Mirabilite gypsum capable of being used as cement retarder

A cement retarder and Glauber's salt technology, which is applied in the field of comprehensive utilization of Glauber's salt tailings, can solve problems such as unstable cement performance and unstable Glauber's salt gypsum content, so as to reduce mining, prolong the service life of development and utilization, and improve enterprise economics benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

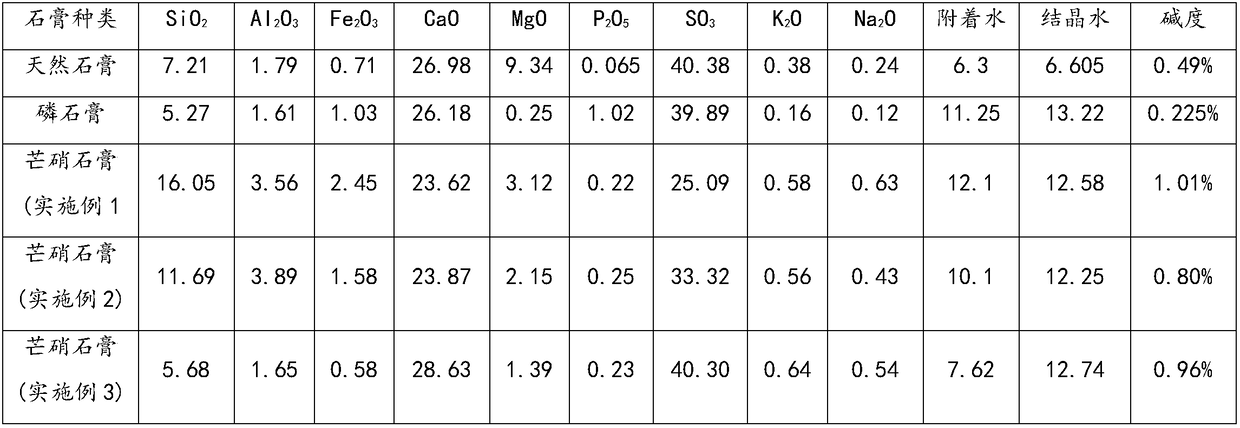

[0020] A kind of Glauberite gypsum that can be used as a cement retarder. Glauberite ore powder with a particle size of less than 10mm is obtained by crushing and ball milling Glauberite ore, and then mixing it with water to form a slurry, and then leaching the slurry, and finally solidifying Liquid separation to obtain Glauber's salt gypsum with a particle size of less than 400mm, said Glauber's salt gypsum includes the following chemical components in weight percentage: 16.05% SiO 2 , 3.56%Al 2 o 3 , 2.45% Fe 2 o 3 , 23.62% CaO, 3.12% MgO, 0.22% P 2 o 5 , 25.09%SO 3 , 0.58%K 2 O, 0.63% Na 2 O; among them, the attached water is 12.1%, the crystal water is 12.58%, and the alkalinity is 1.01%, and the alkalinity is 0.658K 2 O and Na 2 Total amount of O.

Embodiment 2

[0022] The only difference between this embodiment and Example 1 is that the prepared Glauber's salt gypsum includes the following chemical composition in weight percentage: 11.69% SiO 2 , 3.89%Al 2 o 3 , 1.58% Fe 2 o 3 , 23.87% CaO, 2.15% MgO, 0.25% P 2 o 5 , 33.32%SO 3 , 0.56%K 2 O, 0.43% Na 2 O; Wherein, the attached water is 10.01%, the crystal water is 12.25%, and the alkalinity is 0.80%, and the alkalinity is 0.658K 2 O and Na 2 Total amount of O.

Embodiment 3

[0024] The difference between this example and Example 1 is that the prepared Glauber's salt gypsum includes the following chemical composition in weight percentage: 5.68% SiO 2 , 1.65%Al 2 o 3 , 0.58% Fe 2 o 3, 28.63% CaO, 1.39% MgO, 0.23% P 2 o 5 , 40.30%SO 3 , 0.64K 2 O, 0.54Na 2 O; among them, the attached water is 7.62%, the crystal water is 12.74%, and the alkalinity is 0.96%, and the alkalinity is 0.658K 2 O and Na 2 Total amount of O.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com