Patents

Literature

239results about How to "High water retention" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyurethane foam with high water absorption performance and high water retention performance and preparation method of polyurethane foam

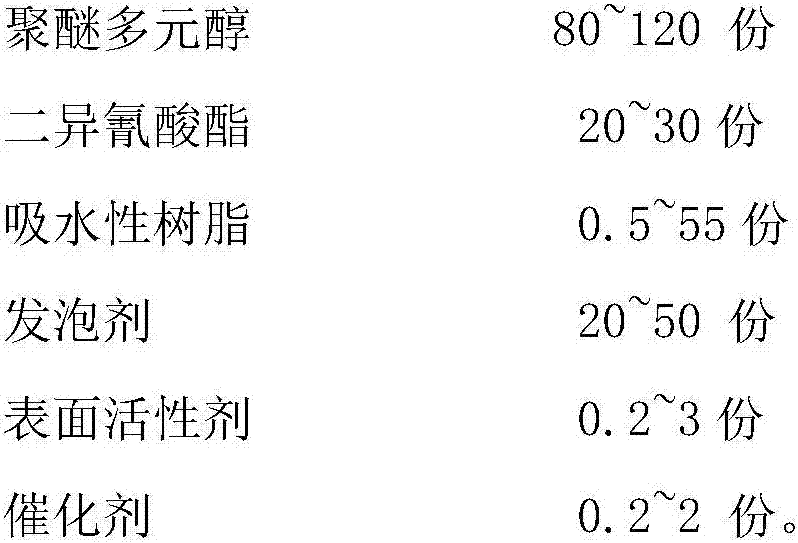

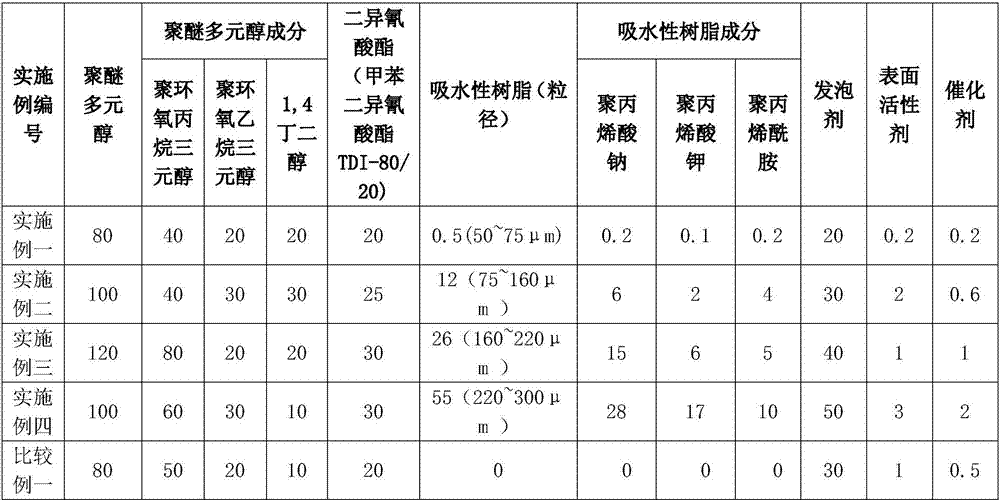

The invention discloses polyurethane foam with high water absorption performance and high water retention performance and a preparation method of the polyurethane foam and belongs to the technical field of chemical engineering in high polymers. The polyurethane foam is prepared from components in parts by mass as follows: 80-120 parts of polyether glycol, 20-30 parts of diisocyanate, 0.5-55 parts of water-absorbent resin, 20-50 parts of a foaming agent, 0.2-3 parts of a surfactant and 0.2-2 parts of a catalyst through mixing. The preparation method comprises two steps of preparation of a prepolymer and preparation of a foam material. The polyurethane foam has the advantages of high water absorption performance, high water retention performance, high resilience, good compression performance and high stability.

Owner:NANJING UNIV OF TECH +1

Phosphogypsum based plastering gypsum

The invention discloses a phosphogypsum based plastering gypsum, and relates to a plastering material for a building wall. The phosphogypsum based plastering gypsum mainly comprises 75 to 95 percent of phosphogypsum based building gypsum, 1 to 3 percent of sierozem powder, 0.1 to 0.5 percent of retarder, 1.1 to 5.5 percent of composite water retention agent, 0.3 to 1 percent of ethylene-vinyl acetate copolymerized latex powder, and 0 to 20 percent of stuffing. The phosphogypsum based plastering gypsum effectively improves water retention property and lowers cost by adopting the combination of cellulose ether water retention agent and bentonite, effectively adjusts settling time and prolongs operable time by adopting the retarder, improves construction property, cohesive property and cracking resistance by doping the stuffing and the latex powder, and reduces adverse effects of impurities on the strength of plastering gypsum by adding the sierozem powder. The phosphogypsum based plastering gypsum has the advantages of good workability and construction property, long operable time, high breaking resistance, compression resistance and adhesion strength, good volume stability, good cracking resistance and lower cost, and can be used for a plastering layer of the building wall.

Owner:CHONGQING UNIV

Polyvinyl formal sponge material with uniform abscesses and rapid imbibition and preparation method thereof

ActiveCN102020816ASolution can not be reusedSolve the shortcomings of high closed cell rate and slow water absorption rate of the productPharmaceutical non-active ingredientsAbsorbent padsCross-linkLiquid waste

The invention discloses a polyvinyl formal sponge material with uniform abscesses and rapid imbibition and a preparation method thereof. The material comprises polyvinyl alcohol, a cross-linking agent, a catalyst and a pore-forming agent, wherein the cross-linking agent is formaldehyde or paraformaldehyde or formaldehyde solution. The preparation method comprises the following steps of: stirring 2-9 parts of polyvinyl alcohol in 100-200 parts of water of which the temperature is 60-98 DEG C to obtain solution, and adding 0.05-8 parts of pore-forming agent to the solution; fully emulsifying the pore-forming agent to form evenly dispersed continuous solution phase; then adding 1-26 parts of catalyst and 1-15 parts of cross-linking agent or 5-50 parts of recovered liquid waste, 1-8 parts of catalyst and 1-15 parts of cross-linking agent, and mixing; pouring the mixture into a mould after 1-60 min for cross-linking reaction for 0.1-2 hours to form the abscesses under the action of the pore-forming agent; and continuing to heat and cure for 2-18 hours to prepare the polyvinyl formal sponge material. The invention has the advantages of good hydrophily, high compression strength, high dry wetting rate, high imbibition ratio and the like.

Owner:克林纳奇(荆州)高分子科技有限公司

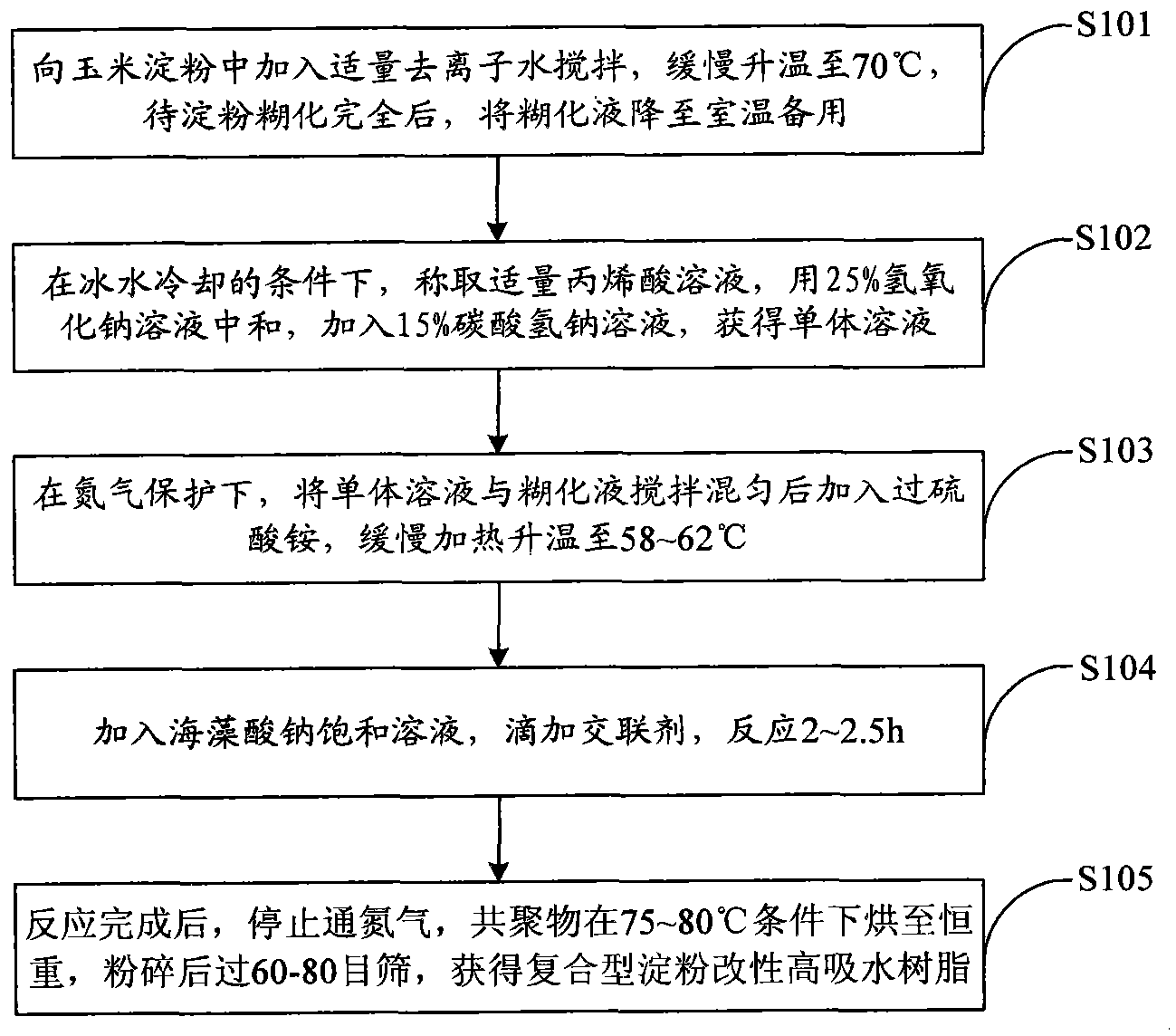

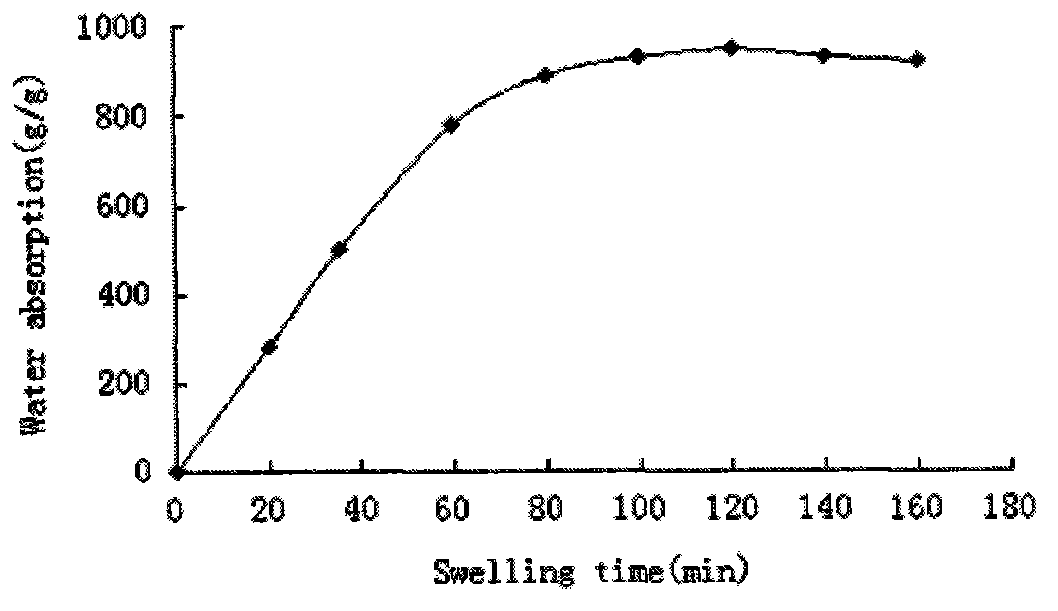

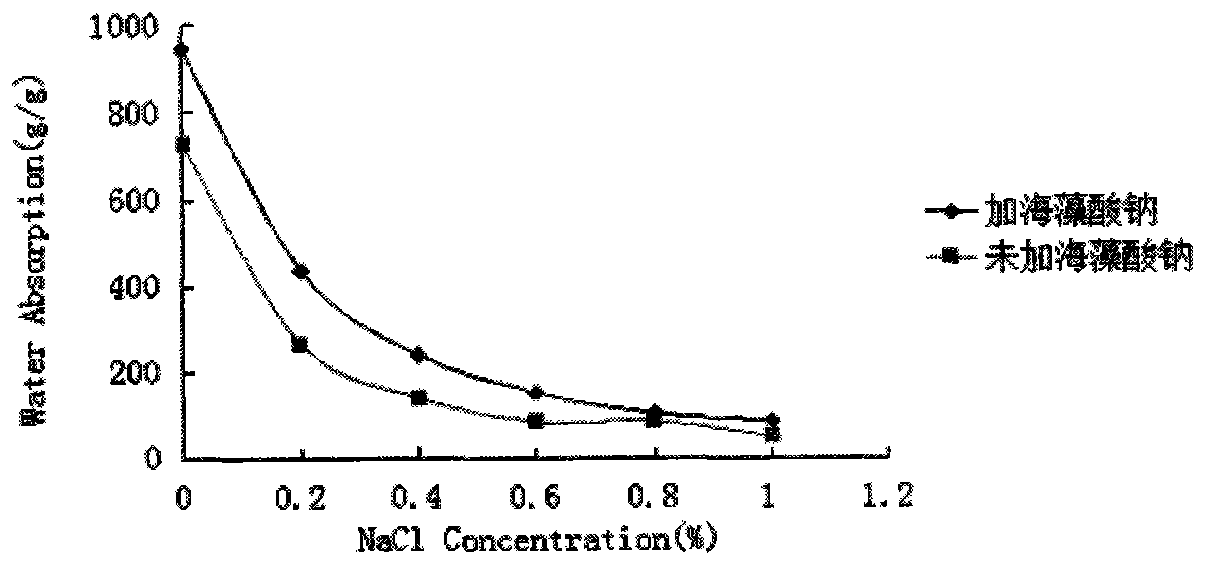

Preparation method of compound-type starch modification super absorbent resin

The invention discloses a preparation method of a compound-type starch modification super absorbent resin. The preparation method comprises the following steps of: adding deionized water to corn starch, stirring, slowly heating to 70 DEG C, and after completely dextrinizing the starch, reducing pasting liquid to a room temperature for standby application; weighting a right amount of acrylic acid solution under the action of ice water cooling, neutralizing by a 25% sodium hydroxide solution, adding 15% sodium bicarbonate as a pH buffering agent, and obtaining a monomer solution; after uniformly mixing the monomer solution and the pasting liquid in the presence of nitrogen, adding ammonium persulfate, and slowly heating to 58 DEG C to 62 DEG C; adding a sodium alginate saturated solution, dropwise adding a cross-linking agent, and reacting for 2-2.5 hours; after reaction is ended, stopping the feeding of nitrogen, drying copolymers to constant weight at 75-80 DEG C, smashing, screening by a 60-80 screen and obtaining the compound-type starch modification super absorbent resin. The environment-friendly water-absorbent resin with high salt tolerance and high water retention rate is prepared by starch graft copolymerization and alginate crosslinking.

Owner:NANJING FORESTRY UNIV

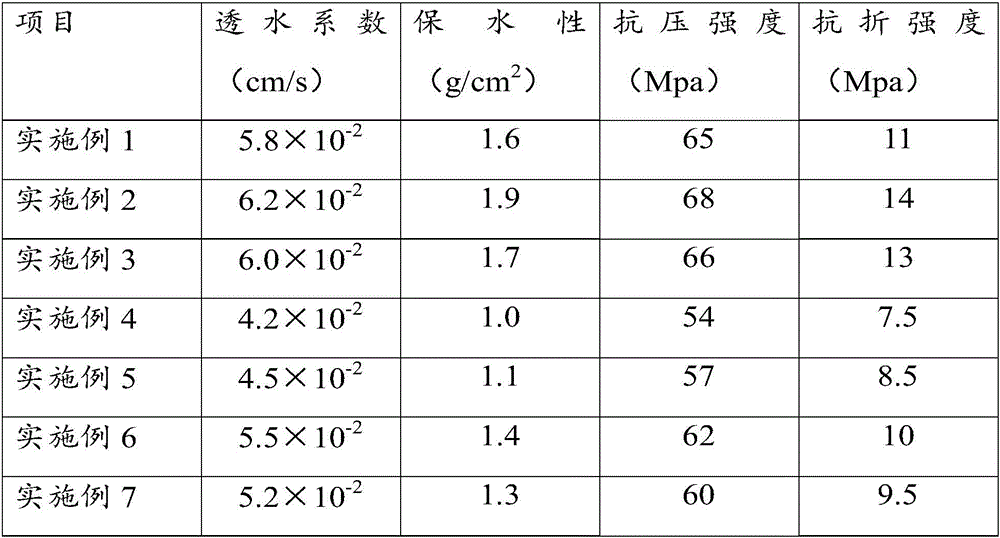

City sponge water permeable structure brick and production technology thereof

InactiveCN106747571AGood water permeabilityHigh water retentionSingle unit pavingsPaving gutters/kerbsBrickCrushed stone

The invention relates to the technical field of building materials, in particular to a city sponge water permeable structure brick and a production technology thereof. The city sponge water permeable structure brick comprises a bottom layer and a surface layer, wherein the surface layer is integrally formed at the upper surface of the bottom layer; the bottom layer is mainly prepared from the following raw materials in parts by weight: 80 to 120 parts of cement, 350 to 450 parts of fine sand, 400 to 550 parts of crushed stone, 50 to 100 parts of solid waste powder and 100 to 150 parts of water; the surface layer is mainly prepared from the following raw materials in parts by weight: 10 to 18 parts of cement, 25 to 45 parts of fine sand, 35 to 55 parts of crushed stone, 2 to 10 parts of white cement, 0.5 to 2 parts of pigment and 1 to 6 parts of water. The city sponge water permeable structure brick has the advantages that the problem of contradiction between mechanical property and water permeation rate of the water permeable brick is solved; the water permeable property, water retention rate and compressive strength are good, the utilization rate of wastes is effectively improved, and the production cost is reduced.

Owner:HENAN GUOLONG IND

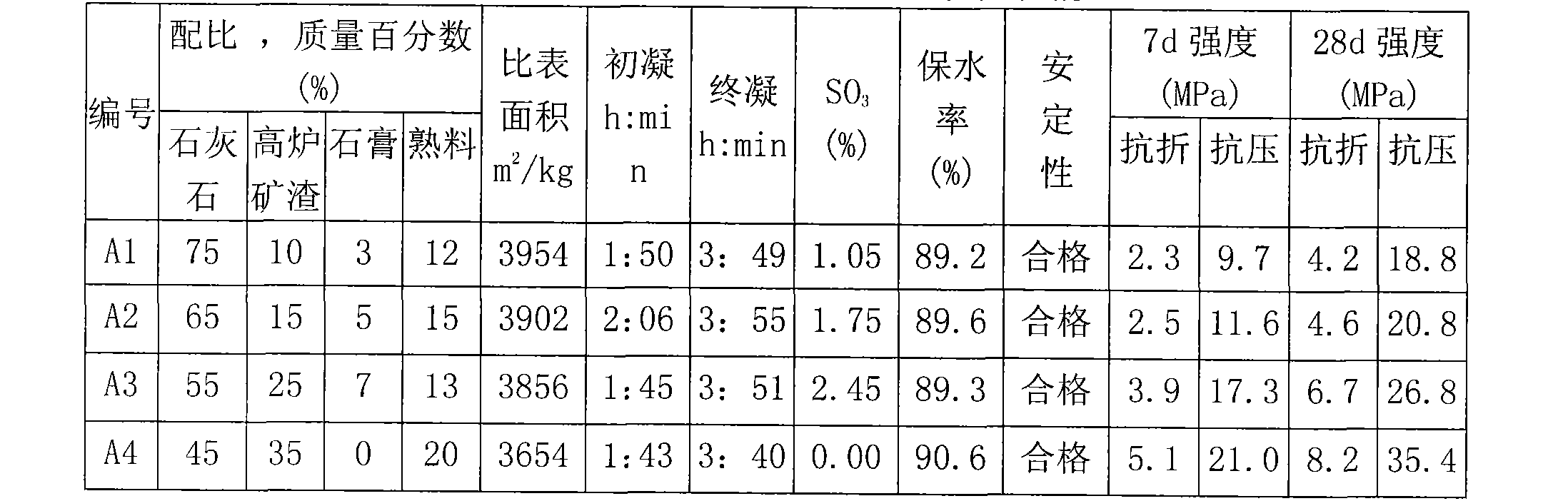

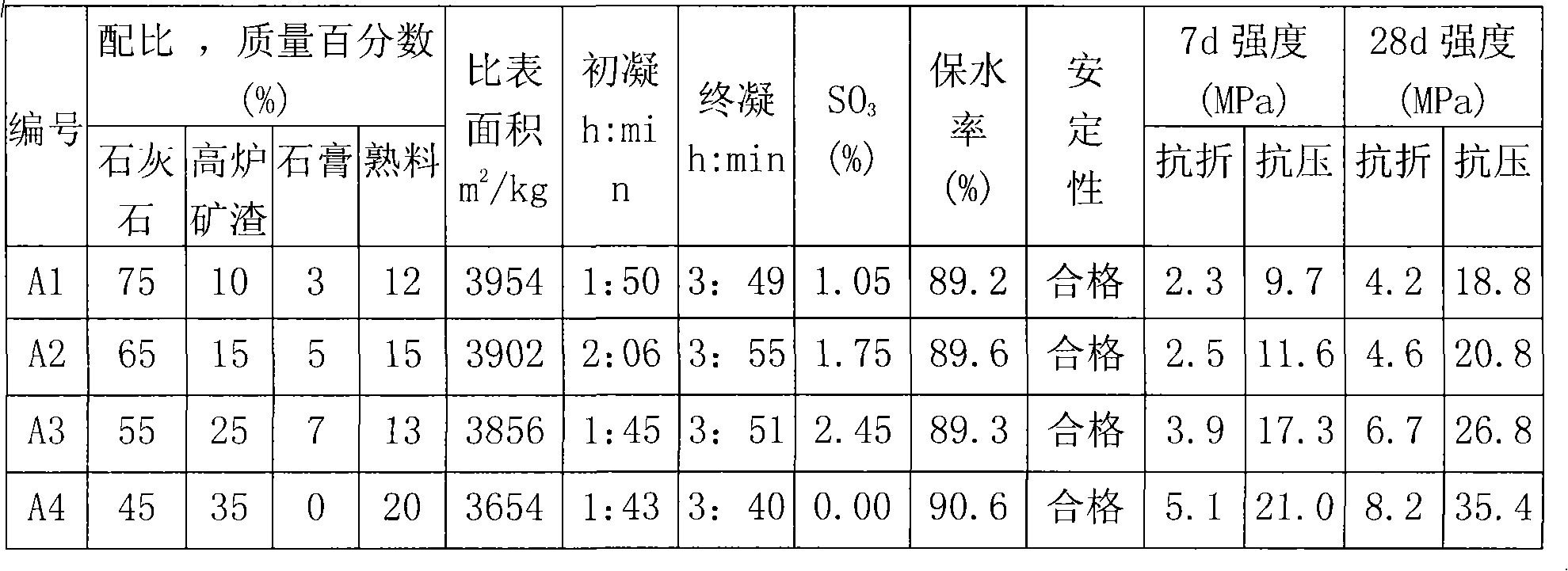

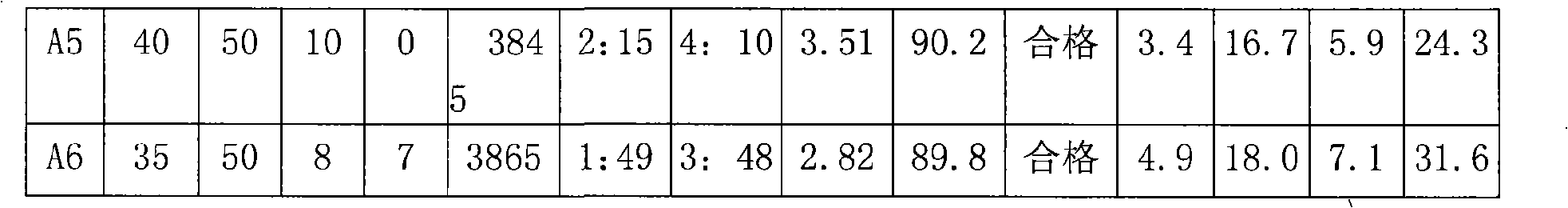

Hydraulicity cementitious materials and preparation method thereof

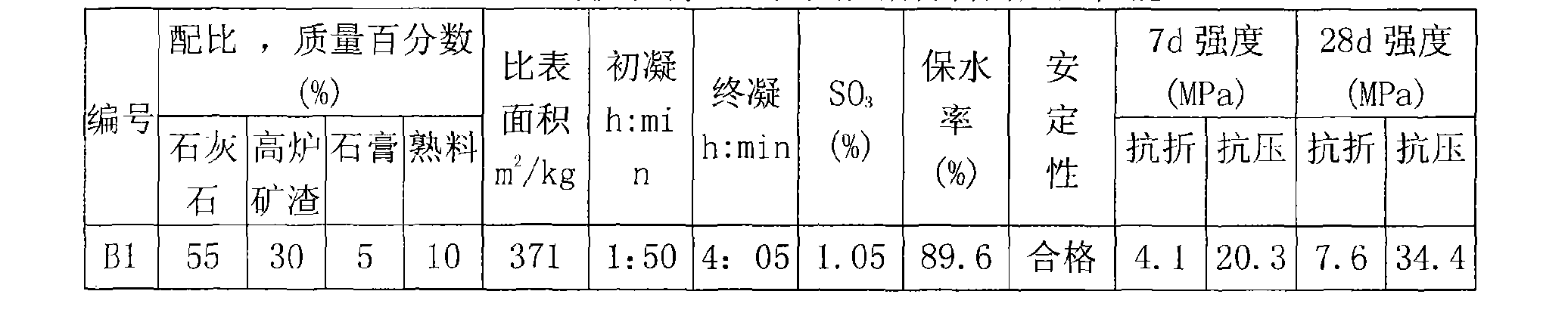

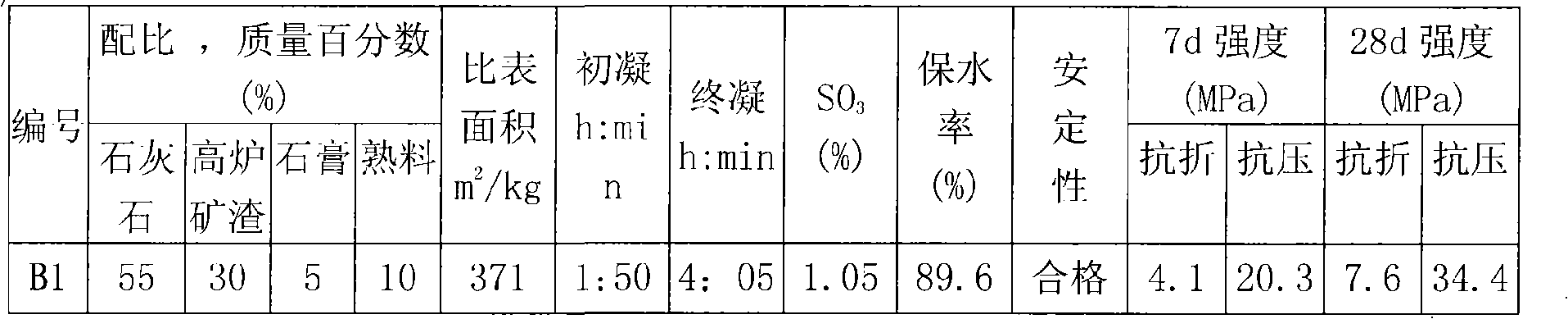

The invention belongs to the field of building materials, and in particular relates to a hydraulic cementing material and a method for preparing the same. The hydraulic cementing material is characterized in that the cementing material is prepared from raw materials of limestone, industrial residue, gypsum and admixture through mixing, and the mass percents of the raw materials are as follows: 35 to 75 percent of the limestone, 5 to 50 percent of the industrial residue, 0 to 10 percent of the gypsum, and 0 to 20 percent of the admixture, wherein the mass percents of the gypsum and the admixture cannot be 0 simultaneously, and the summation of the mass percent of each raw material is 100 percent. The invention can make full use of a large number of the limestone, and the method has the advantages of simple process, low cost, less energy consumption and environmental protection.

Owner:WUHAN UNIV OF TECH +1

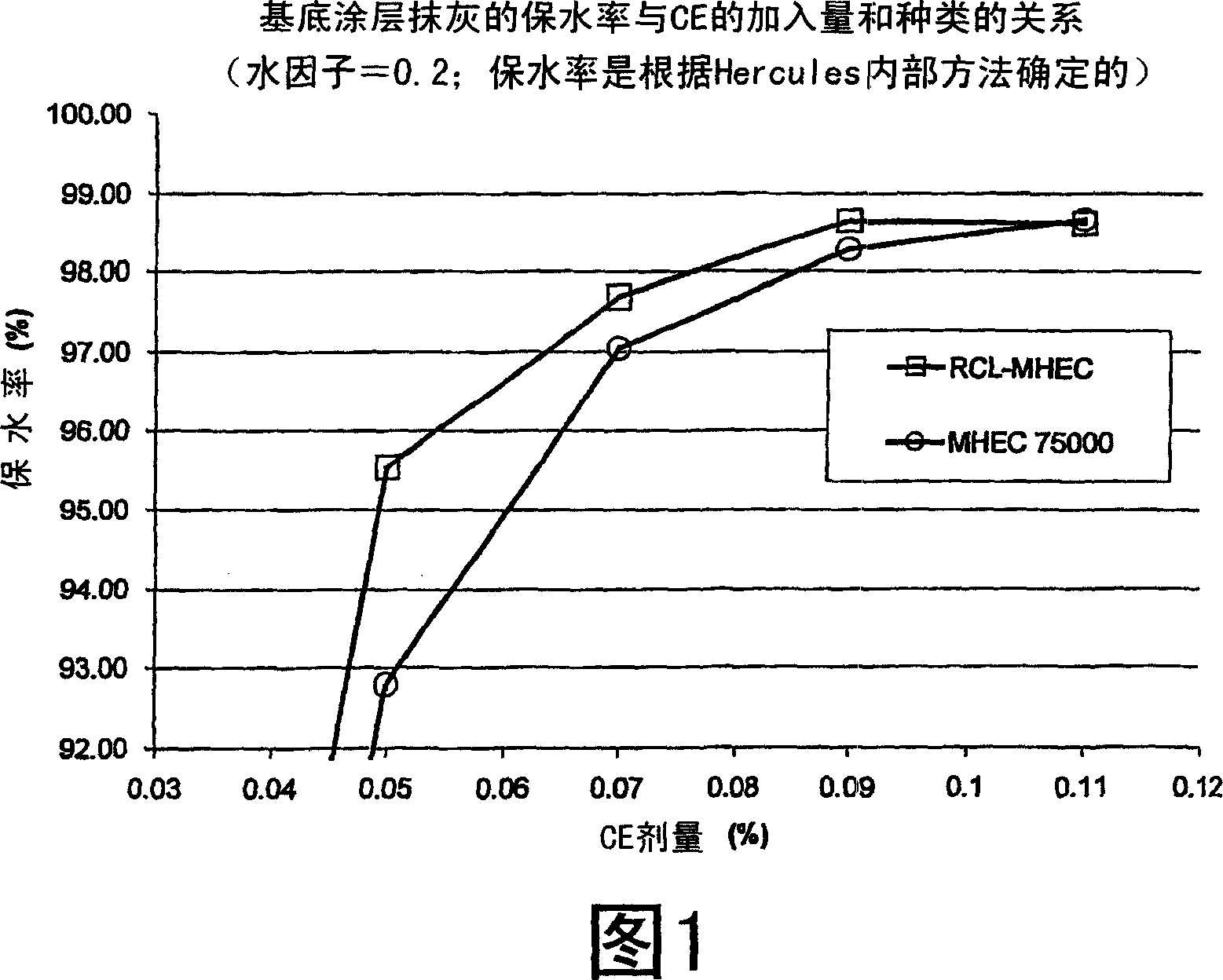

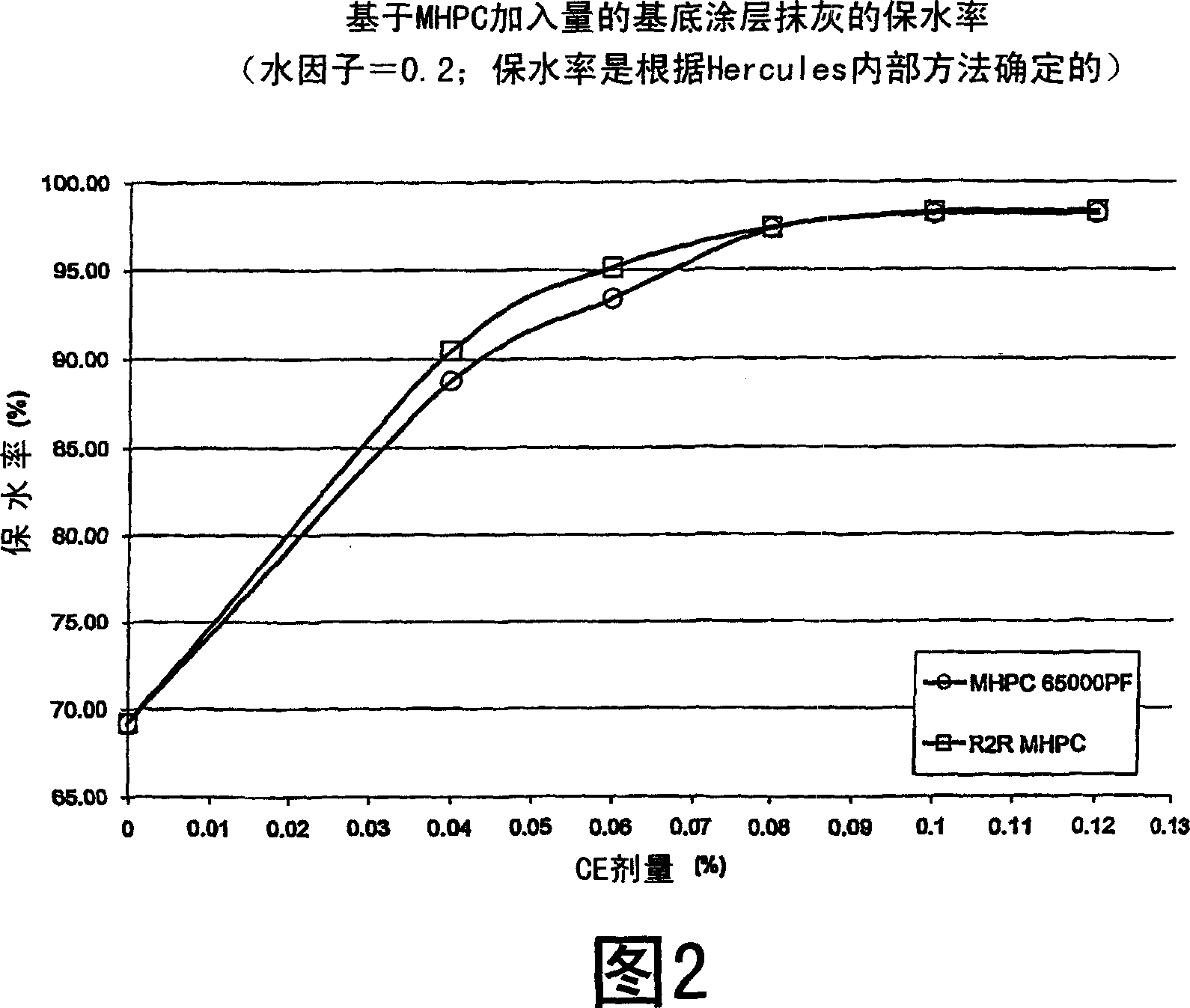

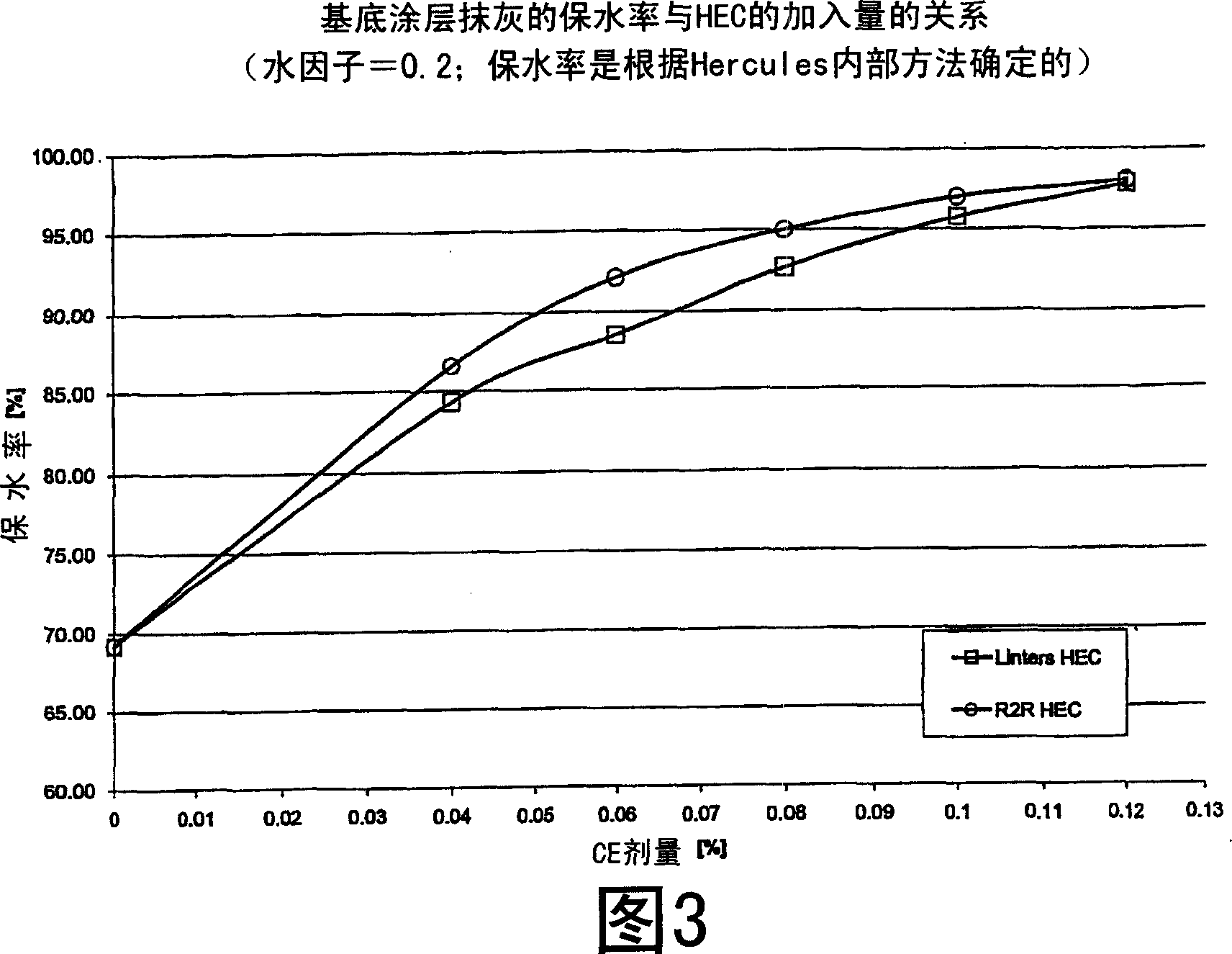

Cement-based plasters using water rentention agents prepared from raw cotton linters

InactiveCN1946648AHigh water retentionGood thickening effectPropellersSolid waste managementEtherMaterials science

A mixture composition of a cellulose ether made from raw cotton linters and at least one additive is used in a cement extrusion mortar composition wherein the amount of the cellulose ether in the cement extrusion mortar composition is significantly reduced. When this cement extrusion mortar composition is mixed with a sufficient amount of water and extruded to form an object with comparable or lower crack formation, the plastification and / or extrusion properties of the resulting wet mortar are improved or comparable as compared to when using conventional similar cellulose ethers.

Owner:HERCULES INC

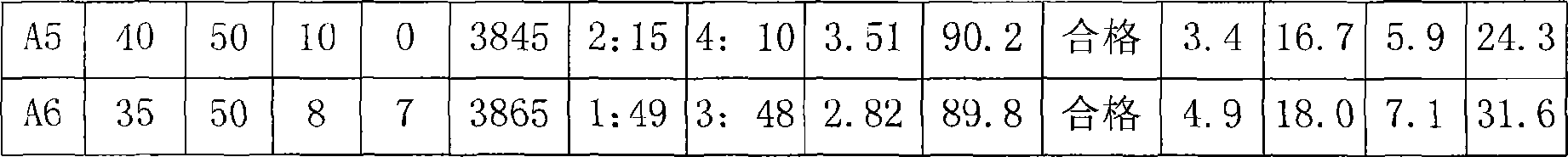

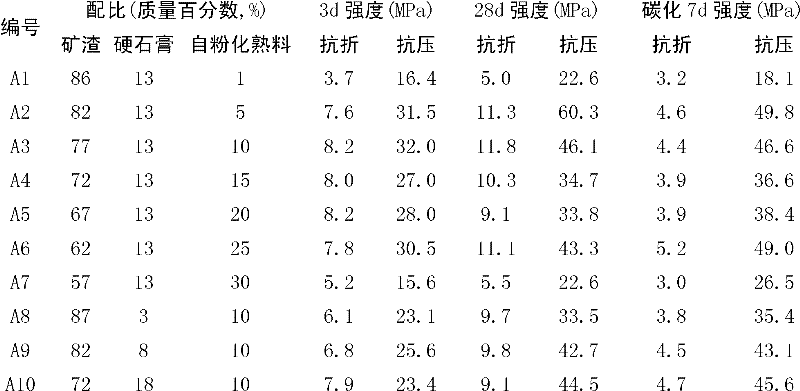

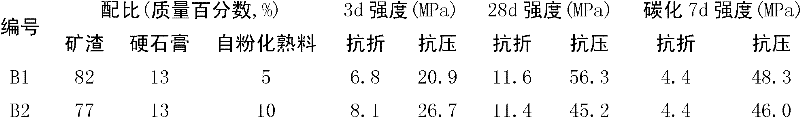

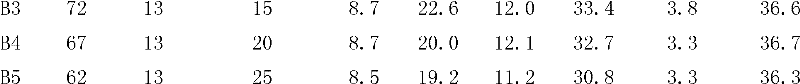

Portland cement made from self-pulverized clinker and slag and preparation method for Portland cement

The invention belongs to the technical field of building materials, and particularly relates to a Portland cement made from self-pulverized clinker and slag and a preparation method for the Portland cement. The Portland cement made from the self-pulverized clinker and the slag is characterized in that the Portland cement is made from the slag, plaster and the self-pulverized clinker by means of mixing and comprises 57%-87% of the slag, 3%-18% of the plaster and 1%-30% of the self-pulverized clinker in weight percent. The self-pulverized clinker is prepared according to the steps of preparing cement raw materials by means of arbitrary combination of the lime saturation coefficient ranging from 0.589 to 0.823, the silica ratio ranging from 2.5 to 4.0 and the alumina ratio ranging from 1.0 to 2.8 of the clinker; and grinding the cement raw materials to the degree with screen residues smaller than 18% by means of sieving of a sieve with the 0.08mm side length of a sieve mesh, calcining the grinded cement raw materials for 0.5 hour to 1.5 hours at the high temperature ranging from 1200 DEG C to 1380 DEG C prior to slowly cooling to the room temperature with the cooling rate of 15-45 DEG C / min, and obtaining the self-pulverized clinker. The method is simple in process, low in calcining temperature and low in grinding power consumption, and carbonization resistance of the Portland cement can be improved by the method.

Owner:WUHAN UNIV OF TECH +1

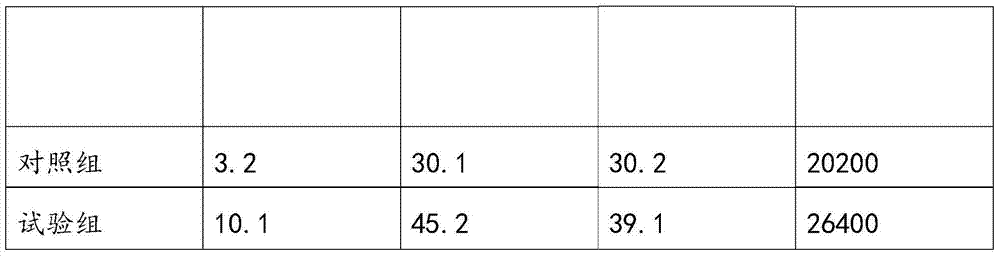

Synergistic compound fertilizer

InactiveCN104211492AIncrease profitImprove disease resistanceFertilizer mixturesContinuous croppingPotassium

The invention relates to a synergistic compound fertilizer. The synergistic compound fertilizer comprises, by weight, 0.1-100 parts of a synergist, 0.3-700 parts of a biological preparation, 1-200 parts of calcium sulfate, 5-500 parts of sodium silicate, and 2-8000 parts of a compound fertilizer, wherein the synergist comprises potassium humate, polyaspartate, chitosan, nonionic polyacrylamide, potassium polyacrylate and poly(potassium silicate); and the biological preparation comprises azotobacteria, phosphate-solubilizing bacteria, potassium releasing bacteria, photosynthetic bacteria, actinomyces, microzyme and Bacillus spp, and the quantity of beneficial live bacteria is greater than 2billions / g. The synergistic compound fertilizer adopting the biological preparation comprising azotobacteria, phosphate-solubilizing bacteria, potassium releasing bacteria, photosynthetic bacteria, actinomyces, microzyme and Bacillus spp and the synergist comprising potassium humate, polyaspartate, chitosan, nonionic polyacrylamide, potassium polyacrylate and poly(potassium silicate) has the advantages of effective improvement of the fertilizer utilization rate, increase of the water retention rate, promotion of the growth of crops, improvement of the continuous cropping and disease resistance of a chemical fertilizer, environmental protection and no pollution.

Owner:PINGLE AGRI CHEM PLANT GUANGXI PROV

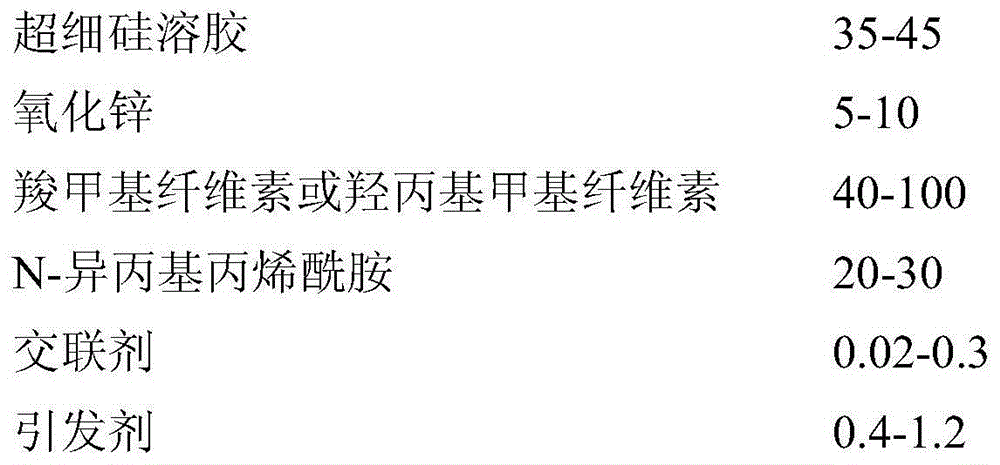

Liquid fertilizing and water-retaining mulching film and preparation method thereof

InactiveCN104804141AImprove physical and chemical propertiesIncreased water-stable aggregatesPlant protective coveringsFertilizer mixturesCross-linkUltra fine

The invention relates to a liquid fertilizing and water-retaining mulching film and a preparation method thereof and belongs to the technical field of agricultural production. The liquid mulching film comprises components in percentage by mass as follows: 1%-10% of a modified macromolecular composite polymer and 90%-99% of a fertilizing agent; the modified macromolecular composite polymer comprises components in parts by weight as follows: 35-45 parts of ultra-fine silica sol, 5-10 parts of zinc oxide, 40-100 parts of carboxymethylcellulose or hydroxypropyl methyl cellulose, 20-30 parts of N-isopropylacrylamide, 0.02-0.3 parts of a cross-linking agent and 0.4-1.2 parts of an initiator; the solid content of the ultra-fine silica sol is in a range of 10-30wt%, and particle sizes of silica in the ultra-fine silica sol are in a range of 1-100 nm. The prepared liquid mulching film can significantly increase the water-retention rate of soil and improve physical and chemical properties of the soil, can be completely degraded, is free of pollution and can substitute for plastic mulching films on a large scale.

Owner:CHANGZHOU GUOBO NEW MATERIAL TECH CO LTD

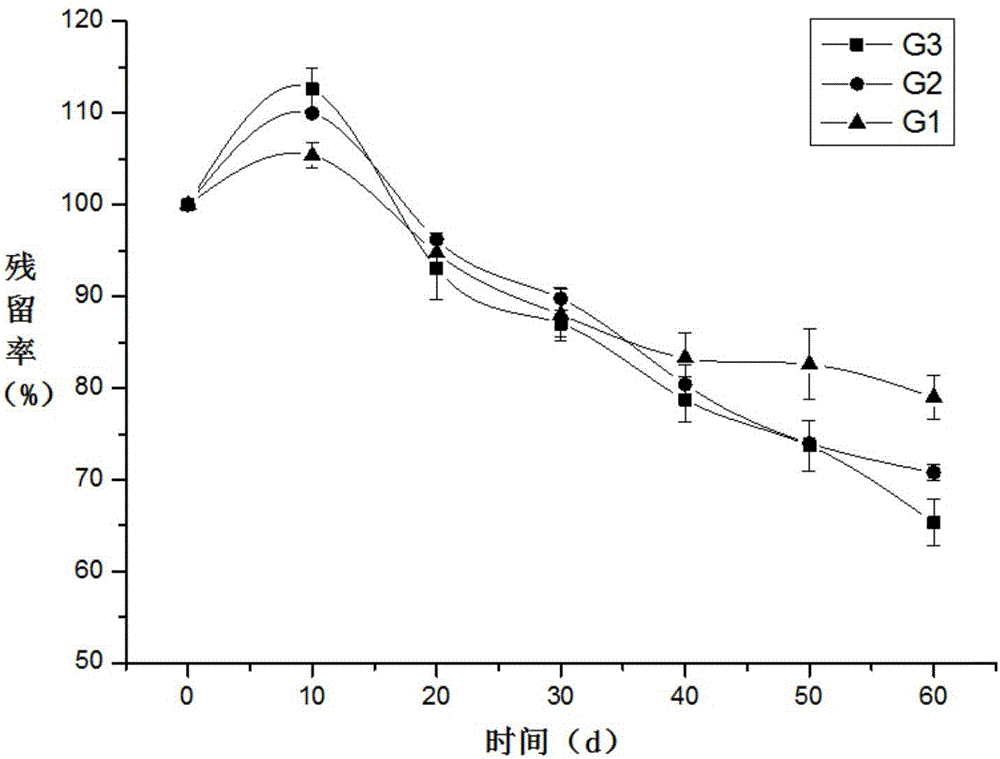

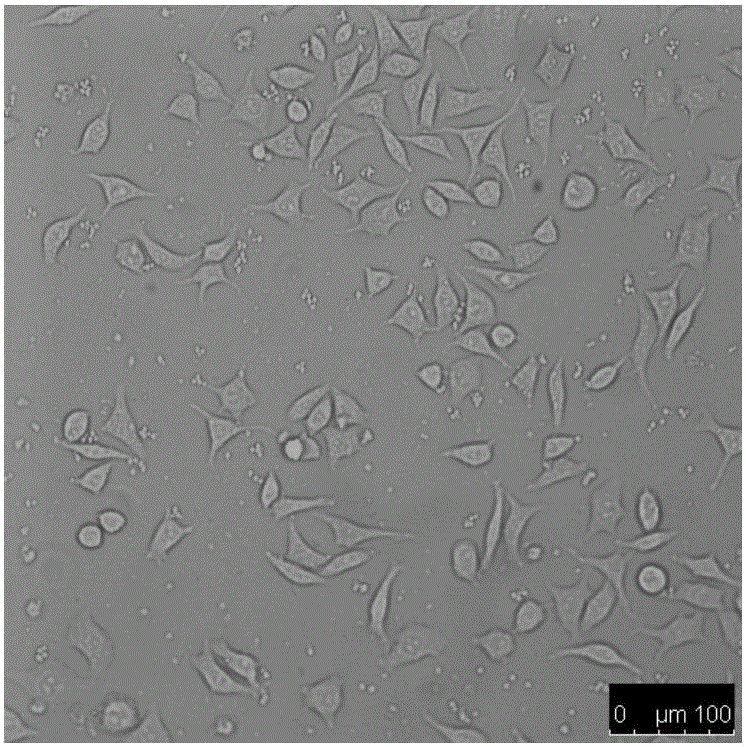

Joint lubricating material and preparation method thereof

InactiveCN106046397AControllable gelation timeIncrease moisture contentSurgeryPharmaceutical delivery mechanismO carboxymethyl chitosanPolymer science

The invention discloses a joint lubricating material and a preparation method thereof. The material is covalent crosslinked O-carboxymethyl chitosan hydrogel, wherein the gelation time is 0.5-10min, the water content is higher than 70%, and the water retention rate is higher than 65%; and the material is prepared by carrying out gelation reaction between O-carboxymethyl chitosan of which the degree of deacetylation is greater than 25% and glutaric dialdehyde. The prepared covalent crosslinked O-carboxymethyl chitosan hydrogel has good biocompatibility, can serve as a joint lubricating agent, is suitable for local injection of joints, and can enable the joints to keep certain capacity and elastic properties within certain time so as to promote cartilage tissue repair.

Owner:SHENZHEN BRIGHT WAY NOVEL BIO MATERIALS TECH CO LTD

Hydraulic gelate material and method for preparing same

The invention belongs to the field of a constructional material, in particular relates to a hydraulic binding material and a preparation method thereof. The hydraulic binding material is characterized in that the hydraulic binding material is prepared with 35 percent to 75 percent of limestone by mass, 5 percent to 50 percent of industrial residue by mass, 0 percent to 10 percent of plaster by mass and 0 percent to 20 percent of additives by mass through mixing. The mass percents of the plaster and the additives are not 0 at the same time, and the total of the mass percents of the raw materials is 100%. The hydraulic binding material and the preparation method can make use of much limestone; the preparation method is simple in process; the cost is low; little energy is consumed; and the hydraulic binding material is environment-friendly.

Owner:WUHAN UNIV OF TECH +1

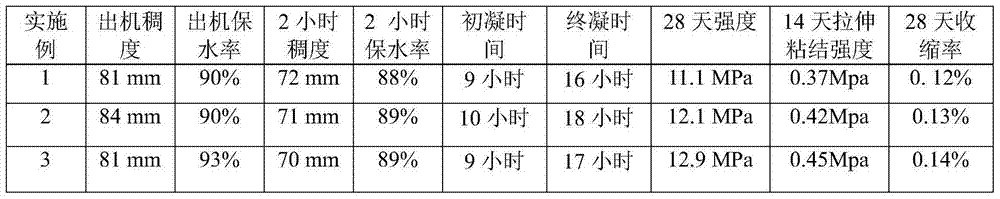

Concrete curing agent and preparation method thereof

The invention provides a concrete curing agent which is prepared from the following components in parts by weight: 90-99 parts of core-shell structure macromolecule emulsion, 0-5 parts of film-forming aid, 0.1-2 parts of defoaming agent, 0-5 parts of leveling agent and 0-1 part of thickening agent. The concrete curing agent is simple in preparation method, the emulsion of a core-shell structure is prepared by using an emulsion polymerization method, hydroxyl groups are introduced into the shell layer, and the hydroxyl groups can have chemical bonding action with silicon atoms on the surface of the concrete, so that the binding force of the curing agent with the surface of the concrete is improved, and the water retention effect of the concrete curing agent is ensured.

Owner:JIANGSU SOBUTE NEW MATERIALS

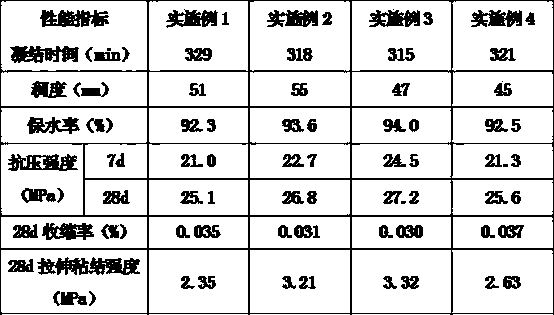

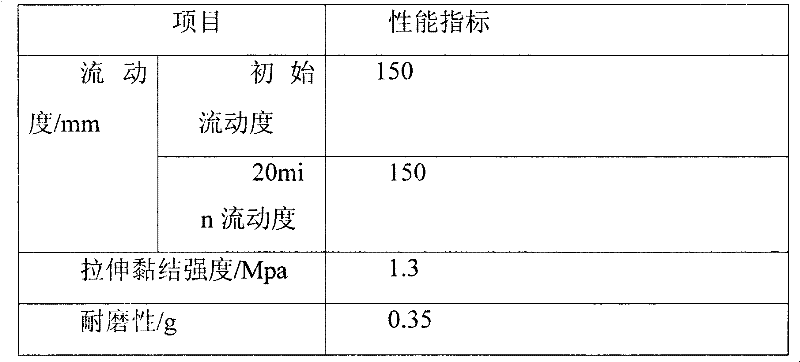

Ceramic tile ready-mixed mortar and production method thereof

InactiveCN104230237AQuality assuranceQuality improvementSolid waste managementCelluloseCompressive resistance

The invention relates to ceramic tile ready-mixed mortar and a production method thereof. The ceramic tile ready-mixed mortar is characterized by comprising the following raw materials in parts by weight: 50-60 parts of artificial sand, 30-35 parts of cement, 10-12 parts of class II pulverized fuel ash, 0.5-1 part of a functional auxiliary agent and 0.1-0.5 part of additives, wherein the functional auxiliary agent comprises redispersible latex powder, cold cut polyvinyl alcohol powder and hydroxypropyl methyl cellulose ether. The ceramic tile ready-mixed mortar disclosed by the invention has tensile adhesive strength and compressive strength, can be used for significantly improving properties such as anti-permeability, crack resistance, water reduction performance and water-retention rate of the mortar, and also has excellent working performance and excellent construction properties such as easy pumping and easy compacting.

Owner:GUANGXI HENGXIAN HENGFENG BUILDING MATERIAL

Wet-mixed masonry mortar prepared by adopting aggregate chips

ActiveCN104496327AEasy to get materialsLow priceSolid waste managementCarboxymethyl celluloseSodium Bentonite

The invention discloses wet-mixed masonry mortar prepared by adopting aggregate chips. The wet-mixed masonry mortar comprises the following components in parts by weight: 18-22 parts of cement, 6-8 parts of pulverized fuel ash, 5-7 parts of mineral powder, 22-25 parts of water, 135-145 parts of aggregate chips and 0.5-2.0 parts of a mortar admixture, wherein the particle size of the aggregate chips is not more than 4.75mm; the mountain flour in the aggregate chips accounts for 2-3 percent by weight; the mortar admixture serves as a thickening agent; the thickening agent comprises the following components in parts by weight: 2-4 parts of a sulfonic acid type air entraining agent, 10-20 parts of a melamine water reducing agent, 1-3 parts of soft sugar, 1-3 parts of a water repellent, 4-6 parts of sodium carboxymethyl cellulose and 40-60 parts of sodium bentonite. The machine-made sand and river sand are replaced by residual aggregate chips after stone processing, the aggregate chips are readily available and low in price, the resources are reasonably utilized, the environmental pollution caused by waste aggregate chips is reduced, and the production cost of the mortar is reduced.

Owner:青岛磊鑫混凝土有限公司

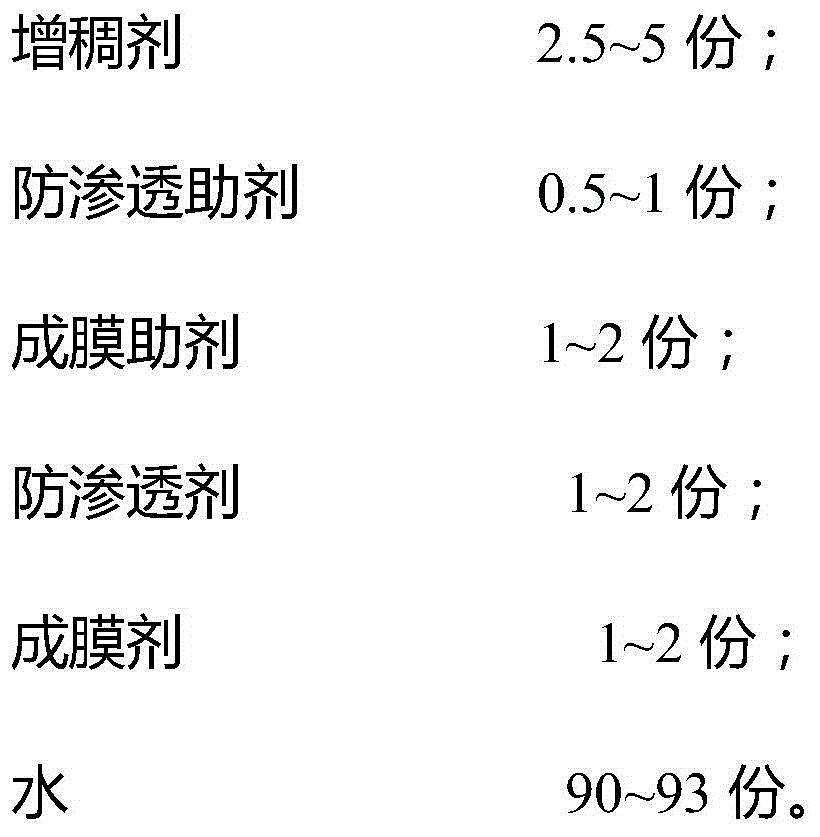

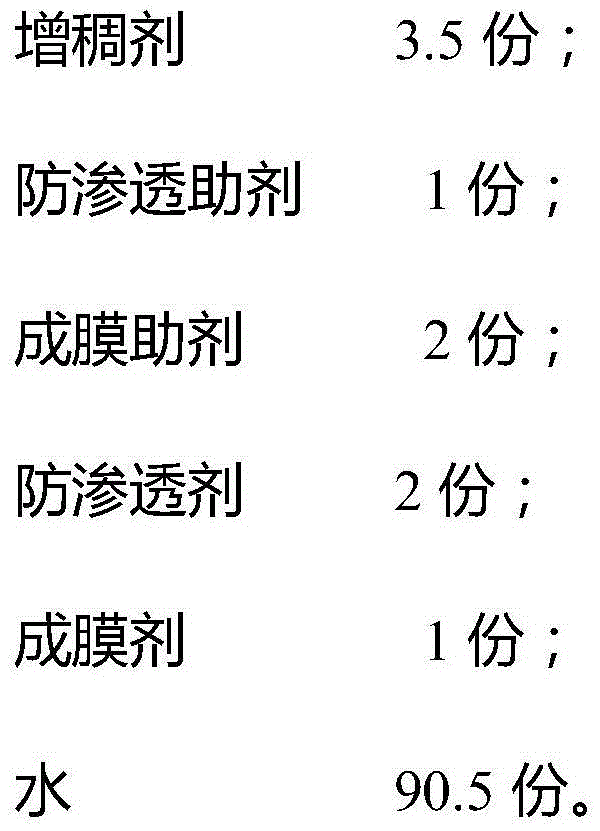

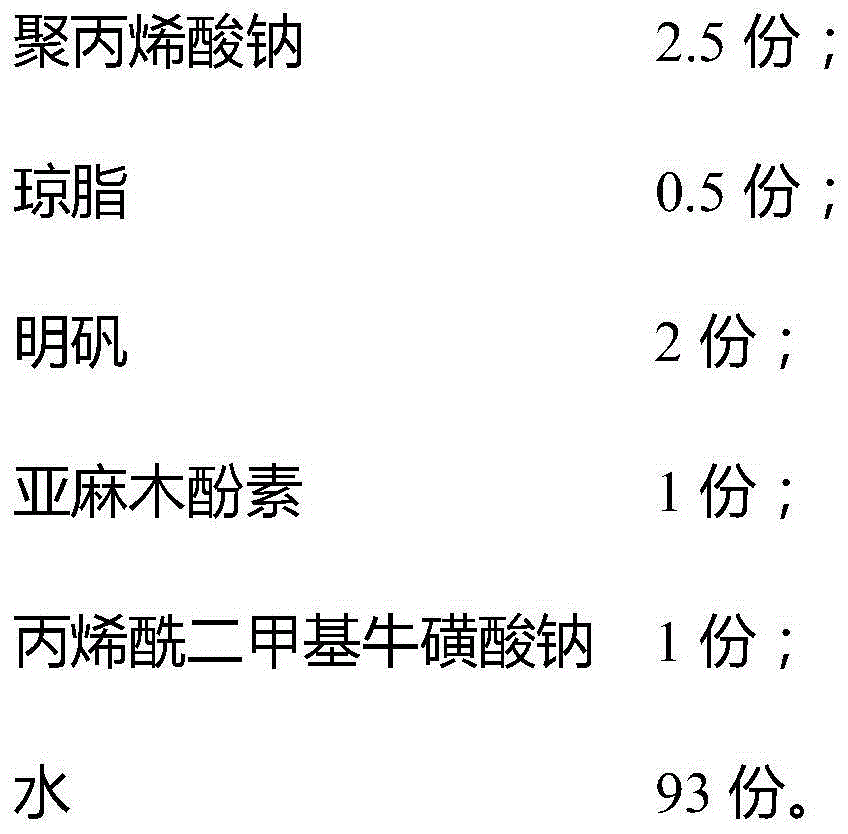

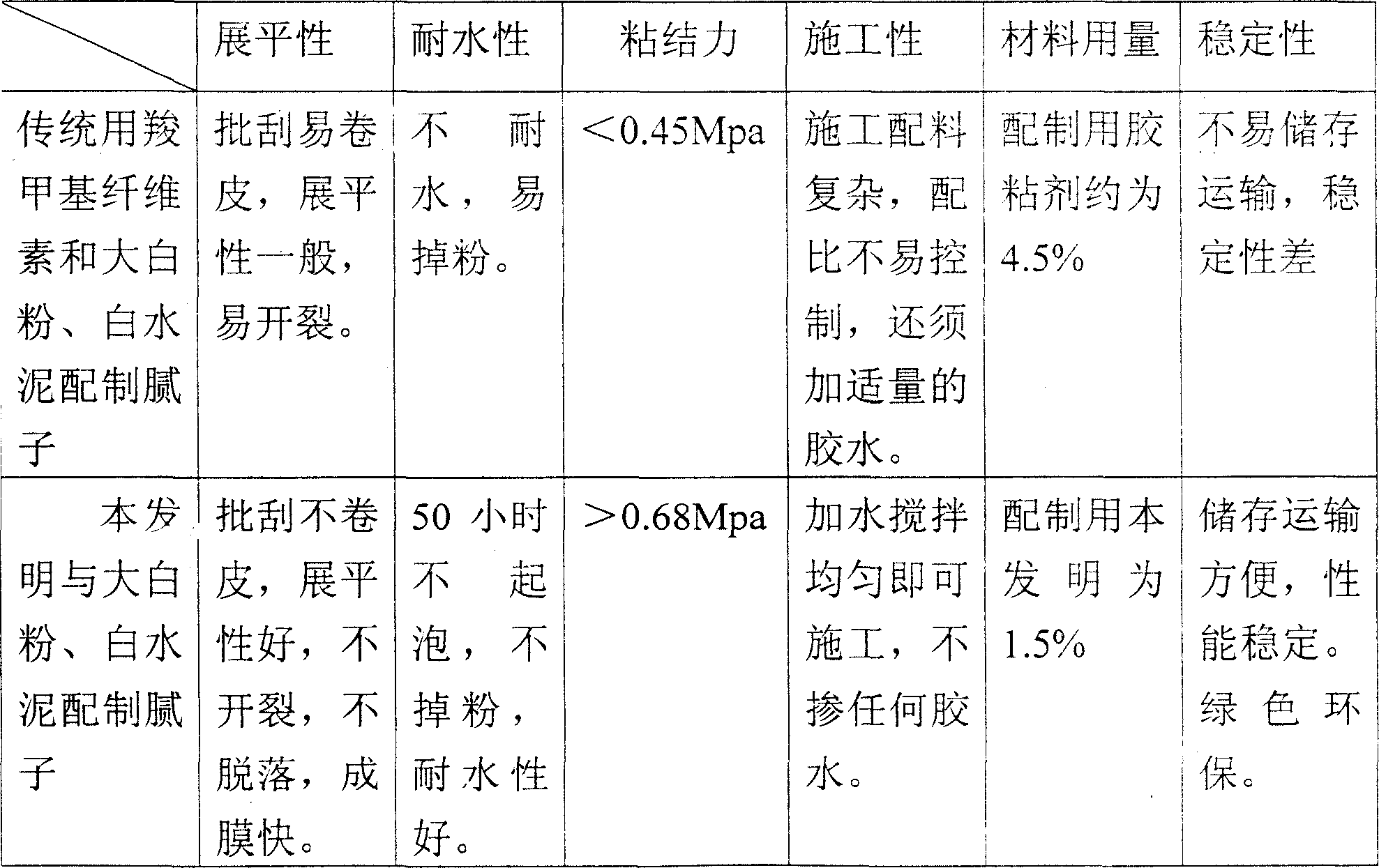

Double-sided digital printing paste with bacteriostasis function

InactiveCN104562777AImprove water retentionPrevent penetrationDyeing processSurface layerEngineering

The invention discloses double-sided digital printing paste with a bacteriostasis function. The double-sided digital printing paste comprises following components which are mixed in parts by weight: 2.5 to 5 parts of a thickening agent, 0.5 to 1 part of an additive, 1 to 2 parts of a film forming additive; 1 to 2 parts of an anti-seepage agent, 1 to 2 parts of a film forming agent and 90 to 93 parts of water. According to the double-sided digital printing paste with the bacteriostasis function, due to the synergistic function of all components, the water-retention rate is obviously higher than that of the printing paste in the prior art; the seepage rate is obviously lower than that of the printing paste in the prior art. The double-sided digital printing paste with the bacteriostasis function has a dyeing effect only for a fabric surface layer. The double-sided digital printing paste is used for digitally printing one side of a fabric, and the printing paste can not seep into the other side of the fabric, so that two sides of the fabric can be printed; the printed fabric is relatively good in bacteriostasis effect, and the body health can be benefited.

Owner:SUZHOU INST OF TRADE & COMMERCE

Water-soluble anticarack gelatine powder, and application in building materials of powder

This invention relates to a construction binder, which is prepared by: adding carboxymethyl amylocellulose ether, hydroxypropyl methylcellulose, lignin fibers, sodium dodecyl benzenesulfonate, bentonite and polyacrylamide into a mixer, and dry-stirring for a certain time until complete mixing. This invention fully exploits the advantages of organic and inorganic materials. The obtained construction binder has such advantages as high binding strength, high water-retaining rate, good anti-crack performance, good waterproof performance, no odor and no toxicity, and is environmentally friendly. The construction binder can be used as an additive for powdery building materials such as dry-mixed heat-insulation mortar, anti-crack mortar, brushing gypsum, putty powder, construction binder and polymeric mortar.

Owner:兰州海锋建材科技有限公司

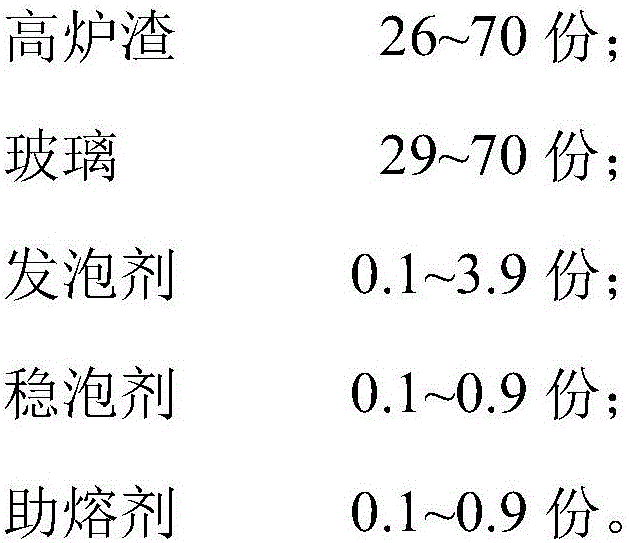

Method for producing foamed glass by melting blast furnace slag

The invention discloses a method for producing foamed glass by melting blast furnace slag. The method comprises the following steps: using the blast furnace slag as a main raw material to produce the foamed glass, wherein the blast furnace slag is metallurgical furnace slag produced online in the ironmaking process of a blast furnace; after acquiring the blast furnace slag from a slag discharge opening of the blast furnace, directly mixing with other raw materials in a high-temperature molten state; finally preparing the foamed glass. The method uses melting blast furnace slag with a high content of glass body as the main raw material, makes full use of residual heat of the melting blast furnace slag and secondary resources, and achieves purposes of energy conservation and environmental friendliness.

Owner:武汉钢铁有限公司

Nutrient capable of improving saline and alkaline resistance ability of plant

The invention discloses a nutrient capable of improving the saline and alkaline resistance ability of a plant. The nutrient comprises the following raw materials in parts by weight: 5-10 parts of water-retaining agents, 0.02-0.04 parts of indolebutyric acid, 0.01-0.03 parts of gibberellin, 0.03-0.05 parts of polyaspartate, 20-30 parts of fully-decomposed crop straws, 30-40 parts of fully-decomposed kraal manure or pigsty manure, 0.06-0.15 parts of yeast, 1-10 parts of quick lime, 10-15 parts of ferrous sulfate, 0.6-3 parts of copper sulfate, 3-6 parts of manganese sulfate and 0.8-3 parts of monopotassium phosphate. The nutrient has the beneficial effect that the water-retaining agent, the indolebutyric acid, the gibberellin, the crop straws and an efficient compound fertilizer are fully mixed, so that the moisture utilization rate and the production efficiency are improved, the requirements of saline and alkaline resistance, high hygroscopicity and durability of the plant are satisfied, and the water-retaining effect of the nutrient is greatly improved.

Owner:LEIBANGSI BIOTECH BEIJING

Concrete water-retaining agent

The invention belongs to the technical field of concrete admixtures, in particular to a concrete water-retaining agent, made from the following materials according to parts by weight: 30-50 parts of hydroxypropyl methylcellulose, 10-18 parts of diatomaceous earth, 5-15 parts of glyceryl monostearate, 3-15 parts of calcium sulfoaluminate and 2-10 parts of alkyl glycoside. The concrete water-retaining agent of the invention has high water-retaining rate and stable properties and can improve the strength, cracking resistance and durability of concrete.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

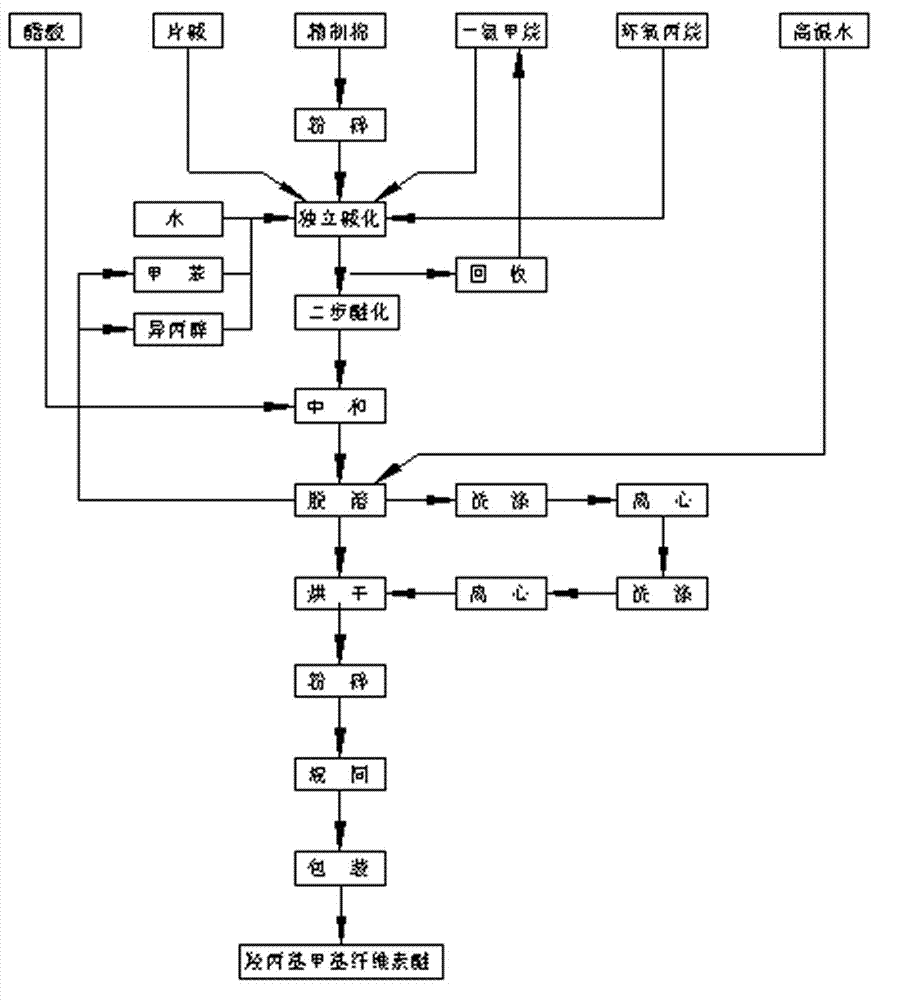

Preparation technology of hydroxypropyl methylcellulose ether (HPMC)

The invention relates to a preparation technology of hydroxypropyl methylcellulose ether (HPMC), belonging to the field of the fine chemical industry. The preparation technology comprises the following steps of: 1) independent alkalization: firstly adding 7-8 parts of caustic soda flakes into a diluting agent system in an alkalization kettle; then heating to increase temperature to 70-80DEG C and then decreasing temperature to 10-25DEG C; and finally adding 8-9 parts of refined cotton into the alkalization kettle and keeping the temperature to be constant at 10-25DEG C for 2-3 hours; and 2) two-step etherification: firstly, feeding alkalized materials in the alkalization kettle into an etherification kettle; then adding etherifying agent and increasing temperature to 53-58DEG C for first-step etherification; increasing temperature to 81-87DEG C for second-step etherification; and finally a proper amount of acetic acid into a reactor for neutralization to obtain the HPMC. Due to the preparation technology, the reaction uniformity is obviously improved; and compared with products which are obtained by adopting the traditional production method, the water retention rate of the HPMC prepared by adopting the technology is improved by more than 20 percent and the viscosity is improved by more than 30 percent.

Owner:新疆光大山河化工科技有限公司

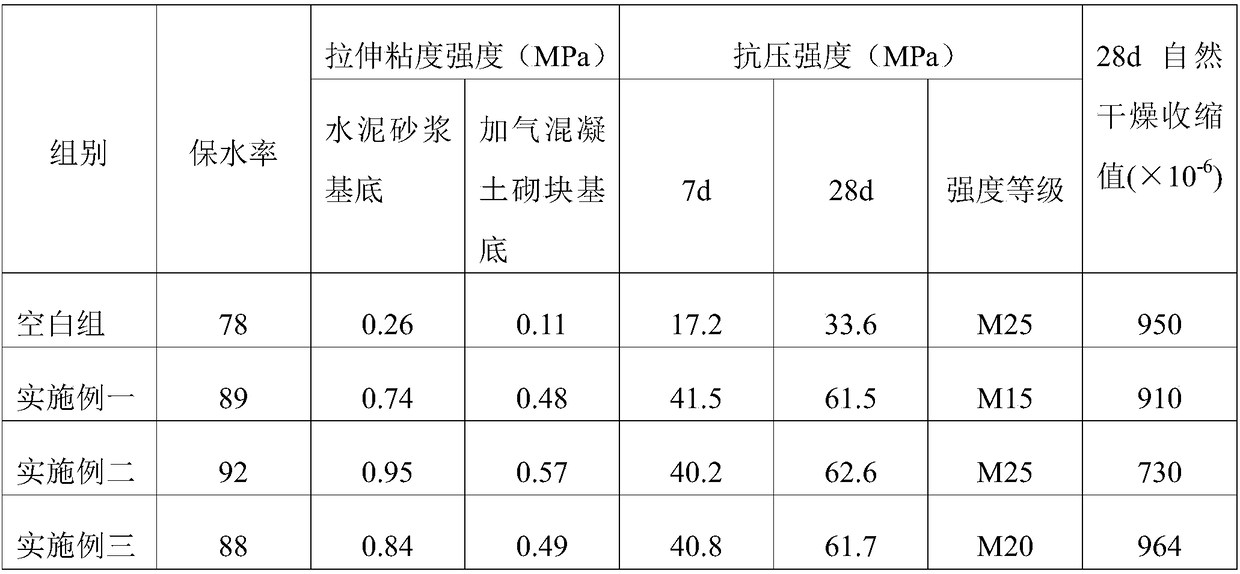

Mortar reinforcing agent and preparation method thereof

The invention provides a mortar reinforcing agent. The mortar reinforcing agent is prepared from the following raw materials in parts by weight: 2 to 10 parts of naphthalene water reducer, 0 to 50 parts of polycarboxylate superplasticizer, 10 to 20 parts of hydroxypropyl methyl cellulose, 10 to 40 parts of calcium silicate powder, 10 to 20 parts of HQS, 5 to 10 parts of calcium chloride, 0 to 50 parts of starch ether, 1 to 10 parts of polyacrylamide, 1 to 10 parts of polyvinyl alcohol powder, 1 to 5 parts of silane hydrophobic agent, 1 to 10 parts of cement reinforcing agent, 1 to 5 parts of mortar plasticizer, and 0 to 50 parts of calcium formate. By adopting the cement mortar reinforcing agent, the physical mechanical performance of mortar can be improved, and the water retaining performance and tensile adhesive strength of the mortar can be improved; since the water retaining rate is higher than the ordinary mortar, the water of the mortar is unlikely to absorb by the aerated concrete, the interface cement of the aerated concrete can be sufficiently hydrated, and the adhesive strength of the mortar and the aerated concrete can be improved, so that the cracking, bubbling and stripping problem of the mortar on the smeared surface of an aerated concrete building block can be effectively solved.

Owner:环秀(青岛)建材科技有限公司

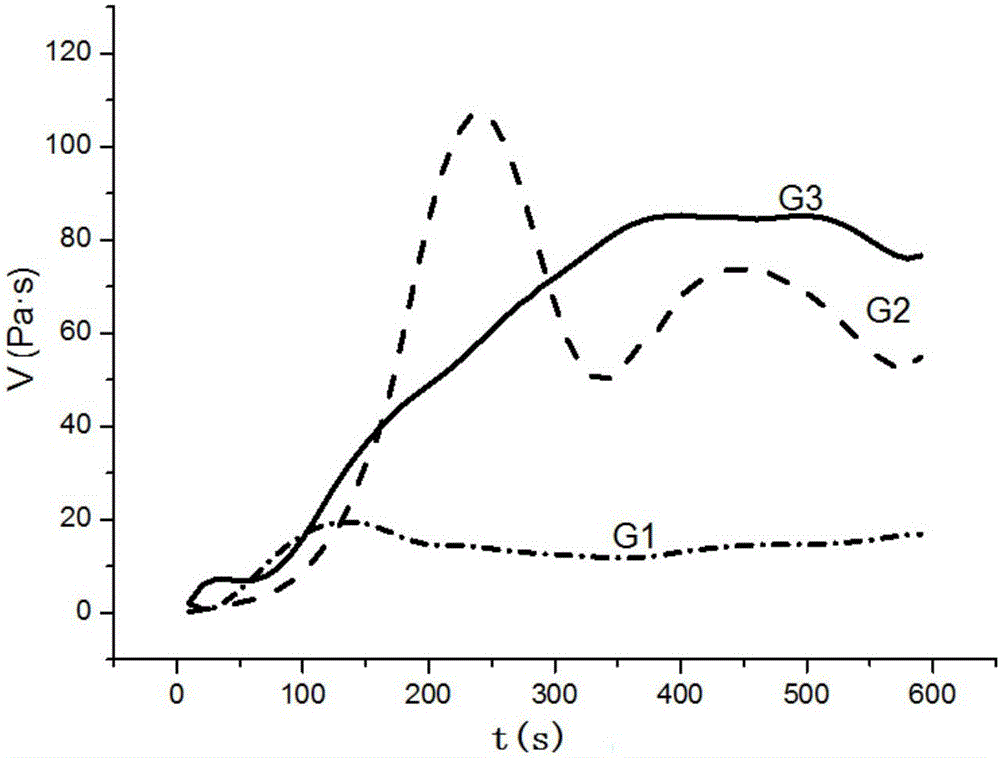

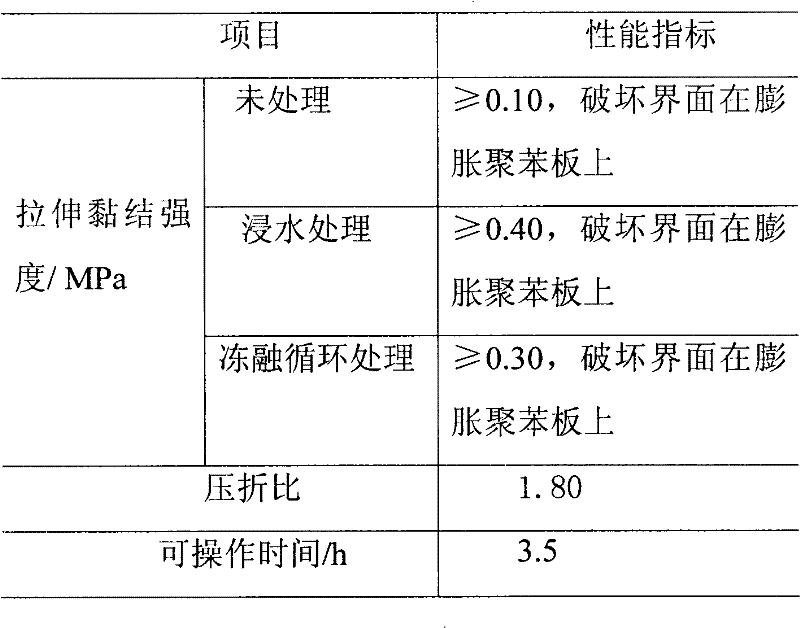

Multifunctional dry-mixed mortar additive and preparation method thereof

InactiveCN102515611AGood dispersionMeet the use requirementsCarboxymethyl celluloseMaterials science

The invention relates to a multifunctional dry-mixed mortar additive and a preparation method thereof. According to the invention, carboxymethyl cellulose is adopted as a raw material; methacrylic acid and 2-acrylamide-2-methylpropyl sulfonic acid are adopted as grafting monomers; ammonium persulfate is adopted as an initiator; and the multifunctional additive is synthesized by copolymerization. The additive has a number average molar weight of 15,000-23,000, and is white or light yellow solid powder. The multifunctional dry-mixed mortar additive is used for preparing various dry-mixed mortars, and provides thickening, water-retaining, water-reducing, dispersing and air entraining functions in dry-mixed mortar. With the additive, comprehensive performance of a mortar hardenite is greatly improved. In a dry-mixed mortar production field, defects such as poor compatibility and poor adaptability caused by using a plurality of single-functional additives are avoided, and production equipment can be simplified.

Owner:JIANGNAN UNIV

Improved production technique for making beancurd jelly from glucolactone

InactiveCN103609745AHigh water retentionDelicate textureCheese manufactureFood scienceProduction rateGlucono delta-lactone

The invention provides an improved production technique for making beancurd jelly from glucolactone, which comprises the following steps: dissolving 3.1-3.7g of glucono-delta-lactone in 30-50 mL of water to obtain a glucono-delta-lactone solution, uniformly mixing soybean milk with the temperature of higher than 95 DEG C with the glucono-delta-lactone solution for slushing, and standing for 5-8 minutes to obtain the coagulated beancurd jelly. Compared with the existing production technique, the improved production technique provided by the invention saves the time for cooling the soybean milk to DEG C before slushing, increases the production rate and ensures the production efficiency. The proper glucono-delta-lactone solution and the soybean milk are proportionally mixed to shorten the standing time from 15 minutes or so to 5-8 minutes, thereby further lowering the time cost for production, and ensuring the increase of production benefit by utilizing production.

Owner:ANHUI XINGZHOU MEDICINE FOOD

Addition agent having synergistic effect on cement and preparing method

InactiveCN105693131AImprove physical and mechanical propertiesWide variety of sourcesSodium phosphatesNitrilotriacetic acid

The invention discloses an addition agent having a synergistic effect on cement.The addition agent is prepared from, by weight, 5.4-5.8 parts of nitrilotriacetic acid, 1.8-2.4 parts of ethylene diamine tetra (methylene phosphonic acid) sodium, 2.4-2.7 parts of triisopropanolamine, 3.7-4.3 parts of acrylamide, 3.2-3.5 parts of alpha-sodium-olefinsulfonate, 3.3-3.6 parts of useless lubricating oil, 3.9-4.4 parts of lauryl sodium sulfate, 4.9-5.7 parts of urea, 2.2-2.5 parts of calcium lignosulfonate, 0.6-0.8 parts of molasses, 2.6-3.0 parts of sodium thiosulfate, 2.1-2.5 parts of a silicone lubricating agent, 1.5-1.9 parts of a fluorine-containing lubricating agent, 2.1-2.5 parts of polysorbate-80 and 2.3-2.7 parts of sorbitol.The construction efficiency can be improved effectively, price is low, the enhancing effect is remarkable, fallen dust is reduced, resources are saved, the raw materials are wide in source, and the manufacturing technology is simple.

Owner:王金奎

Method for preparing all-natural water-retaining agent for chicken products

The invention relates to a method for preparing an all-natural water-retaining agent for chicken products. The method comprises the following steps of: adding 0.05-0.25% (w / v) of carrageenan in a chitosan solution; adding 0.01-0.03% (w / w) of calcium chloride and a sodium alga acid solution at a temperature of 45-55 DEG C while stirring; adding green tea polyphenol, oolong tea polyphenol and kiwi fruit juice in the uniformly mixed solution; uniformly mixing, and carrying out vacuum packing to finally obtain the all-natural water-retaining agent for chicken products. When applied to chicken products, the all-natural water-retaining agent prepared by the method disclosed in the invention can effectively improve the water retention rate of chicken meat and reduce juice loss rate by 26.7 percent in the subsequent processing, and the processed chicken products have fresh and tender taste.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Method for culturing dendrobium officinale

InactiveCN103650810AAngularEasy to breatheCultivating equipmentsSoilless cultivationThiophanate-methylBrick

Provided is a method for culturing dendrobium officinale. A shading greenhouse is adopted, and a culture matrix is prepared through the raw materials, by weight, 3-5 parts of fragmentary bark, 3-5 parts of fragmentary red bricks, and 1-3 parts of fragmentary tree leaves. When the culture matrix is used, the raw materials are evenly mixed, and 1000-times potassium permanganate solutions or 1000-times thiophanate methyl solutions are used for even spraying sanitization. The water retention rate and the drought resisting rate of the culture matrix are high, the fertilizer efficiency is mild and lasting, the fragmentary red bricks have strong hardening resisting performance, growth of the root system of dendrobium officinale is facilitated, the unexpected technical effect is achieved, and culturing quality of dendrobium officinale is greatly improved.

Owner:湖南崀霞湘斛生物科技有限公司

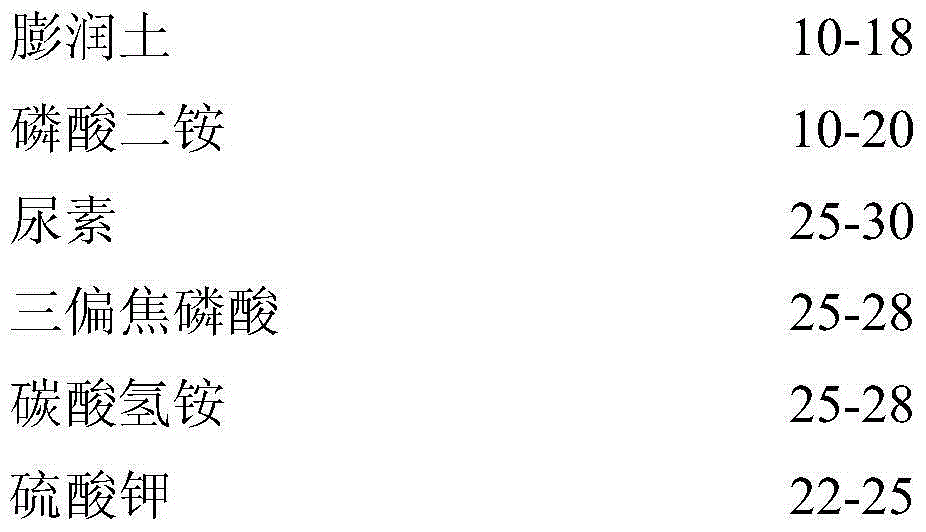

Compound water-retaining agent for edible mushroom production and preparation method thereof

InactiveCN107056400AImprove mildew resistanceHigh water retentionOrganic fertilisersAmmonium salt fertilisersHorticulture

The invention relates to a compound water-retaining agent for edible mushroom production and a preparation method thereof and belongs to the technical field of agricultural production. The compound water-retaining agent can be applied to the edible mushroom production. The invention prepares the compound water-retaining agent for edible mushroom production that is excellent in fungus resistance, free from pollution, high in water-retaining rate and low in production cost, in order to solve the problems that the water loss of an edible mushroom culture medium in a later period is serious, the yield is seriously influenced, the cultivation material needs to be frequently supplemented with water for the purpose of increasing the yield, the manual water supplementation is time-wasting and labor-wasting, the water supplementation is uneven and the water supplementation effect is poor.

Owner:新昌县钧国生物技术有限公司

Building block ready-mixed mortar and production method thereof

InactiveCN104211340AQuality assuranceQuality improvementSolid waste managementPolyvinyl alcoholArchitectural engineering

The invention relates to building block ready-mixed mortar and a production method thereof. The building block ready-mixed mortar is characterized by comprising the following raw materials in parts by weight: 60-70 parts of artificial sand, 12-13 parts of cement, 10-12 parts of grade II coal fly ash, 0.5-1 part of cold soluble polyvinyl alcohol powder and 0.1-0.5 part of additive. The building block ready-mixed mortar provided by the invention can significantly improve adhesion, tensile adhesive strength, compressive strength, impermeability, anti-crack property, shrinkage reduction, water retention rate and other performances of building blocks and simultaneously has excellent working performances and other excellent construction performances and is easy for pumping and compacting.

Owner:GUANGXI HENGXIAN HENGFENG BUILDING MATERIAL

Concrete curing agent

The invention discloses a concrete curing agent. The concrete curing agent comprises the following components in parts by weight: 40-55 parts of a high-molecular emulsion, 3-12 parts of a film-formingagent and 2-6 parts of a penetrating agent; the high-molecular emulsion comprises a core monomer, an external crystal nucleus, an initiator and an emulsifier; the core monomer comprises the followingcomponents in parts by weight: 1-2 parts of styrene, 1-2 parts of vinyl acetate and 5-8 parts of ester components; and the external crystal nucleus comprises the following components in parts by weight: 2-4 parts of fly ash, 3-5 parts of kaolinite powder, 2-3 parts of barite and 1-2 parts of chitosan, wherein the weight ratio of the inner core monomer to the external crystal nucleus is (10-20):1.The concrete curing agent provided by the invention is good in stability, good in continuity, good in durability and high in water retention rate. In a process from initial set to final set of concrete, influence by temperature and humidity is prevented, and the phenomena of peeling, falling, cracking and the like are avoided.

Owner:CHINA ROAD & BRIDGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com