Carbonizing device for solid waste recycled aggregates for concrete

The technology of solid waste and carbonization device is applied in the field of carbonization device for regenerated concrete aggregate of solid waste, and the device field of solid waste solidification and absorption of carbon dioxide. High-value, high-strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

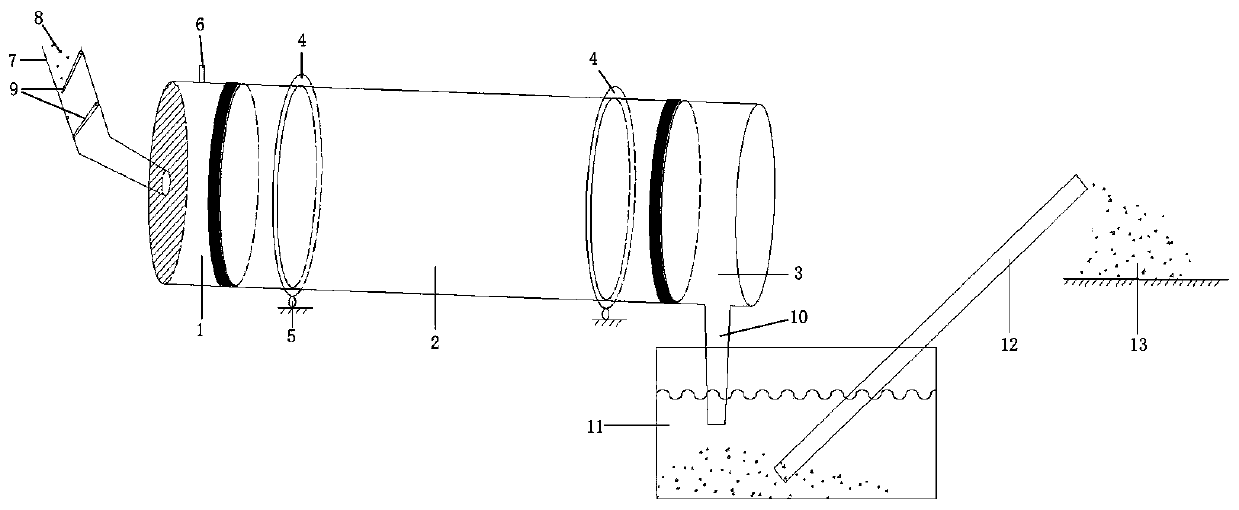

[0026] A carbonization device for regenerated solid waste aggregates for concrete, including a storage bin 1, a drum-type carbonization bin 2 and a storage bin 3. Both ends of the drum-type carbonization bin 2 are equipped with rollers in the circumferential direction. Both the waiting bin 1 and the storage bin 3 are equipped with a circular track interface that is compatible with the drum-type carbonization bin 3. The waiting bin 1 and the storage bin 3 are respectively closed. Set on the two ends of the drum type carbonization chamber 3. The outer surface of the drum-type carbonization chamber 2 is provided with two circles of a circumferential rack 4, and the circumferential rack is meshed with a fixed motor transmission gear 5. Thereby the drum type carbonization bin 2 is driven to roll. There is a double-helix turning plate on the inner wall of the drum-type carbonization bin 2. During carbonization, the double-helix turning plate rotates with the mixing bin to turn up t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com