Water-soluble anticarack gelatine powder, and application in building materials of powder

An anti-cracking rubber powder, water-soluble technology, applied in the field of construction adhesives, can solve the problems of water resistance, cracking, poor adhesion, etc., to achieve good anti-cracking and waterproof performance, high water retention rate, bonding powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Produce 100 kilograms of water-soluble anti-cracking rubber powder, with 45% (45 kilograms) carboxymethyl starch cellulose ether, 20% (20 kilograms) hydroxypropyl methylcellulose, 20% (20 kilograms) wood fiber, 1 % (1 kg) sodium dodecylbenzenesulfonate, 10% (10 kg) bentonite, and 4% (4 kg) polyacrylamide are put into a mixer and stirred for 20 minutes, then they can be bagged into finished products.

Embodiment 2

[0023] A kind of dry powder polymer mortar is made of 300 kilograms of 42.5# ordinary Portland cement, 100 kilograms of calcium carbonate (100-200 orders), 558 kilograms of quartz sand (0.1-0.5mm), 18 kilograms of water-soluble powders in the ratio of embodiment 1 It is dry-mixed with anti-cracking rubber powder, 10 kg of redispersible rubber powder, and 0.5 kg of polypropylene chopped fiber. During the construction process, add water and stir evenly, and scrape the wall surface in batches. After testing, the tensile bond strength is ≥0.6Mpa; the water resistance is ≥0.5Mpa; the compressive strength / flexural strength (cement base) is 2.8Mpa.

Embodiment 3

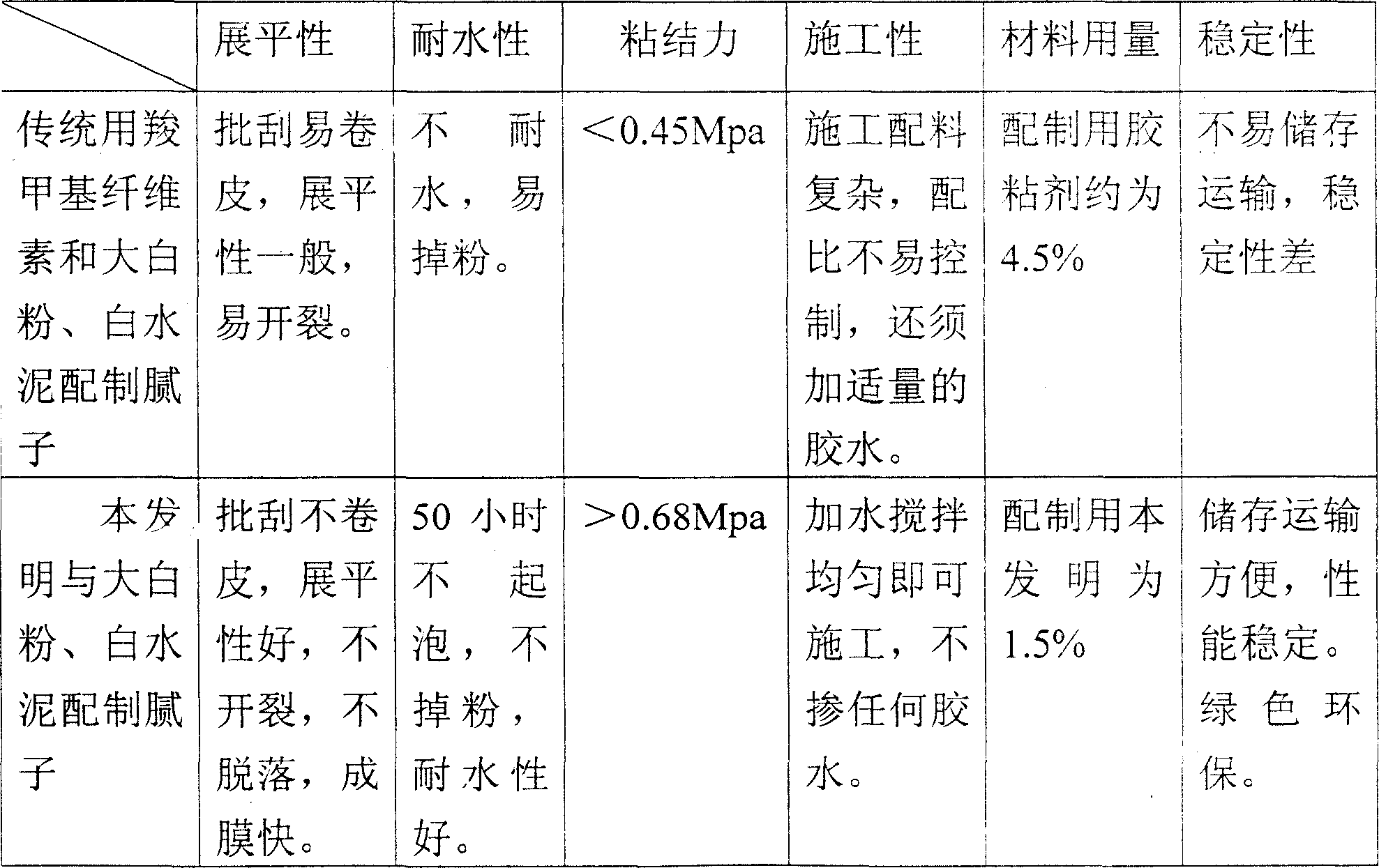

[0025] 300 kilograms of white cement, 335 kilograms of double-flying powder, 340 kilograms of quartz sand (200 orders), 8 kilograms of redispersible rubber powder and 16 kilograms of water-soluble anti-cracking rubber powder of the proportioning of embodiment 1 are mixed, and are mixed with water-resistant putty powder . Its tensile bonding strength> 0.68Mpa; compressive strength> 2.5Mpa; flexural strength> 0.9Mpa water resistance strength: 50 hours without foaming and powder removal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com