtain a mixture; finally calcining the mixture at 1300-1450 DEG C for 20-30 minutes, cooling to room temperature to obtain steel slag with active cement clinker. The steel slag modified by the method provided by the invention has qualified stability, improved activity and can replace part of cement. After replacing the cement with the modified steel slag, the hydration is slowin the early stage, but the 28-day flexural compressive strength is equivalent to that of the cement, and the production cost can be greatly reduced.

Owner:湖南省道同环保科技有限公司

FBC (fluidized bed combustion) ash containing cement and preparation method thereof

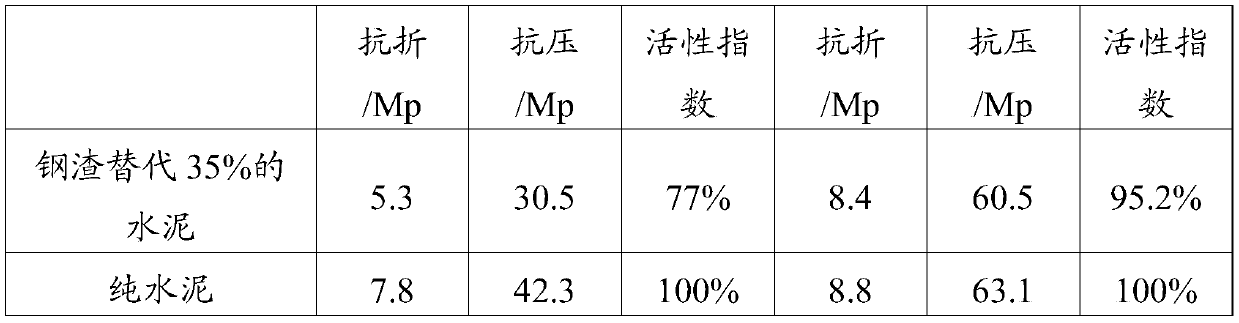

The invention discloses FBC ((fluidized bed combustion) ash containing cement and a preparation method thereof. The FBC ash cement comprises raw materials in parts by weight as follows: 30-50 parts of FBC ashes, 46-66 parts of cement clinker and 2-5 parts of flue gas desulfurization gypsum. According to the FBC ash containing cement, a sulfur-fixing agent comprising calcium oxide, zinc residues, copper residues, an activating agent, a stabilizer and an exciting agent is added to a circulating fluidized bed boiler in the coal combustion process, the utilization rate of the FBC ashes in the cement can be increased by improving the ingredient of the sulfur-fixing agent, the additional value of the FBC ashes can be increased, the production cost of the cement is reduced, and environmental pollution is reduced.

Owner:山西中科赛德能源科技有限公司

Method for processing ardealite by using fluidized bed furnace to prepare special anhydrite cementing material

A method for processing ardealite by using a fluidized bed furnace to prepare a special anhydrite cementing material comprises the following steps that (1) materials are prepared, namely caked ardealite and massive stone coal or waste rock ballast is crushed; (2) burdening is performed, namely 50 to 80 parts of ardealite, 8 to 25 parts of stone coal and 10 to 40 parts of waste rock ballast are burdened and metered by weight; (3) matured slag is prepared, namely the materials are continuously fed into the fluidized bed furnace and calcined in the oxidative atmosphere at the temperature of 850 to 1280 DEG C for 0.3 to 1.5 hours, the materials overflowing from a discharging port are rapidly quenched to be made into the matured slag; (4) the special anhydrite cementing material is prepared, namely the matured slag is grinded into 80-micron powder containing smaller than or equal to 20% of screen residue mass, and the special anhydrite cementing material is obtained. The special anhydrite cementing material prepared by means of the method contains multiple hydrated active minerals, can be widely used in the cement industry, is high in strength in use and can serve as active residue powder or be used for production of construction materials. By means of the method, investment is small, no wastewater and waste residue is produced, and economical efficiency is high.

Owner:湖南省小尹无忌环境能源科技开发有限公司

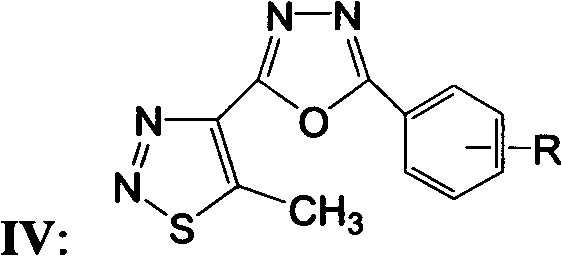

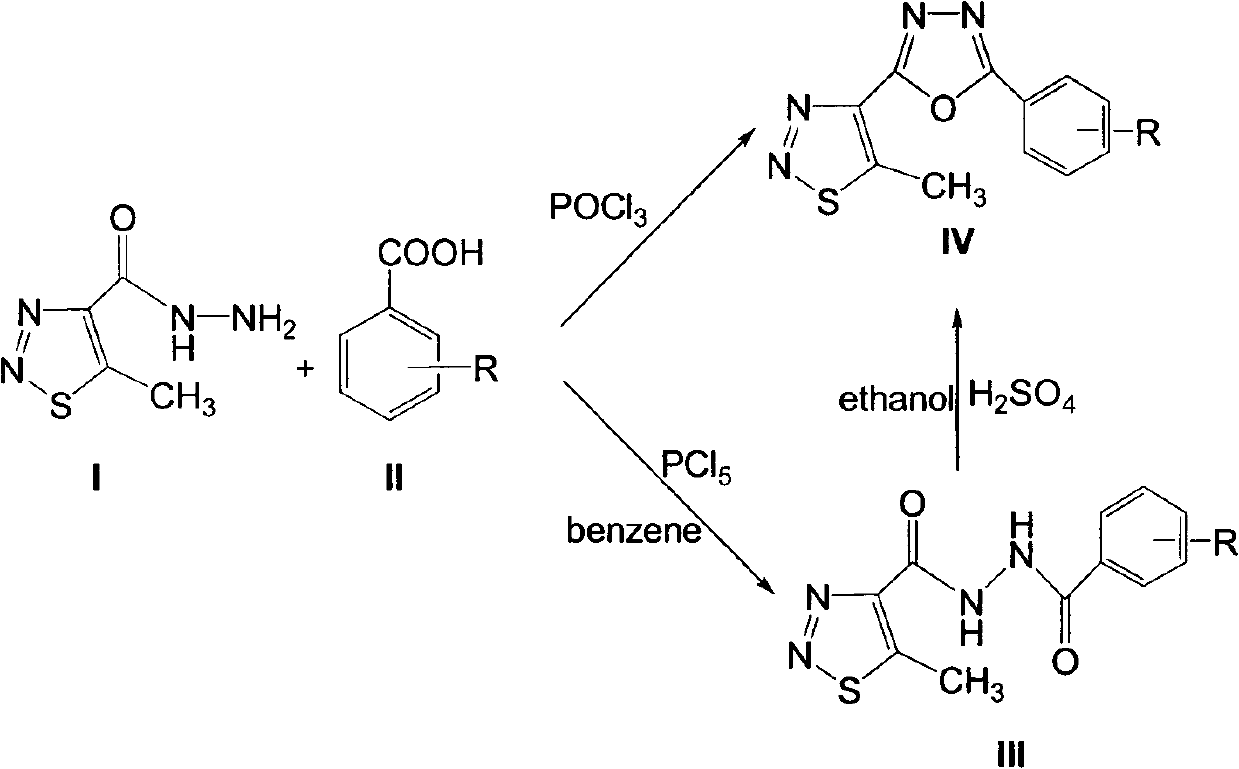

5-methyl-1,2,3-thiadiazole-1,3,4-oxadiazole derivatives, and preparation method and application thereof

InactiveCN102816158AExpand or reduce volumeExpand or shrink in sizeBiocidePlant growth regulatorsAdjuvantStructural formula

The invention provides 5-methyl-1,2,3-thiadiazole-1,3,4-oxadiazole derivatives, and a preparation method and application thereof. The invention relates to heterocyclic compounds containing 1,2,3-thiadiazole and having chemical structural formula IV. The invention discloses the structural general formula, and a synthetic method of the compounds and the application of the compounds for being used as bactericide, plant anti-viral agent and plant activator. The derivatives can be applied for preparing the bactericide, plant anti-viral agent and plant activator in combination with agriculturally acceptable adjuvant or synergist, and the invention also discloses application of the compounds in combination with commercial insecticide, bactericide, plant anti-viral agent and plant activator for treating and controlling diseases, pests and viruses in agriculture, forestry, and gardening industries, and the preparation method.

Owner:JIANGXI JIAYIN PHOTOELECTRIC MATERIAL

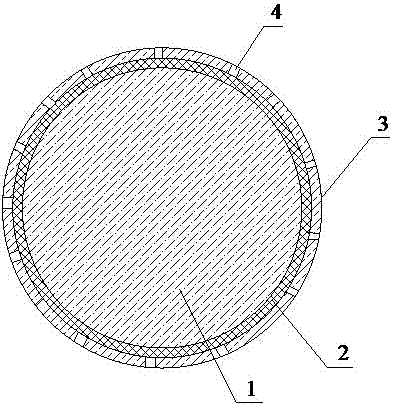

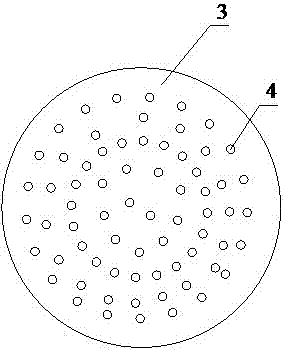

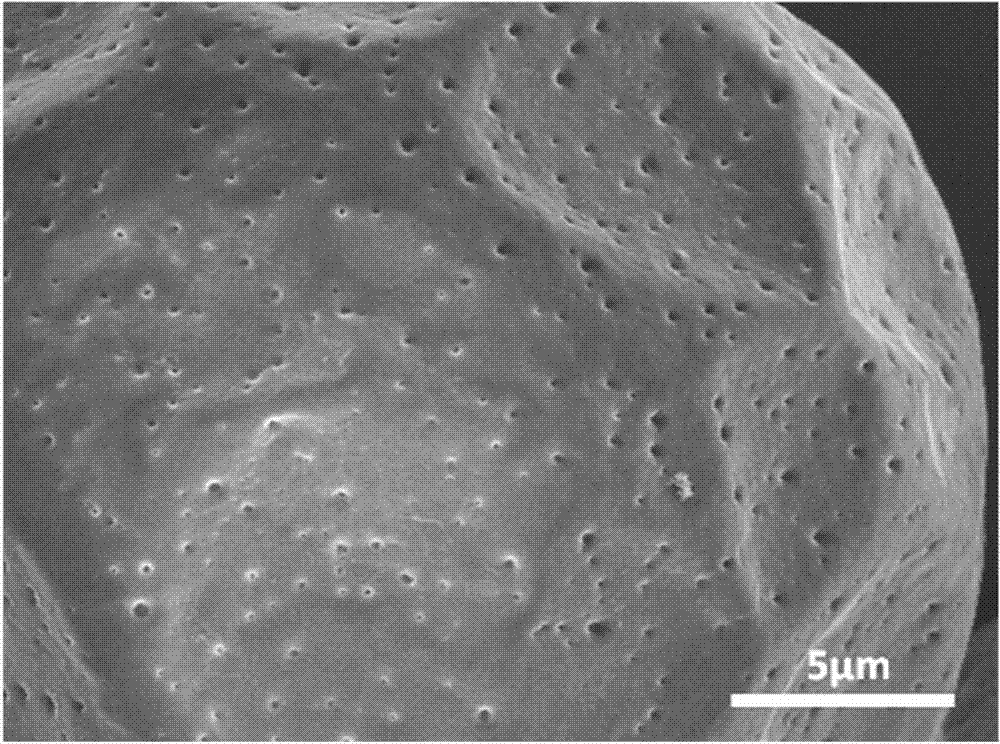

Microcapsule with porous double-layer capsule wall and preparation method of microcapsule

ActiveCN106984248AControl releaseWide adaptabilityMicroballoon preparationMicrocapsule preparationControlled releaseEpoxy

The invention discloses a microcapsule with porous double-layer capsule wall and a preparation method of the microcapsule and belongs to the technical field of microcapsules. The microcapsule has the advantages that the microsphere hole forming technology is used to modify an epoxy resin material to prepare the porous microcapsule, capsule core substance releasing is achieved by regulating pores, the microcapsule technology can be favorably developed from slow release to controlled release, and quite important practical significance is achieved; the microcapsule has the pores in the capsule wall material, the size and number of the pores can be regulated to control the capsule core substance releasing, and the microcapsule is widely applicable to multiple fields such as agriculture, printing and dyeing, ink and phase-change materials; the encapsulation efficiency of a microcapsule suspending agent prepared by the microcapsule is not smaller than 90%, the particle size range of more than 95% of particles of the microcapsule suspending agent is 0.2-30 micrometers, the suspending rate of the microcapsule suspending agent is not smaller than 90%, the persistent foaming property of the microcapsule suspending agent is not larger than 20mL, the pH of the microcapsule suspending agent is 7.0-10.0, and the microcapsule suspending agent is qualified in thermal storage stability and cold storage stability.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

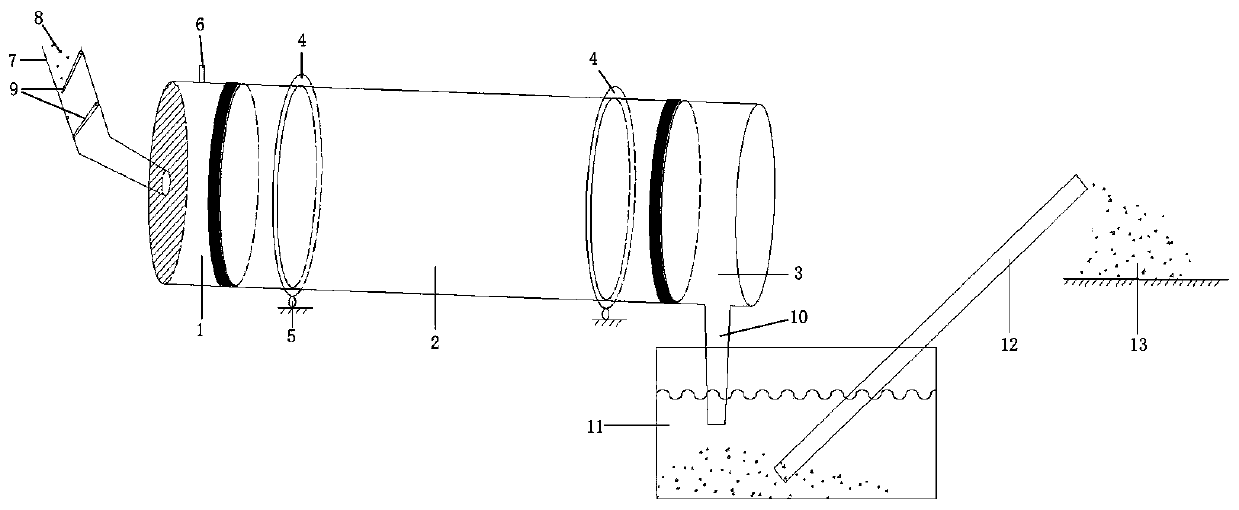

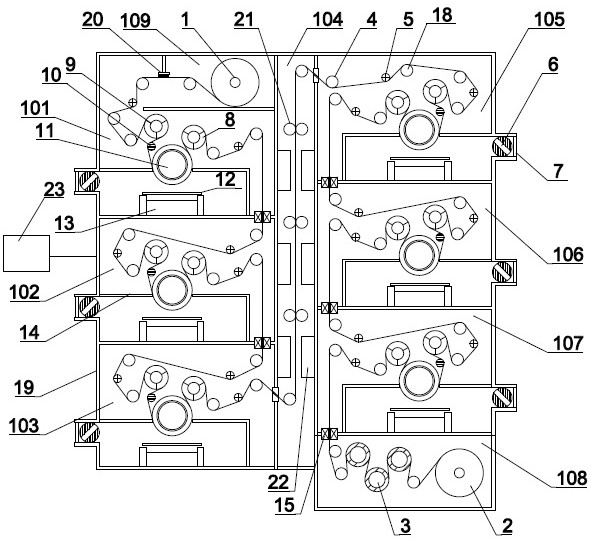

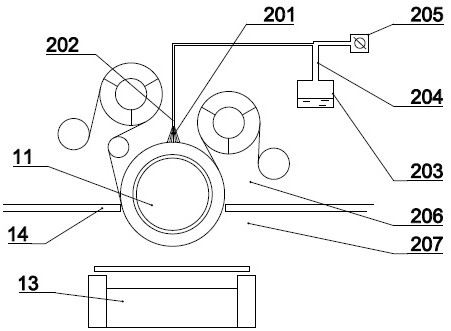

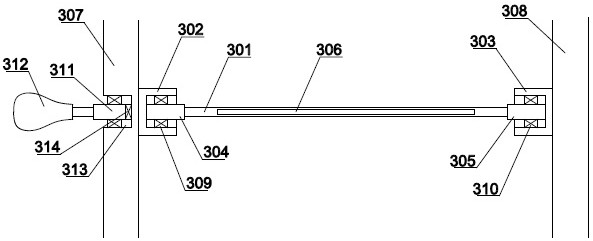

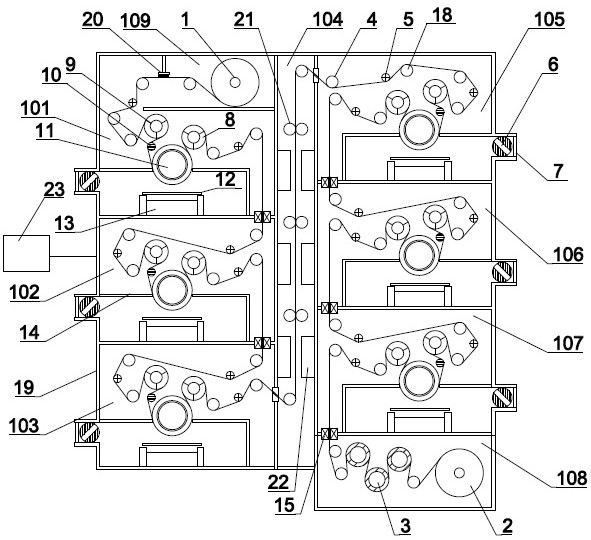

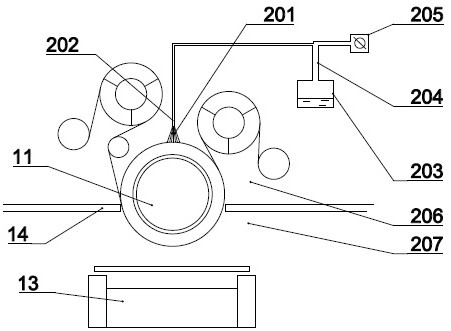

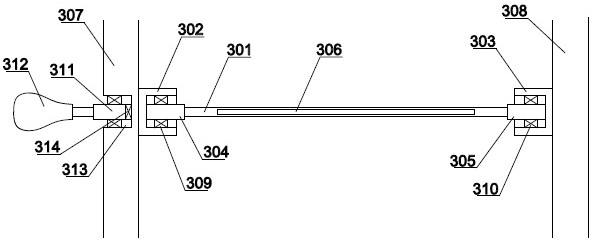

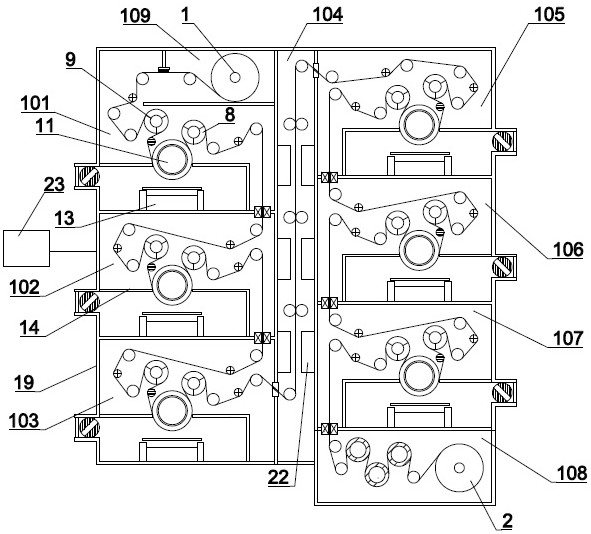

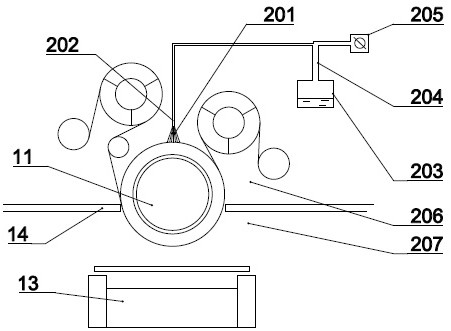

Carbonizing device for solid waste recycled aggregates for concrete

ActiveCN107814502ASolve the unsustainable carbonizationSolve efficiency problemsProductsCarbon compoundsConstruction aggregateVALVE PORT

The invention discloses a carbonizing device for solid waste recycled aggregates for concrete. The device comprises a loading bin, a drum type carbonizing bin and a storage bin, wherein the loading bin and the storage bin are arranged on two ends of the drum type carbonizing bin in a sealing way; a circumferential rack is arranged on an outer surface of the drum type carbonizing bin, and is meshedwith a fixed motor transmission gear. A double-spiral turnover plate is arranged on an inner cylinder wall of the drum type carbonizing bin. The loading bin is provided with a carbon dioxide air inlet, and a feed hopper is arranged on the end part; a discharging leakage pipe is arranged on the bottom part of the storage bin. The feed hopper is sealed by a valve closed by automatic rebound, and adischarge hole is sealed by a water tank. The carbonizing device not only realizes continuous production of recycled aggregates carbonizing, but also realizes full seal of a carbonizing space, guarantees that no CO2 gas is lost during a carbonizing process, and provides a way for industrial production of solid waste recycled aggregates carbonizing. Meanwhile, according to the carbonizing device, the recycled aggregates can fully absorb the CO2 gas, and the mechanical strength of the recycled aggregates is greatly improved.

Owner:CHINA UNIV OF MINING & TECH

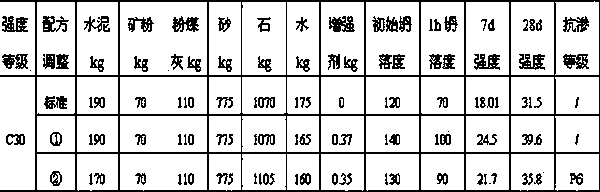

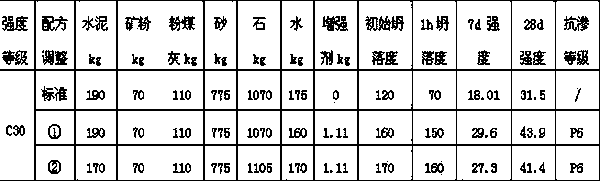

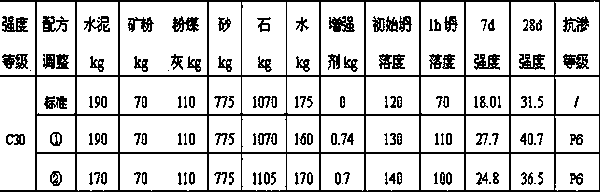

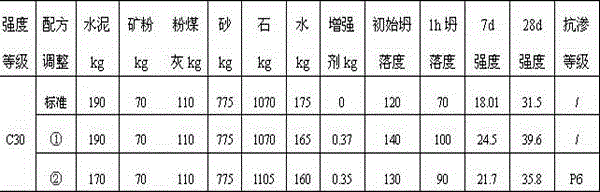

Multifunctional concrete intensifier

A multifunctional concrete intensifier is prepared by a method comprising the following steps: at first, adding polyethers and 70%-75% of deionized water in a reaction vessel according to proportion; when heating to 55-65 DEG C, dropwise adding acrylic acid and an initiator in the reaction vessel and then cooling to 35-45 DEG C, adding caustic soda for neutralizing, stirring for 10-20 min to enable the components to be mixed uniformly to prepare a mixture I; adding triethanolamine, a surfactant and a thickening time control agent in the rest of 25%-30% of deionized water, and sufficiently stirring for 0.2-1 h at 35-45 DEG C to prepare a mixture II; then maintaining the temperature of the mixture I to 35-45 DEG C, stirring and slowly pouring into the mixture II, and sufficiently mixing for 0.5-1.5 h to obtain a light yellow liquid not easy to precipitate. The multifunctional concrete intensifier is chloride-free, is qualified in stability, meanwhile, has multiple functions of saving the comprehensive cost of concrete, improving the concrete workability, and increasing the concrete strength and the like, meets the national harmful substance requirement standard, reduces the cement content, and is simple to use, low in mixing amount, and small in investment.

Owner:衡阳市银利实业有限公司

Continuous winding vacuum coating method for ultrathin base film

PendingCN112853275AIncrease productivityGuaranteed qualityVacuum evaporation coatingSputtering coatingPhysicsPumping vacuum

The invention discloses a continuous winding vacuum coating method for an ultrathin base film. The method is used for preparing multiple film layers on a flexible base film in the field of new energy power batteries, and mainly comprises the following steps: (1) placing the base film on an unwinding roller in an unwinding chamber of a vacuum coating machine, closing a vacuum chamber, and vacuumizing the vacuum chamber; (2) performing vacuum film penetration on the base film on a winding system by adopting a vacuum film penetration mechanism in a vacuum environment; and (3) when the vacuum degree in vacuum evaporation coating chambers and a magnetron sputtering coating chamber of the vacuum coating machine meets the process requirement, starting the winding system, an evaporation device and a magnetron target. The magnetron sputtering coating chamber is vertically arranged, and the vacuum evaporation coating chambers are arranged on the two sides of the magnetron sputtering coating chamber in a stacked mode. The base film passes through the vacuum evaporation coating chamber on one side, the magnetron sputtering coating chamber and the vacuum evaporation coating chamber on the other side in sequence, evaporation coating and magnetron sputtering coating are conducted respectively, and multiple film layers are plated on the two faces of the base film respectively.

Owner:辽宁分子流科技有限公司

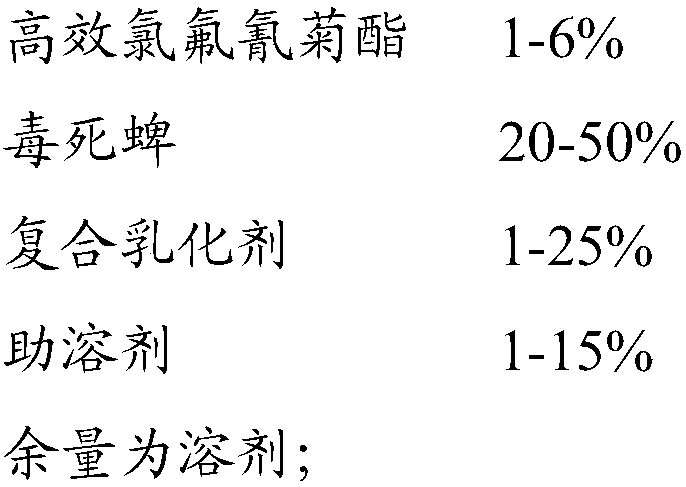

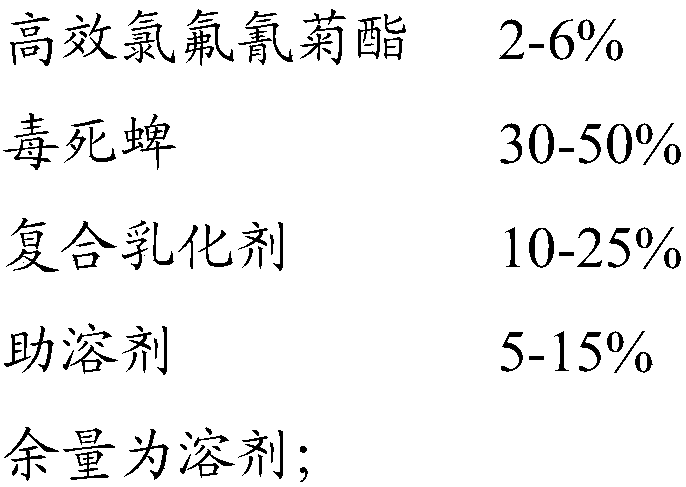

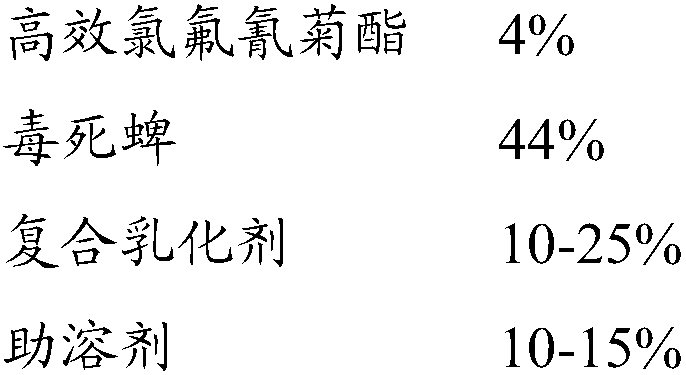

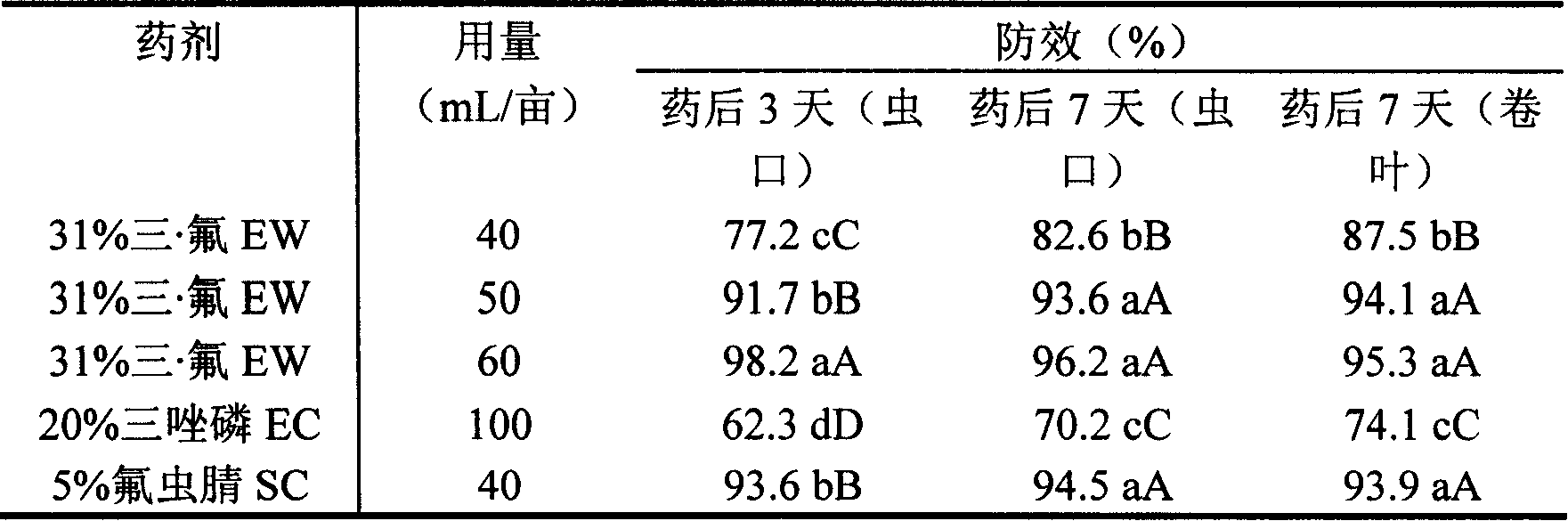

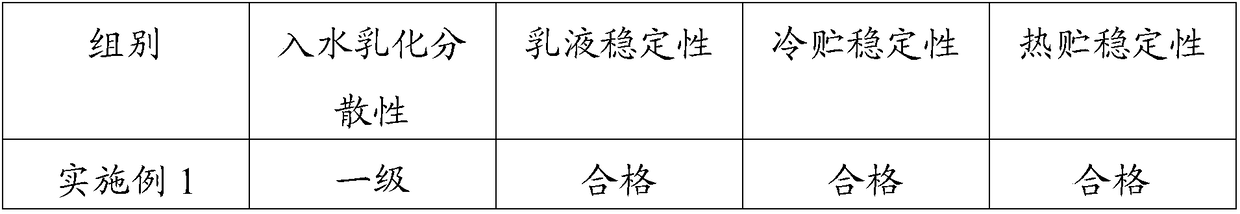

Efficient cyhalothrin-chlopyrifos compound missible oil as well as preparation method and application thereof

ActiveCN107593758AReduce pollutionPromote degradationBiocideAnimal repellantsChlorpyrifosCarboxylic salt

The invention discloses efficient cyhalothrin-chlopyrifos compound missible oil as well as a preparation method and application thereof, and belongs to the field of a pesticide formulation. The efficient cyhalothrin-chlopyrifos compound missible oil is prepared from the following ingredients in percentage by weight: 1 to 6 percent of efficient cyhalothrin, 20 to 50 percent of chlopyrifos, 1 to 25percent of compound emulsifying agents, 1 to 15 percent of cosolvents and the balance of solvents. The compound emulsifying agents are prepared from phenethyl phenol polyoxyethylene ether sulfate, alcohol ether carboxylate, PEG-80 sorbitan laurate according to the weight ratio of 1:(1 to 5) :(1 to 5). The efficient cyhalothrin-chlopyrifos composite missible oil has the advantages that the preparation ingredient system is reasonable; the emulsification effect is good; the environment pollution is reduced; the prevention and control effect on rice planthopper is good; the pest drug resistance can be delayed.

Owner:LIER CROPSCIENCE CO LTD

Double-sided multi-station winding type vacuum coating machine

PendingCN112813400AAvoid exposureGuaranteed qualityVacuum evaporation coatingSputtering coatingPower batteryNew energy

The invention discloses a double-sided multi-station winding type vacuum coating machine, which is used for preparing multiple film layers on a flexible base film in the field of new energy power batteries, and mainly comprises an unwinding chamber, vacuum evaporation coating chambers, a magnetron sputtering coating chamber, a winding chamber and a winding system. The magnetron sputtering coating chamber is vertically arranged and is positioned in the middle of the vacuum coating machine. The 2-10 vacuum evaporation coating chambers are arranged on the two sides of the magnetron sputtering coating chamber in two rows in a stacked mode, and evaporation devices are arranged in the vacuum evaporation coating chambers. The winding system mainly comprises an unwinding roller positioned in an unwinding chamber, a winding roller positioned in a winding chamber, and a main roller, a front pre-cooling roller and a rear pre-cooling roller which are arranged in each vacuum evaporation coating chamber. The main roller located above the evaporation device bears a base film needing to be subjected to evaporation coating, circulating cooling liquid is introduced into the main roller, and subzero treatment is conducted on the base film at the temperature ranging from-150 DEG C to-220 DEG C.

Owner:辽宁分子流科技有限公司

Composite dispersant for pesticide suspension concentrate

The invention relates to a composite dispersant for a pesticide suspension concentrate. The composite dispersant consists of a naphthyl sulfonate formaldehyde condensate and alkylphenol ethoxylates phosphate of which the weight ratio is 1:(1-2). Preferably, the composite dispersant is applied to preparation of an imidacloprid suspension concentrate. The screened specific composite dispersant shows excellent effects, and the suspension concentrate further prepared from the composite dispersant has better suspensibility and dispersity and is qualified in cold and heat storage stability; compared with an individual dispersant, the composite dispersant has a relatively remarkable synergistic interaction effect; when adopted to prepare the imidacloprid suspension concentrate, the composite dispersant has excellent compatibility with the active ingredient (imidacloprid), and the prepared imidacloprid suspension concentrate is very superior in suspensibility, dispersity and cold and heat storage stability.

Owner:ZHEJIANG HISUN CHEM

High-efficient cyhalothrin-phoxim emulsifiable solution and preparation thereof

InactiveCN101326907APrevention and killing effectReduce manufacturing costBiocideArthropodicidesPhoximCotton bollworm

The invention discloses high-efficient Lambda-cyhalothrin phoxim.Phoxim EC, prepared with high-efficient Lambda-cyhalothrin phoxim, Phoxim, emulsifying agent (Model 2201) and xylene solvent. The farm drug-effect test proves that the cotton-bollworm killing efficiency of the insecticide is about 90 percent; therefore, the invention is favorable for farmers to reduce the production cost and increase the income.

Owner:YIYANG RUNKANGBAO CHEM IND

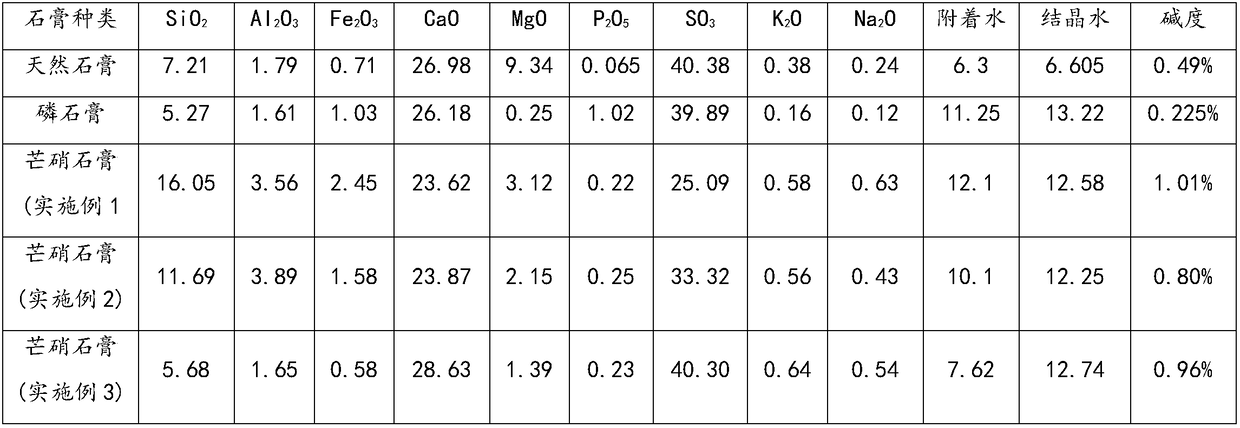

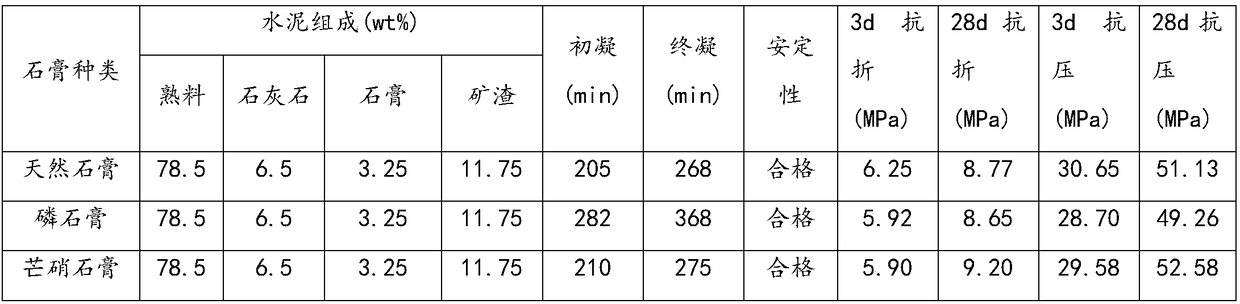

Mirabilite gypsum capable of being used as cement retarder

The invention discloses mirabilite gypsum capable of being used as a cement retarder. The mirabilite gypsum is prepared from the following chemical ingredients in percentage by weight: 5 to 18 percentof SiO2, 1.4 to 5.2 percent of Al2O3, 0.5 to 3.0 percent of Fe2O3, 15 to 35 percent of CaO, 0.5 to 3.5 percent of MgO, 0.2 to 0.35 percent of P2O5 and 25 to 43 percent of SO3, wherein the attached water content is less than or equal to 16 percent, the crystal water content is higher than or equal to 8 percent, and the alkalinity is 0.5 to 1.6 percent. The cement prepared by using the mirabilite gypsum as the cement retarder has qualified stability; the cement intensity is identical to the intensity of cement prepared from natural gypsum and ardealite; the initial setting time and the final setting time are shortened by one hour or above through being compared with that of the ardealite; the natural gypsum and the ardealite can be replaced; the relying degree of the cement production enterprise on the natural gypsum is reduced; in addition, the condensing time is normal; the modification treatment like the ardealite is not needed; the cost is reduced; the economic benefits are improved.

Owner:SICHUAN TONGQING NANFENG

Method for preparing ecological active residues by treating electrolytic manganese residues by using tunnel kiln device

The invention relates to a method for preparing ecological active residues by treating electrolytic manganese residues by using a tunnel kiln device. The method comprises the following steps: (1) blending and homogenizing: blending 45-75 parts of electrolytic manganese residues, 8-25 parts of stone coal, 14.7-45.0 parts of waste rock residues and 0.3-2.0 parts of an alteration agent, grinding the mixture into powder, adding 5-15 parts of water, and uniformly and homogenizing the mixture to a plastified material; (2) molding: molding the plastified material to a rod-like or bulk-like molded material; and (3) calcining the tunnel kiln: sending the molded material in the tunnel kiln, calcining the molded material for 20-60 minutes at 980-1300 DEG C, and quenching the molded material to obtain the ecological active residues. The ecological active residues contain various hydrated active minerals, can be widely used for cement industry, is high in strength if being used, and is easy to slurry and high in strength if being used as masonry cement or cement making bricks. The method provided by the invention is low in investment, free of wastewater and waste residues and good in economical benefit.

Owner:湖南省小尹无忌环境能源科技开发有限公司

Method for processing special anhydrite cementitious material made from phosphogypsum with tunnel kiln equipment

The method for processing special anhydrite cementitious material made of phosphogypsum with tunnel kiln equipment comprises the following steps: (1) batching and homogenization: by weight, 48-75 parts of phosphogypsum, 8-25 parts of stone coal and 15- 50 parts of waste rock slag are used for batching, grinding to make powder, adding 8 to 18 parts of water, and mixing and homogenizing into plastic materials; (2) Forming: forming plastic materials into molding materials; (3) Tunnel kiln calcination: Send it into the tunnel kiln, calcine at 980-1300°C for 20-60 minutes, and quench to obtain special anhydrite slag; (4) Preparation of special anhydrite cementitious material: grinding to obtain special anhydrite glue condensate material. The special anhydrite cementitious material obtained according to the method of the present invention contains a variety of hydration active minerals, can be widely used in the cement industry, has high strength when used, and is used as masonry cement or cement bricks, etc., without cracking and good strength; using this method The inventive method has the advantages of small investment, no generation of waste water and waste residue, and good economic efficiency.

Owner:湖南省小尹无忌环境能源科技开发有限公司

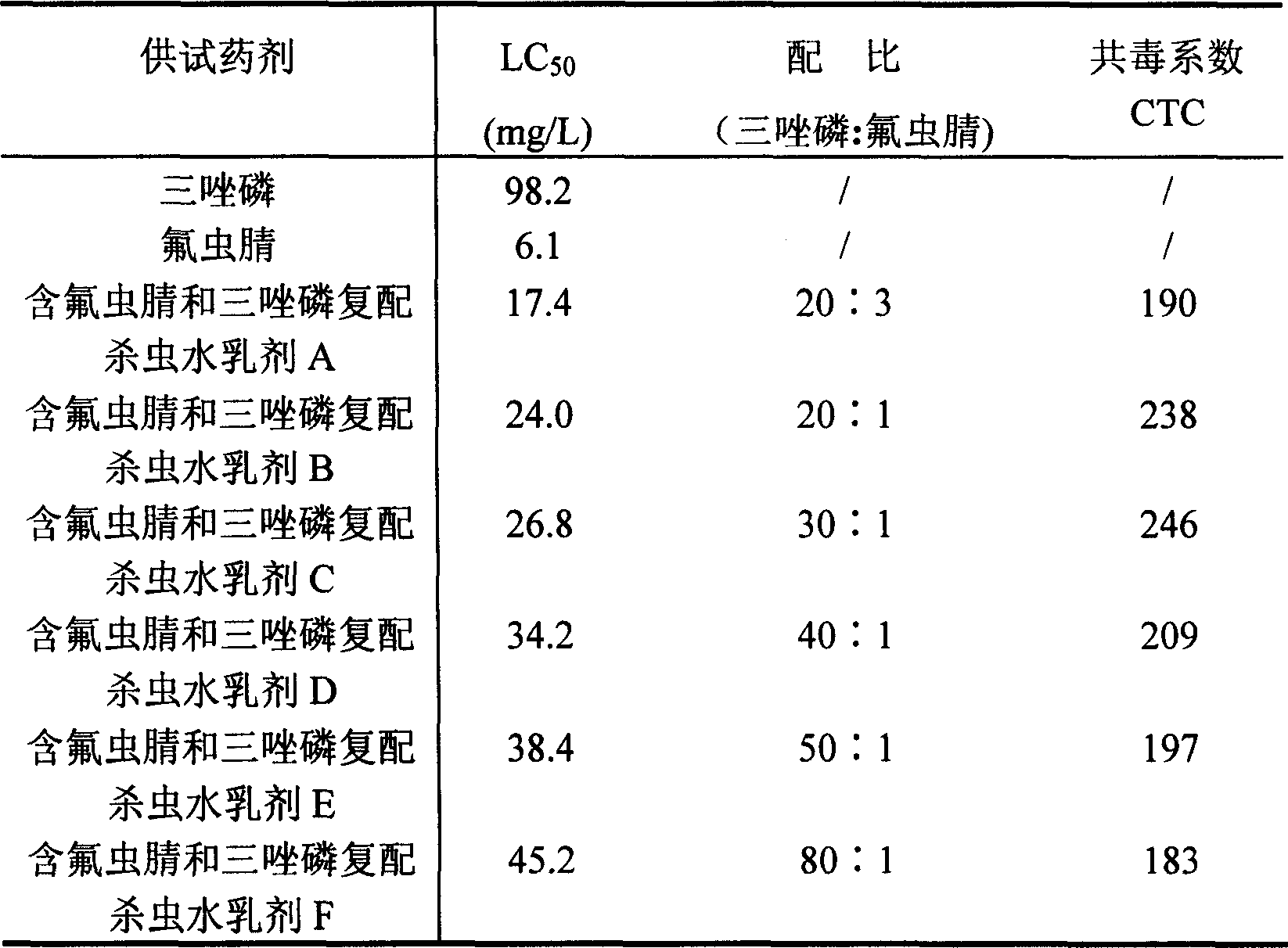

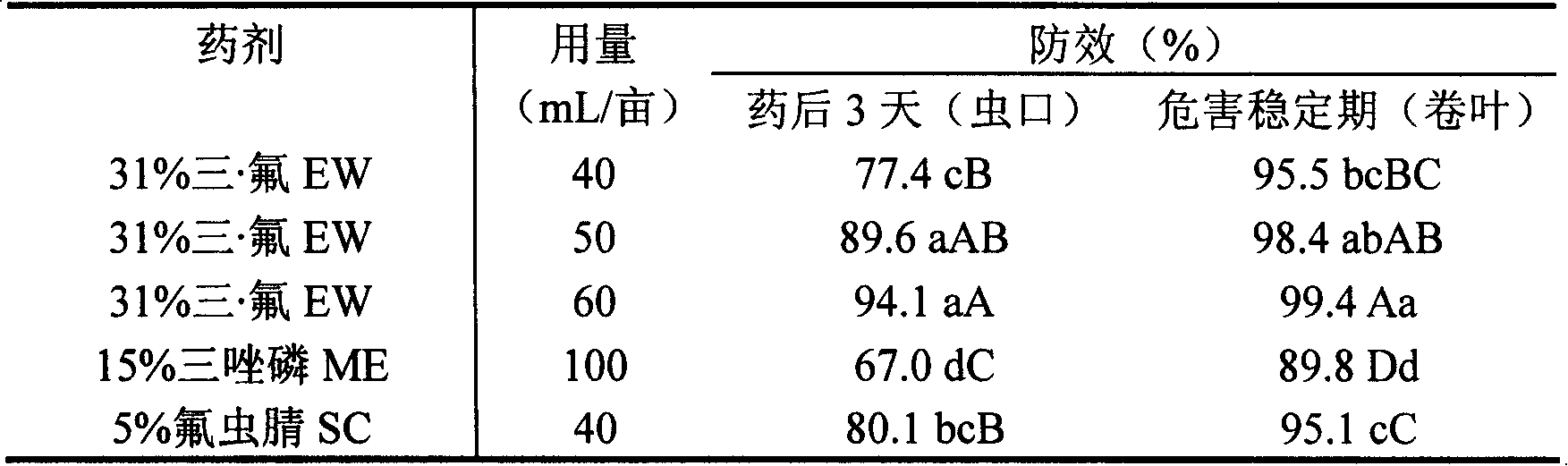

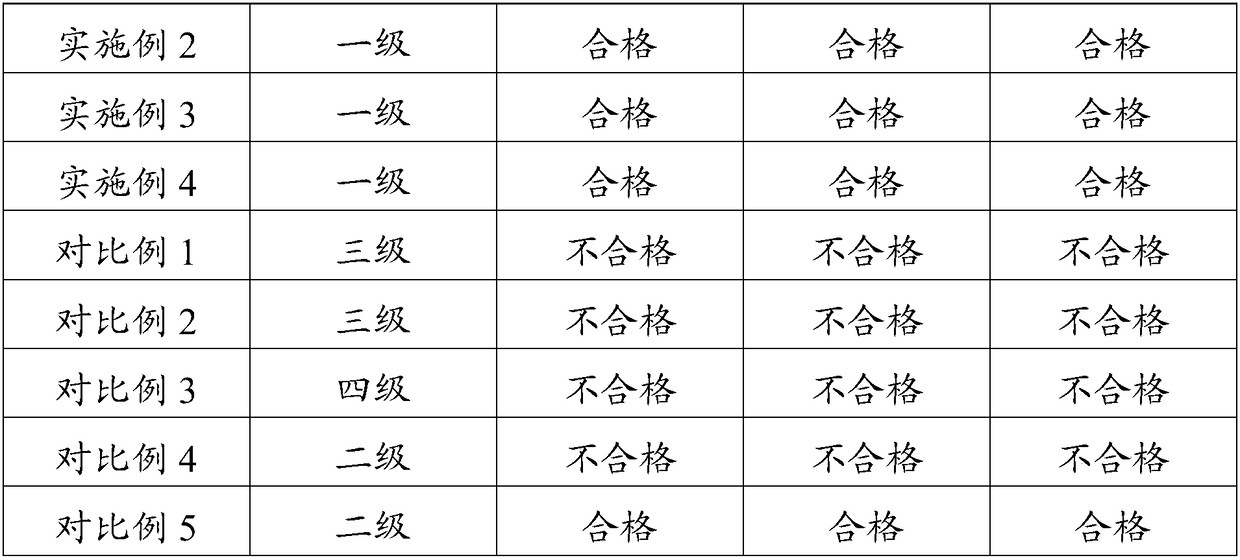

Compound pesticides water emulsion agent containing fipronil and triazophos and preparation method thereof

The invention discloses a compound disinsection water emulsion which contains fipronil and triazophos and a preparation method thereof. The water emulsion comprises 0.5-3 percent of the fipronil, 20-40 percent of the triazophos, 5-12 percent of emulsifier, 0-3 percent of stabilizer, 2-10 percent of cosolvent, 0-5 percent of antifreeze, 0-3.0 percent of thickener and the rest is dispersion medium water, which are dispersed evenly by a high-speed cutting and mixing emulsifier or are homogenized by a high-pressure homogenizer, thus obtaining the invention. The invention does not have insecticide resistance, has high efficacy and special effects on preventing rice stem borers, yellow rice borers, pink rice borers, rice leaf rollers, plutellid moths and diamondback moths; the invention also can control leafhoppers, plant hoppers, flies and coleopteran pests at the same time. The invention adopts the water as the dispersion medium and has the advantages that the invention does not pollute the environment, has no crystallization phenomena after two-year storage and has long shelf life; besides, the invention is not inflammable, can be safely stored and transported and has simple production technique; compared with using the fipronil independently, the cost of the invention can be reduced greatly.

Owner:郦卫弟

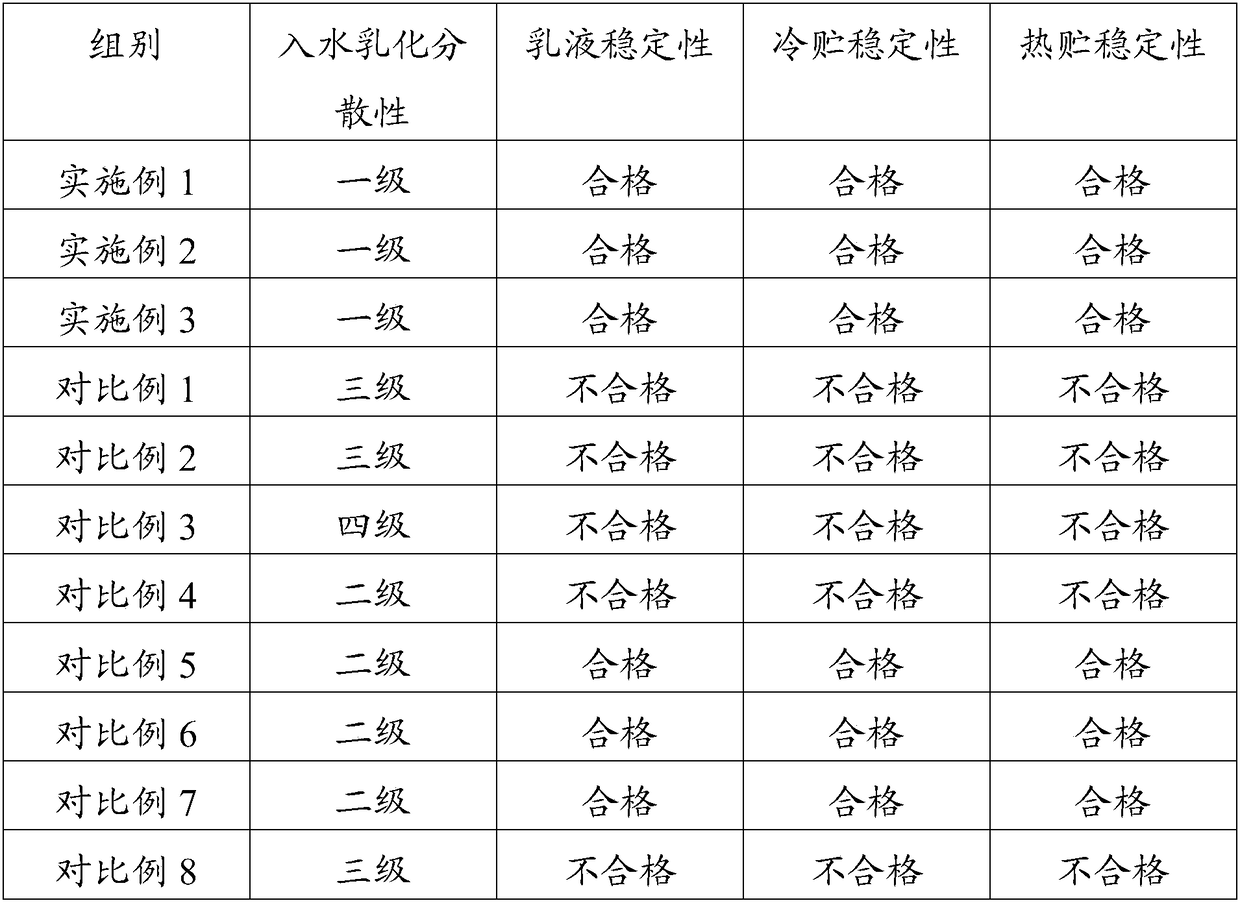

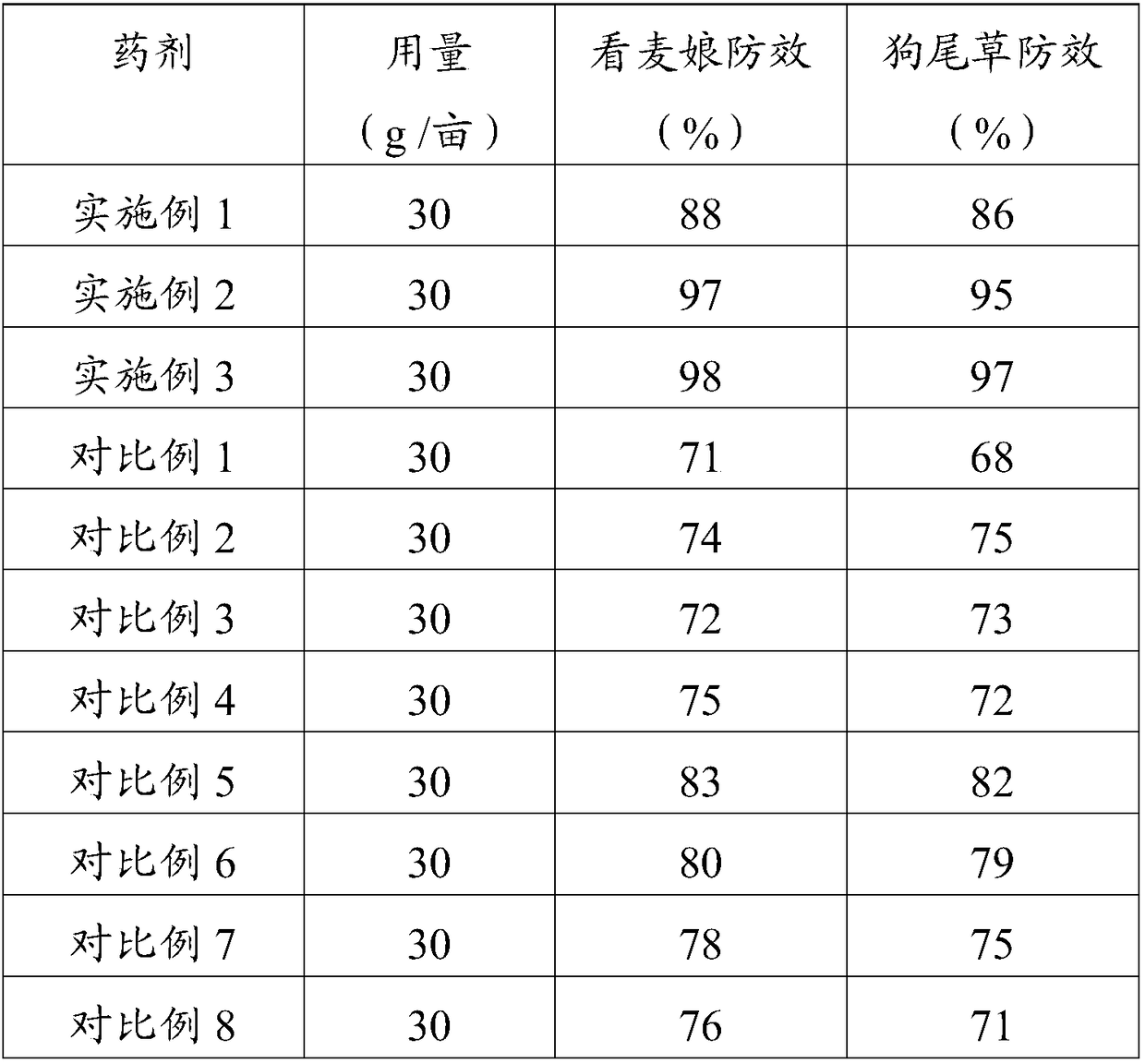

Efficient and environment-friendly fluroxypyr isooctyl emulsifiable concentrate and its preparation method and application

ActiveCN107593693BExcellent performance of the original drugStay decentralizedBiocideAnimal repellantsAdditive ingredientPhosphate

The invention discloses efficient and environment-friendly fluroxypr-mepthyl missible oil as well as a preparation method and application thereof, and belongs to the field of a pesticide formulation.The efficient and environment-friendly fluroxypr-mepthyl missible oil is prepared from the following ingredients including 250 to 400g / L of fluroxypyr-mepthyl, 50 to 150g / L of compound emulsifiers, 10to 50g / L of cosolvents and solvents. The composite missible oil is prepared from aromatic phenol polyoxyethylene ether phosphate and sorbitan tri-oleate according to the weight ratio of 1:(1 to 5). The efficient and environment-friendly fluroxypr-mepthyl missible oil is used for preventing and controlling broad leaved weed of wheat, barley, corn, grape, orchard and lawn. The preparation ingredient system is reasonable; the emulsification effect is good; the environment pollution is reduced.

Owner:LIER CROPSCIENCE CO LTD

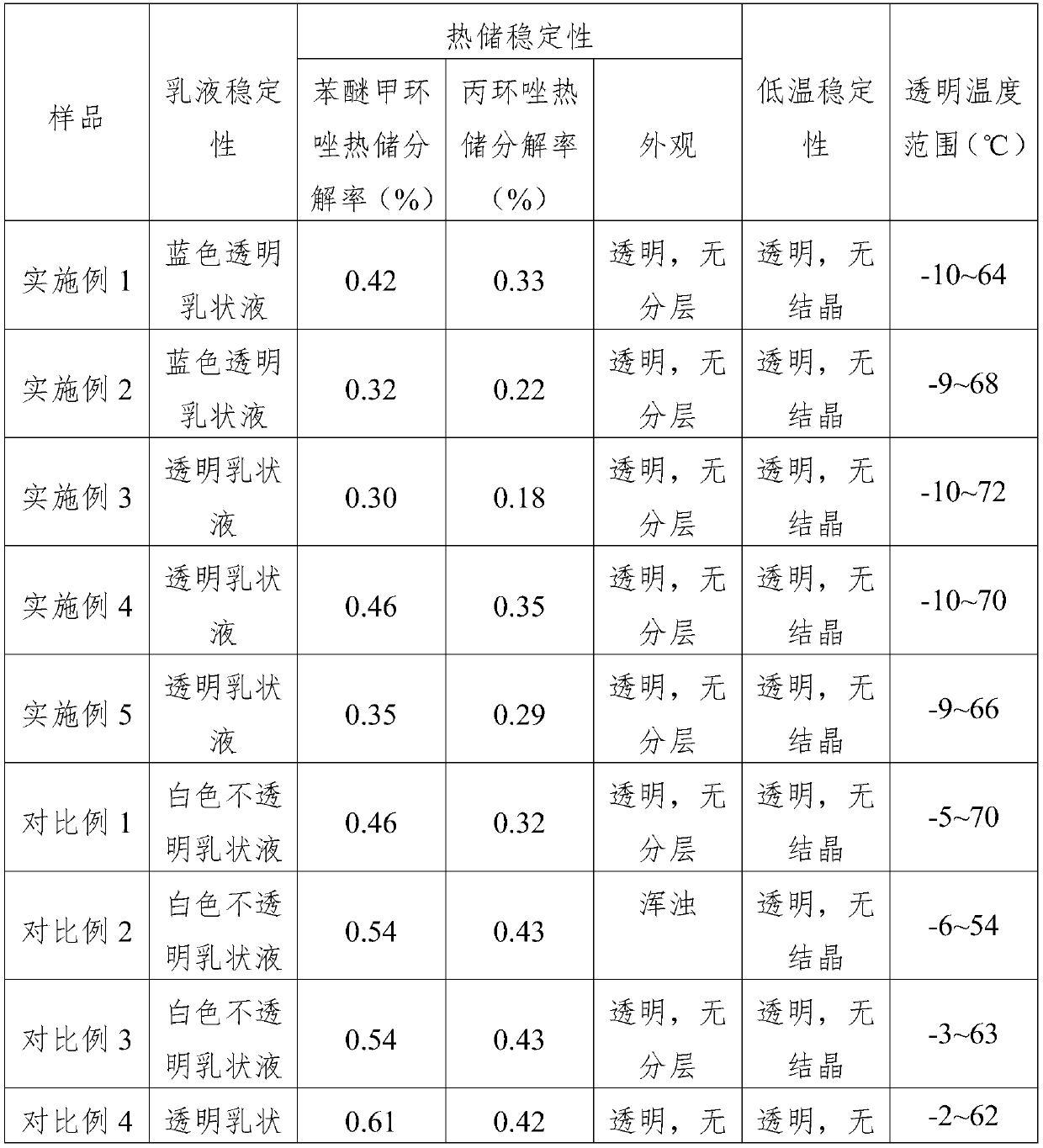

Microemulsion containing difenoconazole and propiconazole and preparation method of microemulsion

ActiveCN110839638ATransparent over a wide temperature rangeIncrease profitBiocideFungicidesPesticideActive agent

The embodiment of the invention discloses a microemulsion containing difenoconazole and propiconazole, and belongs to the technical field of pesticides. 100% of the microemulsion containing difenoconazole and propiconazole is prepared from the following components in percentage by mass: 10-20% of difenoconazole, 10-20% of propiconazole, 10-25% of a surfactant, 20-30% of a solvent, 1-5% of a synergist, 2-5% of an anti-freezing agent, and the balance water; wherein the surfactant is prepared from triphenyl ethyl phenol polyoxyethylene ether, polyoxyethylene ether non-ions and bisamide sodium disulfonate according to the weight ratio of (3 to 6) : (2 to 3) : (2 to 3). The microemulsion provided by the invention is prepared from the environment-friendly solvent, and has the characteristics ofstable performance and obvious control effect; and the problems that a solvent in an existing microemulsion is not friendly to the environment and is not safe to use are solved.

Owner:HUIZHOU YINNONG TECH

Carbonized steel slag building material product prepared from cement kiln tail flue gas and method thereof

The invention relates to the field of comprehensive utilization of resources, in particular to a carbonized steel slag building material product prepared from cement kiln tail flue gas and a preparation method of the carbonized steel slag building material product. The method comprises the following steps: mixing steel slag powder, cement, water, sand and an additive in proportion, hardening under a standard curing condition, and then carbonizing in a cement kiln tail gas kiln to obtain the carbonized steel slag building material product. According to the method disclosed by the invention, the steel slag product is carbonized by utilizing the cement kiln tail flue gas, and the steel slag is converted into the building material product, so that the maintenance period of the steel slag building material product is effectively shortened, the carbon emission of cement enterprises is remarkably reduced, CO2 in the flue gas is turned into wealth, and the problem that the steel slag is difficult to utilize is solved; meanwhile, the temperature of the tail flue gas of the cement kiln is fully utilized in the whole technological process, additional energy consumption is not needed, and the requirement for carbonization reaction equipment and the overall cost are reduced. The steel slag building material product prepared by the method is good in stability and excellent in comprehensive performance, and has a wide application prospect.

Owner:BEIJING UNIV OF TECH +1

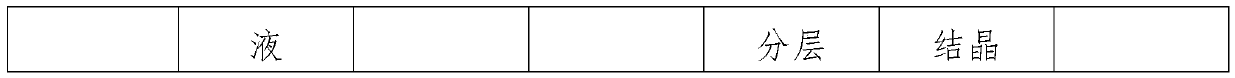

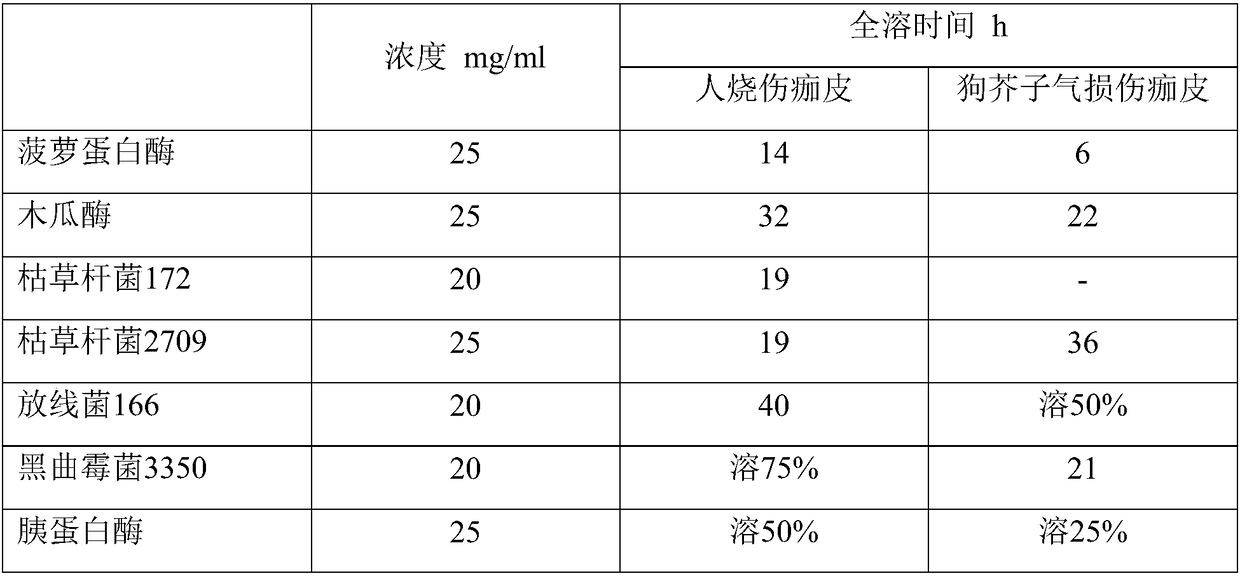

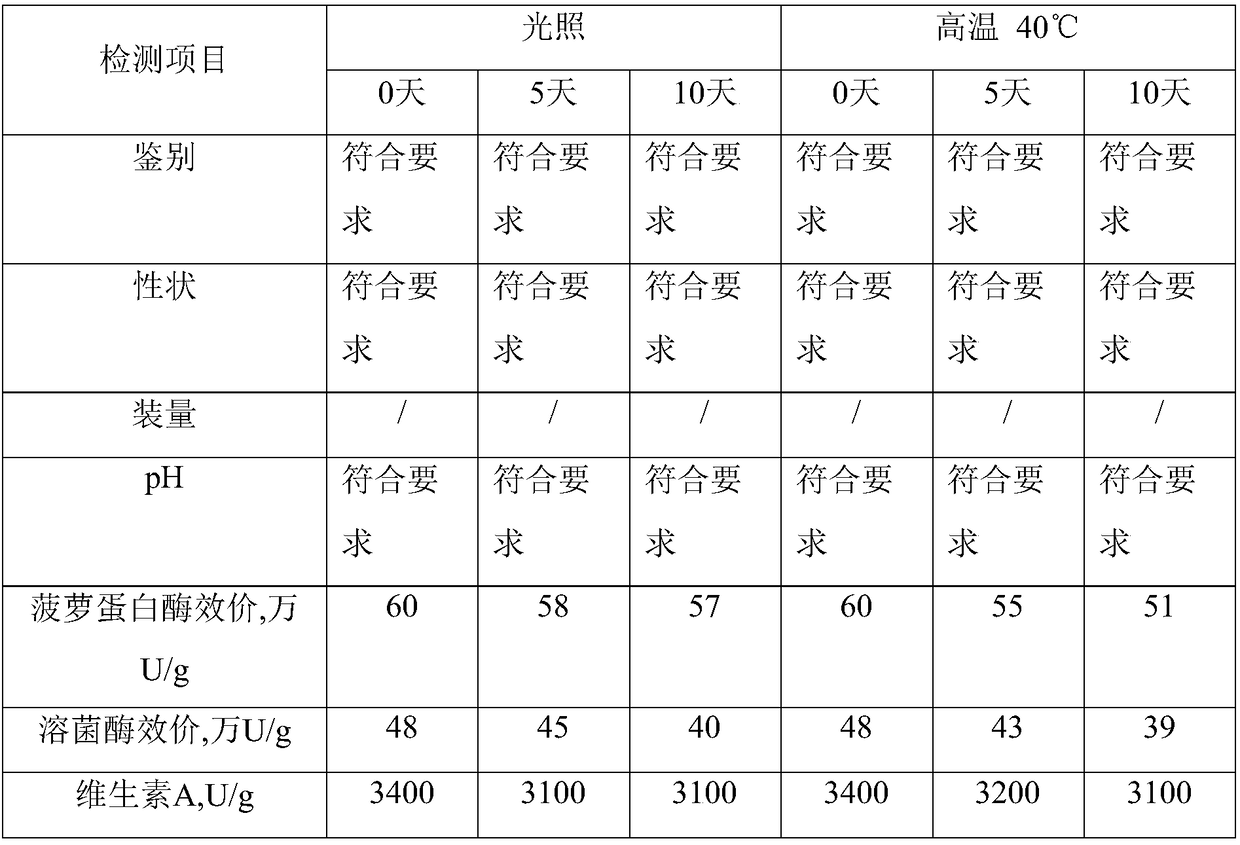

Compound bromelain ointment and preparation method thereof

InactiveCN109364242APrevention and Control of InfectionAids in synthetic maturationPeptide/protein ingredientsHydroxy compound active ingredientsSkin graftingMedicine

The invention discloses compound bromelain ointment and a preparation method thereof. A formula of the compound bromelain ointment is prepared from the following components in percentage by mass: 30 to 40 percent of bromelain, 3 to 7 percent of lysozyme, 0.1 percent of vitamin A, 20 to 50 percent of a matrix and 12.9 to 46.9 percent of water. According to the formula disclosed by the invention, natural decrustation time is quickened through the bromelain, specific sterilization mechanism and broad-spectrum sterilization ability can be increased through the lysozyme, the infection situation during a wound decrustation period can be effectively prevented and controlled, and the vitamin A is beneficial for matural collagen synthesis, epithelialisation and vascularization, so that the compoundbromelain ointment can be used for decrustation of deep II-degree and III-degree burn wounds and has the function of controlling wound infection and inflammation, and the time for skin grafting of patients suffering from deep II-degree and III-degree burn can be quickened. The preparation method is designed according to physicochemical characteristics of the formula, and the drug effect can be expressed to the maximum.

Owner:浙江华缔药业集团有限责任公司

Cement using stainless steel slag tailing mud as admixture and preparation method thereof

PendingCN112374777AProduct performance is stableStability qualifiedCement productionSlagBuilding material

The invention discloses cement using stainless steel slag tailing mud as an admixture and a preparation method thereof, and belongs to the technical field of building materials. The cement comprises the following components in parts by weight: 50-95 parts of Portland cement clinker, 15-20 parts of stainless steel slag tailing mud, and 3-6 parts of gypsum. According to the invention, the stainlesssteel slag tailing mud waste residues are used in cement, the prepared cement has standard consistency of not greater than 28%, initial setting time of not less than 45 min, final setting time of notmore than 600 min and qualified stability, the content of water-soluble hexavalent chromium in cement is not greater than 10 mg / kg, the content of chloride ions is not greater than 0.06%, the compressive strength is not less than 42.5 MPa, and the heavy metal leaching value meets standard requirements, thereby not only facilitating reduction of the comprehensive cost of cement and reduction of energy consumption, but also being of great significance to environmental protection.

Owner:GUANGXI YUFENG CEMENT +1

Efficient and environmentally friendly clodinafop-propargyl emulsifiable concentrate and its preparation method and application

ActiveCN107593696BImprove performanceStay independentBiocideAnimal repellantsPolyethylene glycolSolvent

The invention discloses efficient and environment-friendly clodinafop-propargyl missible oil as well as a preparation method and application thereof, and belongs to the field of a pesticide formulation. The efficient and environment-friendly clodinafop-propargyl missible oil is prepared from the following ingredients in percentage by weight: 1 to 30 percent of clodinafop-propargyl, 1 to 35 percentof compound emulsifiers, 1 to 20 percent of cosolvents, 0.25 to 7.5 percent of safeners and the balance of solvents. The composite missible oil is prepared from phenethylphenol polyoxyethylene ethersulfate, polyoxyethylene lauryl ether and polyethylene glycol aliphatic ester according to the weight ratio of 1:(1 to 5):(5 to 10). The efficient and environment-friendly clodinafop-propargyl missible oil has the advantages that the preparation ingredient system is reasonable; the emulsification effect is good; the environment pollution is reduced.

Owner:LIER CROPSCIENCE CO LTD

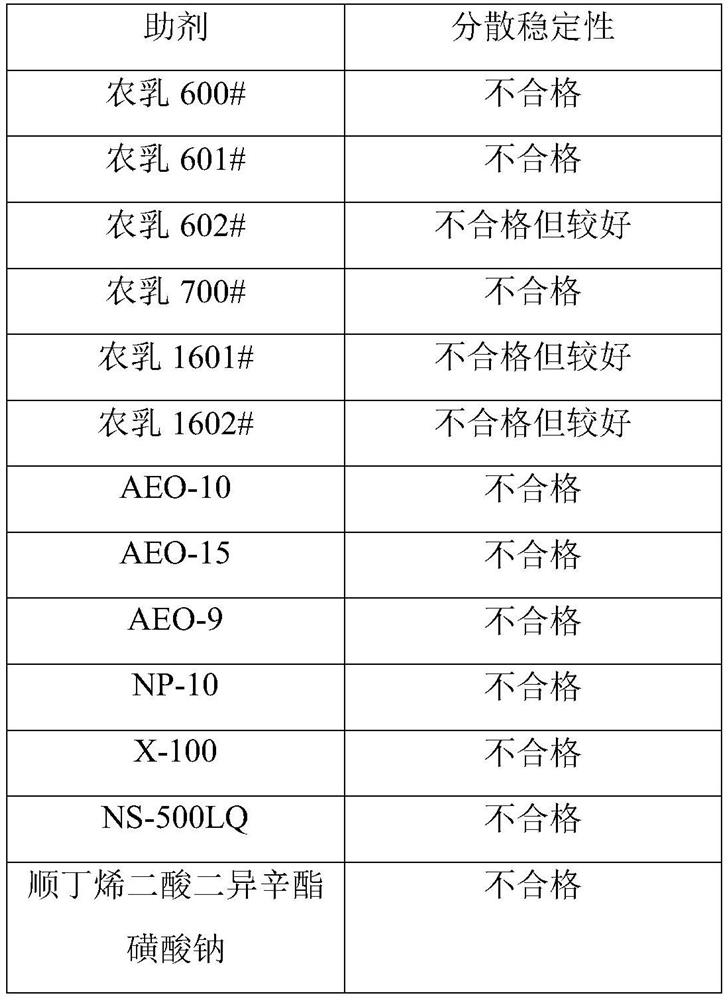

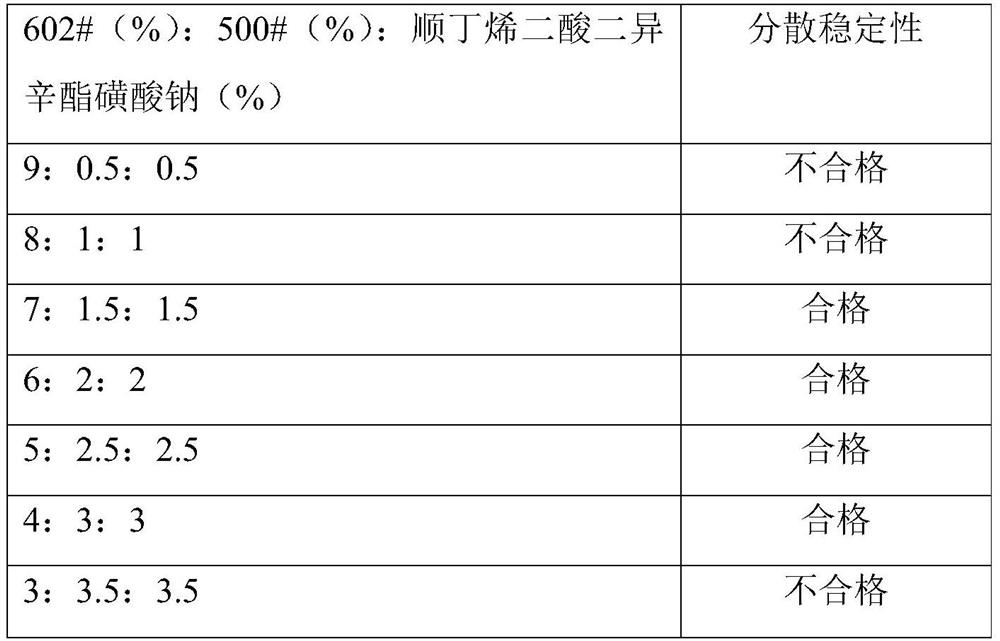

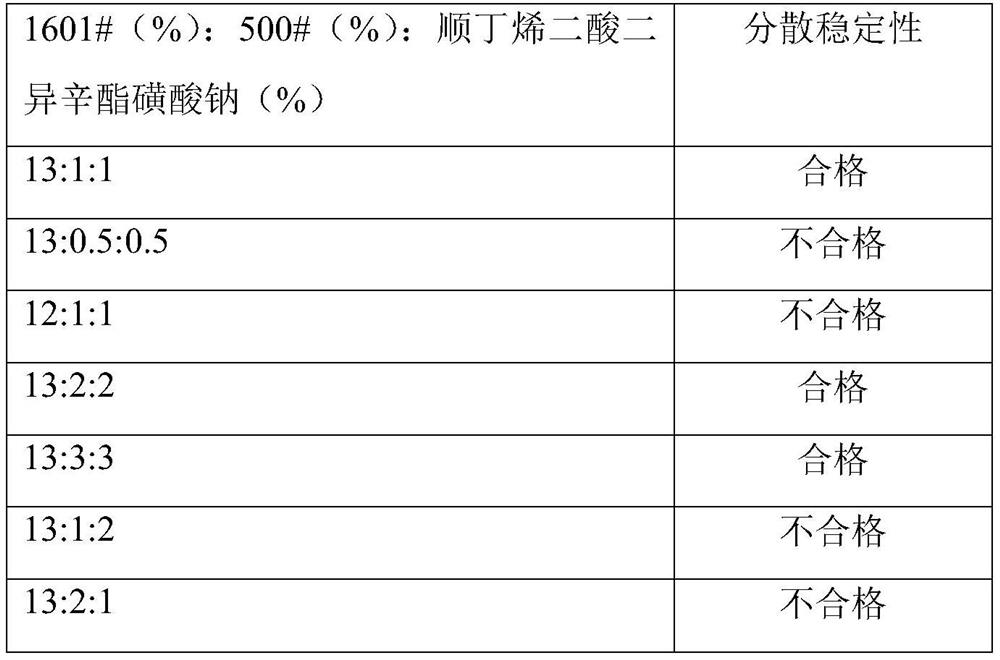

A kind of dispersible liquid agent of flufenuron with high stability

ActiveCN113575606BImprove thermal storage stabilityFast dispersionBiocideAnimal repellantsCyclohexanoneSulfonate

The invention discloses a highly stable dispersible liquid agent of flubendron. The dispersible liquid agent of described flubenzuron is made up of flubenzuron, ethylene glycol, cyclohexanone, N-methylpyrrolidone and auxiliary agent; auxiliary agent is agricultural milk 500#, agricultural milk 1061# and maleic acid A compound of sodium diisooctyl sulfonate; the mass percentage composition of the dispersible liquid is as follows: flubenzuron 2-10%; ethylene glycol 5-20%; cyclohexanone 15-40%; Base pyrrolidone 30 ~ 55%; the balance of additives. The dispersible liquid preparation of fiflubenzuron provided by the present invention has significantly improved heat storage stability, meeting the general requirement of "liquid preparation" in "GB / T 19136-2003 Pesticide Heat Storage Stability Determination Method" and stored at 54°C for 14 days The decomposition rate is lower than 5%, and the water dispersion speed is fast; the dilution stability and dispersion stability are both qualified. In addition, the solvents and emulsifiers used are cheap and easy to obtain, and are safe and environmentally friendly.

Owner:鹤壁全丰生物科技有限公司

multifunctional concrete reinforcement

A multifunctional concrete intensifier is prepared by a method comprising the following steps: at first, adding polyethers and 70%-75% of deionized water in a reaction vessel according to proportion; when heating to 55-65 DEG C, dropwise adding acrylic acid and an initiator in the reaction vessel and then cooling to 35-45 DEG C, adding caustic soda for neutralizing, stirring for 10-20 min to enable the components to be mixed uniformly to prepare a mixture I; adding triethanolamine, a surfactant and a thickening time control agent in the rest of 25%-30% of deionized water, and sufficiently stirring for 0.2-1 h at 35-45 DEG C to prepare a mixture II; then maintaining the temperature of the mixture I to 35-45 DEG C, stirring and slowly pouring into the mixture II, and sufficiently mixing for 0.5-1.5 h to obtain a light yellow liquid not easy to precipitate. The multifunctional concrete intensifier is chloride-free, is qualified in stability, meanwhile, has multiple functions of saving the comprehensive cost of concrete, improving the concrete workability, and increasing the concrete strength and the like, meets the national harmful substance requirement standard, reduces the cement content, and is simple to use, low in mixing amount, and small in investment.

Owner:衡阳市银利实业有限公司

Anti-condensation system for winding type vacuum coating machine

InactiveCN113061869AImprove film qualityImprove qualityVacuum evaporation coatingSputtering coatingPhysicsCell fabrication

The invention discloses an anti-condensation system for a winding type vacuum coating machine. The anti-condensation system is applied to the winding type vacuum coating machine for manufacturing new energy power batteries. The anti-condensation system mainly comprises a banister brush, a capillary tube group, a water storage tank and a gas-liquid separation channel; the banister brush has high hydrophilicity and can continuously absorb tiny water drops from the surface of a main roller, and the root of the banister brush is connected with the capillary tube group; the capillary tube group is composed of more than two capillary tubes, the other end of the capillary tube group is connected with the gas-liquid separation channel, the inner diameter of a pipeline of the gas-liquid separation channel is suddenly increased from the inner diameter of the capillary tubes, the water storage tank is arranged at the tail end of the gas-liquid separation channel, and the capillary tube group continuously conveys water absorbed by the banister brush to the gas-liquid separation channel through the capillary action; and water vapor is subjected to gas-liquid separation in the gas-liquid separation channel, and water is collected into the water storage tank. When the anti-condensation system is used for carrying out evaporation coating on a base film, water vapor removal treatment is continuously carried out on the surface of the main roller in a physical manner.

Owner:辽宁分子流科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com