Cement-based plasters using water rentention agents prepared from raw cotton linters

A technology for stucco, mortar, applied in the direction of supporting elements of blades, machines/engines, solid waste management, etc., able to solve the problems of strong labor, insufficient hydration, low-grade cement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Examples 1 and 2 show some chemical and physical properties of the polymers of the present invention relative to similar commercially available polymers.

[0047] confirmation of replacement

[0048] Modified Zeisel ether cleavage of cellulose ethers with hydroiodic acid at 150 °C. The volatile reaction products formed were determined quantitatively by gas chromatography.

[0049] determination of viscosity

[0050] The viscosities of the aqueous cellulose ether solutions were determined for solutions with concentrations of 1% by weight and 2% by weight. When the viscosity of the cellulose ether solution is determined, the corresponding methylhydroxyalkylcellulose is used on a dry basis, ie the moisture percentage is compensated by a higher amount by weight. Currently available commercially available methyl hydroxyalkyl cellulose based on purified cotton linters or high viscosity wood pulp has a maximum of approximately 70,000-80,000 mPas (using a Brookfield RVT visc...

Embodiment 2

[0062] confirmation of replacement

[0063] Modified Zeisel ether cleavage of cellulose ethers with hydroiodic acid at 150 °C. The volatile reaction products formed were determined quantitatively by gas chromatography.

[0064] determination of viscosity

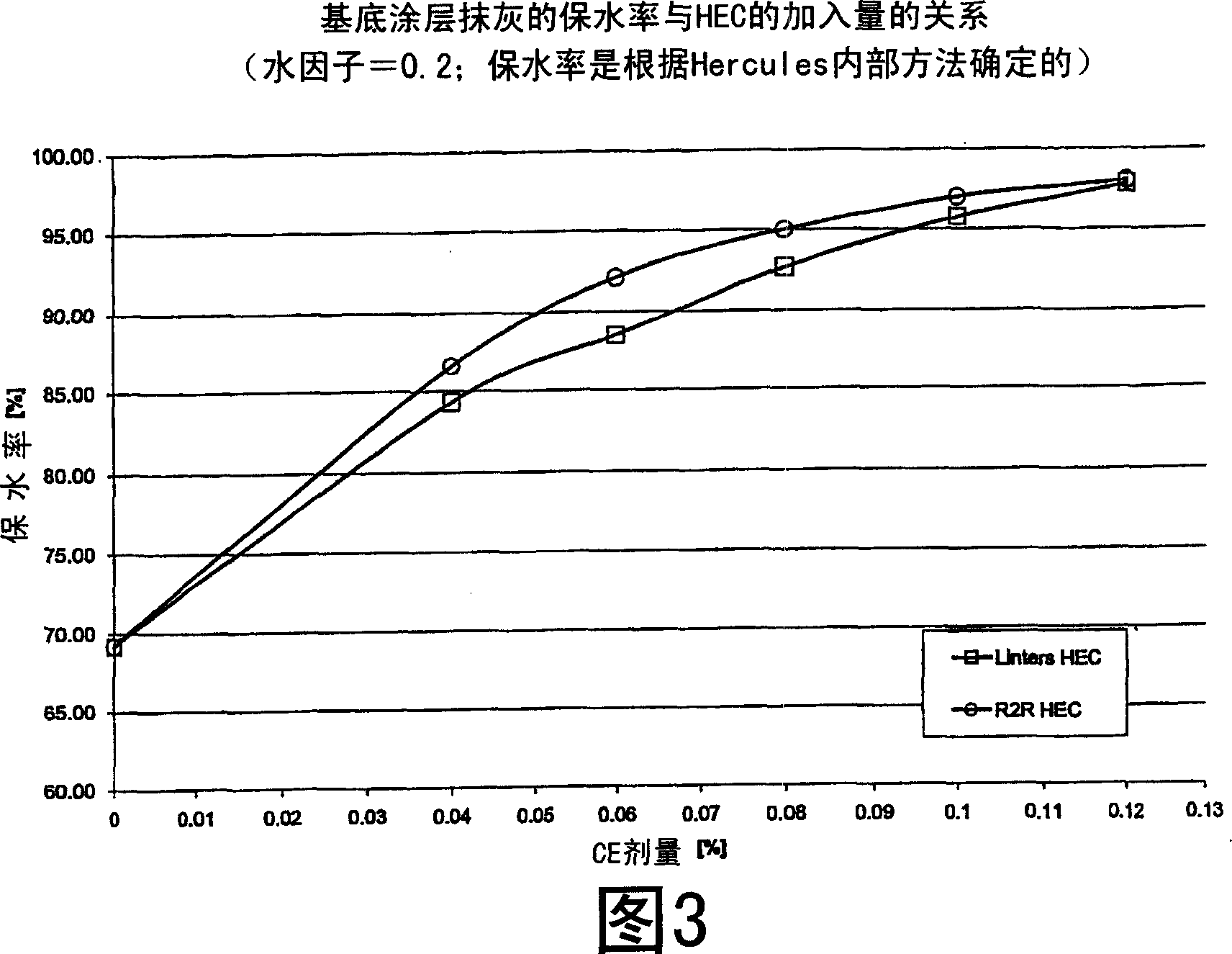

[0065]The viscosity of the aqueous cellulose ether solution is determined for a solution having a concentration of 1% by weight. When determining the viscosity of the cellulose ether solution, the corresponding hydroxyethyl cellulose was used on a dry basis, ie the moisture percentage was compensated by the higher amount by weight.

[0066] To determine the viscosity, a Brookfield LVF rotational viscometer was used. All measurements are made at 25°C and 30 rpm, using propeller No. 4.

[0067] Hydroxyethylcellulose was prepared from purified raw cotton linters in a Hercules' pilot plant reactor. As shown in Table 2, both samples had about the same hydroxyethoxy content. But the viscosity of the formed RCL-based HEC was ...

Embodiment 3

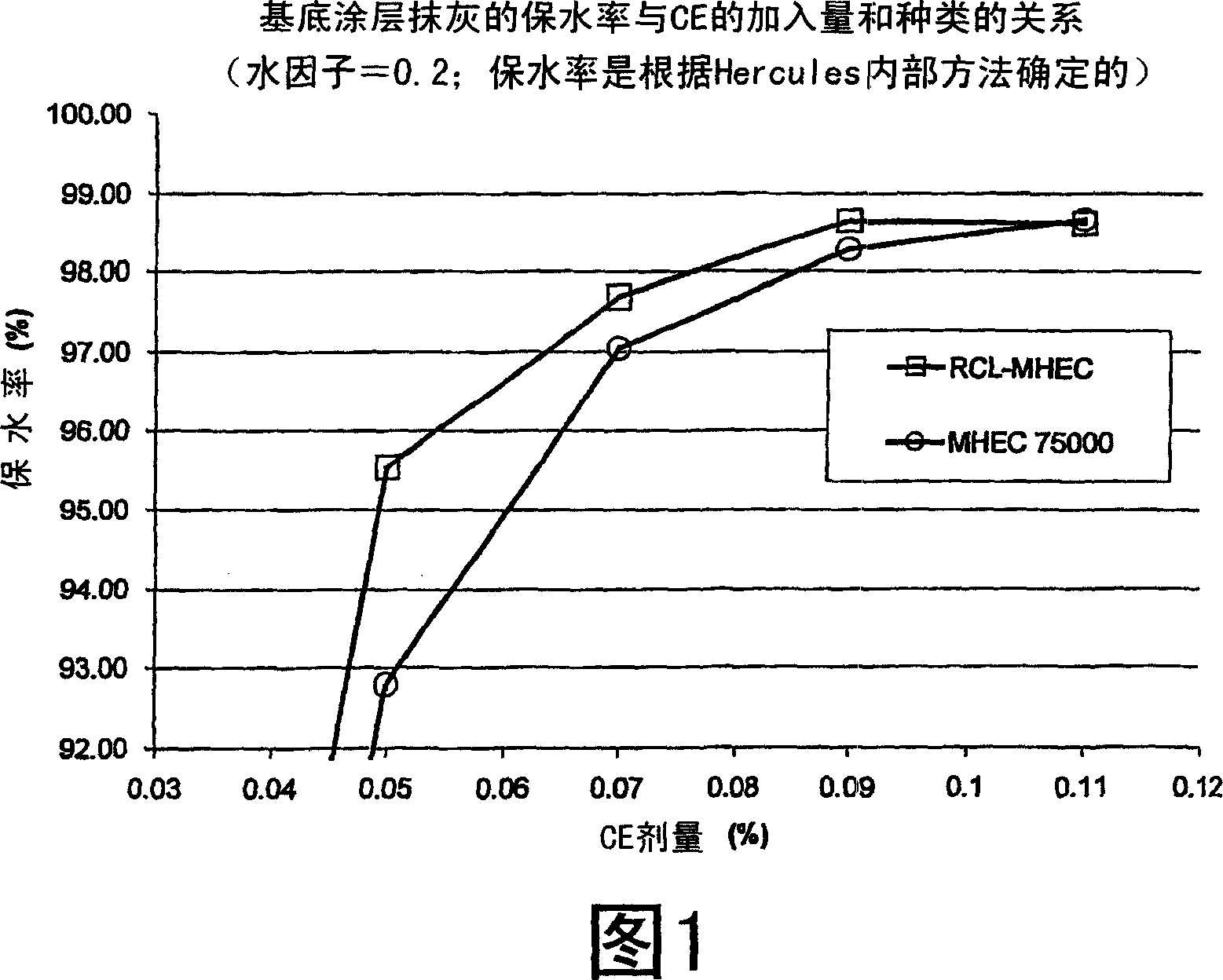

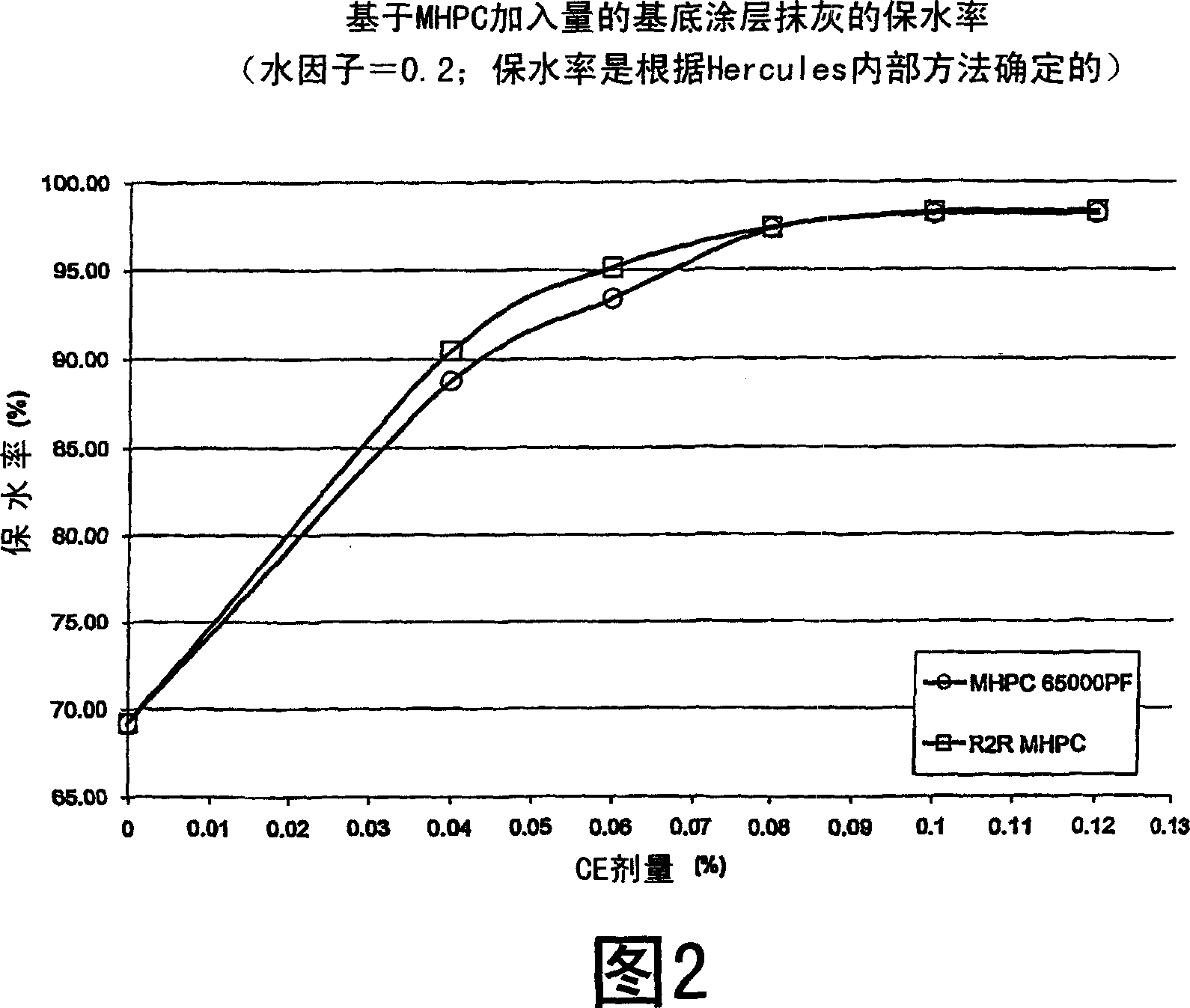

[0070] All tests were performed on a mixture of 14.00% by weight Portland cement CEM I 42.5R, 4.0% by weight slaked lime, 39.0% by weight quartz sand with a particle size of 0.1-0.4mm and 43.0% by weight quartz Sand constitutes a stucco-based coating base mix.

[0071] Water retention

[0072] Water retention is determined according to DIN EN 18555 or internal Hercules / Aqualon operating procedures.

[0073] Hercules / Aqualon Runner

[0074] Within 5 seconds, 300 g of dry mortar were added to a corresponding amount of water (at 20° C.). After mixing the sample for 25 seconds using a Kitchen hand mixer, the resulting sample was allowed to age for 5 minutes. The mortar was then filled into a plastic ring placed on a piece of filter paper. Between the filter paper and the plastic ring, place a piece of fiber wool while placing the filter paper on the plastic dish. The weight of the equipment was measured before and after filling the mortar. From this the weight of the wet mor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com