Hydraulic gelate material and method for preparing same

A technology of hydraulic gelling and raw materials, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve problems such as difficult to meet the requirements of cement use, cement strength decline, etc., to achieve low cost and low energy consumption Less and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

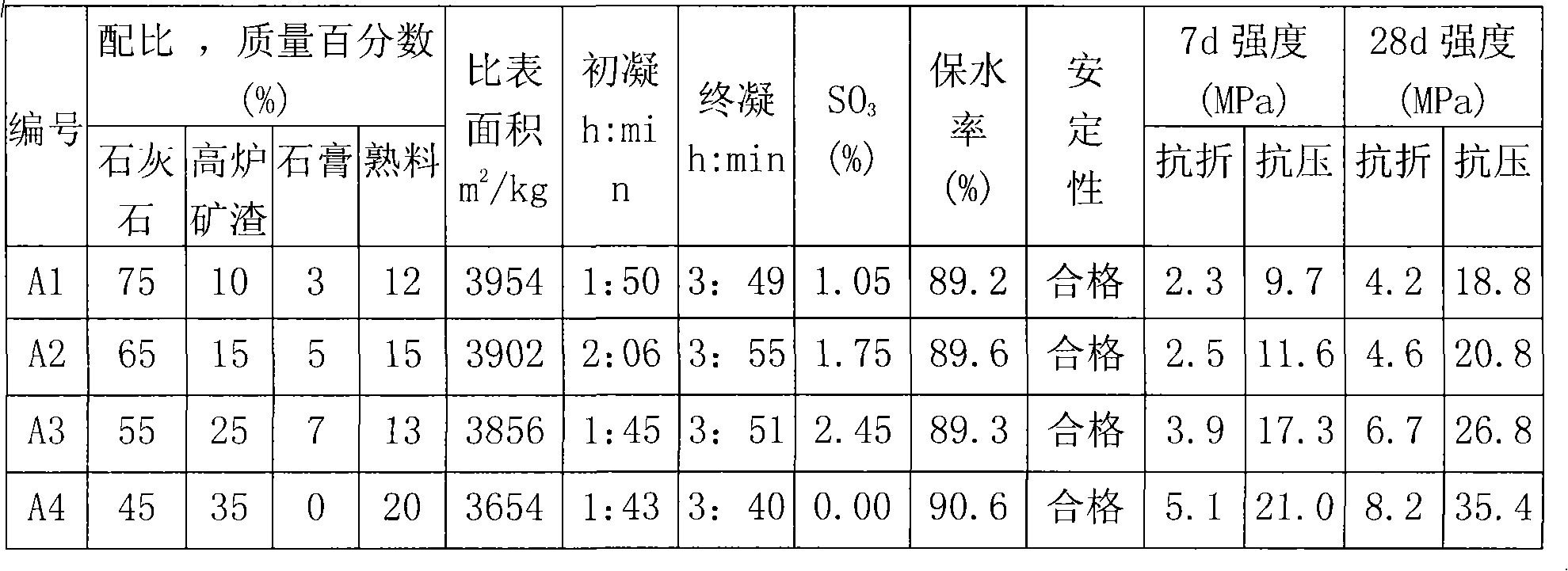

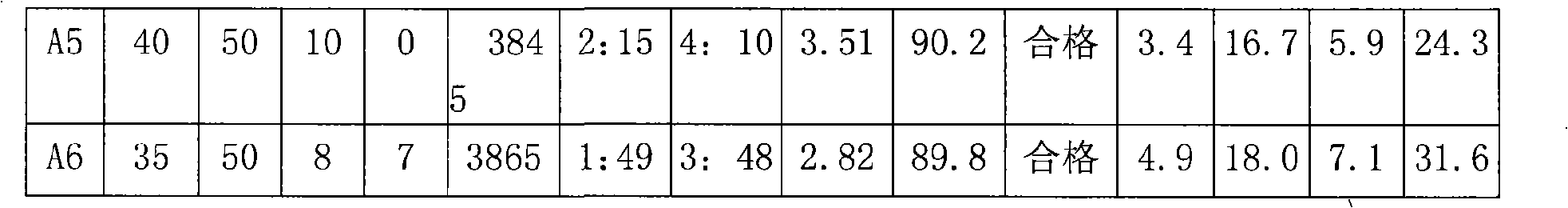

[0022] Mix limestone, industrial waste residue, gypsum and additives according to the ratio in Table 1, and grind until the specific surface area is greater than 280m 2 / kg, the hydraulic gelling material is obtained. The industrial waste slag is blast furnace slag, and the admixture is Portland cement clinker mainly composed of calcium silicate, calcium aluminate and calcium aluminoferrite (ie the clinker in Table 1). Then according to the national standard of GB / T 3183-2003 masonry cement, the results are shown in Table 1. It can be seen that each proportion meets the technical requirements of GB / T 3183-2003 masonry cement.

[0023] Table 1. Proportion and properties of hydraulic cementitious materials

[0024]

[0025]

[0026] Note: The limestone used in Table 1 is based on calcium carbonate (CaCO 3 ) as the main component of natural ore, and the gypsum used is natural dihydrate gypsum.

Embodiment 2

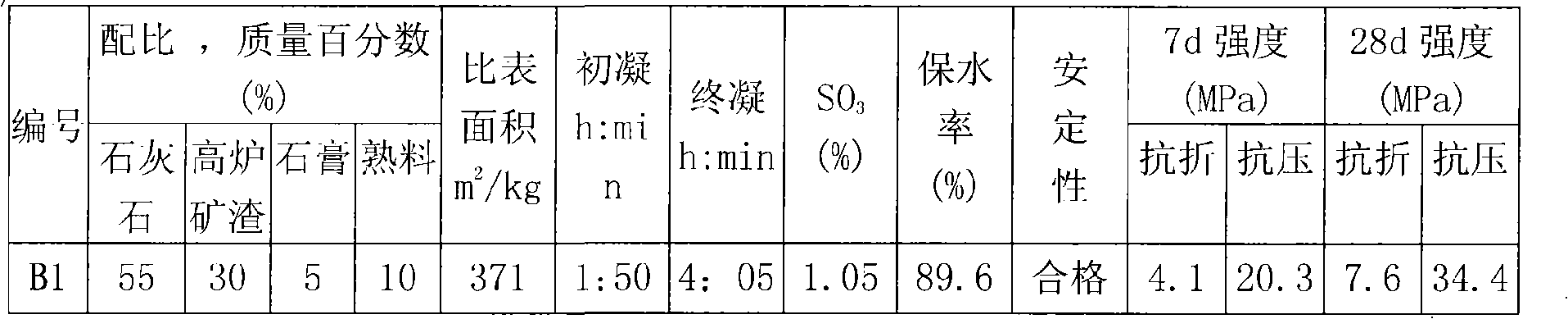

[0028] According to the mass percentage of each raw material: limestone 55%, industrial waste residue 30%, gypsum 5%, admixture 10%, choose limestone, industrial waste residue, gypsum and admixture raw materials, standby; used limestone is calcium carbonate (CaCO 3 ) as the main component of natural ore, the gypsum used is natural dihydrate gypsum, the industrial waste slag is blast furnace slag, and the admixture is Portland cement cooked with calcium silicate, calcium aluminate and calcium aluminate iron as the main components. material (ie the clinker in Table 2).

[0029] First mix and grind limestone, clinker and gypsum until the specific surface area is 375m 2 / kg. Separately grind the blast furnace slag to a specific surface area of 363m 2 / kg. Then, the mixed powder obtained by grinding the three materials of limestone, clinker and gypsum is evenly mixed with blast furnace slag powder to make a hydraulic cementitious material. According to the national standard o...

Embodiment 3

[0033] Mix various materials according to the ratio in Table 3, and grind until the specific surface area is greater than 280m 2 After / kg, get the hydraulic cementitious material, then check by the national standard of GB / T 3183-2003 masonry cement, the result is as shown in table 4, it can be seen that each proportioning all meets GB / T 3183-2003 masonry cement technical requirements.

[0034] Table 3. Proportioning of hydraulic gelling material, mass percentage (%)

[0035]

serial number

stone

blast furnace

steel

slag

pink

Ash

Gangster

stone

dihydrate

plaster

hard

stone

ointment

half water

plaster

ointment

Hydroxy

Calcium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com